http://www.iaeme.com/IJMET/index.asp 1079 editor@iaeme.com

International Journal of Mechanical Engineering and Technology (IJMET)

Volume 10, Issue 03, March 2019, pp. 1079-1087. Article ID: IJMET_10_03_109

Available online at http://www.iaeme.com/ijmet/issues.asp?JType=IJMET&VType=10&IType=3

ISSN Print: 0976-6340 and ISSN Online: 0976-6359

© IAEME Publication Scopus Indexed

INVESTIGATING PYROLYSIS

CHARACTERISTICS OF DENDROCALAMUS

ASPER BAMBOO

*Teodoro A. Amatosa, Jr.

Engineering Graduate Program, School of Engineering, University of San Carlos, Talamban

Campus, Cebu City, 6000 Philippines

Michael E. Loretero

Department of Mechanical and Manufacturing Engineering, University of San Carlos,

Talamban Campus, Cebu City, 6000 Philippines

Yee-wen Yen

Department of Materials Science and Engineering, National Taiwan University of Science

and Technology, Taipei 106, Taiwan

Andromeda Dwi Laksono

Institut Teknologi Kalimantan, Kampus ITK Karang Joang, Balikpapan 76127, Kalimantan

Timur, Indonesia.

*Corresponding Author

ABSTRACT

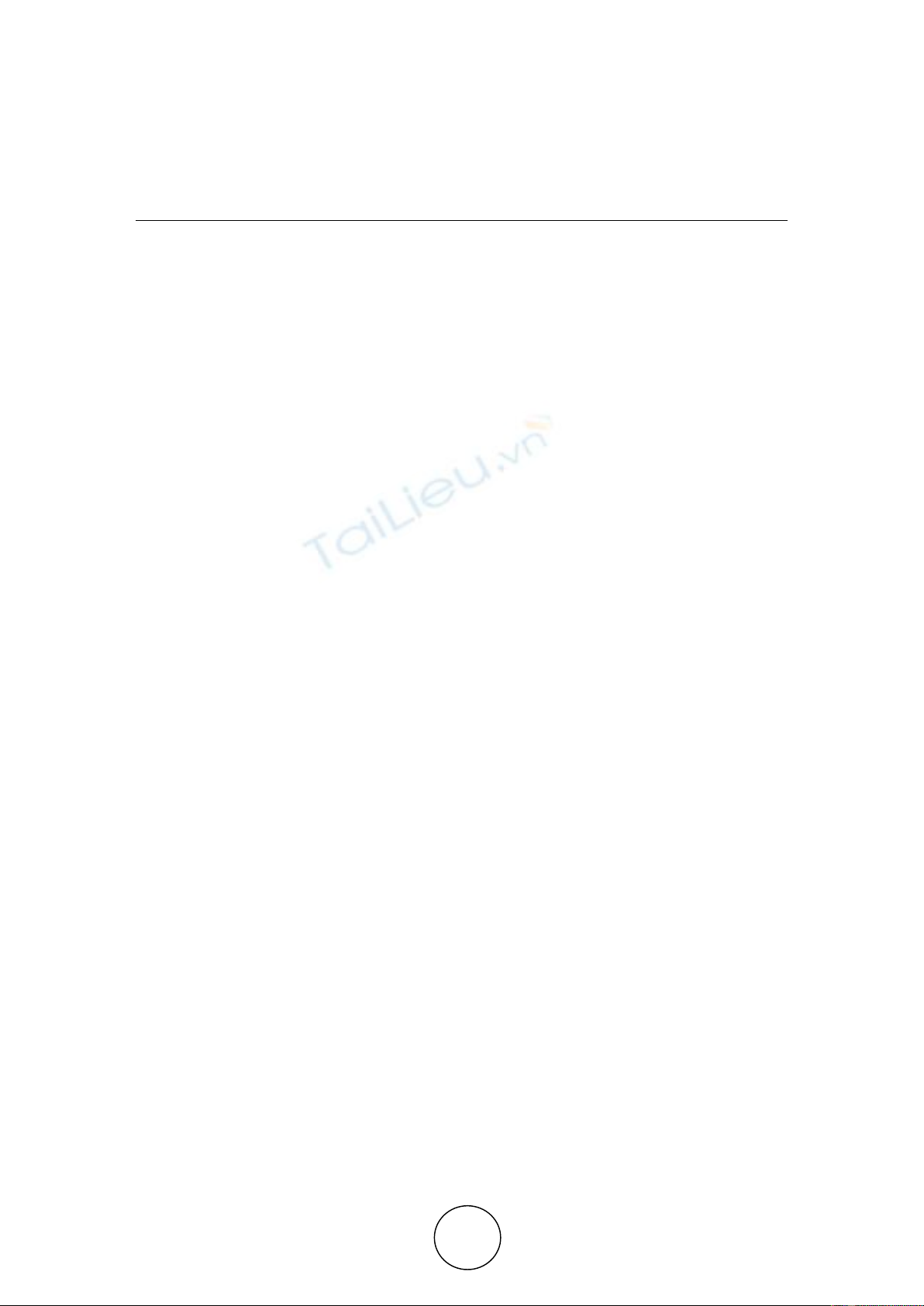

Green engineering investigated as a possible organic green material in the

combustion process and heating applications. A bioreactor system processed

Dendrocalamus asper bamboo culms as green engineering materials to theto industrial

process that produces valuable elements from a natural treatment by soaking with an

average of pH 7.6 level of sea-water. Pyrolysis Combustion Flow Calorimeter and

Differential Scanning Calorimetry (DSC) to utilized the precise heat capacity extent to

characterize the materials. A waste product in this process is the activated carbon,

which is highly in demand for water cleansing system and sold to neutralize the fuel

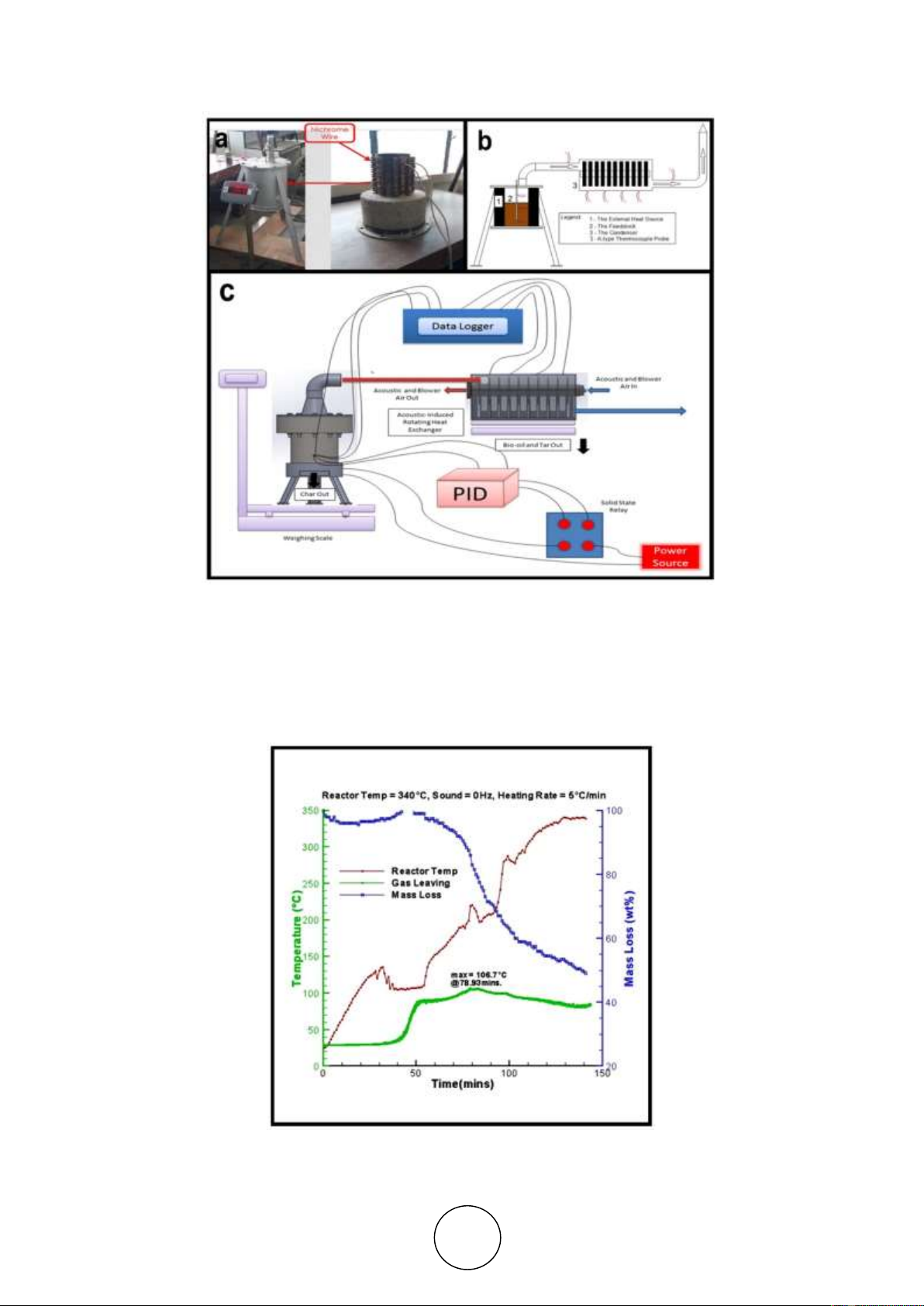

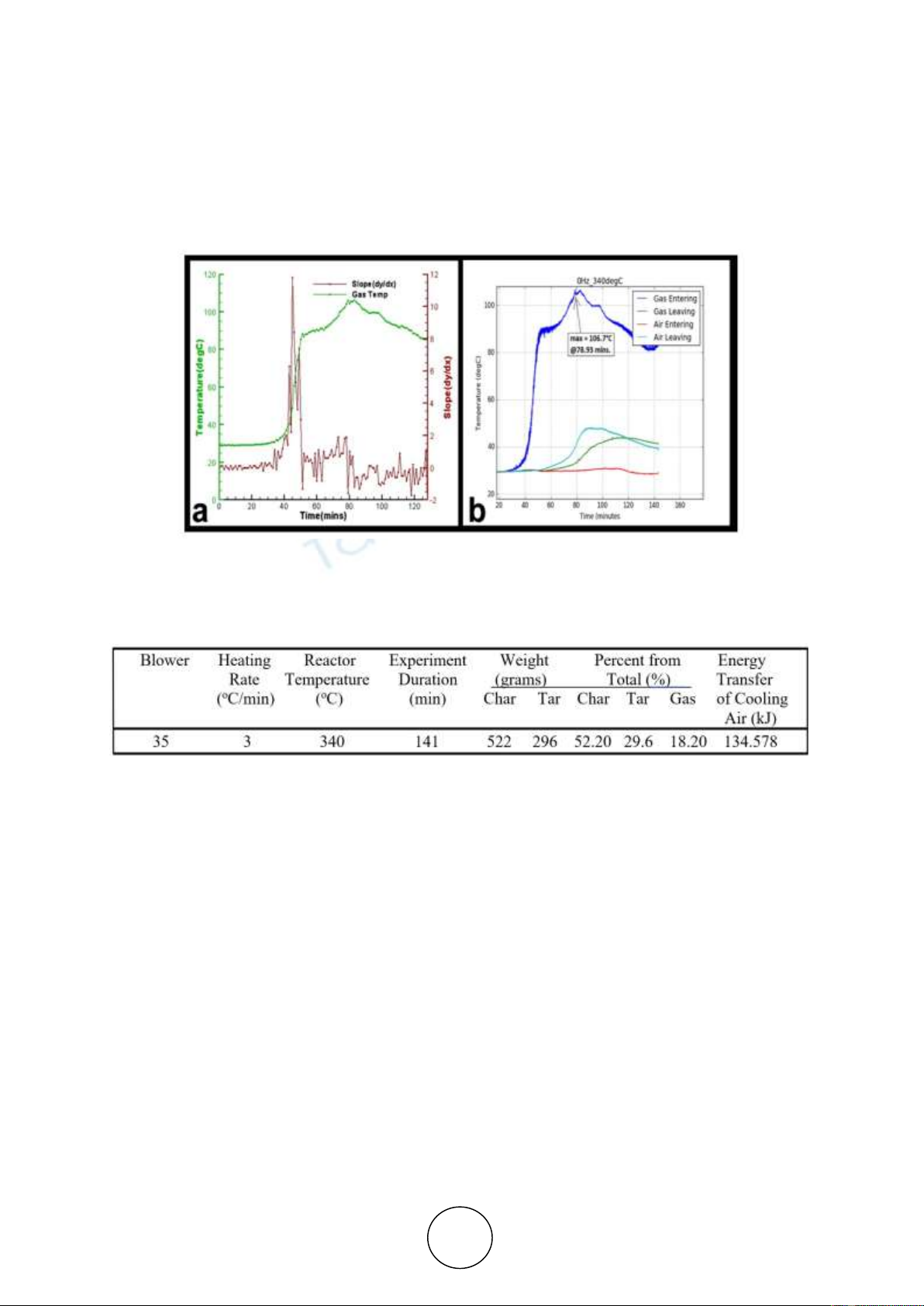

cost. The primary stage at 68-89oC is the exothermic dehydration of the biomass with

the release of water and low-molecular-weight gases like carbon monoxide (CO) and

carbon dioxide (CO2). The results from this research will be significant and helpful to

develop and utilize the wastes from Dendrocalamus asper bamboo with 134.58 kJ for

any renewable energy product.

Keywords: natural treatment, pyrolysis, green engineering, biomass.