Galactosyl-mimodye ligands for

Pseudomonas fluorescens

b-galactose dehydrogenase

Design, synthesis and evaluation

C. F. Mazitsos

1

, D. J. Rigden

2

, P. G. Tsoungas

3

and Y. D. Clonis

1

1

Laboratory of Enzyme Technology, Department of Agricultural Biotechnology, Agricultural University of Athens, Greece;

2

Embrapa Recursos Gene

´ticos e Biotecnologia, Brası´lia, Brazil;

3

Department of Pharmaceutical and Biological Chemistry,

School of Pharmacy, University of London, UK

Protein molecular modelling and ligand docking were

employed for the design of anthraquinone galactosyl-bio-

mimetic dye ligands (galactosyl-mimodyes) for the target

enzyme galactose dehydrogenase (GaDH). Using appro-

priate modelling methodology, a GaDH model was build

based on a glucose-fructose oxidoreductase (GFO) protein

template. Subsequent computational analysis predicted

chimaeric mimodye-ligands comprising a NAD-pseudomi-

metic moiety (anthraquinone diaminobenzosulfonic acid)

and a galactosyl-mimetic moiety (2-amino-2-deoxygalactose

or shikimic acid) bearing an aliphatic linkermolecule. In

addition, the designed mimodye ligands had an appropriate

in length and chemical nature spacermolecule via which

they can be attached onto a chromatographic support

without steric clashes upon interaction with GaDH. Fol-

lowing their synthesis, purification and analysis, the ligands

were immobilized to agarose. The respective affinity adsor-

bents, compared to other conventional adsorbents, were

shown to be superior affinity chromatography materials for

the target enzyme, Pseudomonas fluorescens b-galactose

dehydrogenase. In addition, these mimodye affinity adsor-

bents displayed good selectivity, binding low amounts of

enzymes other than GaDH. Further immobilized dye-lig-

ands, comprising different linker and/or spacer molecules, or

not having a biomimetic moiety, had inferior chromato-

graphic behavior. Therefore, these new mimodyes suggested

by computational analysis, are candidates for application in

affinity labeling and structural studies as well as for purifi-

cation of galactose dehydrogenase.

Keywords: affinity chromatography; biomimetic ligands;

galactose dehydrogenase; molecular modelling; triazine dyes.

Galactose dehydrogenase (GaDH;

D

-galactose: NAD

+

1-oxidoreductase; EC 1.1.1.48) catalyses the dehydrogena-

tion of b-

D

-galactopyranose in the presence of NAD

+

to

D

-galacto-1,5-lactone and NADH, acting on the C1 posi-

tion of the sugar substrate. The enzyme generally shows no

absolute specificity either for NAD

+

,asNADP

+

is also

used, albeit to a lesser degree. Nor is the enzyme specific for

D

-galactose, as

D

-fucose is a better substrate, although other

sugars (e.g.

L

-arabinose, 2-deoxy-

D

-galactose) are less

reactive. The kinetic mechanism is ordered Bi-Bi, with the

NAD

+

binding first to the enzyme [1]. GaDH from

Pseudomonas fluorescens is the best studied example, as it

has been cloned and expressed in Escherichia coli [2] and its

full nucleotide sequence determined [3]. The active macro-

molecule possesses two binding sites [4] and consists of two

identical subunits each of 33 kDa (304 amino-acid residues)

[3]. GaDH from Pseudomonas saccharophila has been

studied to a lesser extent [5], whereas the enzyme has been

identified in plants (e.g. green peas, oranges and Arabidopsis

thaliana), algae (e.g. Iridophycus flaccidum) and several

mammals including humans. No information is available

regarding the catalytic mechanism of GaDH, and its

structure has not been determined experimentally or

modelled.

GaDH is an important analytical tool as at alkaline pH

the product galactonolactone is hydrolysed, so that the

reaction becomes irreversible. The enzyme is therefore

useful for the determination of b-

D

-galactose and

a-

D

-galactose, after the latter is converted to the former

by the application of exogenous mutarotase. GaDH is

also exploited for the determination of lactose; the milk

sugar is hydrolysed by lactase, coupled to GaDH which

acts on the resulting b-

D

-galactose. Despite the utility of

GaDH, a simple and rapid purification method is not

available.

The ability to combine knowledge of X-ray crystallo-

graphic studies, NMR and homology structures with

defined or combinatorial chemical synthesis and advanced

computational tools has made rational design of affinity

ligands more feasible, powerful, logical and faster [6]. In the

present work, rigorous protein molecular modelling was

Correspondence to Y. D. Clonis, Laboratory of Enzyme Technology,

Department of Agricultural Biotechnology, Agricultural

University of Athens, 75 Iera Odos Street, GR-11855 Athens,

Greece. Fax: + 30 210 5294307, Tel.: + 30 210 5294311,

E-mail: clonis@aua.gr

Abbreviations: ADH, alcohol dehydrogenase; BM, biomimetic ligand

or mimodye ligand; CB3GA, Cibacron blue 3GA; GaDH, galactose

dehydrogenase; GaO, galactose oxidase; GFO, glucose-fructose

oxidoreductase; GlDH, glucose dehydrogenase; GlO, glucose oxidase;

VBAR, Vilmafix Blue A-R; CDI, 1,1¢-carbonyldiimidazole.

Enzymes: galactose dehydrogenase (GaDH;

D

-galactose: NAD

+

1-oxidoreductase; EC 1.1.1.48).

(Received 31 May 2002, revised 16 August 2002,

accepted 28 August 2002)

Eur. J. Biochem. 269, 5391–5405 (2002) FEBS 2002 doi:10.1046/j.1432-1033.2002.03211.x

used to create an objectively sound model of GaDH using as

the best available template glucose-fructose oxidoreductase

(GFO). This model was then exploited in the design of novel

galactosyl-biomimetic chlorotriazine dye-ligands (mimodye

ligands) with bifunctional or chimaeric characteristics. In

particular, these galactosyl-mimodye ligands are designed to

bear a structural portion that interacts with the NAD

+

-

binding site and a biomimetic moiety that interacts with the

sugar-binding site of GaDH. The effectiveness of the

bifunctional (chimaeric) ligand concept has been previously

demonstrated with ketocarboxyl- [7,9] and glutathionyl-

biomimetic [10] ligands but never with sugar ones. These

mimodye ligands are expected to become useful tools for the

identification of amino-acid residues of the binding sites of

GaDH after affinity labelling. For this purpose, the

galactosyl-mimodyes were designed to bear a reactive

chloro-triazine structural scaffold, present in all reactive

triazinyl-dye ligands including the archetypal CB3GA and

VBAR. Other mimodyes and certain conventional triazine

dyes are known to act as affinity labels due to their

chlorine(s) atom(s) which react with appropriate residues

of the targeted enzyme active site [11–13]. Furthermore,

when the chlorine was substituted with a carefully chosen

spacer molecule, a nonreactive biomimetic ligand was

obtained which could be immobilized on a chromatography

support. We envisage that these immobilized ligands will be

of great use in the purification of GaDH from different

sources.

EXPERIMENTAL PROCEDURES

Materials

b-Galactose dehydrogenase (EC 1.1.1.48, P. fluorescens

gene expressed in E. coli), galactose oxidase crude lyophi-

lized powder (EC 1.1.3.9, from Dactylium dendroides),

glucose oxidase crude lyophilized powder (EC 1.1.3.4,

from Aspergillus niger, crude),

D

(+)-galactosamine

(2-amino-2-deoxy-

D

-galactopyranose; chondrosamine),

D

(+)-galactose (minimum 99%),

D

(+)-glucose, 1,3-diamino-

2-hydroxypropane, bromoacetic acid N-hydroxysuc-

cinimide ester, e-amino-n-caproic acid, ethylene-diamine,

1,5-diaminopentane, 1,6-hexane-diamine, 1,12-diaminodo-

decane, 1-ethyl-3-(3-dimethylamino-propyl) carbodiimide

(EDAC), 1,1¢-carbonyldiimidazole, o-tolidine, o-dianisi-

dine, lipophilic Sephadex LH-20, CM–Sepharose CL-6B

and DEAE–Sepharose CL-6B were obtained from Sigma

(St Louis, MO, USA). All other diaminoalkanes were

obtained from Aldrich (USA), whereas, shikimic acid was

obtained from Fluka (USA). Peroxidase (from horseradish,

grade I), NAD

+

(crystallized lithium salt c. 100%) and

crystalline bovine serum albumin (fraction V) were obtained

from Boehringer Mannheim (Germany). Hexylamine and

nutrient broth (for microbiology) were obtained from

Merck (Germany). The agarose chromatography gel

Sepharose CL-6B was obtained from Pharmacia. F324

P. fluorescens biovar V1 was kindly donated by G. J.

Nychas (Laboratory of Microbiology and Biotechnology

of Foods, Agricultural University of Athens). Baker’s

yeast, green peas and rabbit liver were purchased at the

local market. Glucose dehydrogenase was extracted from

P. fluorescens and baker’s yeast, while alcohol dehydro-

genase was extracted from baker’s yeast and green peas.

Protein modelling

Fold recognition methods [14–17] were employed to deter-

mine the best template to use for construction of a model of

GaDH. Given the low sequence identity between GaDH

and the GFO template used (17%) a rigorous modelling

strategy was used, as previously (e.g [18,19]). In this way the

challenge of modelling based on low sequence identity was

met with a strategy designed to maximize model accuracy.

Although errors will undoubtedly remain, the probability of

producing a useful model is thereby enhanced. The essential

elements of this strategy are the construction and analysis of

multiple models (20 in this case), derived from limited

randomization of initial coordinates and made with the

program

MODELLER

[20], followed by analysis of packing

and solvent exposure characteristics with

PROSA

II [21]. The

resulting profiles showed regions of unusual protein struc-

ture characteristics as peaks attaining positive values. These

regions may result from locally inaccurate target-template

alignment so that variant alignments, altered in these

doubtful regions, were tested through further cycles of

model construction and analysis. When better

PROSA

results

were obtained for the variant alignment it was assumed to

be more correct than the original. Stereochemical analysis

using

PROCHECK

was also employed, particularly when the

optimal target-template alignment had been reached. Pro-

tein models were visualized using O [22]. Structurally similar

proteins to the template were sought in the FSSP database

(http://www.ebi.ac.uk/dali/fssp) [23].

STRIDE

[24] was used

for the definition of secondary structure.

Ligand design and docking

The ideal biomimetic would combine moieties that bind

both to the cofactor NAD and the substrate binding sites.

The initially considered building elementswere two com-

mercially available compounds: (a) anthrquinone-diamino-

benzosulfonyl-dichlorotriazine (Vilmafix blue A-R or

VBAR) containing three of the four ring systems of the

well known dye Cibacron Blue 3GA (CB3GA), both known

binding mimics of NAD(P) [8,9,25] and (b) 2-amino-

2-deoxygalactose, a substrate of GaDH [1]. Both these

molecules have readily modifiable chemical groups to which

could be attached an appropriate linkermolecule in order

to effect their fusion. 1-Amino-1-deoxygalactose, although

commercially available, was not considered as GaDH

attacks at the C1 position of the substrate, so that this

position was thought better preserved in the ligand.

However, in place of galactose shikimic acid was considered

which, although only moderately structurally similar to

GaDH substrates, has a clear advantage over them in terms

of chemical stability. Finally, a spacermolecule of appro-

priate length and chemical nature was designed to chemi-

cally attach the complete ligand, via its triazine group (ring

3), to the chromatographic matrix.

The HIC-UP database of heterocompounds [26] was

used as a source of the Cibacron Blue-derived, b-

D

-galactose

and shikimic acid components. These were rotated and

translated with respect to the protein model using

O

[22]

until optimal steric and chemical complementarity was

reached. The tendency of Cibacron Blue-like ring systems

to bind in NAD(P) binding sites with anthraquinone

mimicking adenine, along with biochemical data regarding

5392 C. F. Mazitsos et al. (Eur. J. Biochem. 269)FEBS 2002

sugar binding to related enzymes provided useful informa-

tion to guide the docking, as described later. Side chain

reorientations to rotameric conformations were allowed

where they significantly enhanced interactions with ligands.

The mimodye ligands (e.g. BM1 and BM2) were mod-

elled through the fusion of their respective enzyme-bound

components and the resulting complexes refined using

CNS

[27]. Topology and parameter files for energy minimization

of the ligand were generated using

XPLO

2

D

[28] and hand-

edited to reflect ideal stereochemical values.

Synthesis and purification of the dye-ligands

Amino-alkyl-VBAR dyes. (Table 1, structures aVBAR-

fVBAR). Solid commercial VBAR (50 mg, 0.045 mmol

dichloroform, purity 61.3%, w/w) was added to cold water

(2 mL) and the solution was slowly introduced under

stirring to a solution (3 mL) of the alkyl-diamines

(0.73 mmol). The pH was adjusted to 8.9–9.0 and kept at

this value with NaOH (0.1

M

) until the end of the reaction

(2.5–3 h, 25 C). The progress of each reaction was

monitored by TLC (1-butanol-2-propanol-ethylacetate-

wate, 2 : 4 : 1 : 3 v/v/v/v) upon completion of the reaction,

solid NaCl was added (final content 3%, w/v) and the

mixture was left at 4 C. The pH of the mixture was

adjusted with HCl (1

M

) to 1.0 and the precipitate was

filtered (Whatman paper filter 50, hardened), washed with

5mLeachofHCl(1

M

) and cold acetone, then with 7 mL

of diethyl ether and dried under reduced pressure. The solid

dye (approximately 30 mg) was dissolved in 50 : 50 water/

methanol (50%) and dimethylsulfoxide (50%) mixture, and

purified on a lipophilic Sephadex LH-20 column

(30 ·2.5 cm) [29]. The purified product was stored in a

desicator at 4 C.

Hydrophilic spacer-VBAR dye. (Table 1, structure

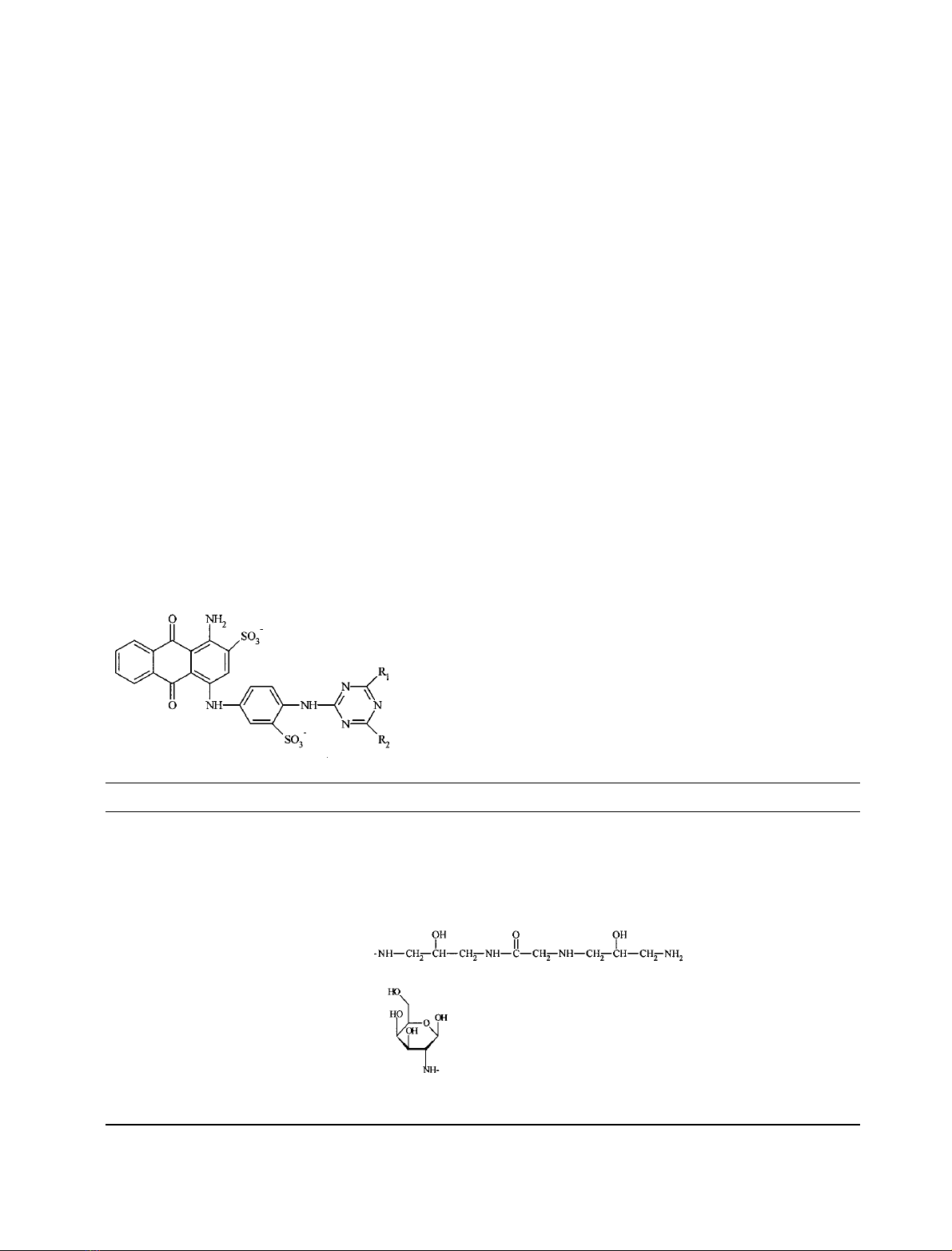

gVBAR; Fig. 1). Stage 1: solid commercial VBAR

(20 mg, 0.018 mmol dichloroform, purity 61.3%, w/w)

was added to cold water (1 mL) and the solution was slowly

introduced under stirring to 1,3-diamino-2-hydroxypropane

(3 mL, 0.29 mmol). The pH was adjusted to 8.9–9.0 and

kept at this value with NaOH (0.1

M

) until the end of the

reaction (2.5–3 h, 25 C). The progress of the reaction was

monitored by TLC (1-butanol-2-propanol-ethylacetate-

water, 2 : 4 : 1 : 3 v/v/v/v). Upon completion of the

reaction, the dye was purified according to the method

already described (see above). Stage 2: the purified product,

1,3-diamino-2-hydroxypropano-VBAR, was dissolved in

dimethylsulfoxide/water (3 mL, 50 : 50, v/v) and the pH

was adjusted to 7.5 with NaOH (0.1

M

). 0.2 mmol of

bromoacetic acid N-hydroxysuccinimide ester [30,31]

were dissolved in dioxane (1 mL) and this solution was

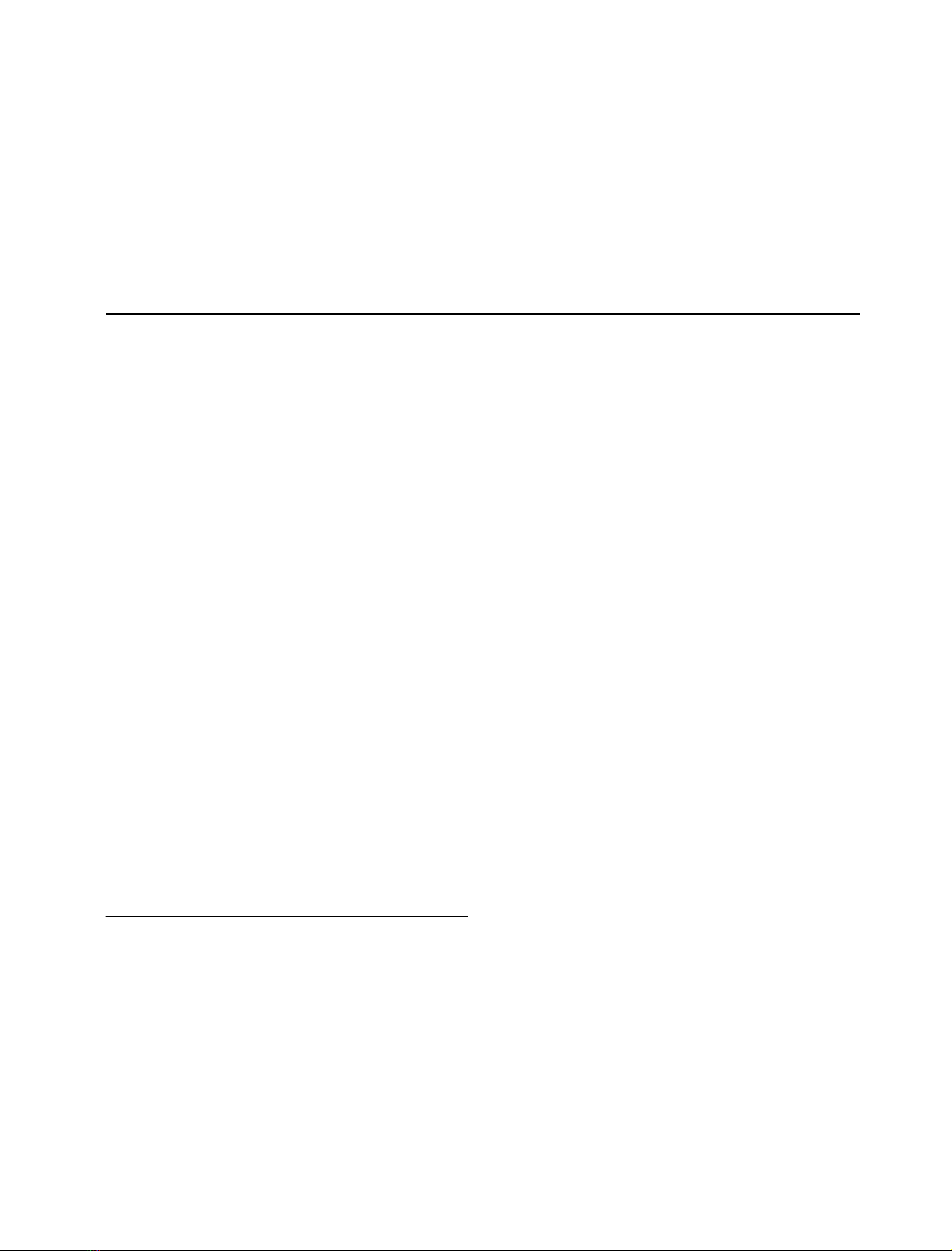

Table 1. The structures of amino-alkyl-VBAR dyes (a-fVBAR), hydrophilic spacer-VBAR dye (gVBAR), galactosamine-VBAR dye and archetypal

VBAR dye.

Ligand R

1

R

2a

aVBAR –NH-(CH

2

)

2

-NH

2

–NH

2

bVBAR –NH-(CH

2

)

4

-NH

2

–NH

2

cVBAR –NH-(CH

2

)

6

-NH

2

–NH

2

dVBAR –NH-(CH

2

)

8

-NH

2

–NH

2

eVBAR –NH-(CH

2

)

10

-NH

2

–NH

2

fVBAR –NH-(CH

2

)

12

-NH

2

–NH

2

gVBAR –NH

2

Galactosamine-VBAR

b

–Cl

VBAR –Cl (– NH

2

)

a

–Cl

a

Following ligand immobilization, the -NH

2

group has replaced the -Cl atom.

b

The galactosamine-VBAR dye was synthesized employing

the procedure for amino-alkyl-VBAR dyes but using the amino-sugar instead the diamino-alkane.

FEBS 2002 Galactosyl-mimodyes for galactose dehydrogenase (Eur. J. Biochem. 269) 5393

introduced to the dye solution. The pH was maintained to

7.5 until the end of the reaction (1.5 h, 4 C, as judged by

TLC). The progress of the reaction was monitored by TLC

(1-butanol-2-propanol-ethylacetate-water, 2 : 4 : 1 : 3 v/v/

v/v). Upon completion of the reaction, the mixture was

lyophilized and the dye was purified on the lipophilic

Sephadex LH-20 column [29]. Stage 3: the purified product,

bromoacetylated 1,3-diamino-2-hydroxypropano-VBAR,

was dissolved in 0.1

M

NaHCO

3

, pH 9.0 (2 mL) and the

solution was slowly introduced under stirring to a solution

of 0.4

M

1,3-diamino-2-hydroxypropane in 0.1

M

NaHCO

3

,

pH 9.0 (2 mL), while maintaining the pH to 9.0 with HCl

(1

M

). The solution was then left under stirring for another

48–72 h (25 C), without further adjustment of the pH. The

progress of the reaction was monitored by TLC (1-butanol-

2-propanol-ethylacetate-water, 2 : 4 : 1 : 3 v/v/v/v). Upon

completion of the reaction, the dye was purified according

to the method already described (see above).

Biomimetic dye BM1. (Table 2, structure BM1; Fig. 1)

Stage 1: purified hydrophilic spacer-VBAR, structure g

(approx. 15 mg, 0.017 mmol) was dissolved in dimethyl-

sulfoxide/water (3 mL, 50 : 50, v/v) and the solution was

introduced under stirring to e-amino-n-caproic acid (2 mL,

0.17 mmol). The pH was adjusted to 9.0 and the mixture

was left shaking at 60 C for 3 h. The progress of the reaction

was monitored by TLC (1-butanol-2-propanol-ethylacetate-

water, 2 : 4 : 1 : 3 v/v/v/v). Upon completion of the

reaction, the dye was purified according to the method

already described (see above). Control dye C

6

gVBAR

(Table 2) was synthesized in the same way. Stage 2: the

purified product obtained from stage 1, was dissolved in

dimethylsulfoxide/water (3 mL, 50 : 50, v/v), introduced to

a solution of

D

(+)-galactosamine (3 mL, 0.62 mmol), and

the pH was adjusted to 4.6, before freshly prepared solution

of 1-ethyl-3-(3-dimethylaminopropyl)carbodiimide (0.3 mL,

250 mg) was introduced dropwise under stirring over a

period of 5 min, while maintaining the pH at 4.6–5.0. The

reaction was stirred for 20 h at 25 C without pH

adjustment and monitored by TLC (1-butanol-2-propanol-

ethylacetate-water, 2 : 4 : 1 : 3 v/v/v/v). A silver nitrate

ammonia solution was used as a spray reagent for detecting

the galactose-analogue in the newly synthesized dye [32].

The product, structure BM1, was precipitated by addition

of solid NaCl (final content 15%, w/v), filtered and washed

with 7 mL of NaCl solution (15%, w/v) and 5 mL of cold

acetone, and dried under reduced pressure. The product was

re-suspended in 2 mL of water and precipitated by addition

of solid NaCl (final content 10%, w/v). The precipitate was

filtered and washed with 7 mL each of NaCl solution (10%,

w/v) and cold acetone, desiccated with 7 mL of diethyl ether

and dried under reduced pressure.

Biomimetic dye BM2. (Table 2, structure BM2; Fig. 2).

Stage 1: solid commercial VBAR (20 mg, 0.018 mmol

dichloroform, purity 61.3%, w/w) was added to cold water

(1 mL) and the solution was slowly introduced under

stirring to a solution (3 mL) of 1,3-diaminopropane

(0.29 mmol). The pH was adjusted to 8.9–9.0 and kept at

this value with NaOH (0.1

M

) until the end of the reaction

(2.5–3 h, 25 C). The progress of each reaction was

monitored by TLC (1-butanol-2-propanol-ethylacetate-

water, 2 : 4 : 1 : 3 v/v/v/v). Upon completion of the

reaction, the dye was purified according to the method

already described (see above). Stage 2: the purified product,

VBAR-1,3-diaminopropane, was dissolved in dimethylsulf-

oxide/water (3 mL, 50 : 50, v/v), introduced to a solution of

shikimic acid (3 mL, 0.62 mmol), and the pH was adjusted

to 4.6, before freshly prepared solution of 1-ethyl-3-(3-

dimethylaminopropyl)carbodiimide (0.3 mL, 250 mg) was

introduced dropwise under stirring over a period of 5 min,

while maintaining the pH at 4.6–5.0. The reaction was

stirred for a further 20 h at 25 C without pH adjustment

and monitored by TLC (1-butanol-2-propanol-ethylacetate-

Fig. 1. Steps for the synthesis of gVBAR dye and of mimodye BM1.

5394 C. F. Mazitsos et al. (Eur. J. Biochem. 269)FEBS 2002

water, 2 : 4 : 1 : 3 v/v/v/v). The product, VBAR-1,3-diami-

nopropano-shikimic acid, was precipitated by addition of

solid NaCl (final content 15%, w/v), filtered and washed

with 7 mL of NaCl solution (15%, w/v) and 5 mL of cold

acetone, and dried under reduced pressure. The product was

dissolved in a 50 : 50 water:methanol (50%) and dimeth-

ylsulfoxide (50%) mixture, and purified to homogeneity on

a lipophilic Sephadex LH-20 column (30 ·2.5 cm) [29].

Control dyes C

6

NgVBAR and C

3

NgVBAR (Table 2) were

synthesizedinthesamewasasinstages1and2.Stages3–5:

the purified product, VBAR-1,3-diaminopropano-shikimic

acid, was dissolved in dimethylsulfoxide/water (3 mL,

50 : 50, v/v/v) and the solution was introduced under

stirring to 1,3-diamino-2-hydroxypropane (2 mL,

0.17 mmol). The pH was adjusted to 9.0 and the mixture

was left shaking at 60 C for 3 h. The progress of the reaction

was monitored by TLC (1-butanol-2-propanol-ethylacetate-

water, 2 : 4 : 1 : 3 v/v/v/v). Upon completion of the

reaction, the dye was purified according to the method

already described (as above). The purified product, 1,3-

diamino-2-hydroxypropano-VBAR-1,3-diaminopropano-

shikimic acid, was dissolved in dimethylsulfoxide/water

(3 mL, 50 : 50, v/v) and the pH was adjusted to 7.5 with

NaOH (0.1

M

). 0.2 mmol of bromoacetic acid N-hydroxy-

succinimide ester were dissolved in dioxane (1 mL) and this

solution was introduced to the dye solution. The pH was

maintained at 7.5 until the end of the reaction (1.5 h, 4 C,

as judged by TLC). The progress of the reaction was

monitored by TLC (1-butanol-2-propanol-ethylacetate-

water, 2 : 4 : 1 : 3 v/v/v/v). Upon completion of the

reaction, the mixture was lyophilized and the dye was

purified by applying preparative TLC as follows: lyophilized

reaction mixture was dissolved in dimethylsulfoxide/water

(0.4 mL, 50 : 50, v/v) and the solution applied on a

Kieselgel 60 plate (silica gel 60, 0.2 mm, 20 ·20 cm,

Merck). The plate was developed using a 1-butanol-2-

propanol-ethylacetate-water (2 : 4 : 1 : 3 v/v/v/v) mixture.

Following completion of the chromatography, the plate was

dried and the band of interest was scraped off. The desired

dye was extracted from the silica gel with water, filtered

through a Millipore cellulose membrane filter (0.45 lm pore

size) and lyophilized. The purified product, bromoacetylated

1,3-diamino-2-hydroxypropano-VBAR-1,3-diaminopropano-

shikimic acid, was dissolved in 2 mL of 0.1

M

NaHCO

3

,

pH 9.0, and the solution was slowly introduced under

stirring to a 2-mL solution of 0.4

M

1,3-diamino-2-hydroxy-

propane in 0.1

M

NaHCO

3

, pH 9.0 (the pH maintained at 9

using 1

M

HCl). The solution was then left under stirring for

another 48–72 h (25 C), without further adjustment of the

pH. The progress of the reaction was monitored by TLC

(1-butanol-2-propanol-ethylacetate-water, 2 : 4 : 1 : 3 v/v/

v/v). Upon completion of the reaction, the product,

hydrophilic spacer-VBAR-1,3-diaminopropano-shikimic

acid, was precipitated by addition of solid NaCl (final

content 15%, w/v), filtered and washed with 7 mL of NaCl

solution (15%, w/v) and 5 mL of cold acetone, and dried

under reduced pressure. The product was re-suspended in

2 mL of water and precipitated by addition of solid NaCl

(final content 10%, w/v). The precipitate was filtered

and washed with 7 mL each of NaCl solution (10%, w/v)

and cold acetone, desiccated with 7 mL of diethyl ether and

dried under reduced pressure.

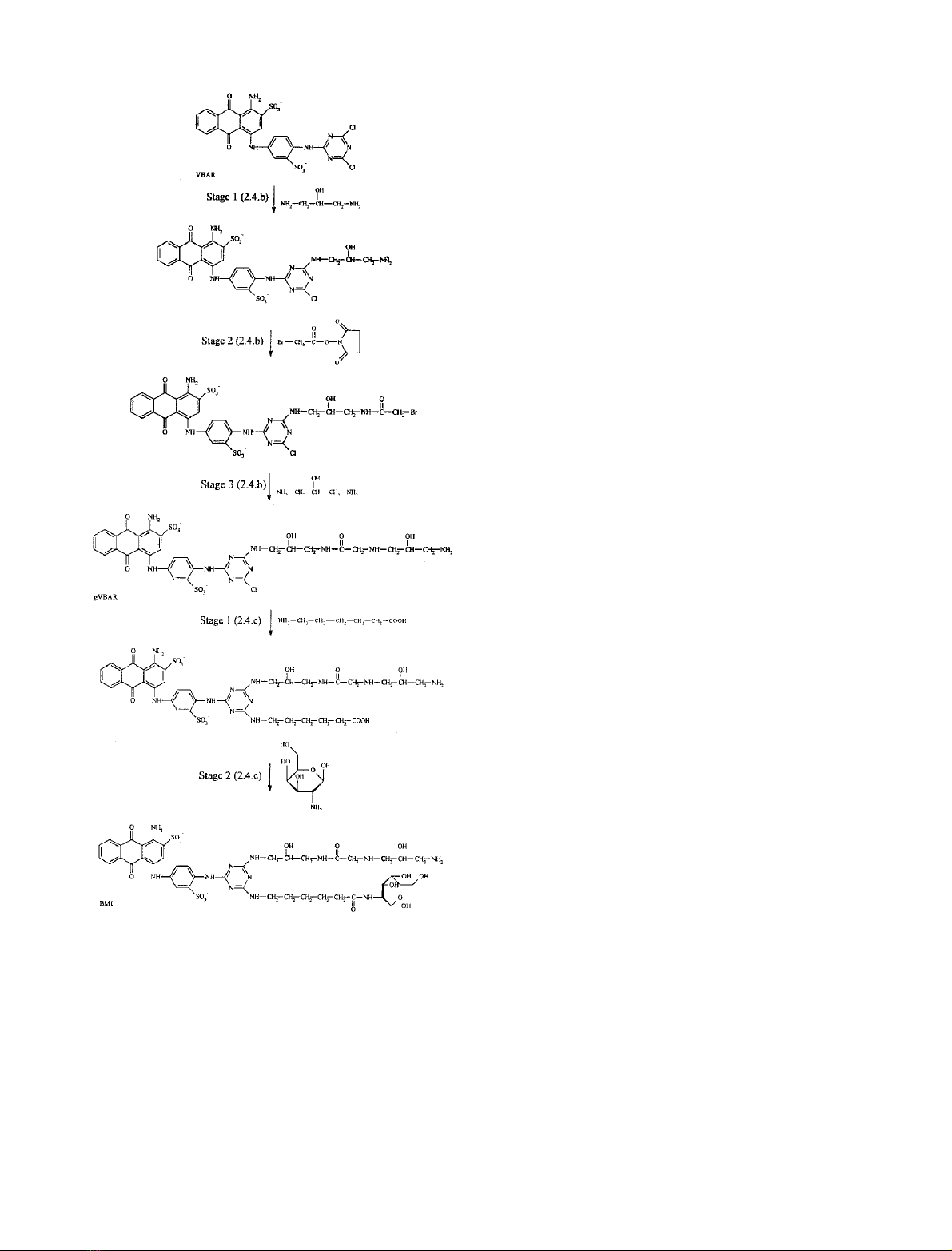

Table 2. The structures of the mimodyes BM1 and BM2 and the control dyes.

Dye-ligand –R

BM1

BM2

C

6

gVBAR

C

6

NgVBAR

C

3

NgVBAR

FEBS 2002 Galactosyl-mimodyes for galactose dehydrogenase (Eur. J. Biochem. 269) 5395

![Bộ Thí Nghiệm Vi Điều Khiển: Nghiên Cứu và Ứng Dụng [A-Z]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20250429/kexauxi8/135x160/10301767836127.jpg)

![Nghiên Cứu TikTok: Tác Động và Hành Vi Giới Trẻ [Mới Nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20250429/kexauxi8/135x160/24371767836128.jpg)