http://www.iaeme.com/IJMET/index.asp 1636 editor@iaeme.com

International Journal of Mechanical Engineering and Technology (IJMET)

Volume 10, Issue 03, March 2019, pp. 1636-1644. Article ID: IJMET_10_03_165

Available online at http://www.iaeme.com/ijmet/issues.asp?JType=IJMET&VType=10&IType=3

ISSN Print: 0976-6340 and ISSN Online: 0976-6359

© IAEME Publication Scopus Indexed

PRELIMINARY CUTTERING OF A CORN COB

FOR PREPARATION OF FODDER

Mustafin Zhasulan

S.Seifullin Kazakh Agrotechnical University, Zhenis 62, 010011, Nur-Sultan, Kazakhstan

Kaspakov Yesen

S.Seifullin Kazakh Agrotechnical University, Zhenis 62, 010011, Nur-Sultan, Kazakhstan

Akhmetov Yerzhan

S.Seifullin Kazakh Agrotechnical University, Zhenis 62, 010011, Nur-Sultan, Kazakhstan

Kayrzhanova Zhainagul

S.Seifullin Kazakh Agrotechnical University, Zhenis 62, 010011, Nur-Sultan, Kazakhstan

Ismagulova Venera

S.Seifullin Kazakh Agrotechnical University, Zhenis 62, 010011, Nur-Sultan, Kazakhstan

ABSTRACT.

Justification of the optimal values of corn cob grinder in the process of pre-grinding

the corn cob, reduce energy consumption and improve productivity. Thus, the urgent

problem of today is the need to develop a new technology for grinding corn cobs for

small peasant and personal subsidiary farms that have a productivity that meets their

needs.

Keywords. Corn cob, chopper, drums, energy intensity, feed, technology, sawtooth

rings,

Cite this Article Mustafin Zhasulan, Kaspakov Yesen, Akhmetov Yerzhan,

Kayrzhanova Zhainagul and Ismagulova Venera, Preliminary Cuttering of a Corn Cob

For Preparation of Fodder, International Journal of Mechanical Engineering and

Technology, 10(3), 2019, pp. 1636-1644.

http://www.iaeme.com/IJMET/issues.asp?JType=IJMET&VType=10&IType=3

1. INTRODUCTION.

The growth of livestock numbers is about 3 ... 6 percent per year. Therefore, at present, to

provide livestock available on farms with nutritious feed is one of the main tasks of agriculture.

To address this issue, farmers are engaged in obtaining nutrient feed, using the components

they have on hand. Many farmers produce nutritious food by grinding dried corn on the cob

with grains. Therefore, for the purpose of mechanization and electrification of Kazakh

Preliminary Cuttering of a Corn Cob For Preparation of Fodder

http://www.iaeme.com/IJMET/index.asp 1637 editor@iaeme.com

agricultural enterprises, small crushing and grinding machines DIK-1.5 began to be introduced

into production, used for grinding corn cobs and AKM-4, DU-11 units producing feed for

livestock. These crushing and grinding machines and grinding units of stalk and grain crops

consume 4 ... 6 kWh / t of electricity, and 12.83 kWh / t of corncob crushing, that is, 2 ... 3

times more compared with the cost of electricity to other feed [1].

2. HEADINGS

In this position, even when the dried corn cobs are in the grinding chamber in length, they are

fed there with a solid, uniform mass. To crush them, the impactors hit the mass at a speed of 60

m / s, as a result of which a very large impact force is obtained. This impact force leads to a

manifold increase in the cost of power. To solve this problem, we offer the following scientific

solution.

When grinding the corn cob, getting rid of a large impact force can reduce energy costs, and

to increase productivity, you must first divide the solid mass of the cob into small parts, then

crush these parts with impact grinders, that is, apply the technology of grinding the cob in parts.

In order to implement the proposed method, a literary review was conducted on the methods of

grinding all types of feed, and in particular on the methods of grinding corn cob. Conducting a

pilot study of the methods of work of plusiki grain, was considered the work of A. M.

Andrianov, along with research and theoretical works of such scholars as P. A. Afanasiev, p. P.

Tarutin, V. I. Il'chenko, A. V. Panchenko, V. A. Olevskii. The review of research papers it was

found that studying the techniques of grinding corn cobs were engaged only in Kazakhstan such

scientists as: V. Golikov N. Emiliano T. and D. T. Emelianov In these studies, the physical and

mechanical properties of the cob were established and the problem of directed supply of the

corn cob to the grinding chamber was revealed [2, 3].

As a result of these studies, began to be introduced into the production of different types of

universal units for livestock feed. But to date, given the overall structural structure of the corn

cob, has not yet been found the technology of grinding the cob in parts, which would provide

an overall reduction in the energy costs of the installation and increase its productivity.

However, not yet defined some of the constituent physical and mechanical properties of corn

ears. In the course of these studies, in order to reduce the energy costs of grinding the cob

divided into parts and identifying the optimal parameters of the grinder, the main task was to

determine the economic profitability of the proposed hypothesis and technology.

3. INDENTATIONS AND EQUATIONS.

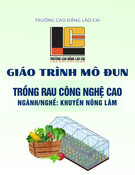

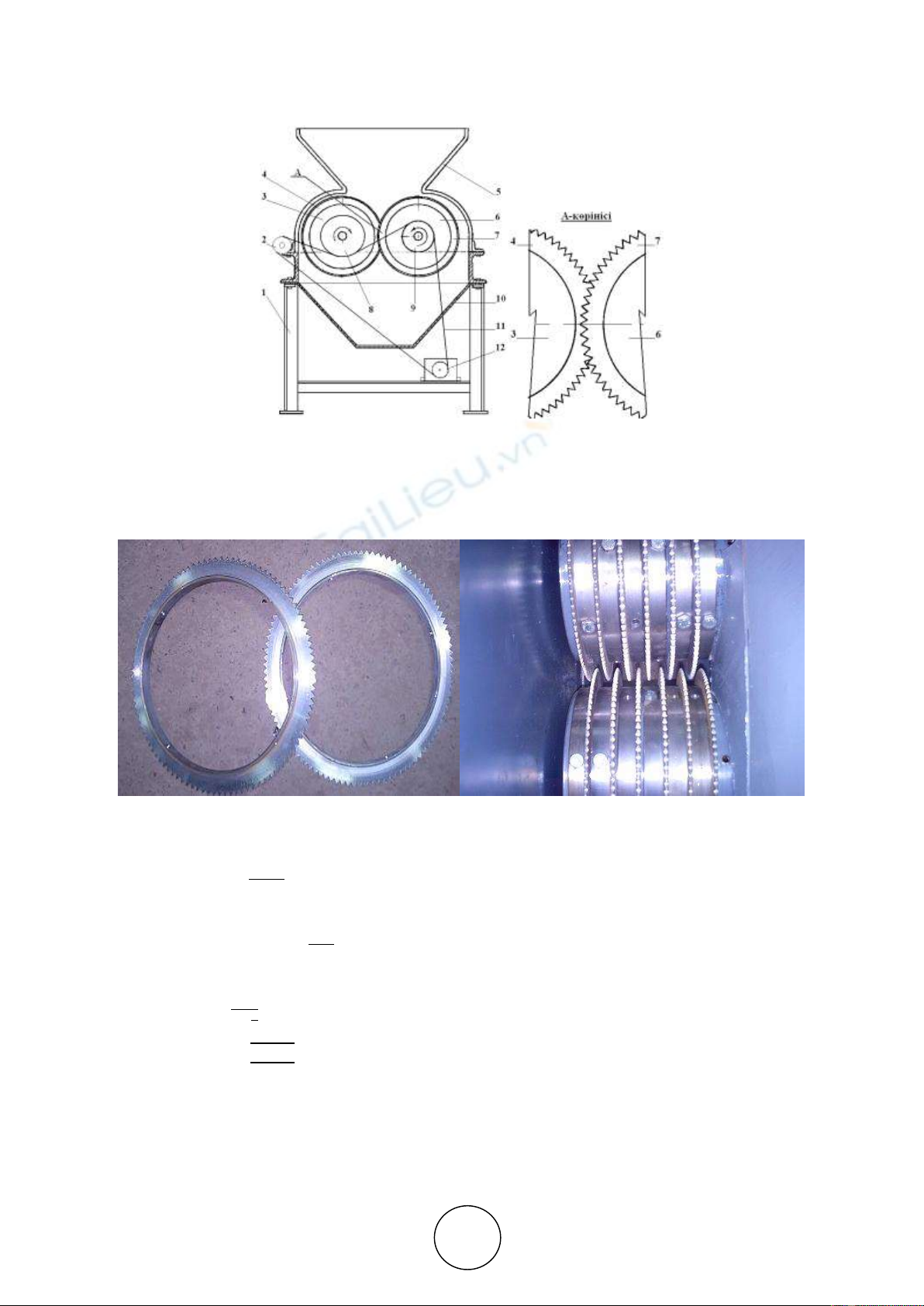

Studies of the transverse section of the cob showed that the outer layer of the cob consists of

grains, inside of a solid layer of thickness 5...6 mm, and in the middle of a soft core. It is

established that the grains of the cob are easily separated by the sharp working part of the

installation. The destruction of the cylinder-shaped solid layer is possible by the use of

oppositely rotating roller saws for this purpose [4]. During experiments it was found that the

teeth slowly rotating blade to guide the ear and the teeth of the second fast-rotating blade to

complete the task of cutting into the cob to pieces. So in order to implement the proposed new

technology, which consists in performing the operation of splitting the cob into parts, a

structural and technological scheme of the grinding plant was prepared. (Figure-1) In the course

of the conducted theoretical researches, after the establishment of the angle of grinding of the

cob at different roller diameters drank, it was determined the optimal value of the diameters of

saws, oscillating between 0.3 and 0.35 m.

Mustafin Zhasulan, Kaspakov Yesen, Akhmetov Yerzhan, Kayrzhanova Zhainagul and

Ismagulova Venera

http://www.iaeme.com/IJMET/index.asp 1638 editor@iaeme.com

Figure - 1 - Scheme of the proposed installation of the chopper corn cob in parts.

1 - housing; 2 - collecting device; 3,6 - opposite-false-rotating drums; 4,7 - oppositely-

rotating with regard to roller saw blade; 5-koronarolitiki; 8,9 - two stars; 10 - vent pipe; 11-

chain transfer; 12-a gear motor.

From mechanics it is known, according to the rule of the triangle of velocities, the relative velocity

must be closed by the absolute velocity. In this case, you can use the sine theorem:

𝑉𝑎=𝑉от2 𝑠𝑖𝑛𝑀

𝑠𝑖𝑛𝑀0. (1)

From the equality of Modes 2=M it Follows that in the triangle MN0T1BT1=<MO

Therefore: 𝑀𝑜=𝜋−𝛼

2. (2)

Substituting (1) and (3) into (2) we obtain [5]:

𝑉𝑎=𝑉𝑠𝑖𝑛𝛼

𝑐𝑜𝑠𝛼

2 (3)

𝑉𝑎=2𝑉√1−𝑐𝑜𝑠𝛼

2. (4)

Before making it so as to ensure an equal value of the speed of the teeth of a slowly rotating

saw and the speed of the cob sliding along the wall of the hopper, determine the speed of the

teeth by the following formula [6]:

Preliminary Cuttering of a Corn Cob For Preparation of Fodder

http://www.iaeme.com/IJMET/index.asp 1639 editor@iaeme.com

)cos(sin fq

l

l

V

к

к

жо

(5)

Also, to determine the ratio of the speeds of slow and fast rotating roller saws, the formula

is used:

1

2

1

2

1

2

1

2

n

n

V

V

(6)

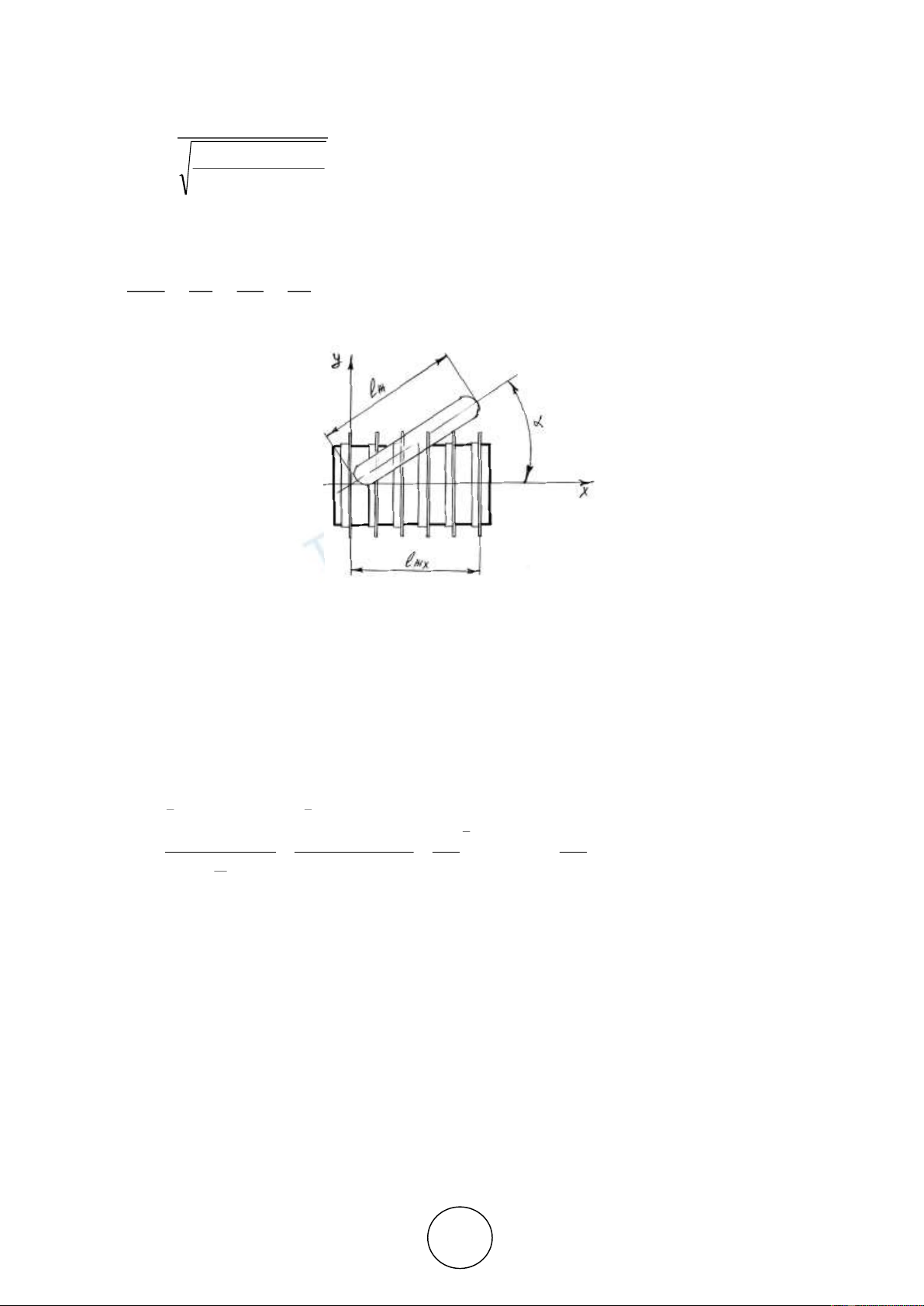

Figure 2 is a View of the ear of corn prior to passing through the gap between the two drums.

If ACC is taken as the length of the cob, its projection to the x-axis line will be determined

by the following formula (figure-2):

cos*

жжх ll

(7)

In this case, the projection to the x-axis line, that is, the average length of the cob passing

between the two reels and depending on the change of angle α, is determined by the probability

theory as follows:

2

0

2

0

2

02

*cos

2

*cos*2

2

*cos*

жж

жж

жх

l

d

l

dldl

l

(8)

So with the help of probability theory, the length at which the corn cob should pass between

the two reels was calculated.

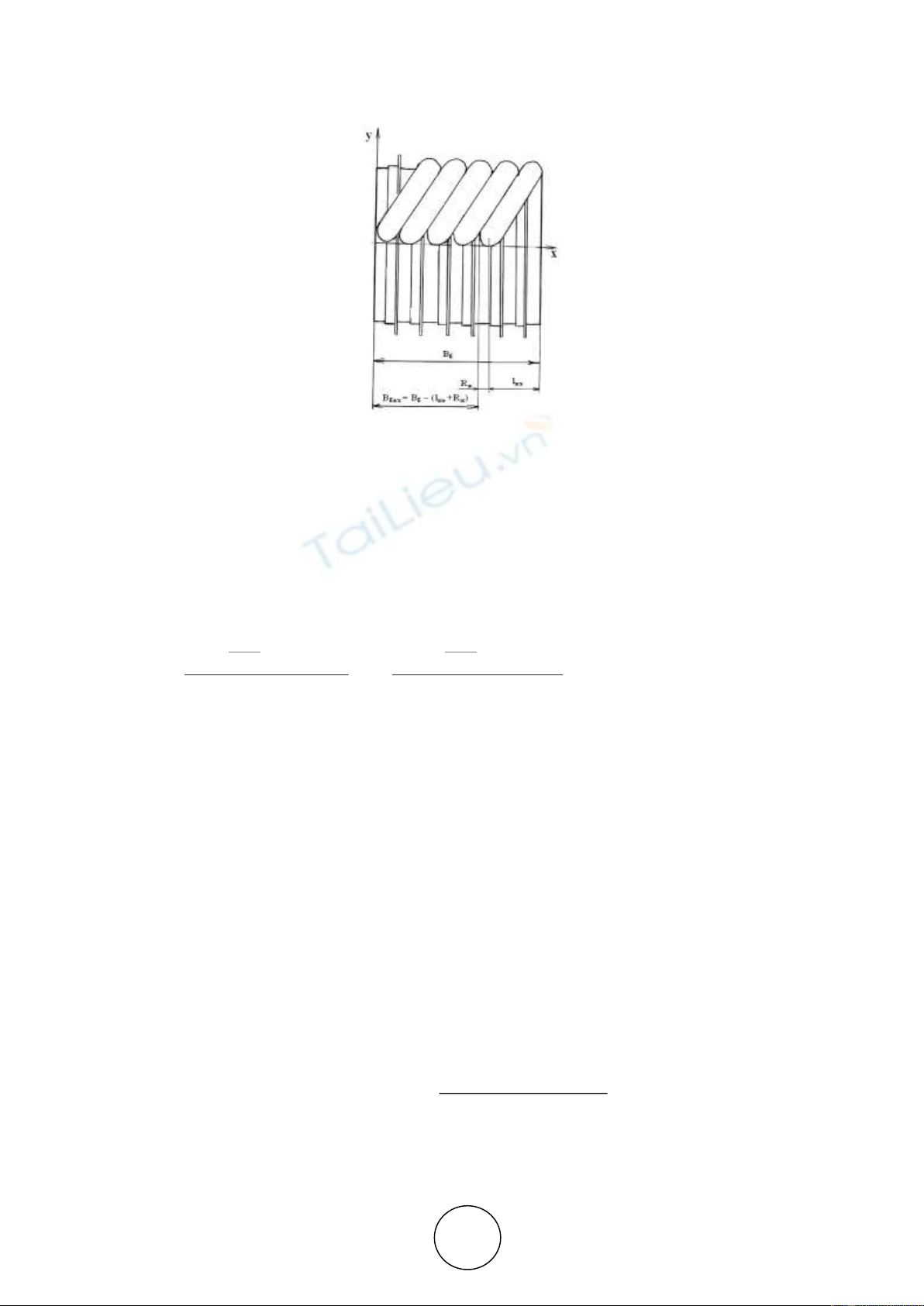

Now you need to determine how many corn ears should pass between the two rams for a

certain period of time. Here we cannot say that one ear passes, that is, in this position we accept

that several ears pass in a row. (Figure-3)

Mustafin Zhasulan, Kaspakov Yesen, Akhmetov Yerzhan, Kayrzhanova Zhainagul and

Ismagulova Venera

http://www.iaeme.com/IJMET/index.asp 1640 editor@iaeme.com

Figure 3 - Scheme of location of the ears of corn on the x axis

If we take the length of the drum or the width of the hopper of the chopper equal to WB,

then determine the number of corn ears located along the x and y axes and perpendicular to the

angle α along the entire length of the drum, we calculate the total number of ears located in the

side of the drum, following formula:

To determine the performance of the installation, the mass and the number of corn cobs are

taken into account in the shredder drum, an analytical expression was obtained.

áæî

æ

æ

æ

á

æ

æ

æ

án*G*1

R

sin*R

l*2

Ä

*1

R

cos*R

l*2

Â

*60Q

(9)

4-figure shows the scheme of the process of grinding corn ears. In this case, the high-speed

shaft influencing resistance force (Fn) is determined by the formula:

cos

an FF

(10)

Where Fa° is the tangential fracture force of the cylinder cob

With the teeth of a saw, N; is the angle between the radius of the teeth of the destruction of

the cob.

According to (10) formula, the force of destruction of the teeth of the cob, you can determine

the tangential force,

cossin

ak FF

(11)

From this, grinding one cob to determine the total moment of resistance. To determine the

total moment of the drum chopper, multiply the moment of resistance of one saw by the number

of saws.

a

жжб

aaаккж t

dсoslВ

RFКММ

cossin

1

(12)