Journal of Pharmaceutical Research and Drug Information 2025; 00(00); 000–000

_________________________________________

*Correspondence: vuongttt@hup.edu.vn; 1

http://doi.org/10.59882/1859-364X/264

Journal homepage: jprdi.vn/JP

Journal of Pharmaceutical Research and Drug Information

An official journal of Hanoi University of Pharmacy

Research article

Simultaneous determination of two UV filters

(octylmethoxycinnamate, octylsalicylate) in sunscreen creams

by high performance thin layer chromatography (HPTLC)

Minh Thuy Ngoa, Thi Bich Dao Danga, Dinh Chi Leb, Thi Thanh Vuong Tonga,*

a Department of Analytical Chemistry and Drug Quality Control, Hanoi University of

Pharmacy, 13-15 Le Thanh Tong Street, Hoan Kiem District, Hanoi, Vietnam

b National Institute of Pharmaceutical Technology, Hanoi University of Pharmacy, 13-15 Le

Thanh Tong Street, Hoan Kiem District, Hanoi, Vietnam.

*Corresponding author: Thi Thanh Vuong Tong - vuongttt@hup.edu.vn

Article history:

Received 05 December 2024

Resived 10 January 2025

Accepted 17 January 2025

ABSTRACT

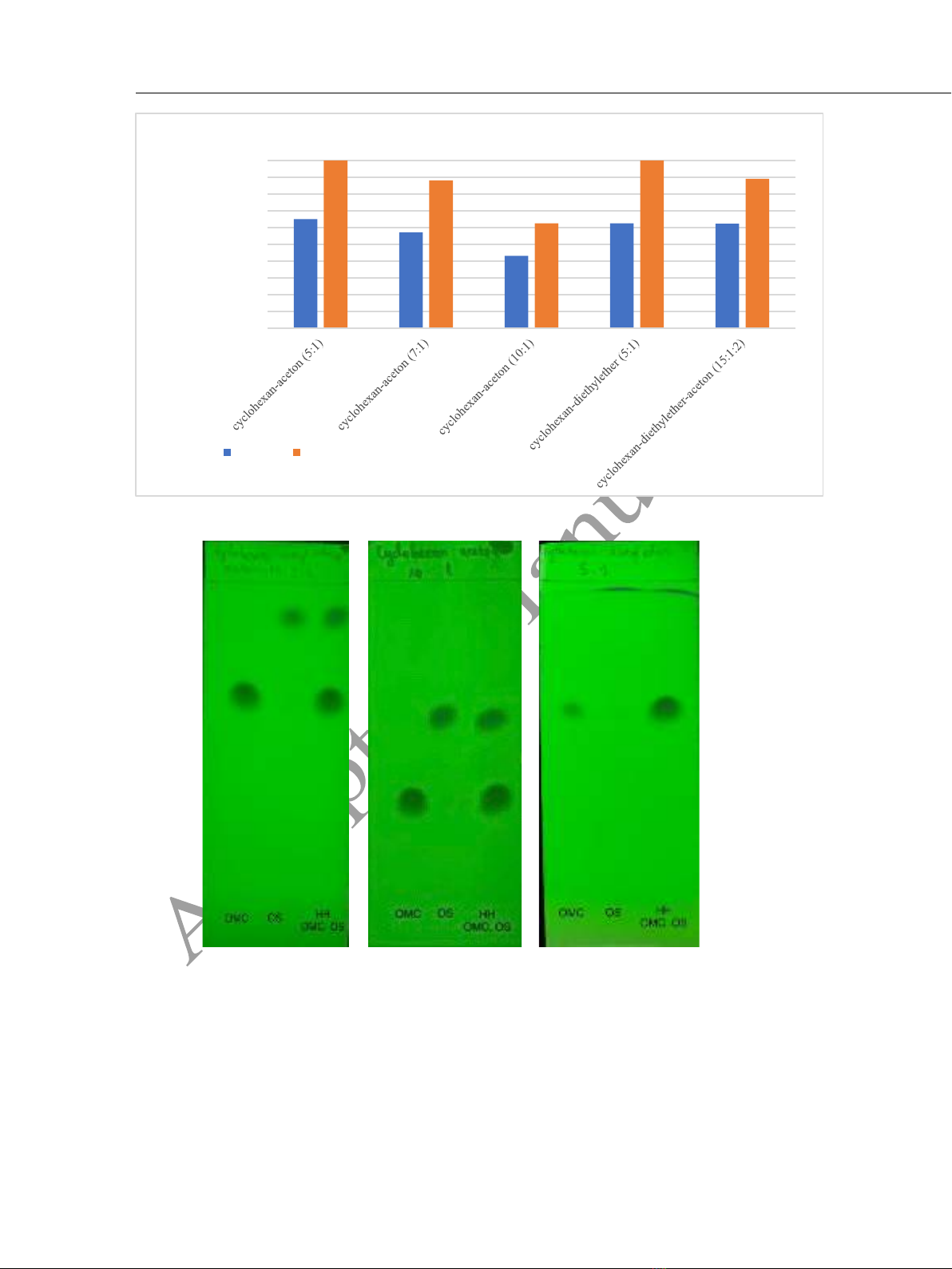

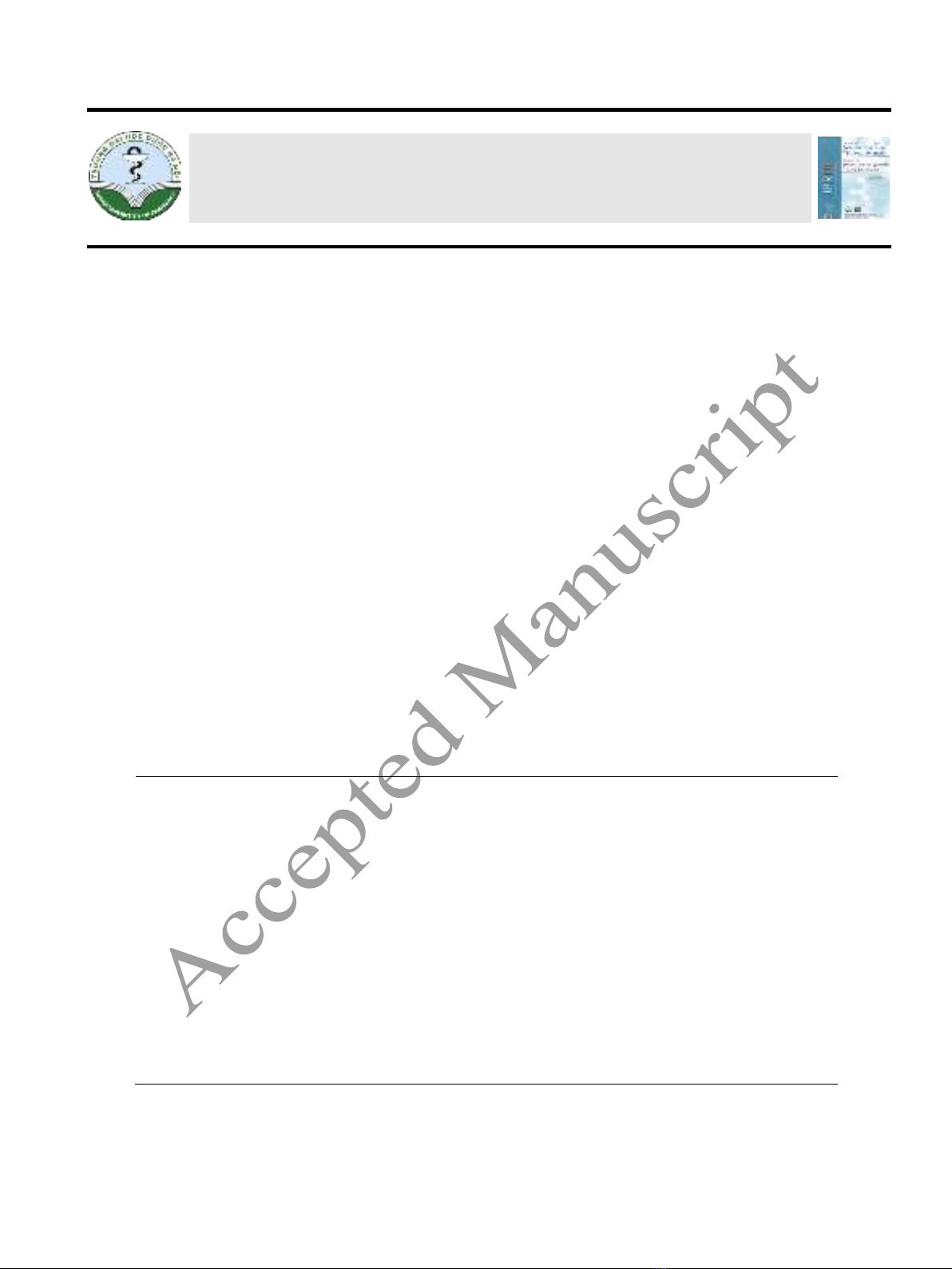

Octylmethoxycinnamate (OMC), octylsalicylate (OS) are UV filters commonly used in

sunscreen creams for skin protection against UV radiations. In this study, an HPTLC

method was developed and validated for simultaneous determination of OMC and OS in

sunscreen creams. The method was carried out using an silica gel 60 F254 thin layer plate

(20 cm × 10 cm) with a mixture of cyclohexane - aceton (10:1, v/v) as mobile phase.

Samples were applied on thin layer plate as 4-mm bands with applied volume at 7.0 µL per

band and the distance between two consecutive bands was 9 mm. The chromatograms

were developed over a distance of 80mm, then scanned and recorded at 307 nm for peak

detection and calculation of peak area. The method was fully validated according to

requirements on analytical method performance of AOAC International. The linearity

ranges of the method were from 17.9 to 32.2 µg/mL for OMC and from 16.3 to 29.4

µg/mL for OS, respectively, and its accuracy (recovery rate from 97.4% to 102.2% for