Can Tho Journal of Medicine and Pharmacy 9(6) (2023)

120

RESEARCH ON THE PREPARATION OF

PARACETAMOL 650 MG PROLONGED-RELEASE TABLETS

Huynh Thi My Duyen*, Nguyen Huu Nhan, Le Thi Minh Ngoc

Can Tho University of Medicine and Pharmacy

*Corresponding author: htmduyen@ctump.edu.vn

Received: 16/5/2023

Reviewed: 27/5/2023

Accepted: 19/9/2023

ABSTRACT

Background: Paracetamol is one of the most commonly used active ingredients, even

without a doctor's prescription for most people. It has effects on relieving pain and treating fever,

especially with an analgesic effect for the elderly who have to suffer from degenerative joint disease.

However, the half-life of paracetamol is relatively short, from 1 to 3 hours, so patients need to use

it many times a day. The use of large amounts of paracetamol for a long time constantly can cause

irreversible liver damage, so the prolonged release dosage form is chosen for the following reasons.

Not only does it maintain the therapeutic drug concentration, and help reduce the number of use

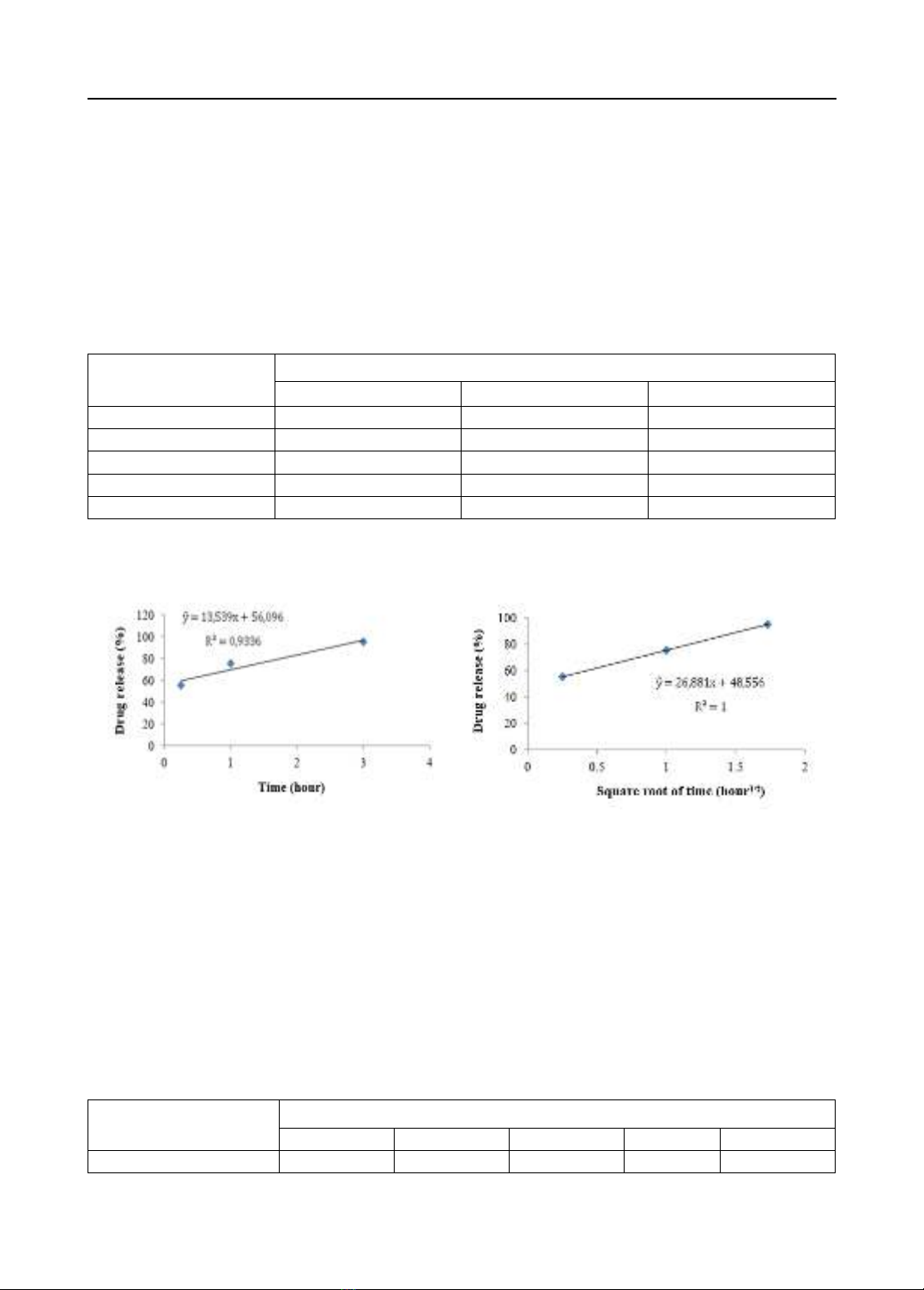

times but it also limits unwanted side effects. Objectives: the dissolution and the release kinetics of

the active ingredient of the reference tablet Tylenol 8 Hour 650 mg were surveyed in order to

formulate the paracetamol 650mg prolonged release tablet and there was an in vitro equivalent

evaluation between the prepared paracetamol 650mg prolonged release tablet and the reference

tablet Tylenol 8 Hour 650 mg. Materials and methods: an active ingredient (paracetamol);

excipients are used in double-layer formulations that include an immediate release layer and a

![Study on toxicities of 10β-[(2'β-hydroxy-3'- imidazol) propyl] deoxo-artemisinin (32) in reproductive and developmental progresses of mice](https://cdn.tailieu.vn/images/document/thumbnail/2025/20250228/viinuzuka/135x160/8021740737116.jpg)