40

Research Article

Preparation of probiotic oil suspension containing

Lactobacillus acidophilus

Ngoc Khanh Lea, Khac Tiep Nguyena, Thi Thanh Duyen Nguyenb, Thi Phuong Linh Lea, Dieu Ly Nguyena,

Thi Hoa Nguyena, Thi Phuong Vua, Thanh Xuan Dama,*

aFaculty of Biotechnology, Hanoi University of Pharmacy, 13-15 Le Thanh Tong, Hanoi, Vietnam

bFaculty of Pharmaceutics and Pharmaceutical Technology, Hanoi University of Pharmacy, 13-15 Le Thanh Tong, Hanoi, Vietnam

Journal of Pharmaceutical Research and Drug Information, 2023, 14 (5): 40-46

A R T I C L E I N F O

Article history

Received 04 May 2023

Revised 17 Sept 2023

Accepted 25 Nov 2023

Keywords

Dispersion method

L. acidophilus

Oily suspension

Probiotic

Paediatric uses

A B S T R A C T

Probiotics are defined as microorganisms that, when administered in sufficient

quantities, confer a health benefit on the host. As they are very susceptible to

environmental conditions, solid dosage forms are used to increase their

stability. In pediatric use, liquid preparations of edible oily suspensions

containing probiotics are more favorable since they help overcome the

difficulty of oral administration in children. However, few research articles

related to the preparation process of these oily suspensions were reported in

Vietnam. Our study focuses on preparing an oily suspension containing L.

acidophilus at a laboratory scale, oriented for use in infants and children under

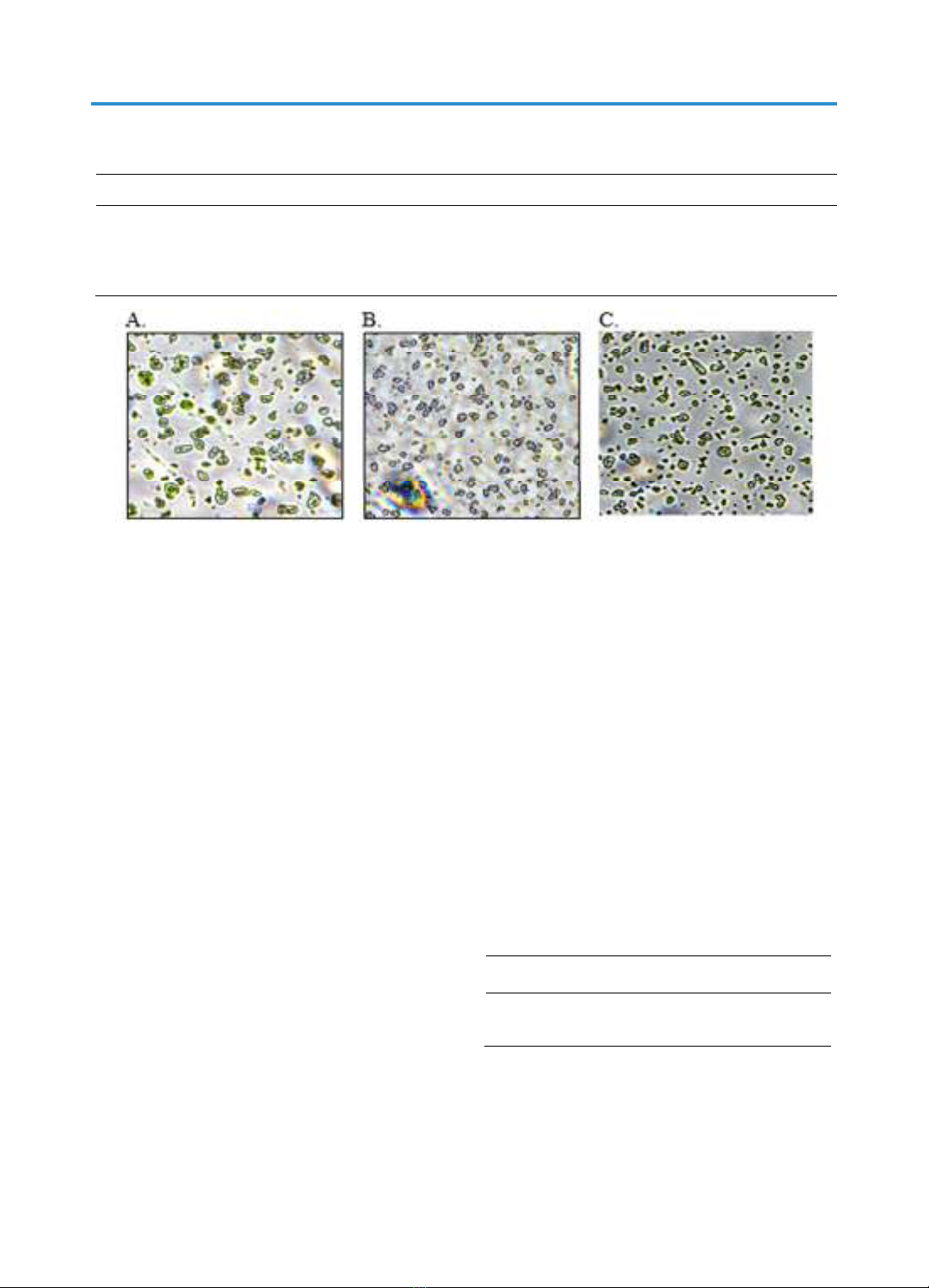

two years of age. The oily suspension was prepared using the dispersion

method. Different mixtures of oil and dispersing agents were studied for their

effect on the stability of the suspension in terms of sedimentation rate, drop

time, average particle size, and the amount of L. acidophilus. The results

showed that an oily suspension containing L. acidophilus could be made using

the dispersion method with a mixture of oils as the dispersion medium and

Aerosil and aluminum tristearate as dispersing agents. The prepared

suspension had an appropriate sedimentation rate of about 10–20%, an

average drop time of 1,0 drop/s, an average particle size of 3–3,5 µm, and an

amount of L. acidophilus above 3 x 108- 5 x 108CFU/ml. Our study

successfully prepared an oily suspension containing L. acidophilus using the

dispersion method. The prepared suspension had good physical stability, and

the number of L. acidophilus remained over 108CFU/ml during two months

of storage.

*Corresponding author: Thanh Xuan Dam; e-mail address: xuandt@hup.edu.vn

https://doi.org/10.59882/1859-364X/141

Journal homepage: jprdi.vn/JP

Journal of Pharmaceutical Research and Drug Information

An official journal of Hanoi University of Pharmacy