Degumming

of

silk

fabrics

with

tartaric

acid

Giuhano Freddi", Giulia Allara and Guido Candianit

Stazionr Sprimentale per

la

Seta,

Via

G

Colombo 81,20133 Milan,

Italy

Ratti

Echnologies,

Lung0 Lario Trento 9,22100

Corno,

ltaly

The effectiveness

of

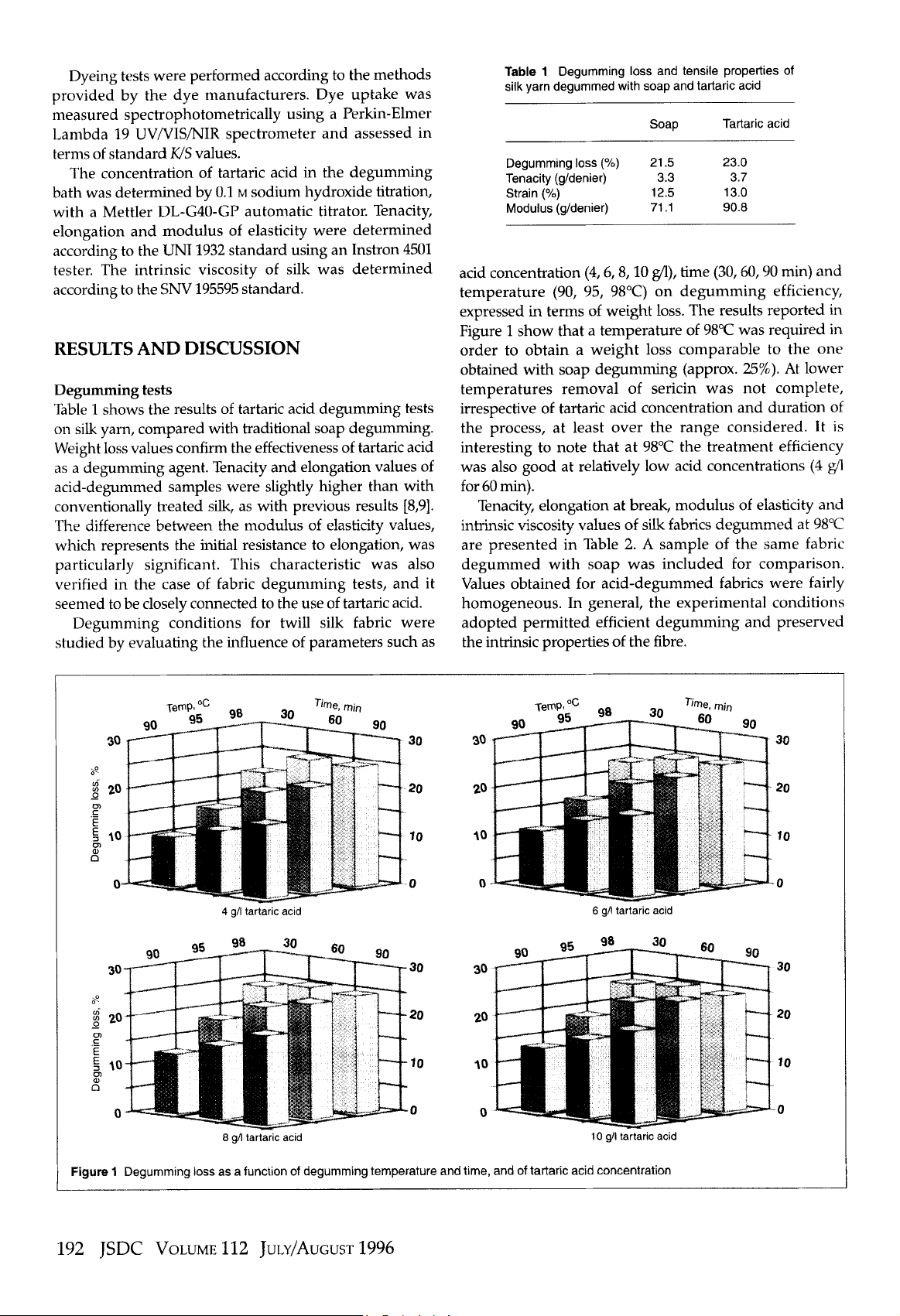

the tartaric acid degumming process for silk has been evaluated as a function of

temperature, time and acid concentration in the degumming bath. The degummed samples were

characterised as regards physico-mechanical properties (tenacity, elongation at break, modulus

of

elasticity) and intrinsic viscosity. Dyeability with acid, metal-complex and reactive dyes has been

determined spectrophotometrically. The possibility of carrying

out

subsequent degummings with the

same bath was investigated. The effect of centrifuging and replenishing the bath with fresh

degumming solution was also considered in relation

to

degumming efficiency. The results obtained

are quite promising as a basis for possible future industrial application.

INTRODUCTION

Degumming of silk has traditionally been carried out in

boiling alkaline baths, containing 6-10

g/l

soap [l].

Nowadays this method is

still

considered the best. Soap-

degummed

silk

shows good brightness, and it also offers

good strength and elasticity, because of the low

degradative action of soap on the fibre.

In recent years continuous degumming systems have

been developed, and newly formulated synthetic

detergents have been adopted as alternatives or adjuncts

to soap

[2,3].

Soap does not allow the degumming bath to

be repeatedly reused, since its alkalinity cannot

compensate for the acidity introduced by sericin

hydrolysis products accumulating in the bath.

Other methods have been used to remove sericin, such

as enzyme treatment [4,5], widely utilised nowadays in

Japan, particularly for kimono fabric degumming.

Treatment with organic acids has also been extensively

studied 16-81. Recent studies show that the action of these

acids is generally less aggressive than the action of alkali.

Furthermore, acid-degummed fabrics seem to have better

aesthetic characteristics, better comfort properties and

better dyeabihty with acid dyes.

Among the different acids considered, tartaric and

succinic acids have given good results, both in terms of

sericin removal efficiency and of intrinsic physico-

mechanical properties of the fibre. The purpose of the

present work was to define the optimum conditions for

fabric degumming with tartaric acid, with reference to the

possibility of reusing the degumming bath many times.

Process pdrameters were evaluated with a view to

developing

a

future industrial application.

*

To

whom

all

correspondence

should

be addressed

Paper prrsrntcd at the dyeing, printing and finishing section

of

the

20th Conge55

of

the Internahonal Silk Association, Brighton, May

1995

EXPERIMENTAL

Materials

Degumming tests on yarn were carried out on 20/22

denier Chinese raw

siLk

samples, 500 m

in

length. Similar

tests on fabric were carried out on 100 g/m2 twill fabric

samples, 15

x

15 cm (4.5

x

50

cm for physico-mechanical

characterisation), having

the

following specifications: weft

count 75 dtex (3

x

20/22 den), warp count 72 dtex

(3

x

20/22

den).

Marseilles soap (Mira Lanza) was utilised for

degumming tests under alkaline conditions. Tartaric acid

WE-ACS 99.5% (Carlo Erba) and nonionic wetting agent

Diadavin

EW200

(BAY)

were used for degumming tests

under acidic conditions.

(a) Levelling acid dye: Nailamide Blue E-BA (Acna,

CI

(b)

Milling acid dye: Nailamide Blue

J-R

(Acna, CI Acid

(c) 1:2 Metal-complex dye: Acidol Dark Blue M-TR (BASE

(d) Reactive dye: Primazin Blue Brilliant

BL

(BASE

CI

The following dyes were used:

Acid Blue

25),

3%

Blue 62), 1.5%

CI Acid Blue 193),

3%

Reactive Blue 27),2%.

Methods

Alkaline degumming was performed with

7

g/l

Marseilles

soap, over 60 min at 98"C, liquor ratio 1OO:l. Acid

degumming was performed under different conditions of

time, temperature and acid concentration, with

3

g/l

nonionic wetting agent, liquor ratio

1OO:l.

Degummed

samples were washed with cold and warm water, and

then dried at room temperature. Weight loss was

measured after conditioning the samples at

20

k

2°C and

65

f

2%

RH.

Centrifuging of the degumming bath was carried out at

31

0008

for

15

min

using

a Beckman J2-21 centrifuge (fixed

angle rotor

JA-20).

JSDC

VOLUME

112

JULY/AUGUST

1996

191