15 Hand Tools

When we thin k about hand tool s, we norm ally think of hamm ers, screwdri vers, or

pliers, but a toothbrus h, a spoon, a pen, scis sors are also hand tool s. They are

examples of tools that are used to concent rate force and help to carry out a variety

of tasks .

For most of us, h and tools are nonpow ered tools and incl ude chise ls, handsaws,

wrenches, shovel s, and knives . Many injuries can result when using hand tools

including cuts, lacer ations, eye injuries , overus e (ergon omi c related injuries ), and

at times slips, trips, and falls. In most inst ances these injuries occur due to the

incorrect use, use of the wrong tool, or improper maintenan ce of tools. Appro xi-

mately 8% of all indus trial accide nts a re caused by hand tools. The Mine Health and

Safety Admini stration found that one out of every four accide nts was due to hand

tools. Some examp les of hand tool accide nts are as foll ows:

.Using a screwdri ver as a chise l may cause the tip of the screw driver to break

off and fly, hitting the user or other empl oyees.

.If a wood en handle on a tool such as a hammer or ax is loose, spli ntered, or

cracked, the head of the tool may fly off and strike the user or another

worker.

.A wrench must not be used if its jaws are sprung, because it might slip.

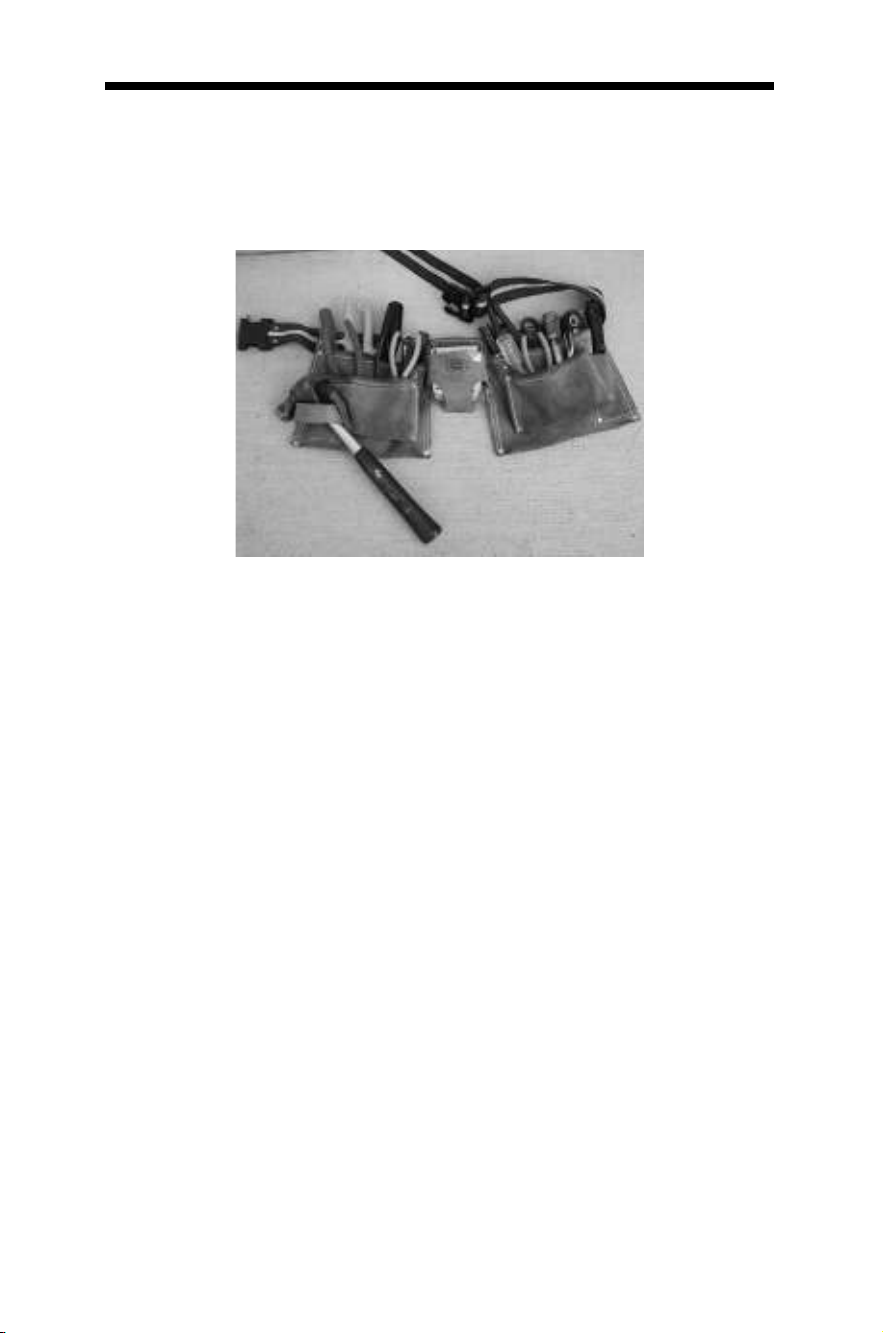

.Impact tools such as chisels, wedges, or drift pins are unsafe if they have

mushroomed heads that might shatter on impact, sending sharp fragments

flying (Figur e 15.1).

A variety of hand tools are necessary for day-to-day general maintenance.

ß2008 by Taylor & Francis Group, LLC.

The employer is responsible for the safe condition of tools and equipment used by

employees, even personal tools if being used in the workplace. The employer should

not issue or permit the use of unsafe hand tools. Damages or broken hand tools

should be removed from service and a tag placed on them saying, ‘‘Do Not Use’’ or

‘‘Removed from Service’’ if the tools are not thrown away. Employers should assure

that employees are trained in the proper use and handling of hand tools and other

equipment.

Employees, when using saw blades, knives, or other tools, should direct tools

away from aisle areas and away from other employees working in close proximity.

Knives and scissors must be sharp; dull tools can cause more hazards than sharp

ones. Cracked saw blades must be removed from service.

Wrenches must not be used when jaws are sprung to the point that slippage

occurs (Figure 15.2). Impact tools such as drift pins, wedges, and chisels must

be kept free from mushroomed heads. The wooden handle of tools must not be

splintered.

Iron or steel hand tools may produce sparks that can be an ignition source

around flammable substances. Where this hazard exists, spark-resistant tools made

of nonferrous materials should be used where flammable gases, highly volatile

liquids, and other explosive substances are stored or used.

Poor condition

Dressed Spread Mushroomed

FIGURE 15.1 From safe to unsafe chisels. (Courtesy of the Department of Energy.)

Teeth on jaws wom

Tight fitting wrenches

on bolts

FIGURE 15.2 Wrenches from good to worn. (Courtesy of the Department of Energy.)

ß2008 by Taylor & Francis Group, LLC.

Appropri ate person al prote ctive equipment (PPE ) such as safety eyew ear and

gloves must be worn to protect against hazards that may be encount ered while using

hand tool s. Workpl ace floors are to be kept clean and as dry as possible to prevent

slips wi th or around da ngerous hand tools.

15.1 PREVENTING HAND TOOL ACCIDENTS

To prevent hand tool accide nts certa in safe work pract ices should be follow ed.

Before using han d tool s selec t the correct tool for the job. Do not use tool s for

jobs they are not inte nded for. Provid e workers with training and informat ion about

safer work practices and the c orrect methods, p osture, and use of tool s. Other work

practices that should be addres sed are as follows:

.Always use tools in such a way that a slip or mis s does not result in an

injury, e.g., when using sharp tool s for cutt ing alw ays cut away from the

body or hand.

.Keep the wor k area free of clut ter and waste.

.Ensure the work area has ad equate ligh ting.

.Tools, equipment , and mat erials should n ot be throw n or dropped from one

employee to another or from one level to anothe r. Hand them, h andle first,

directly to other wor kers or use a hand line.

.Ensure wor kers are wearing appropr iate prote ctive clot hing and PPE such

as goggle s, safety shoes, and gloves .

15.1.1 HAND T OOL K EY P OINTS

Wear approve d PPE such as safety shiel ds, respirato rs, safety toed shoes, high-top

shoes, hard hats, bump caps, leat her gloves, leat her aprons , coveral l, and safety

eyewear with side shields of industrial quality that conform to the ANSI Z87.1

standard.

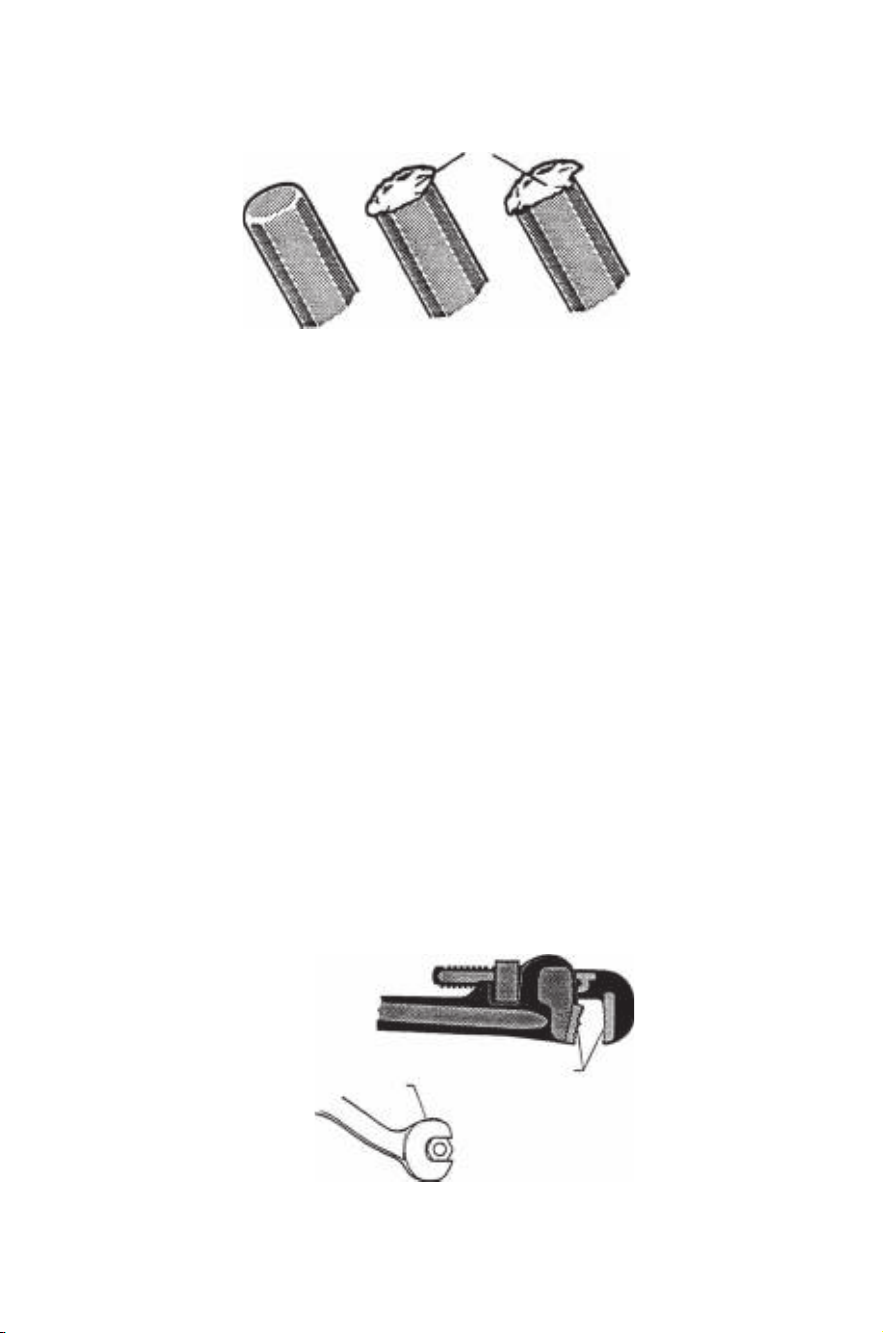

A variety of gloves exist that have different functional use regarding hand tools.

Today there are cut resistant g loves made of Kevl ar as seen in Figure 15.3 , mech-

anics gloves with rubber gripping surfaces, mesh gloves that protect from cuts,

antivibration or shock absorbing gloves, and the common leather glove that is always

a good option if it fits properly since too tight a glove tires the hand and fingers and

too loose a glove decreases dexterity.

Wearing proper clothing varies depending on the type of hand tools that are

being used. Work clothing should not be loose, baggy, or highly flammable. To

protect against burns, wear clothing such as coveralls, high-top shoes, leather aprons,

and leather gloves. Remove all paper from pockets and wear cuff less pant. When

working with heavy metals or items wear hard toed shoes with nonskid soles. Avoid

synthetic clothing because they have low flash points which can result in severe

burns. Do not wear jewelry especially rings when using hand tools since it may

result in rings getting caught or contacting electricity. Jewelry can get caught on

moving parts.

ß2008 by Taylor & Francis Group, LLC.

Protect the hair, scalp, and head by pulling back long hair in a band or a cap to

keep it from getting caught in tools. Be extremely careful with long hair when using

a rotating tool. When handling carpentry materials wear a hard hat or bump cap to

protect the head.

Protect the fingers, hands, and arms by wearing leather gloves or cut resistant

gloves and forearm shields. When workers are hammering, care must be taken to

strike the object not the hand or fingers.

Avoid horseplay and loud talking so the mind is not distracted from the task at

hand. Pushing, running, and scuffling while working with hand tools can result in

serious accidents. Be alert and work defensively.

As has been said earlier, the greatest accident potential results from misuse and

improper maintenance of hand tools. By adhering to the following procedures we

can mitigate this problem:

.Hold supervisors responsible for the safe condition of tools and equipment

used by workers, but workers must also use and maintain tools properly.

.Saw blades, knives, or other tools should be directed away from aisle areas

and other workers working in close proximity.

.Knives and scissors must be kept sharp. Dull tools can result in the use of

more force and slippage and are more dangerous than sharp tools.

.When working with hand knives, boning knives, drawknives, and scissors,

workers should use appropriate PPE such as mesh gloves, wrist guards, arm

guards, and aprons or belly guards.

FIGURE 15.3 Cut resistant Kevlar gloves.

ß2008 by Taylor & Francis Group, LLC.

.Avoid flammable substances since sparks produced by iron or steel hand

tools can be a dangerous ignition source. Where these types of hazards

exists use spark-resistant tools made of brass, plastic, aluminum, or wood.

.Do not overwork a tool’s capabilities. Probably the most common error is to

use a ‘‘cheater’’ to increase leverage of a wrench.

.Avoid striking one tool with another. Certain tools are made to strike

other specific tools or materials. Use only the proper striking tools for

these jobs. Do not use a wrench to drive a nail or use one hammer to strike

another.

.Use the right tools and use them correctly. Even the best made tool will

botch a job when used incorrectly. Striking a nail with a hammer cheek

instead of its face can cause a nailing problem or accident. Handling a chisel

incorrectly such as pushing a chisel with one hand while the other holds the

work in front of the cutting edge can cause severe injury. The solution is to

clamp in a vise so both hands are free to handle the tool.

.Improper maintenance. A worn tip on a screwdriver can result in a gashed

hand. Similarly, a loose or damaged handle can turn a hammer into a deadly

flying object.

15.1.2 STORING HAND TOOLS

All tools not in use should be stored where they are not a hazard. Sharp edges or

pointed tools should have the edge or point guarded at all times when not in use.

Shovels and rakes should have the sharp or pointed edges toward the ground.

15.1.3 OLD HAND TOOLS

Old tools may be unsafe if they lack up-to-date safety features. Instead of buy-

ing new good quality hand tools, many workers fill their toolboxes with hand-me-

down or cheap (poorly made) tools from discount stores. Although second-hand

tools may be cheaper, they can be quite unsafe. Any tool with makeshift repairs

should be removed from service and discarded so no one is tempted to use it and

be injured.

Any damaged or outdated tool should be removed from service and affixed with

a tag that says, ‘‘Remove from Service. Do Not Use’’ or discarded as waste so it

cannot be used again.

15.1.4 ERGONOMICS AND HAND TOOLS

The use of hand tools places a great deal of stress on bones, tendon, ligaments,

nerves, and soft tissue. Often the use of hand tools can lead to what are called

overuse or repetitive injuries. Some of the ways to prevent these injuries are by

.Alternating repetitive and nonrepetitive activities

.Varying or rotating job task

.Taking frequent, short breaks

ß2008 by Taylor & Francis Group, LLC.

![Bài tập Con người và sức khỏe: [Mô tả chi tiết hoặc lợi ích của bài tập]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20251123/thaohoang9203@gmail.com/135x160/95031763951303.jpg)

![Tài liệu Triệu chứng học nội khoa [mới nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20251204/oanhlahet@gmail.com/135x160/5231764900514.jpg)

![Bài giảng Vi sinh vật: Đại cương về miễn dịch và ứng dụng [chuẩn nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20251124/royalnguyen223@gmail.com/135x160/49791764038504.jpg)