http://www.iaeme.com/IJMET/index.asp 1894 editor@iaeme.com

International Journal of Mechanical Engineering and Technology (IJMET)

Volume 10, Issue 03, March 2019, pp. 1894-1899. Article ID: IJMET_10_03_192

Available online at http://www.iaeme.com/ijmet/issues.asp?JType=IJMET&VType=10&IType=3

ISSN Print: 0976-6340 and ISSN Online: 0976-6359

© IAEME Publication Scopus Indexed

STUDY OF SPECIFIC ENERGY IN ELASTIC

PHASE OF THE DIFFERENT METALLIC

MATERIALS: ALUMINIUM, COPPER AND

STEEL

H. Ouaomar

Industrial Engineering Laboratory, Faculty of Science and Technology, Sultan

MoulaySlimane University,

BeniMellal, Morocco.

M. Lahlou and M. El Ghorba

Laboratory of Control and Mechanical Characterization of Materials and Structures, National

Higher School of Electricity and Mechanics, BP 8118 Oasis, Hassan II University,

Casablanca, Morocco

N. Mouhib

Laboratory of Control and Mechanical Characterization of Materials and Structures, National

Higher School of Electricity and Mechanics, BP 8118 Oasis, Hassan II University,

Casablanca, Morocco

ISEM/Higher Institute of Maritims Studies, Km 7 Road El Jadida Casablanca Morocco

ABSTRACT

Metallic materiels require a compromise of mechanical and energy characteristics

to achieve the desired functions. They often face aggressive conditions such as

mechanical vibration, heat stress, penetration of moisture or even abuse. These

conditions favor the appearance of more or less serious defects ranging from a simple

crack in the material.

However, To better predict their ruin, it is important to understand the mechanical

behavior of the materials and their damage mode depending on the type of load they

undergo and either the generated default. The reliability of materials is an important

concept to be regarded in estimating service life of materials.

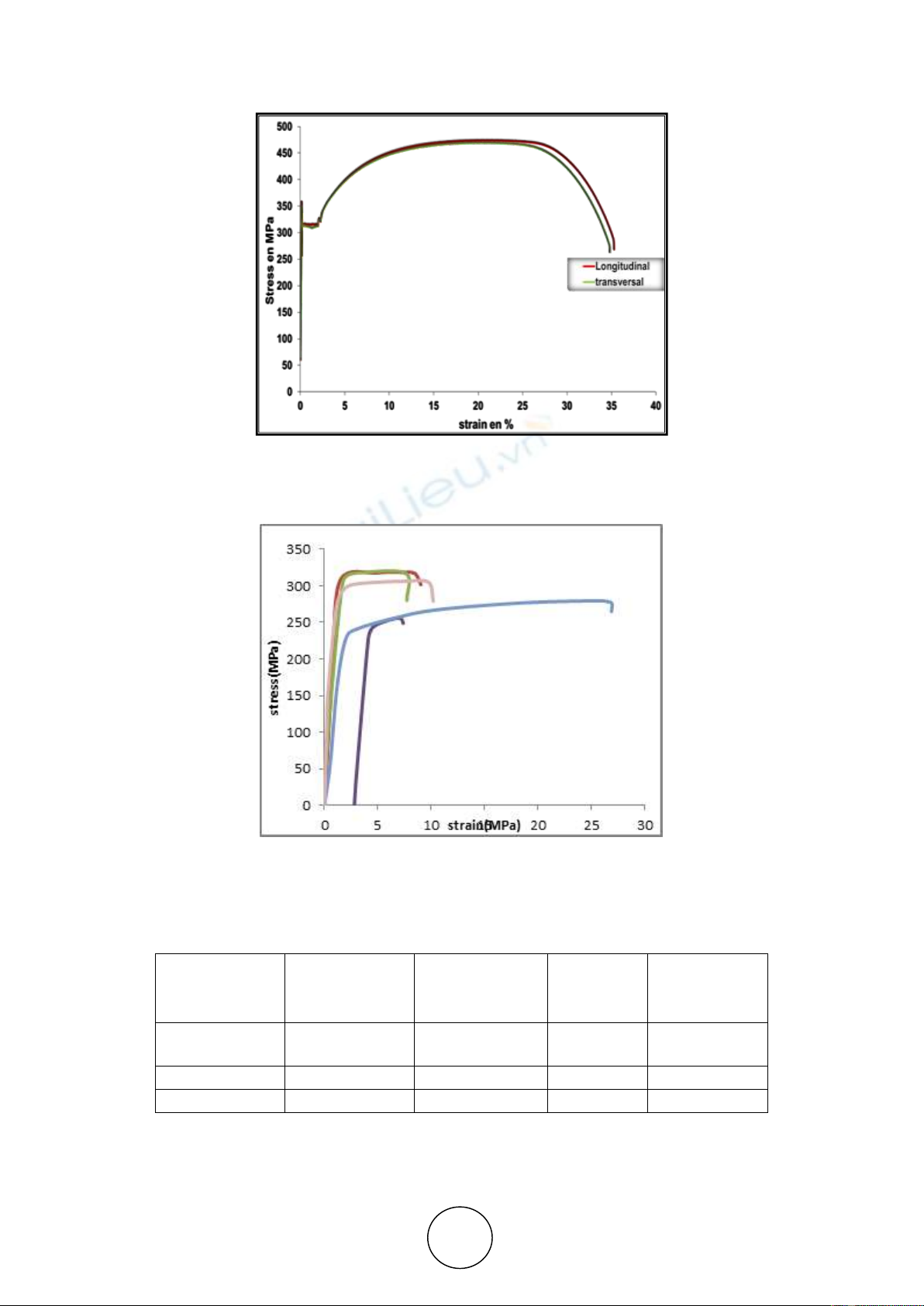

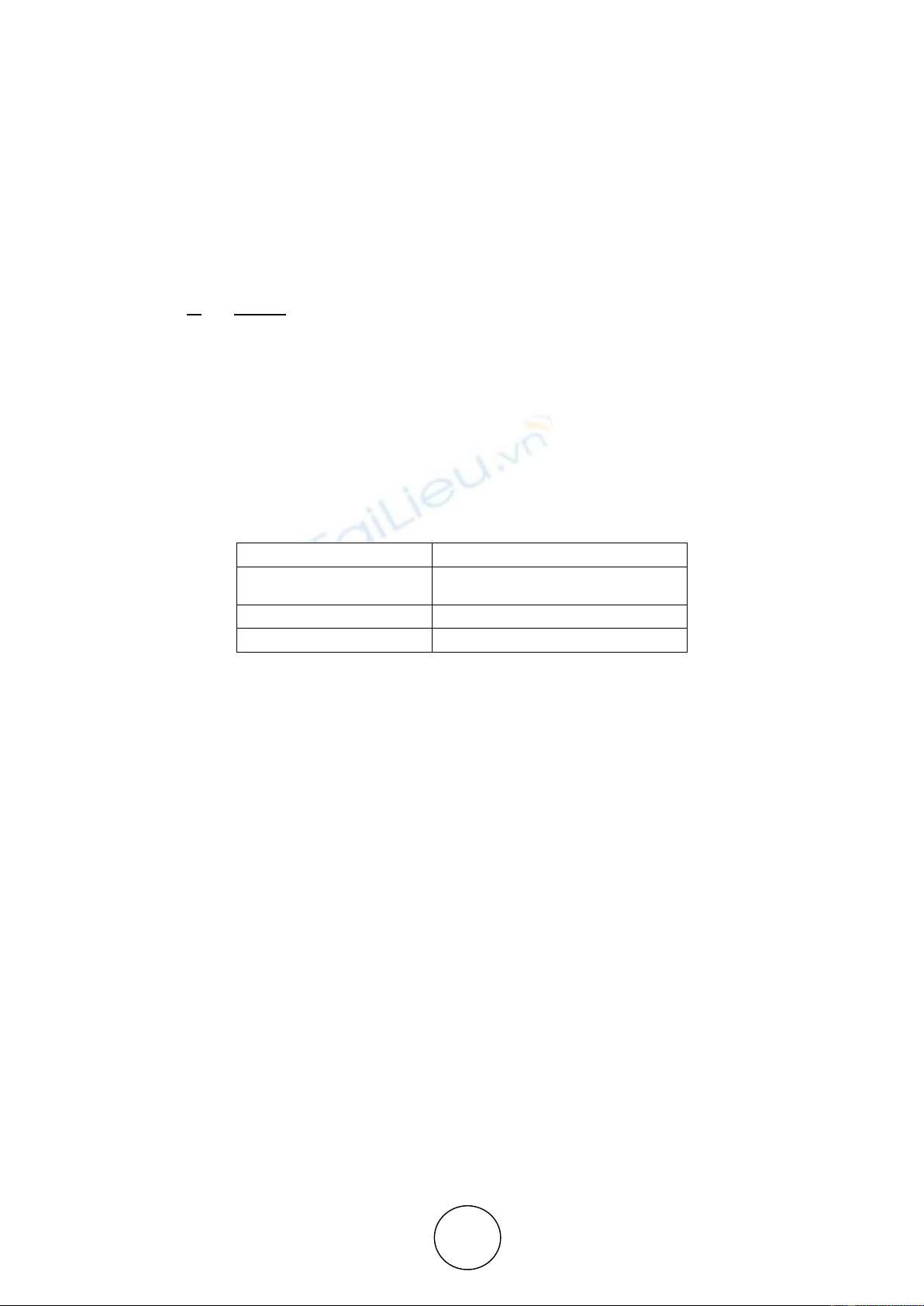

For this, the present work aims to familiarize the mechanical behavior of different

materials, in our study we performed a comparison between the different specific

energies elastic phase of the elements of study.