MIL-HDBK-1003/3

Reprinted by permission of ASHRAE, from ASHRAE Handbook, Fundamentals.

a) Hot Water Piping to Coil. Water coils will not perform if there

is air in the piping. Ensure that the piping from the main, to the coil, and

to the return main is appropriately sloped up and vented to eliminate

entrained air that can air lock the flow.

b) Hot Water Coil Selection. Consult the manufacturer's catalog

data to decide the best selection, number of rows, parallel or counter flow,

turbulators or serpentines, and other selection information. Using the

appropriate type, make the coil selection:

(1) Capacity required

(2) Water temperature in and out

(3) Air temperature in and out

(4) Airflow

(5) Water flow

(6) Air pressure drop

72

Simpo PDF Merge and Split Unregistered Version - http://www.simpopdf.com

MIL-HDBK-1003/3

(7) Water pressure drop

(8) Coil face velocity

(9) Any special requirements

After the coil selection has been made and documented

in the design analysis, be sure to provide the above data in the

coil schedule on drawings. This will ensure a good bidding

climate, with equipment manufacturers knowing what to bid, and

what to submit in the shop drawings phase.

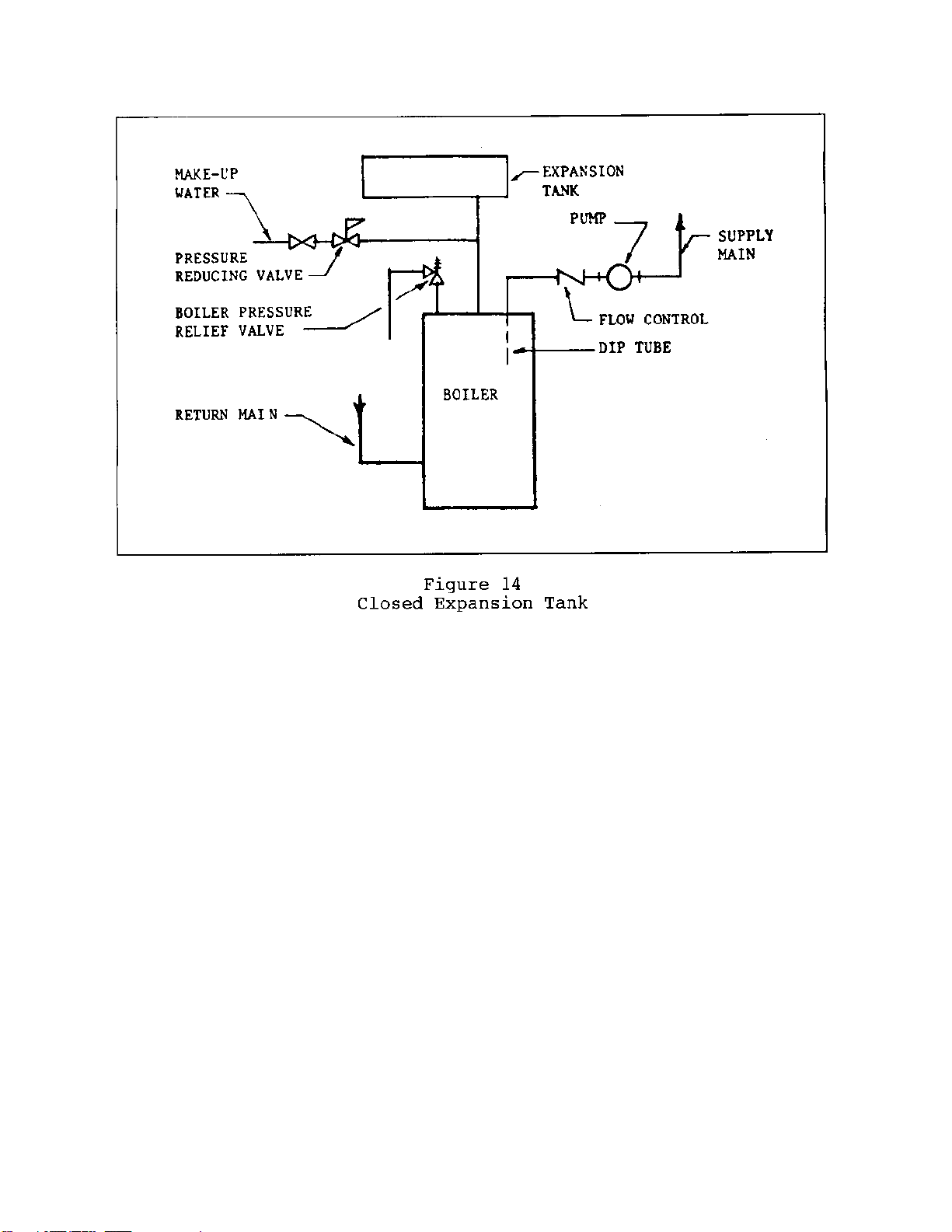

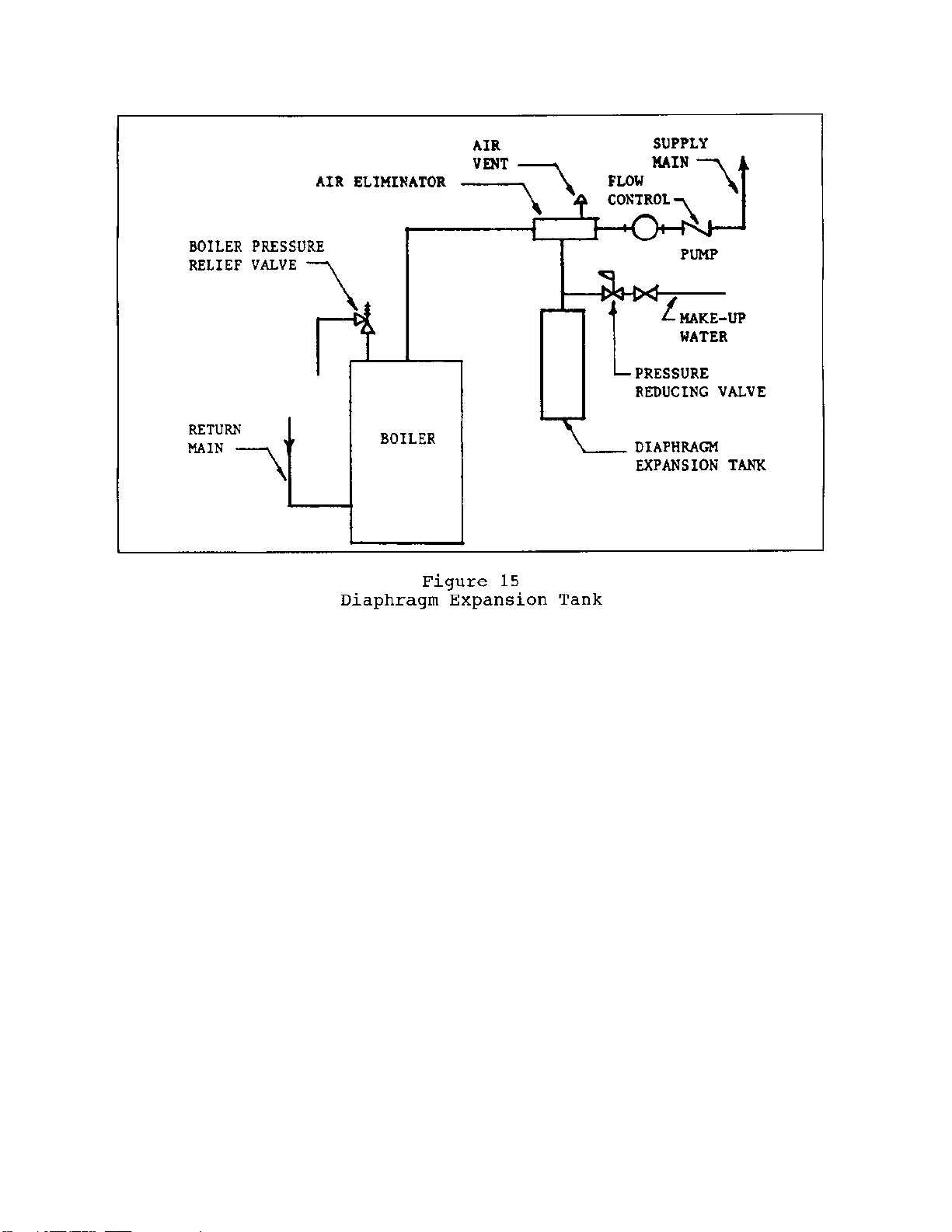

7.2.2.3 Expansion Tanks and Air Separator

a) Expansion Tanks General. When water in a hot water

heating system is heated, water expands and occupies more volume.

System pressure control is needed to:

(1) Limit pressure in all parts of the system to

the allowable working pressure.

(2) Maintain minimum pressure in the system to

prevent pump cavitation and to prevent boiling of system water.

(3) Minimize addition of makeup water.

b) Expansion Tank With Air Separator. An expansion

tank with an air separator performs these system pressure control

functions. Since this section does not address medium

temperature hot water system (250 to 350 degrees F) or high

temperature hot water system (above 350 degrees F); discussion

will be limited to the following types of tanks:

(1) Closed expansion tanks with an air cushion.

See Figure 14.

(2) Diaphragm (or bladder) type closed expansion

tanks. See Figure 15.

Open expansion tanks located at the system high point

will also work on low temperature hot water systems, but are not

generally used on Navy building projects.

c) Expansion Tanks. Some specifics regarding

expansion tanks are as follows:

(1) Expansion tanks are required on chilled water

and hot water systems.

73

Simpo PDF Merge and Split Unregistered Version - http://www.simpopdf.com

MIL-HDBK-1003/3

(2) Locate the tank on the suction side of the

system pump so that system pressure is always positive with

respect to atmospheric pressure.

(3) Do not install a shutoff valve between the

heat source and the expansion tank.

(4) Refer to ASHRAE Handbook, HVAC Systems and

Application or manufacturer's literature for tank sizing.

(5) See Figure 14 for closed expansion tank

placement.

(6) See Figure 15 for diaphragm expansion tank

placement.

(7) Do not use a gage glass on the expansion tank.

A gage glass on a steam boiler is permitted since the wet steam

vapor keeps the upper glass packing tight. With an expansion

tank, the air will dry out the upper gage glass packing and cause

air leaks.

7.2.2.4 Domestic Hot Water Generator. An interface occurs

between the heating system and the plumbing system when boiler

steam or boiler hot water is used to heat water for plumbing

fixtures. Some points to consider in heating domestic hot water

are as follows:

a) Domestic water can be heated by the boiler (steam

or hot water) or a separate hot water generator, if the heating

source is available during the summer. If heated by the space

heating boiler, evaluate boiler efficiency for summer operation.

b) If the space heating boiler provides hot water,

evaluate if it should be an instantaneous heater, a semi-

instantaneous heater, or a storage type hot water generator. The

selection will affect the boiler capacity specified. Refer to

NAVFAC DM-3.01, Plumbing Systems for domestic hot water system

design.

With these decisions made, select the hot water system

and equipment. See Figure 16 and Figure 17.

7.2.2.5 Heat Exchangers. Heat exchangers are used for steam to

heat water. One medium flows through the shell, and the other

medium flows through the tubes in the tube bundle. Include the

following in the equipment schedule:

a) Water flow

74

Simpo PDF Merge and Split Unregistered Version - http://www.simpopdf.com

MIL-HDBK-1003/3

75

Simpo PDF Merge and Split Unregistered Version - http://www.simpopdf.com

MIL-HDBK-1003/3

76

Simpo PDF Merge and Split Unregistered Version - http://www.simpopdf.com

![Hệ thống HVAC và Dehumidifying: Tổng quan [Năm hiện tại]](https://cdn.tailieu.vn/images/document/thumbnail/2012/20120202/luly_meo1/135x160/hvac_and_dehumidifiying_systems_b_split_14_8134.jpg)

![Hệ thống HVAC và Dehumidifying: Tổng quan [Năm hiện tại]](https://cdn.tailieu.vn/images/document/thumbnail/2012/20120202/luly_meo1/135x160/hvac_and_dehumidifiying_systems_b_split_13_3651.jpg)

![Hệ thống HVAC và Dehumidifying: [Thêm từ mô tả/định tính để tăng CTR]](https://cdn.tailieu.vn/images/document/thumbnail/2012/20120202/luly_meo1/135x160/hvac_and_dehumidifiying_systems_b_split_12_8041.jpg)

![Hệ thống HVAC và Dehumidifying: [Thông tin chi tiết/Hướng dẫn/Lựa chọn]](https://cdn.tailieu.vn/images/document/thumbnail/2012/20120202/luly_meo1/135x160/hvac_and_dehumidifiying_systems_b_split_11_4149.jpg)

![Hệ thống HVAC và hệ thống hút ẩm: [Thông tin chi tiết/Hướng dẫn/Lựa chọn tốt nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2012/20120202/luly_meo1/135x160/hvac_and_dehumidifiying_systems_b_split_10_7992.jpg)

![HVAC và Hệ thống Hút Ẩm: [Thêm thông tin chi tiết để tối ưu SEO]](https://cdn.tailieu.vn/images/document/thumbnail/2012/20120202/luly_meo1/135x160/hvac_and_dehumidifiying_systems_b_split_9_3668.jpg)

![HVAC và Dehumidifying Systems: Hệ thống điều hòa không khí và hút ẩm [chuẩn SEO]](https://cdn.tailieu.vn/images/document/thumbnail/2012/20120202/luly_meo1/135x160/hvac_and_dehumidifiying_systems_b_split_7_2859.jpg)

![Hệ thống HVAC và Dehumidifying: [Thông tin chi tiết/Hướng dẫn/Lựa chọn]](https://cdn.tailieu.vn/images/document/thumbnail/2012/20120202/luly_meo1/135x160/hvac_and_dehumidifiying_systems_b_split_5_3816.jpg)

![HVAC và Dehumidifying Systems: [Thêm thông tin chi tiết để tối ưu SEO]](https://cdn.tailieu.vn/images/document/thumbnail/2012/20120202/luly_meo1/135x160/hvac_and_dehumidifiying_systems_b_split_4_7836.jpg)

![Ngân hàng trắc nghiệm Kỹ thuật lạnh ứng dụng: Đề cương [chuẩn nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20251007/kimphuong1001/135x160/25391759827353.jpg)