See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/288218298

The rolling resistance and tractive performance of a small agricultural tractor

with different surface and moisture conditions on Bangkok clay soil

Article · January 2014

CITATIONS

2

READS

4,894

4 authors, including:

Jannatul Ferdous

BRAC University

5 PUBLICATIONS66 CITATIONS

SEE PROFILE

Peeyush Soni

Indian Institute of Technology Kharagpur

166 PUBLICATIONS3,065 CITATIONS

SEE PROFILE

Madhav D Gholkar

23 PUBLICATIONS128 CITATIONS

SEE PROFILE

All content following this page was uploaded by Madhav D Gholkar on 19 January 2021.

The user has requested enhancement of the downloaded file.

1

___________________________________________________________________________________________________________

The authors are solely responsible for the content of this technical presentation. The technical presentation does not necessarily reflect

the official position of the International Society for Terrain Vehicle Systems (ISTVS), and its printing and distribution does not constitute

an endorsement of views which may be expressed. Technical presentations are not subject to the formal peer review process by ISTVS

editorial committees; therefore, they are not to be presented as refereed publications. Citation of this work should state that it is from an

ISTVS meeting paper. EXAMPLE: Author's Last Name, Initials. 2014. Title of Presentation. The 18th International ISTVS Conference

Seoul, Korea. For information about securing permission to reprint or reproduce a technical presentation, please contact ISTVS at 603-

646-4405 (72 Lyme Road, Hanover, NH 03755-1290 USA)

___________________________________________________________________________________________________________

Proceedings of the 18th International Conference of the ISTVS 2014

THE ROLLING RESISTANCE AND TRACTIVE PERFORMANCE OF A SMALL

AGRICULTURAL TRACTOR WITH DIFFERENT SURFACE AND MOISTURE

CONDITIONS ON BANGKOK CLAY SOIL

Jannatul Ferdousa, Peeyush Sonia, Madhav D. Gholkara, Alex Keenb

aAgricultural Systems and Engineering Dept., Asian Institute of Technology, Pathumthani, Thailand.

bSchool of Engineering and Technology, Kaziranga University, Jorhat, India.

corresponding author: alexkeen@blueyonder.co.uk

________________________________________________________________________________________________

Abstract

Cultivations in paddy fields can take place with a wide range of surface conditions and soil moisture which can have

a considerable effect on tractive performance and the maximum tractive efficiency that can be achieved. The aim of

this research was to investigate the rolling resistance and tractive performance of a small agricultural tractor of 18.7 kW

and 0.99 tonnes operating in two wheel drive (2WD) and four wheel drive (4WD) on Bangkok clay soil under different

surface and moisture conditions. The four surface and moisture conditions were bare and grass surfaces on soft plastic

soil and bare and grass surfaces on hard plastic soil. Torque transducers were fitted to each wheel to measure the

longitudinal wheel forces. Wheel slip and drawbar pull were also measured enabling rolling resistance and tractive

efficiency to be determined. Experiments were conducted at the agricultural fields and laboratories of the Agricultural

Systems and Engineering department, Asian Institute of Technology, Thailand. The highest rolling resistance was

observed in 2WD on soft plastic soil with a bare surface, and the lowest rolling resistance was in 4WD on hard plastic

soil with a grassy surface. At the same wheel slip, wheel thrust and drawbar pull were highest in 4WD on hard plastic

soil, and the lowest thrust was in 2WD on soft plastic soil. The highest maximum tractive efficiency was 62% in 4WD

on the hard plastic soil with a grassy surface, and the lowest maximum tractive efficiency was 24% in 2WD on the soft

plastic soil with a bare surface.

Keywords: traction, rolling resistance, wheel thrust, drawbar pull, tractive efficiency, wheel torque sensors, Bangkok clay

________________________________________________________________________________________________

1. Introduction

Traditional intensive lowland rice production is

carried out in flooded conditions and to enable primary

cultivation with small two and four wheel tractors this

cultivation is usually carried out after field flooding. As

Salokhe [1] has stated, the performance of pneumatic

tyres decreases as the moisture content increases and

becomes very poor in flooded soil. Problems of tractors

fitted with pneumatic tyres in wetland conditions

include tractors becoming stuck, breaking through the

hardpan and the blocking of tyre treads which takes

place particularly in sticky soil conditions. Cage

wheels are an effective traction aid in wetland

conditions [2] where the tractive performance is

increased by cutting through soft soil in the plough

layer and getting better grip and traction on the harder

compacted soil in the hardpan [3] but they can also

have the effect of increasing the depth of the hardpan

[4]. Tanaka [3] states that on surface conditions where

there is no hardpan strong enough to support the

vehicle, immobilization may take place requiring

vehicles to operate with less ground contact pressure

by using tracks or floats. As moisture content

increases, soil strength reduces and cultivation forces

become less but traction becomes more difficult,

tractive efficiency reduces and soil damage and long

term soil sustainability becomes more problematic [5].

The majority of existing models for the prediction

of the tractive performance of driven wheels relate to

soil moisture conditions up to a plastic state but not for

saturated soil [6]. Also, there is little published

research that considers tractive performance in the

context of soil management in lowland intensive rice

production and long term sustainable soil use, the

2

Proceedings of the 18th International Conference of the ISTVS 2014

energy inputs required and the environmental impact

[5]. Evans et al. [7] have stated that a vehicle’s fuel

economy is influenced by tyre rolling resistance, and,

therefore, it is important to have a stronger

understanding of tire rolling resistance for improving

efficiency and thereby fuel saving in farm operations.

Energy consumption of tractors depends on tractive

performance and prevailing field conditions.

Quantification of tractive efficiency and tractive

performance is part of increasing understanding and

making improvements. Furthermore, as field surface

conditions greatly determine the system performance

of off-road wheeled and tracked vehicles, it is

important to include the contribution of soil surface

condition. Upadhyaya et al. [8] identified that the

changes in soil conditions influence tyre performance

much more than changes in tyre loading and

dimensions.

To specifically address the need of having clearer

insight on a farm tractor’s response to prevailing field

surface conditions, the aim of this research was to

investigate and evaluate tractive performance of a

small agricultural tractor of 18.7 kW and 0.99 tonnes in

2WD and 4WD operating on Bangkok clay soil when

the soil is in a plastic state and before soil moisture

increases to a more problematic sticky soil state, and

includes the effect of surface condition. The specific

objectives reported here were to:

a) measure the actual rolling resistance from field tests.

b) compare the coefficients of rolling resistance to

those derived from existing models.

c) evaluate the tractive efficiency of a small 18.7 kW

agricultural tractor under various surface conditions

and soil moisture contents.

2. Material and Methods

2.1. Rolling Resistance and Tractive Performance

Measurement

Hall and Moreland [9] define tire rolling resistance

as the energy consumed per unit distance of travel as a

tire rolls under load. Rolling resistance can be

measured from the difference between wheel gross

thrusts measured at the wheels and net thrusts

measured as drawbar pull. Wheel thrust measurement

required recording the torque value in each of the four

wheels. Drawbar pull was measured by a load cell

attached to the drawbar of the test tractor (a Kubota

L2050) and pulling through this load cell a ‘loading’

tractor (a Kubota L345II). Measurement of wheel slip

required the actual travel speed and the theoretical

travel speed of the slipping wheels. For this, a rotation

position sensor was attached to each wheel of the test

tractor to measure its wheel rotation speeds and a

dynamo was mounted on the front wheel of the loading

tractor to measure the actual travel speed. The

coefficient of rolling resistance (CRR), calculated from

the test data, was compared with existing empirical

models (see Table 1). The coefficient of rolling

resistance was calculated from test data using the

following expression:

CRR = RR/ W (1)

Where:

CRR = coefficient of rolling resistance, RR =

rolling resistance (N), W = Vertical load (N)

Tractive performance of the test tractor was

computed as tractive efficiency (TE) and net traction

ratio (NTR) by using the following expressions:

⁄

⁄

(

)

(2)

Where:

NT = Net traction; Wd = Dynamic weight; GT = Gross

traction; Va = Actual travel speed; Vt = Theoretical

travel speed; NTR = Net traction ratio; and GTR =

Gross traction ratio.

During the tests, tire inflation pressures for both

rear and front wheels were kept constant at 100 and

200 kPa, respectively; and no extra load was added on

drive axle. The tests were replicated three times in both

2WD and 4WD under all the test conditions.

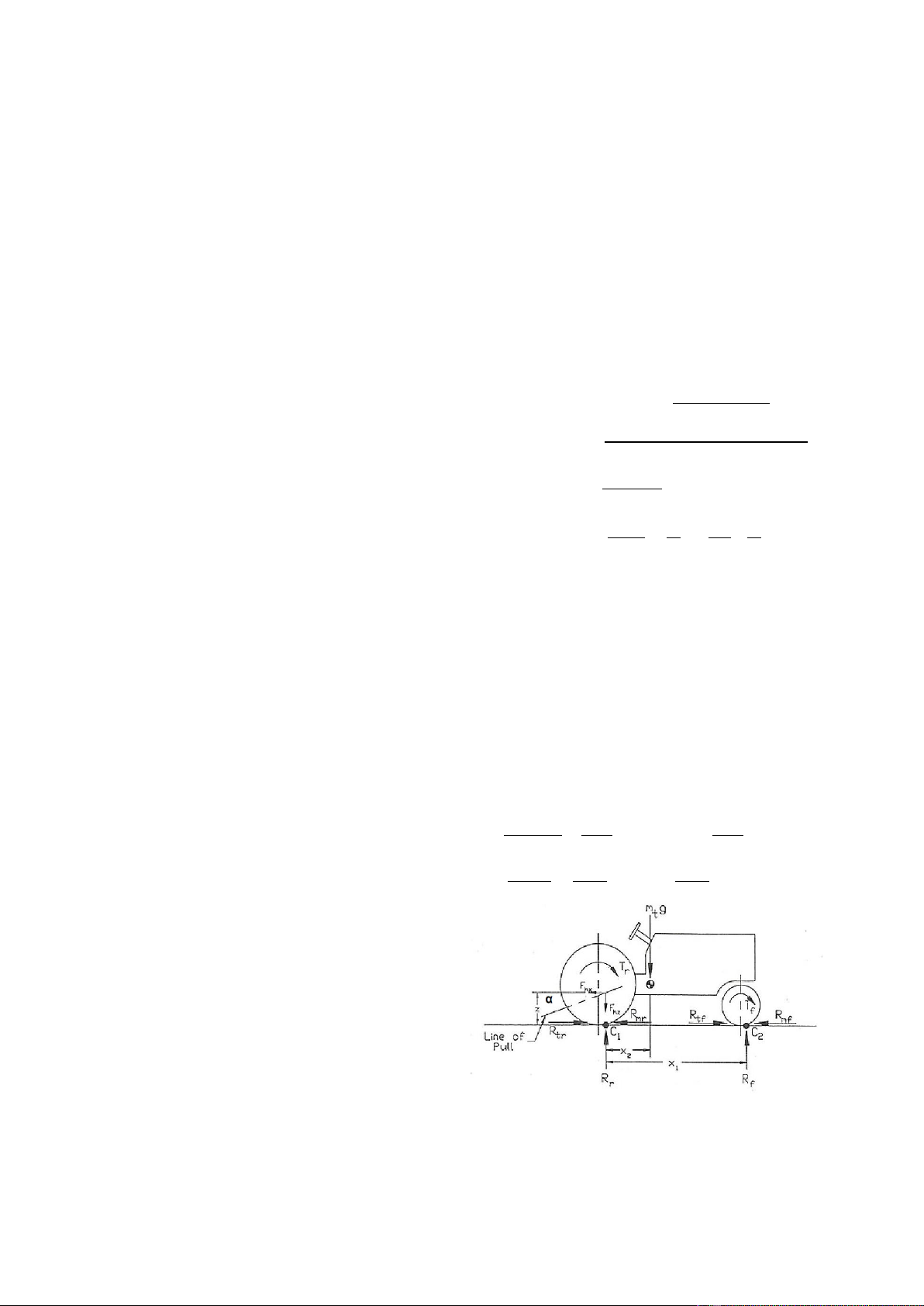

Dynamic loads on the front and rear tyres were

determined for the NTR calculation using the

expressions given by Evans et al. [13]:

(3)

(4)

Fig. 1. Dynamic forces acting on a tractor pulling an

implement, from Evans et al. [13]( α=0 in these tests)

Where:

Rro= static rear wheel reaction, kN; Rfo= static front

wheel reaction, kN; Rmi= motion resistance force, kN;

3

Proceedings of the 18th International Conference of the ISTVS 2014

Rti= traction force, kN; Rr= dynamic vertical reaction

on rear wheels, kN; Rf= dynamic vertical reaction on

front wheels, kN; Fhx= horizontal component of

drawbar pull, kN; Fhz= vertical component of drawbar

pull, kN; mt= tractor mass (Mg); g = acceleration of

gravity; x1= wheelbase, mm; x2= distance between the

rear axle centre to vehicle centre of gravity, mm; z =

distance from ground to intersection of Rr with line of

pull, mm; i = f (front wheel) r (rear wheel): α=0 (line of

pull was horizontal).

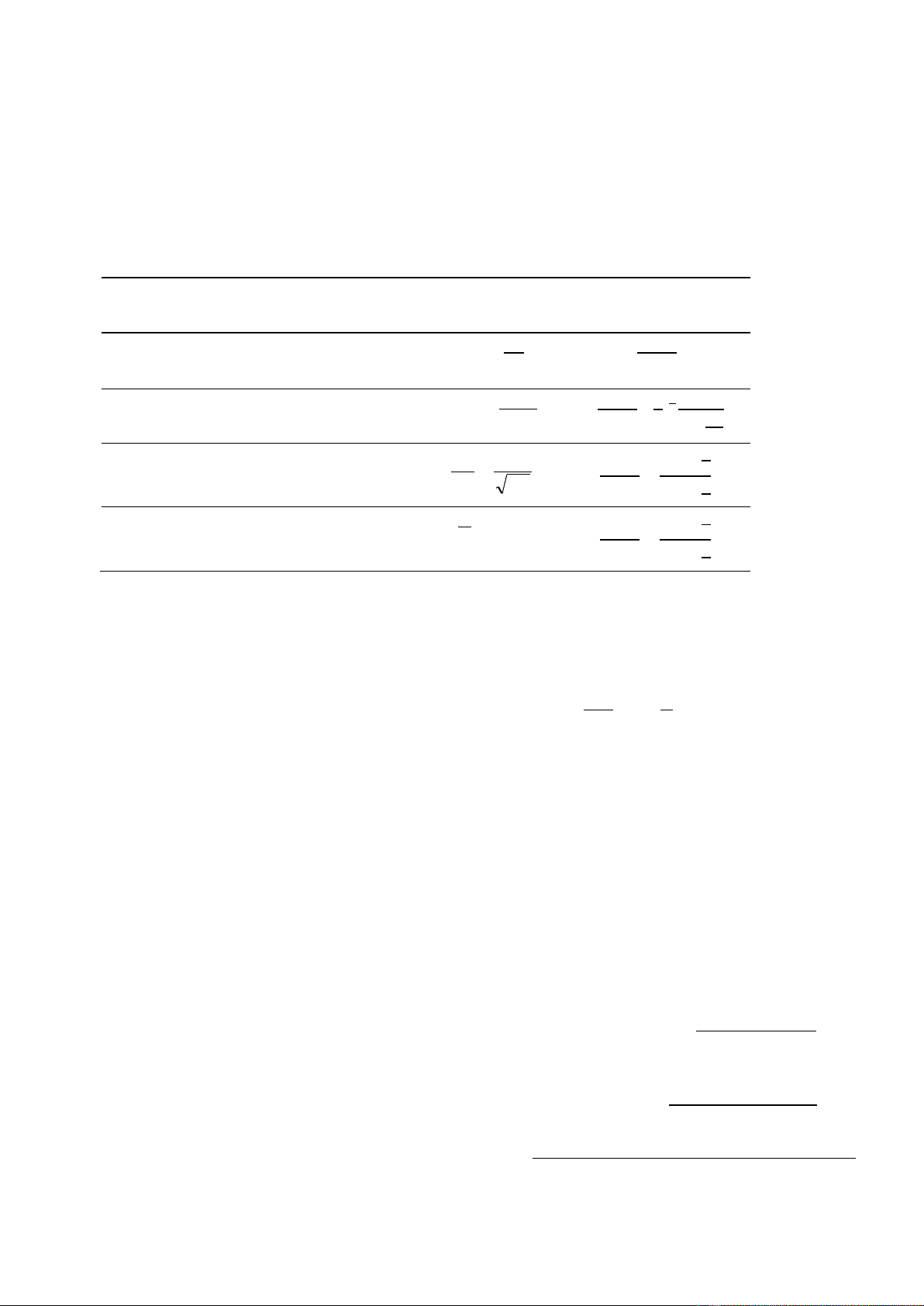

Table 1. Empirical models for estimating coefficient of rolling resistance

Empirical

model

Developed for specific

surface

Coefficient of

Rolling Resistance

(CRR)

Mobility Number (M or

Bn) used in the model

Wismer and

Luth [10]

Bias ply agricultural tyres for

agricultural soil

(

)

Gee-Clough

[11]

Agricultural soil

(

)

Brixius [12]

soil

Bn

S

Bn

5.01

(

)(

)

Evans et al.

[13]

Grass surface

(

)(

)

Where: CI = Cone Index (kPa); b = Tire width (m); d = Tire diameter (m); W=Vertical load (kN);

δ = Deflection (m); and h = Section height (m): S=wheel slip.

2.2 Tractor Instrumentation

An 18.8 kW tractor (a Kubota L 2050) was used as

the test tractor and a 25.5 kW tractor (a Kubota L 345

II DT) was used as the loading tractor. The test tractor

was instrumented with strain gauge based torque

transducers which included load cells for measuring

torque and slip rings for carrying signals through the

rotating wheel, and wheel position sensors to measure

the wheel rotation speed. A load cell was used to

measure the drawbar pull.

2.2.1 Torque Measurement

Four strain gauge based transducers, designed by

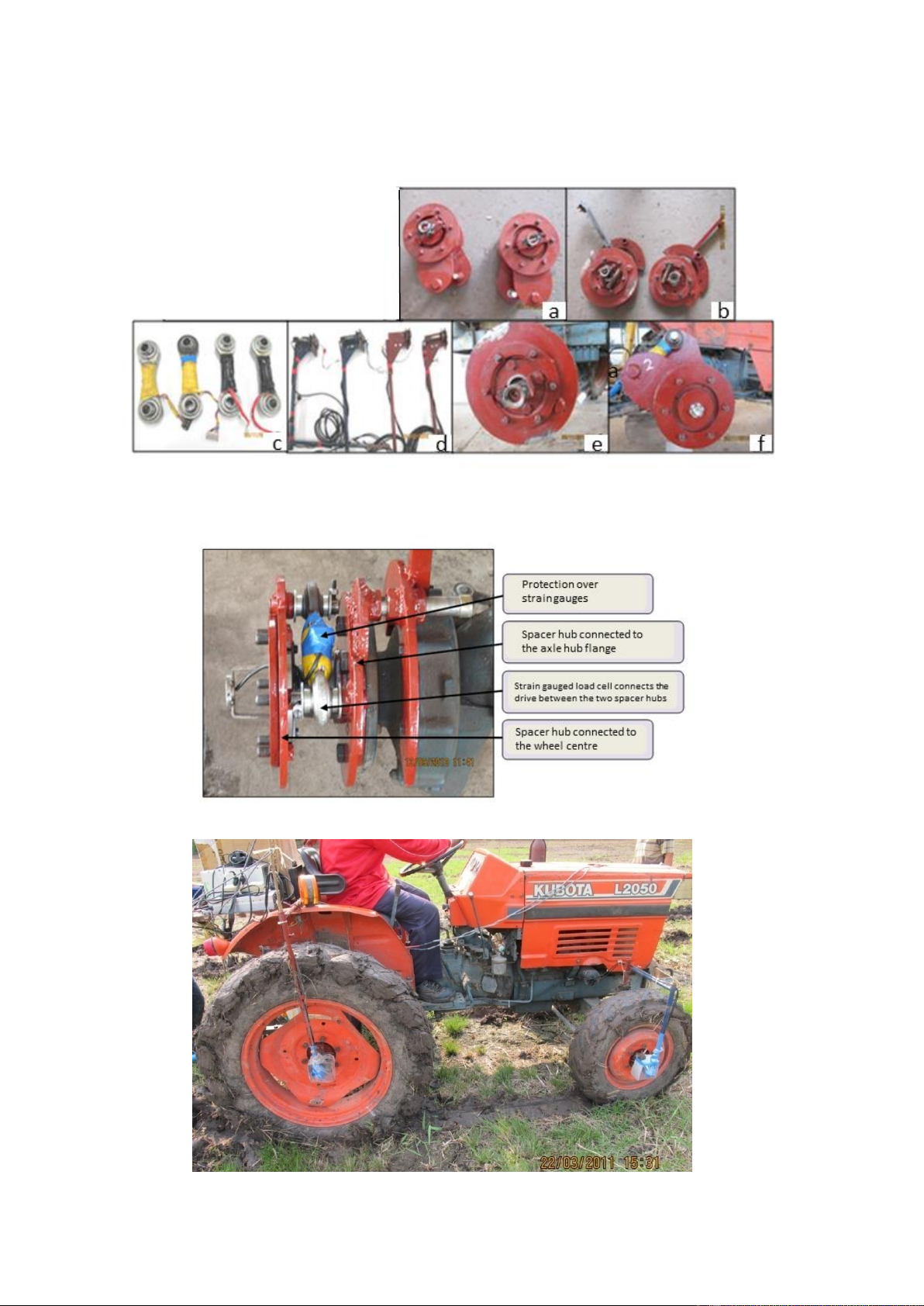

Keen et al.[14], were used to measure the wheel

torque. Transducer load cells were mounted at the

wheel centre by using spacer hubs, which allowed

uninterrupted power transmission through each wheel

while simultaneously measuring torque. The

arrangement of spacer hubs on the tractor wheel is

shown in Fig. 2 and the instrumented tractor is shown

in Fig. 3. The transducers used a full Wheatstone

bridge circuit formed by the four strain gauges and the

voltage output was proportional to torque input.

The torque transducers were calibrated in the

laboratory. All static calibrations showed high linearity

of the measurements with correlation coefficients

approaching unity. Calibration equations for all four

transducers were individually obtained by the least

squares method.

2.2.2 Wheel slip measurement

Wheel slip (S), was calculated by:

(5)

Where: S= Slip; = Theoretical travel speed;

= Actual travel speed

Rotary optical encoders (Figure 4) were used to

measure the actual rotations of each of the four wheels

of the test tractor as recommended by Lee and Kim

[15]. Wheel rotation was converted into digital square

pulses by rotary encoders, the data were then post

processed using routines written in MathCAD. Linear

distance per pulse was calculated from overall distance

travelled during calibration runs. From the distance per

pulse, the rolling radiuses of all four wheels were

calculated for calibration of the speed sensor optical

encoder by the following relationship:

therefore,

4

Proceedings of the 18th International Conference of the ISTVS 2014

Fig. 1. Components of the torque measurement device:(a) and (b) transducer arrangements for rear and front wheels; (c)

transducers; (d) full sets of optical encoders and slip rings; (e) and (f) front and rear wheel arrangements on the

tractor without wheel fitted.

Fig. 2. Arrangement of torque transducer on to the test tractor axle

Fig. 3. Instrumented test tractor