http://www.iaeme.com/IJMET/index.asp 1931 editor@iaeme.com

International Journal of Mechanical Engineering and Technology (IJMET)

Volume 10, Issue 03, March 2019, pp.1931-1938. Article ID: IJMET_10_04_196

Available online at http://www.iaeme.com/ijmet/issues.asp?JType=IJMET&VType=10&IType=3

ISSN Print: 0976-6340 and ISSN Online: 0976-6359

© IAEME Publication Scopus Indexed

DESIGN AND TESTING OF COOKING VESSELS

OF SOLAR BOX COOKER FOR EVENING

COOKING

Ajeet Kumar Rai and Sanjay Kumar Srivastava

Mechanical Engineering Department, VIAET, SHUATS, Prayagraj, 211007, (U.P.) India

ABSTRACT

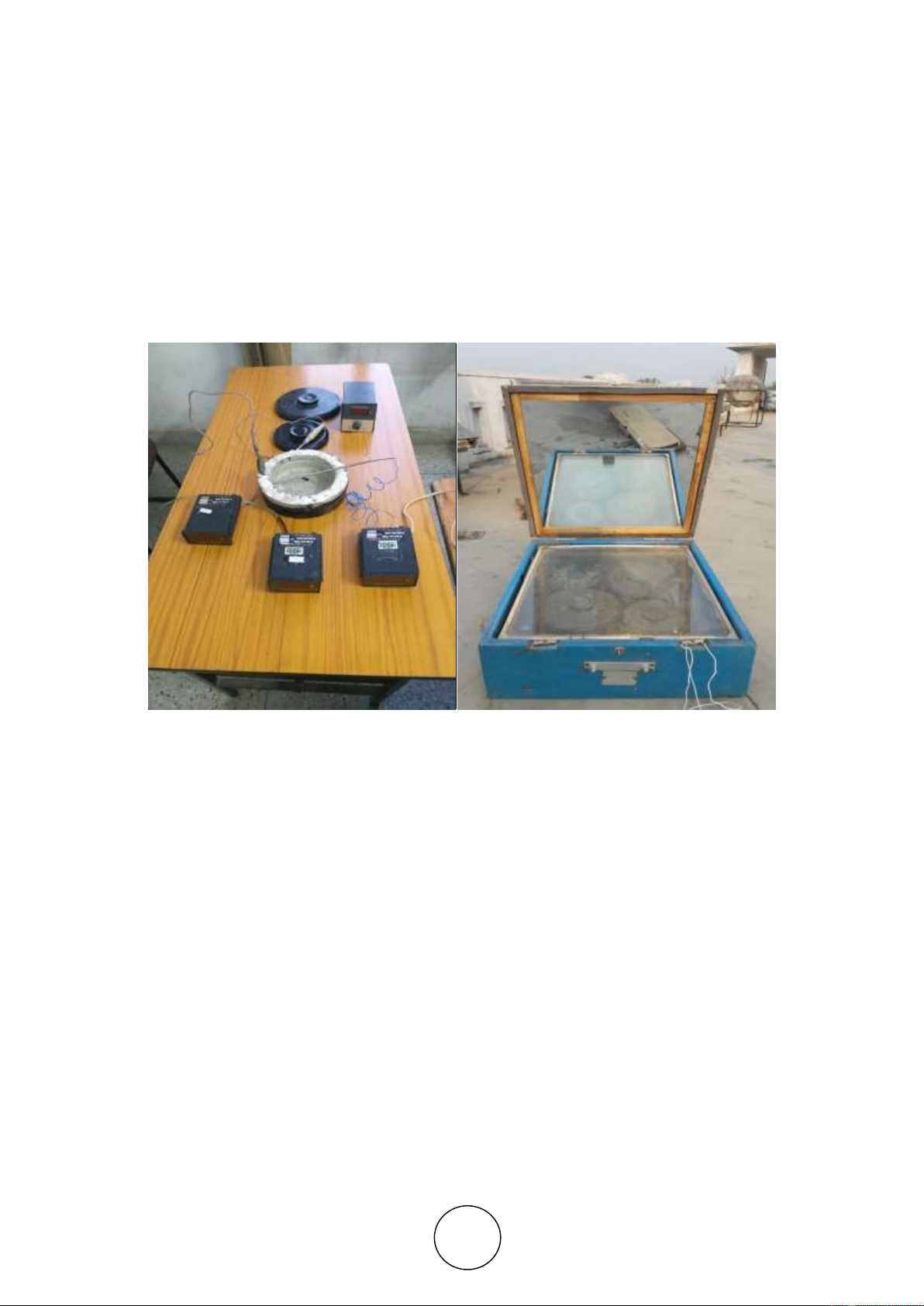

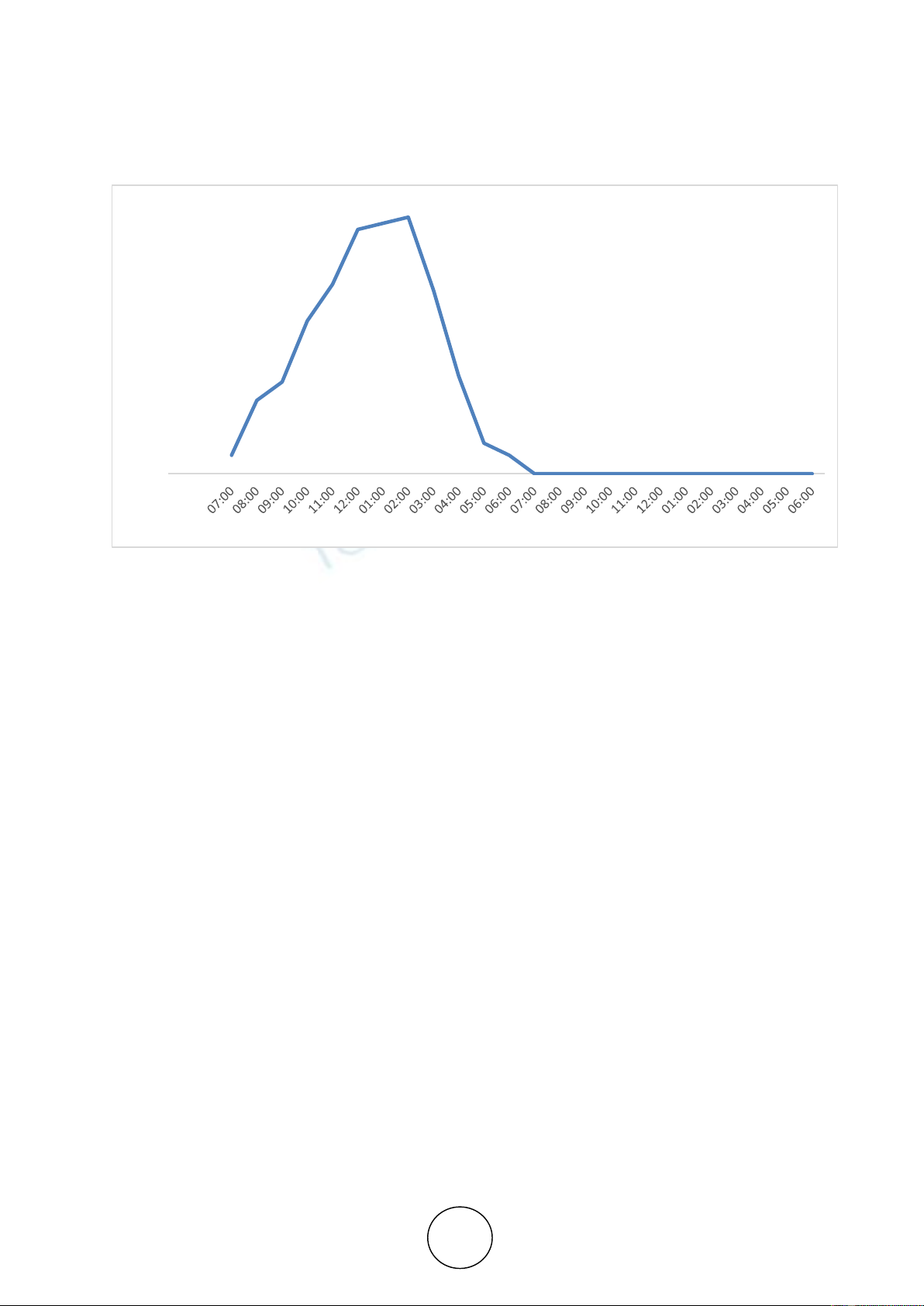

In the present work, an attempt has been made to design and test the performance

of box type solar cooker with cooking pots of different materials filled with latent heat

energy storage mediums to perform the cooking in sun shine and off sun - shine

conditions. The box type solar cookers are not common in use due to limited availability

of solar energy. Latent heat energy storage materials are used to store solar energy

available in day time to use in evening and off sunshine hours. Paraffin wax is used as

energy storage material (PCM) to improve the performance of the system in off sunshine

conditions. PCM filled aluminium pots are suitable for day time cooking. It is observed

from full load test that the water temperature in PCM filled steel pots are maintained

above 950C for more than 3 hours than PCM filled aluminium pots in off sunshine

conditions.

Keywords: Box Type solar cooker, Latent heat energy storage, cooking vessel.

Cite this Article: Ajeet Kumar Rai and Sanjay Kumar Srivastava, Design and Testing

of Cooking Vessels of Solar Box Cooker for Evening Cooking, International Journal

of Mechanical Engineering and Technology, 10(3), 2019, pp. 1931-1938.

http://www.iaeme.com/IJMET/issues.asp?JType=IJMET&VType=10&IType=3

1. INTRODUCTION

Energy is essential to sustain life on the earth. Energy is available in various forms on the earth.

A major amount of total available energy is utilized for cooking. Heat energy is the most

suitable form of energy to cook food. Heat generation by burning of fossil fuels is common

practice for cooking applications in developing countries. But fast depletion of resources and

environmental problems associated with use of fossil fuels has restricted its use. Utilization of

renewable energy based technologies is the most promising options for cooking applications.

Since cooking requires 36% of total primary energy consumptions in India [1]. In present days

14% of total world energy demand is supplied by renewable energy sources [2]. Therefore,

there is a rising attention concerning the renewable energy options to meet the cooking

requirements of people in developing countries. Since it is free of cost and environment

friendly, the solar energy is recognized as one of the most promising choice among other clean