http://www.iaeme.com/IJMET/index.asp 39 editor@iaeme.com

International Journal of Mechanical Engineering and Technology (IJMET)

Volume 10, Issue 04, April 2019, pp. 39-48. Article ID: IJMET_10_04_006

Available online at http://www.iaeme.com/ijmet/issues.asp?JType=IJMET&VType=10&IType=4

ISSN Print: 0976-6340 and ISSN Online: 0976-6359

© IAEME Publication Scopus Indexed

CASSAVA FOLIAGE HARVESTING MACHINE

SELECTION DECISION MAKING FACTORS:

THE CASE STUDY IN THAILAND

Supattra Buasaengchan

Technopreneurship and Innovation Management, Graduate School, Chulalongkorn

University, Bangkok, Thailand.

Somchai Pengprecha

Faculty of Science, Chulalongkorn University, Bangkok, Thailand.

Pakpachong Vadhanasindhu

Faculty of Commerce and Accountancy, Chulalongkorn University, Bangkok,Thailand.

Kriengkri Kaewtrakulpong

Faculty of Agriculture, Kasetsart University, Bangkok, Thailand.

ABSTRACT

Machine and tooling selection are very important for agriculture economy which

base on labor intensive that increase time usage and cost. Cassava foliage harvesting

selection is very challenging in choosing the machine since it will be the key importance

to change the cassava supply chain that cannot bring cassava foliage to use in the

commercial way. The framework of this study start from the cassava farmers’ aspect,

link with factors concerned from literature review and then grouping the suitable

criteria and sub-criteria. The specific questionnaire was conducted with the

representative of the cassava farmer, agriculture machine maker and the expert user in

cassava foliage. The Analytical Hierarchy Process (AHP) is used to set the hierarchy

structure of the criteria, rating and prioritization. The results of the study illustrate the

machine factors and cost for cassava foliage harvesting machine selection decision

making. The prioritized factors are durability, low cost of harvesting, safety, technology

and quality of output respectively. It can be used not only cassava foliage harvesting

machine selection case but also the other agriculture machine or equipment.

Keywords: cassava foliage harvesting machine, AHP, agriculture machine selection,

multi criteria decision making

Cassava Foliage Harvesting Machine Selection Decision Making Factors: the Case Study in

Thailand

http://www.iaeme.com/IJMET/index.asp 40 editor@iaeme.com

Cite this Article Supattra Buasaengchan, Somchai Pengprecha, Pakpachong

Vadhanasindhu and Kriengkri Kaewtrakulpong, Cassava Foliage Harvesting Machine

Selection Decision Making Factors: The Case Study in Thailand, International Journal

of Mechanical Engineering and Technology, 10(4), 2019, pp. 39-48.

http://www.iaeme.com/IJMET/issues.asp?JType=IJMET&VType=10&IType=4

1. INTRODUCTION

Cassava foliage, cassava leaf or cassava hay in Thailand is accepted in the high crude protein

nutrition for animal feeds comparing to the other sources such as fish meal or soy bean. From

the prior empirical study of the author “The reason why we can’t use cassava leaf for

commercial purpose in Thailand” [1] shows the importance of machine as unmet need. 75% of

the samples are interested in harvesting tools due to the lack of labor, wastes in process, time

which bring to the high cost of harvesting and unprofitability.

The objective of the study is to identify the suitable factors for cassava foliage harvesting

machine selection decision making that can generate revenue and profit from the cassava

foliage with productivity, fit to Thai farming characteristics, easy to use, and reduce labor cost.

The suitable model for machine selection factors and process are essential in order to maximize

the harvesting outcome.

This article is divided into five sections. The introduction shows the importance for this

study, literature review with the theoretical base and relevant researches, and the methodology

of the study. The result of the study from both the survey and the Analytical Hierarchy Process

(AHP). The last section is conclusion, discussion of the result, and the recommendation for

further study.

2. LITERATURE REVIEW

Analytic Hierarchy Process (AHP) method is one of the well-known decision-making

consideration with multiple criteria developed by Thomas Saaty [2]. AHP can be used in both

qualitative and quantitative criteria for the judgment in decision-making. The steps in AHP

comprise of structuring the framework, questionnaire design, sampling & questionnaire survey,

weight the priorities, and then summarize the results and conclusions.

In the process of comparison, the numbers are identified accordingly to the importance scale

of each comparison in line with the definition [3]. The absolute numbers are assigned for each

pair of factors to represent the importance of factor to be selected by the respondent and then

calculated to be used for the systematic decision making.

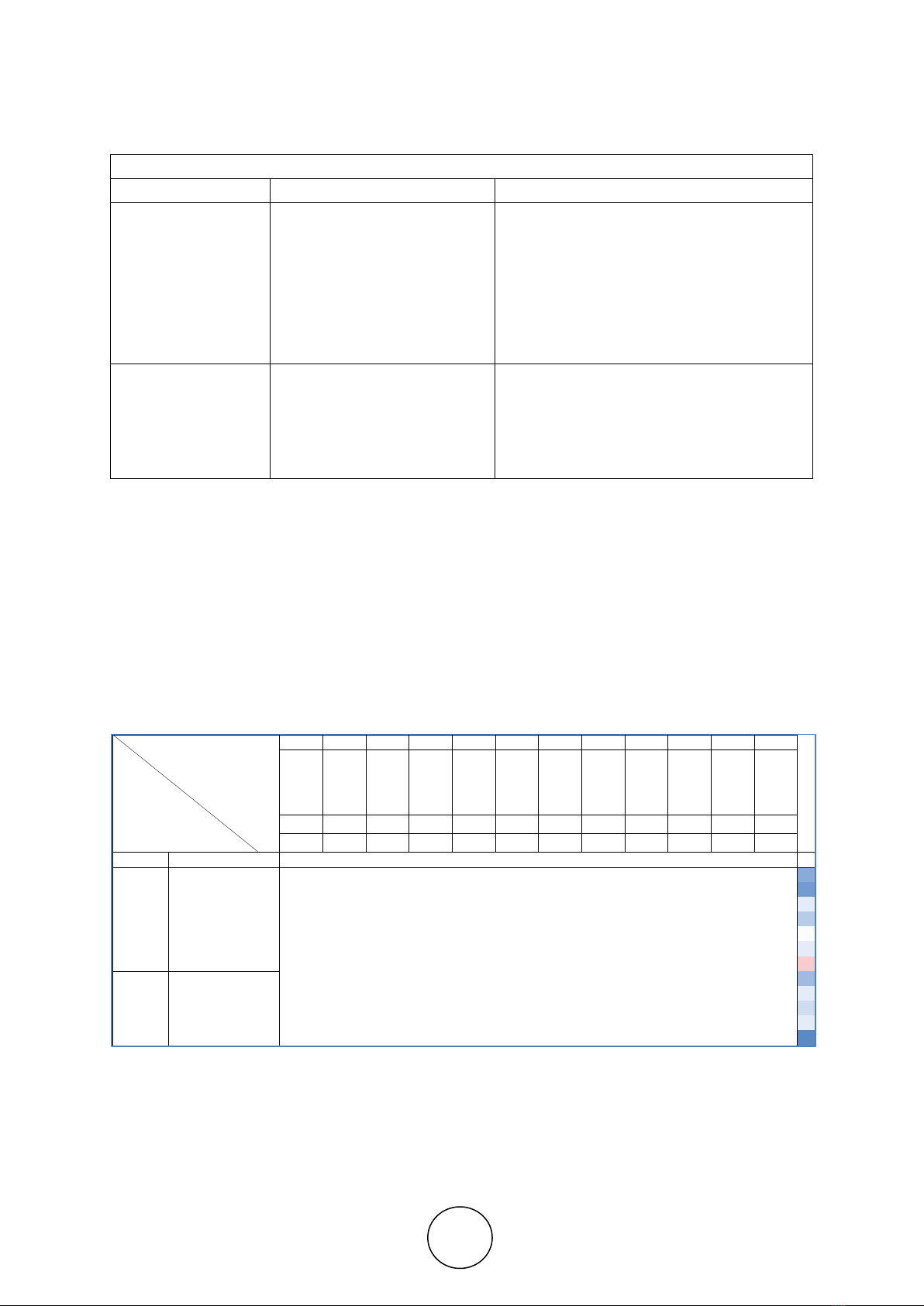

From the literature review, the criteria, machine and cost, and sub-criteria are defined as in

Table1 in order to group the various criteria and definition from the twelve literatures together

with the result from the empirical study. The factors are 2 major criteria: the Machine factor

and the Cost factor. The machine factors consist of 7 sub-criteria: easy to use, productivity,

quality, suitability to scale of production, safety, durable and technology.

For the Cost Factor, the 5 sub-criteria are economical investment, reduce labor, energy

saving, maintenance cost and low cost of harvesting.

Supattra Buasaengchan, Somchai Pengprecha, Pakpachong Vadhanasindhu and Kriengkri

Kaewtrakulpong

http://www.iaeme.com/IJMET/index.asp 41 editor@iaeme.com

Table 1 Expected Cassava Foliage Harvesting Factors and Definition

Agriculture machine selection is one of the importance topics for agriculture development

purpose in many countries. Twelve papers published during the year of 2008 to 2019 was

reviewed as shown in Table 1. The tools reference in each paper are various, 50% were in

machine design to meet customers’ expectation [4-9]. Thirty three percent use AHP Model [10-

13], the others uses descriptive statistics [14] and purposive interview [15].

The twelve literature review of the criteria and sub-criteria are scored as shown in Table2.

Low cost of harvesting has the highest score at 10 among all criteria. The second one is

productivity with 9 scores, the third one is easy to use with 8 scores. These criteria will be used

to map with the factors in the questionnaire as shown in the framework of the study (Figure.1).

Table 2 Literature Review on Agriculture Machine Design and Selection

3. METHODOLOGY

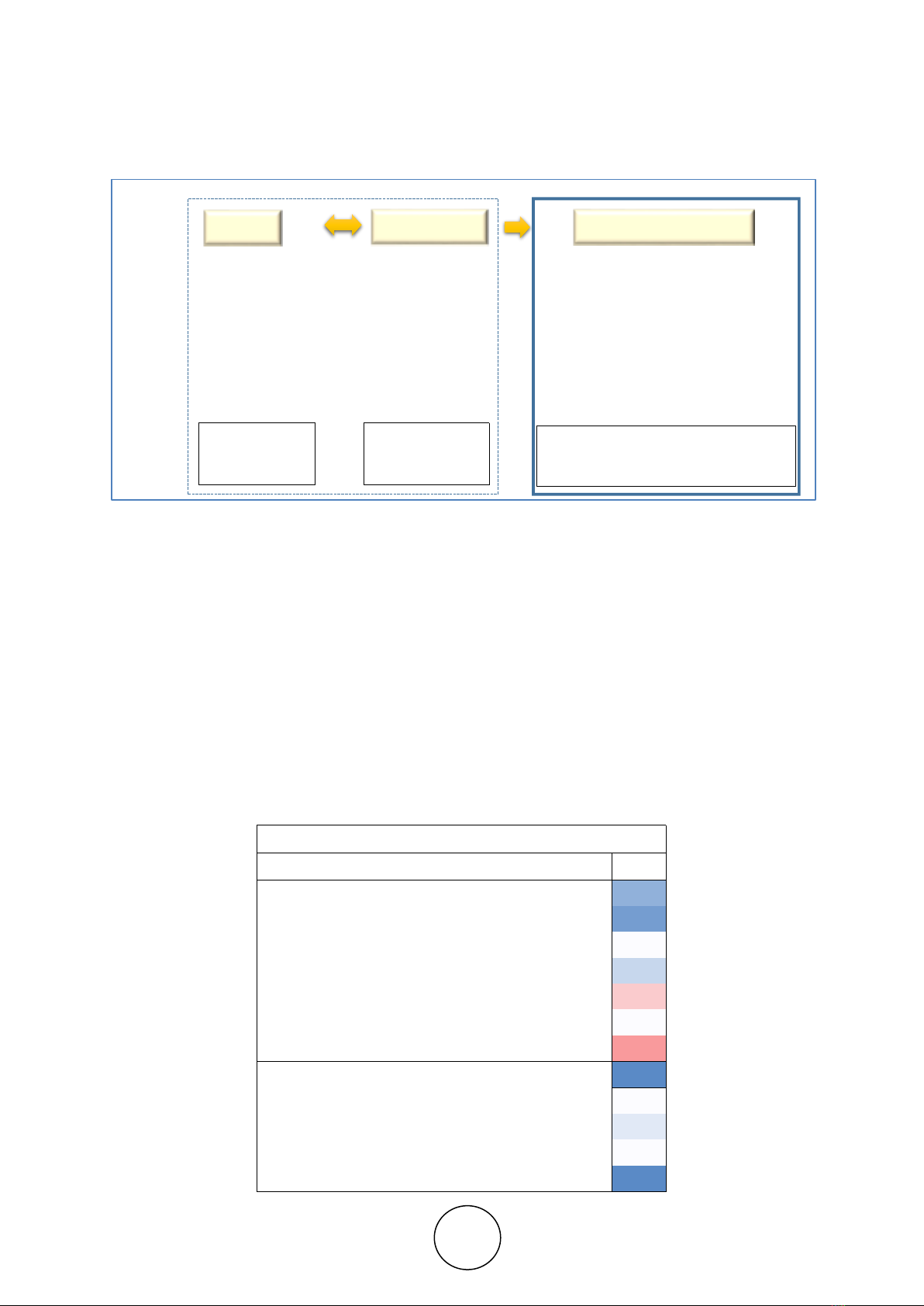

The framework of cassava foliage harvesting machine selection decision making factors (Figure

1.) for this study was set in 3 steps. The first step is the result summary of the cassava foliage

harvesting perception from the author’s prior empirical study [15]. The second step is the

questionnaire design covering the factors concluded from literature review and the survey

Main Criteria Sub-Critetia Definition

1 Machine Factors 1-1 Easy to Use Easy to Use/Control/Ergonomics

1-2 Productivity Effectiveness/Reduce Harvesting Time/Productivity

1-3 Quality of Output Quality/Low Foreign material

1-4 Suitability to Scale of production Suitability to Scale of production/Shape of Tree

1-5 Safety Safety

1-6 Durable Durable

1-7 Techonology Techonology/ Automation

2 Cost Factors 2-1 Economical Investment Economical Cost of M/C

2-2 Reduce Labor Cost Reduce Labor Cost

2-3 Energy Saving Energy Saving

2-4 Maintenance Cost Maintenance Cost

2-5 Low Cost of Harvesting Low Cost of Harvesting

Expected Cassava Foliage Harvesting Factors and Definition

1 2 3 4 5 6 7 8 9 10 11 12

Supplier Slection

in Automobile

industry

Development of a

Mechanical

Harvesting

Machine for High-

density Citrus

Groves

Manufacturing

local machine suit

for harvesting

sugar beet

Factors

Influencing

Decision Making to

Middle Size Tractor

Jewel Factory

Machine Selection

Rice Farmers’

Decision to

Purchase

Agricultural

Machine for Land

Preparation

Machine Selection

by AHP and

TOPSIS Methods

Design And

Calculation Of

Solar Power

Operated

Sugarcane

Harvesting Machine

DESIGN AND

FABRICATION OF

HARVESTING

MACHINE-Reaper

M/C Soybean

Multi-Crop

Harvesting Machine

Olive harvesting

Machine

Harvesting and

Postharvest

Management

Surakrit

Redmond Ramin

Shamshiri

A. F. Abed

Rabou,et al

Atthasat et al Rattarut Kritsada

Rubayet Karim, et

al

Prashant

Inkane,et al

Amar et al

Ravindra Lahane

et al

Ashkan Carl J. Bern

AHP

Purposive

Interview+LR

Machine Design Machine Design AHP

Descriptive

statistics

AHP and TOPSIS Machine Design Machine Design Machine Design AHP Machine Design

Main Criterias Sub Criterias 2008 2009 2011 2013 2014 2014 2016 2017 2018 2018 2018 2019 Scores

1. Machine Factors

1-1 Easy to Use ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ 8

1-2 Productivity ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ 9

1-3 Quality of Output ✓ ✓ ✓ ✓ 4

1-4 Suitability to Scale of production ✓ ✓ ✓ ✓ ✓ ✓ 6

1-5 Safety ✓ ✓ ✓ 3

1-6 Durable ✓ ✓ ✓ ✓ 4

1-7 Techonology ✓ ✓ 2

2. Cost Factors 2-1 Economical Investment ✓ ✓ ✓ ✓ ✓ ✓ ✓ 7

2-2 Reduce Labor Cost ✓ ✓ ✓ ✓ 4

2-3 Energy Saving ✓ ✓ ✓ ✓ ✓ 5

2-4 Maintenance Cost ✓ ✓ ✓ ✓ 4

2-5 Low Cost of Harvesting ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ 10

Reference Literatures

Criteria-Subcriteria and Scores

Cassava Foliage Harvesting Machine Selection Decision Making Factors: the Case Study in

Thailand

http://www.iaeme.com/IJMET/index.asp 42 editor@iaeme.com

mentioned in step 1. The last importance step is the AHP analysis of the data gathered from the

result of the study in step 2.

Figure 1. Framework of Cassava Foliage

Harvesting Machine Decision Making Selection Factors

3.1. Prior Empirical Survey

The author’s empirical survey for the cassava foliage harvesting machine selection to know the

factors concerned revealed 2 factors comprised of machine factors and cost factors.

3.2. Factors Review from Literature

The further step is to review factors from the interview and literature that can be grouped into

2 main criteria which are machine factors and cost factors. The sub-criteria of each factor are

summarized as shown in Table 3.

Table 3 Factors concerned from Literature Review

Framework of Cassava Foliage Harvesting Machine Decision Making Selection Factors

Prior Empirical

Study

Literature Review AHP

Survey

1 Structuring the Framework

2. Questionnaire Design

5. Results and Conclusion

1. Review Literature

empharsized on

Agriculture Machine

Selection Factors

260 Samples

Cassava Farmers

Samples

Description

12 Papers on

Agriculture

Machine Design

7 Samples

2-Cassava Farmers : Head of the Association/ Cooperation

2-Machine Designer & Maker

3-Agriculture Expert (Cassava Foliage)

2. Factors Concerned

Grouping

1. In-depth Interview

for factors concerned

2. Machine Selection

Factors in

Qualitative

Interview

3. Conclusion

3. Review Factors on

Interview and

Literature

Process

Source

4. Weigh the priorities

3. Sampling & Questionnaire Survey

Main Criteria Sub-Criteria Scores

1 Machine Factors

1-1 Easy to Use 8

1-2 Productivity 9

1-3 Quality of Output 4

1-4 Suitability to Scale of production 6

1-5 Safety 3

1-6 Durable 4

1-7 Techonology 2

2 Cost Factors 2-1 Economical Investment 7

2-2 Reduce Labor Cost 4

2-3 Energy Saving 5

2-4 Maintenance Cost 4

2-5 Low Cost of Harvesting 10

Factors concerned from Literature Review

Supattra Buasaengchan, Somchai Pengprecha, Pakpachong Vadhanasindhu and Kriengkri

Kaewtrakulpong

http://www.iaeme.com/IJMET/index.asp 43 editor@iaeme.com

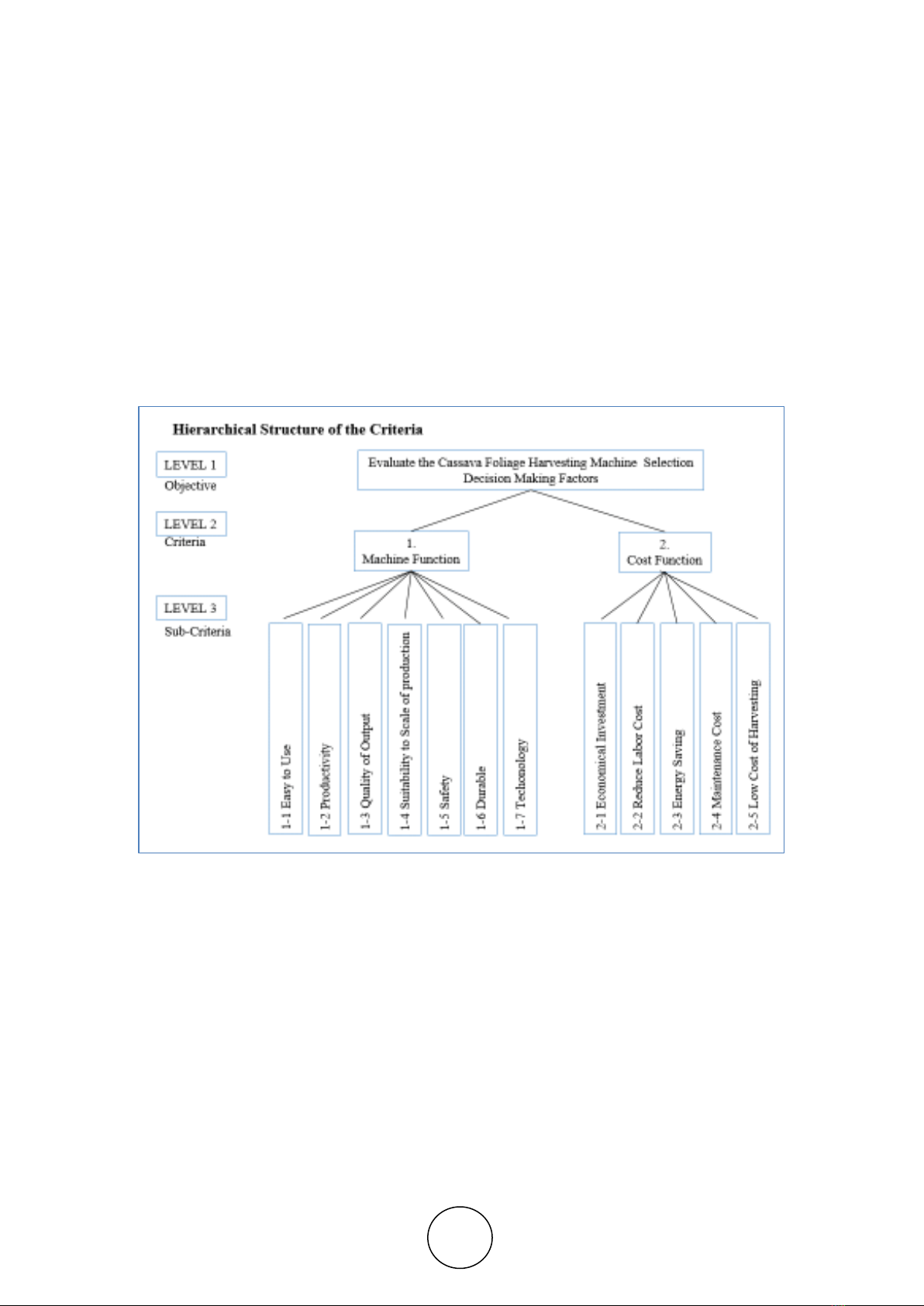

3.3. AHP Survey

The step of AHP survey are as followed. There are five phases which are structuring the

framework, questionnaire design, sampling and questionnaire survey, weigh the priorities and

results and conclusion.

3.3.1. Structuring the framework

From the factors identified, the hierarchical structure of the criteria is conducted as in Figure 2.

Starting from the top of the hierarchical structure, Level 1, the objective of the model is to

evaluate the cassava foliage harvesting machine selection decision making factors. In Level 2,

the main criteria in both machine function and cost function are directly related to Level 1.

Level 3, the sub-criteria directly linked to criteria in Level 2 are set to evaluate the multiple

alternative in decision-making process.

Figure 2. Hierarchical Structure of the Criteria

3.3.2. Questionnaire Design

We design questionnaire to interview the samples using the pairwise comparison for each

factor. The sample of the questionnaire are shown as below: (Table 4)