http://www.iaeme.com/IJMET/index.asp 1556 editor@iaeme.com

International Journal of Mechanical Engineering and Technology (IJMET)

Volume 10, Issue 03, March 2019, pp. 1556–1565, Article ID: IJMET_10_03_156

Available online at http://www.iaeme.com/ijmet/issues.asp?JType=IJMET&VType=10&IType=3

ISSN Print: 0976-6340 and ISSN Online: 0976-6359

© IAEME Publication Scopus Indexed

STUDY ON MORPHOLOGY AND MECHANICAL

PROPERTIES OF STOICHIOMETRICALLY

DEVELOPED AL-CU-MG CAST ALLOY

Rakesh Kumar and Varinder Sahni

Department of Mechanical Engineering

Sant Longowal Institute of Engineering and Technology, Longowal, INDIA

ABSTRACT

The present study was carried out to investigate the mechanical properties of newly

developed cast aluminum alloy with the (1.0 at. %) of copper and (1.0 at. %) magnesium

addition in the mole ratio of 1:1:1 of Al-Cu-Mg in as - cast and thermally aged

conditions. The atomic weight (at. %) selection of Cu-Mg on the basis of stoichiometric

calculations, 1 unit (at. %) of copper and 1 unit (at. %) of magnesium preheated at

200

C were mixed in liquid aluminium base material, heated in an electric furnace and

melting temperature was kept at 750

C for about 10 min alone and this melt was hold

at 7300C with alloying additions of copper and magnesium for about 30 min to ensure

complete homogenisation, Further, this liquidous aluminium metal matrix was stirred

at 800 rpm for five minutes and poured at temperature 7000C

10 0C in permanent mild

steel mould preheated at 2000C in order to achieve as- cast aluminium alloy.

The solution treatment at temperature 5000C for 2h followed by a quenching in

water at 60 °C. Further, it was thermally aged at temperature 1600C for 6 h followed

by quenching at room temperature. The effect of solution and aged temperature on

mechanical properties by changing metallurgical morphology and further the role of

intermetallic compounds on mechanical properties of as-cast alloy have been studied.

The optical microscopy and scanning electron microscopy (SEM) equipped with energy

dispersive spectroscopy (EDS) were used to identify the intermetallic phases and

formation of different precipitates were studied by using X-ray diffraction (XRD). The

improvement in hardness values 35.55% at 1% Cu &Mg as-cast alloy with solution

temperature 500 0C,2h and 56.66 % have been recorded and reported at 1% Cu &Mg

as-cast alloy with 160 0C,6h.

Key words: 6xxx Al alloys, Mechanical properties, Solution treatment Temperature,

Thermal Aged temperature

Cite this Article: Rakesh Kumar and Varinder Sahni, Study on Morphology and

Mechanical Properties of Stoichiometrically Developed Al-Cu-Mg Cast Alloy,

International Journal of Mechanical Engineering and Technology 10(3), 2019, pp.

1556–1565.

http://www.iaeme.com/IJMET/issues.asp?JType=IJMET&VType=10&IType=3

Rakesh Kumar and Varinder Sahni

http://www.iaeme.com/IJMET/index.asp 1557 editor@iaeme.com

1. INTRODUCTION

Aluminum alloys are next to steels in use as space vehicles, aircrafts as well as many types of

surface and water borne vehicles [1]. In automobiles, the components such as engine blocks,

head, pistons and wheels etc. are generally aluminum based cast alloys [2]. The low cost and

continuous demands for weight reduction and improvements in fuel efficiency have increased

pace of research in developing aluminum-based cast alloys [3].

The Al-Cu-Mg alloys offer high hardness and strength. Its components contribute the high

degree of damage tolerance [6-8]. The first age-hardening of aluminum alloy as reported in

literature was performed by Alfred Wilm in year 1909 who patented duralumin of casting

components containing Cu and Mg substances [3]. The steps consist of solution treatment,

quenching and artificial aging mechanism is responsible for strengthening is based on the

formation of intermetallic compounds during decomposition of a metastable supersaturated

solid solution by performing solution treatment and quenching [10-13]. Additionally, hardness

and mechanical strength can be increased by aging heat treatment [14-15]

The composition of the alloying elements and casting conditions influence the state of

intermetallic phases and finally the mechanical properties of the alloy [ 16-19]. To improve the

mechanical properties of this aluminium alloys are frequently heat treated by a two-step process

i) solution heat treatment and ii) Thermal aging [20].

The copper and magnesium in combination have been used for improving the aging

characteristic of the alloys. Some of the investigators have taken compositions of alloying

elements in weight fraction or volume fraction but in arbitrary manner. They have used design

of experiments for material compositions as input parameters and different mechanical

properties as responses, and finally optimum values of alloying elements are suggested for the

given objective.

In place of taking the fraction of alloying elements in arbitrary manner, a pattern based on

stoichiometric weight fraction is explored and presented in the paper. Study has been made on

Al-Cu-Mg casting and results in terms of metallurgical and mechanical properties have been

presented. Therefore, this study undertakes the effect of the addition of up to1 at.% of Cu-Mg

and solution treatment time of 2 h on Al-Cu -Mg alloy to understand the resultant

microstructure and its respective hardness. The variation of microstructure, size, morphology

and distribution of precipitates, as well as Brinell Hardness are presented and discussed .

2. EXPERIMENTATION

2.1. Methodology

Initially to start with stoichiometric ratio of Al-Cu-Mg as 23.496 -55.338 -21.165. Such a high

percentage of Cu and Mg cannot be a suitable condition for formation of the Al based alloy,

hence 1 (at. %) each of Cu and Mg as per stoichiometric ratio were taken for mixing with the

base metal.

A graphite crucible of 2-kg capacity was used in electric resistance furnace, and the melting

temperature was kept at 750 0C [7] for 5 min. The Cu and Mg as decided above were preheated

at 200C for 30 minutes and mixed in liquidous aluminium metal and stirred for five minutes.

The melts were hold at 7300C for about 30 min [17] to ensure complete homogenisation and

poured after degassing into a permanent mould. It refines the microstructure of metallic material

which change the morphology and distribution of intermetallic particulates to enhance the

mechanical properties of as-cast aluminium alloy. Finally, metallographic and mechanical

properties of the as-cast alloy have been analysed.

Study on Morphology and Mechanical Properties of Stoichiometrically Developed Al-Cu-Mg Cast Alloy

http://www.iaeme.com/IJMET/index.asp 1558 editor@iaeme.com

2.2. Metallographic tests

The cast specimens were polished as per standard metallographic procedure by using emery

paper of progressive finer grades 400,600,800,1000,1200,1500,2200,2500 and 3000 grit size

with single disk machine. They were polished with alumina powder to obtain a mirror like

surface by solvyt polishing cloth and continue water supply. Kroll’s etchant (Distilled water

(92 ml) +Nitric acid (6ml) +Hydrofluoric acid (2ml) was applied for 15 seconds to reveal

microstructure. Optical microscopy was used to capture microstructures of as-cast and

thermally aged aluminium alloy shown in figure-4. Fractography was done to determine type

of fracture for tensile and CVN samples using scanning electron microscopy (SEM) JEOL

(JSM-6510LV).

2.3. Testing for mechanical properties

Tensile specimen samples were tested on a servo hydraulic based digital controlled tensile

testing machine of having capacity 50 kN (make: Tinius Olsen, UK, Model-H50KS) and

ultimate tensile strength for as- cast alloy and thermally aged cast base alloys was determined.

The tensile specimens were prepared in accordance with ASTM E08/E8M-09 standard as

shown in Figure 3. The Charpy V-notch (CVN) test was done to measure the fracture toughness

of as-cast and aged as-cast material. The sample for Charpy V-notch test was prepared as per

ASTM E23-12c standard and shown in Fig. 2. Micro hardness measurements were taken using

Brinell hardness tester (make-: Miraj, Model-B3000(O) with 10 mm diameter indenter at load

500kgf .

3. RESULTS AND DISCUSSION

3.1. Spectro analysis

The chemical compositions were tested as per ASTM E 1251-17a using spark emission

spectrometer analysis (Model No: LMF-01, Spectromaxx, Make: Germany). The chemical

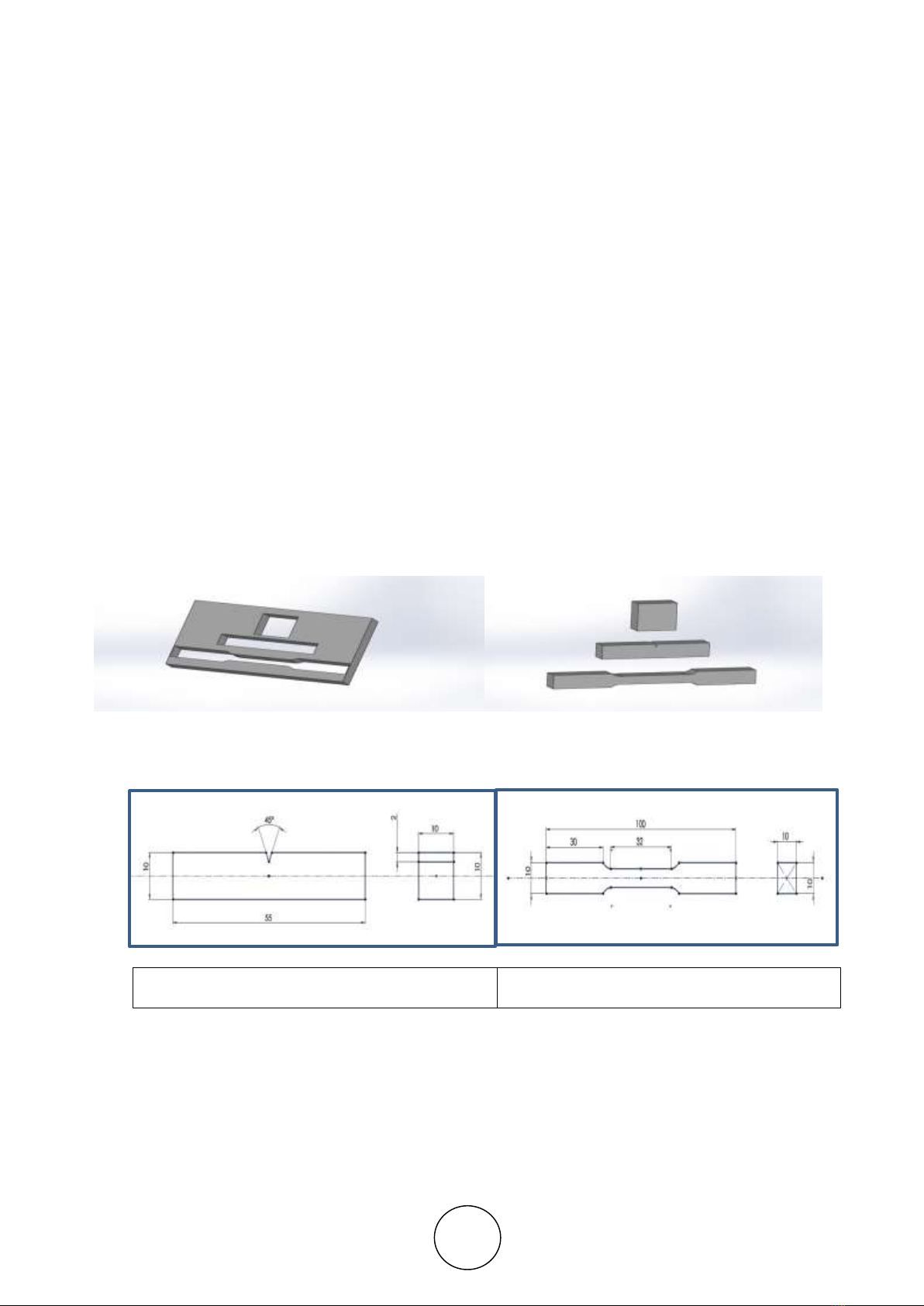

Figure 1. Test specimen extracted from as-cast plate as per ASTM standard

Figure 2. Impact Test Specimen

Figure 3. Tensile Test Specimen

Rakesh Kumar and Varinder Sahni

http://www.iaeme.com/IJMET/index.asp 1559 editor@iaeme.com

compositions of as-cast alloy and thermally aged alloy were tested using spectrometer and

shown in Table 1.

Table 1. Alloying elements composition (wt.%)

Si

Cu

Mg

Fe

Zn

Ni

Mn

Cr

Ti

Sn

Pb

V

Al

1% Cu

&Mg as-

cast

alloy

with

solution

temperat

ure 500

0C,2h

0.42

2

0.28

07

0.5

699

0.60

6

0.00

56

0.00

16

0.01

07

0.00

27

0.1

396

0.00

38

0.00

41

0.00

79

97.9

3

1% Cu

&Mg as-

cast

alloy

with

160

0C,6h

0.47

3

0.31

44

0.6

114

0.64

2

0.00

70

0.00

24

0.01

09

0.00

26

0.1

536

0.00

51

0.00

44

0.00

83

97.7

5

The chemical composition 1% Cu &Mg as-cast alloy with solution temperature 500 0C,2h

and 1% Cu &Mg as-cast alloy with 160 0C,6h from spectrometer analysis on addition (1.0 at.

%) copper and magnesium in the base material, there is significant development of alloying

elements in aluminium metal matrix.

3.2. X-Ray Diffraction (XRD)

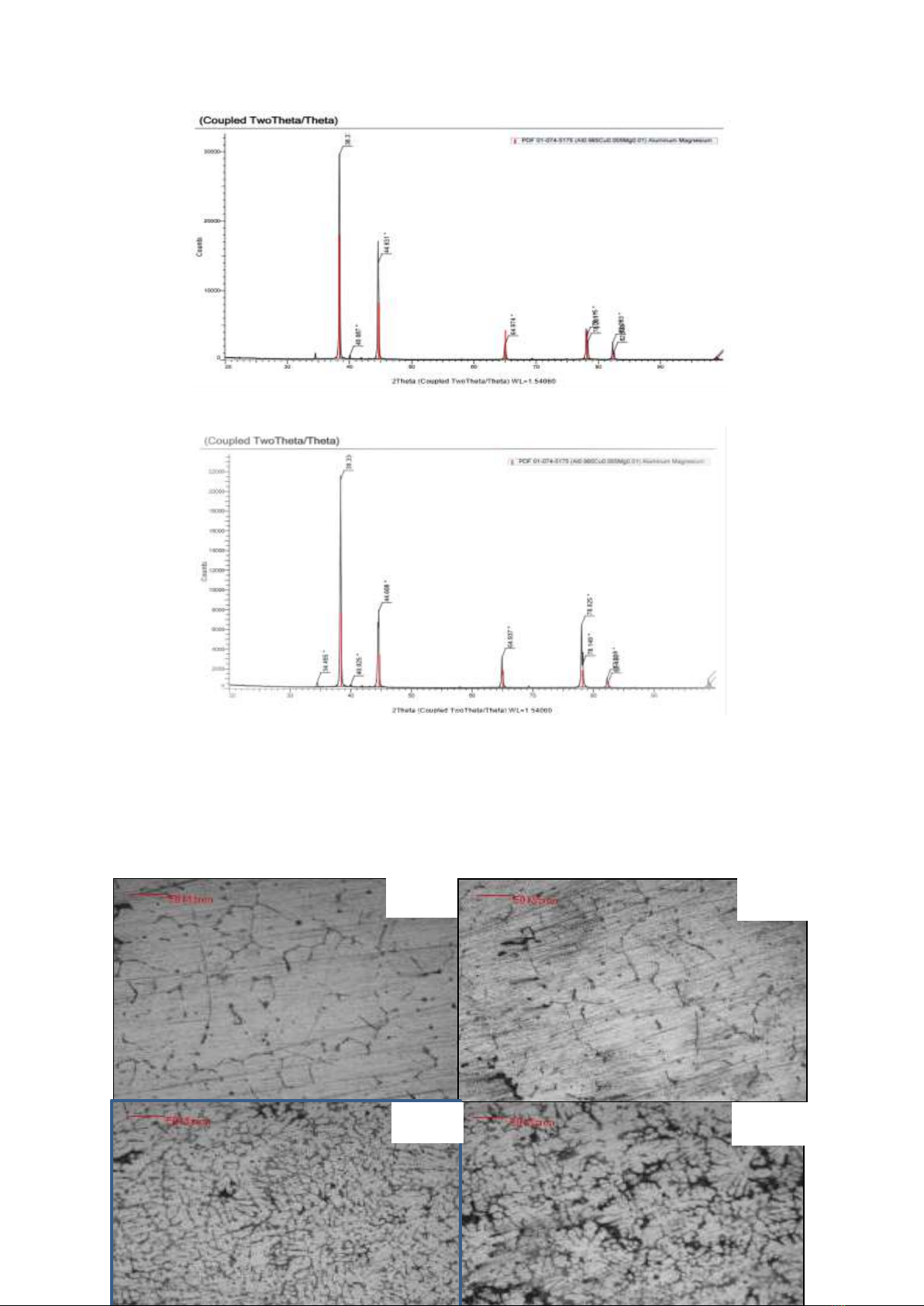

The X-ray diffraction (XRD) technique was used to show different intermetallic precipitate

formations in as-cast and thermally aged alloy which has been observed in XRD spectra as

shown in figure 4(a)&(b).

In as-cast base aluminium alloy, AlCu compound has less strength and Al12Mg17 compound

contributes to hardness of as-cast alloy. However, when aging was done to 160C, formation

of Al5Cu6Mg, sigma phase takes place which increases the tensile strength of the material. At

the elevated temperature coarse precipitate AlCuMg was also formed. The aging treatment

dissolves the AlCu compound and forms complex precipitate compounds which enhance the

strength of the matrix.

The complex compounds occur and formation of coarse precipitates such as Al2CuMg and

Al14Mg13, which enhances the toughness and strength at high temperatures. Sigma phase

precipitation was noticed in as cast and aged aluminium alloyed with copper and magnesium

which enhances their strength as compared to cast base material.

Study on Morphology and Mechanical Properties of Stoichiometrically Developed Al-Cu-Mg Cast Alloy

http://www.iaeme.com/IJMET/index.asp 1560 editor@iaeme.com

Figure 4 (a)

Figure 4 (b)

Figure 4. Intermetallic precipitate formation as per XRD diffraction patterns for (a) 1% Cu &Mg as-

cast alloy with solution temperature 500 0C,2h (b) 1% Cu &Mg as-cast alloy with 160 0C,6h.

3.3. Optical Microscopy (OM) studies

a

b

d

c

![Công Thức Vật Lý Đại Cương: Nắm Vững Kiến Thức Cơ Bản [Chuẩn Nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20250702/kexauxi10/135x160/74531767988159.jpg)