MIL-HDBK-1003/3

b) Do not use vacuum condensate returns. Since high pressure steam

is hotter than low pressure steam, provide adequate cooling legs of

uninsulated steam pipe or a length of finned radiation between the last steam

main takeoff and the drip assembly. Failure to do this will cause the hot

condensate to flash back into steam at the trap. Use vented flash tank as a

solution. Refer to par. 7.3.3.5 for condensate pumps and flash tank.

7.3.3.2 Boiler. Refer to MIL-HDBK-1003/6.

7.3.3.3 Heat Exchanger. Refer to par. 7.2.2.5.

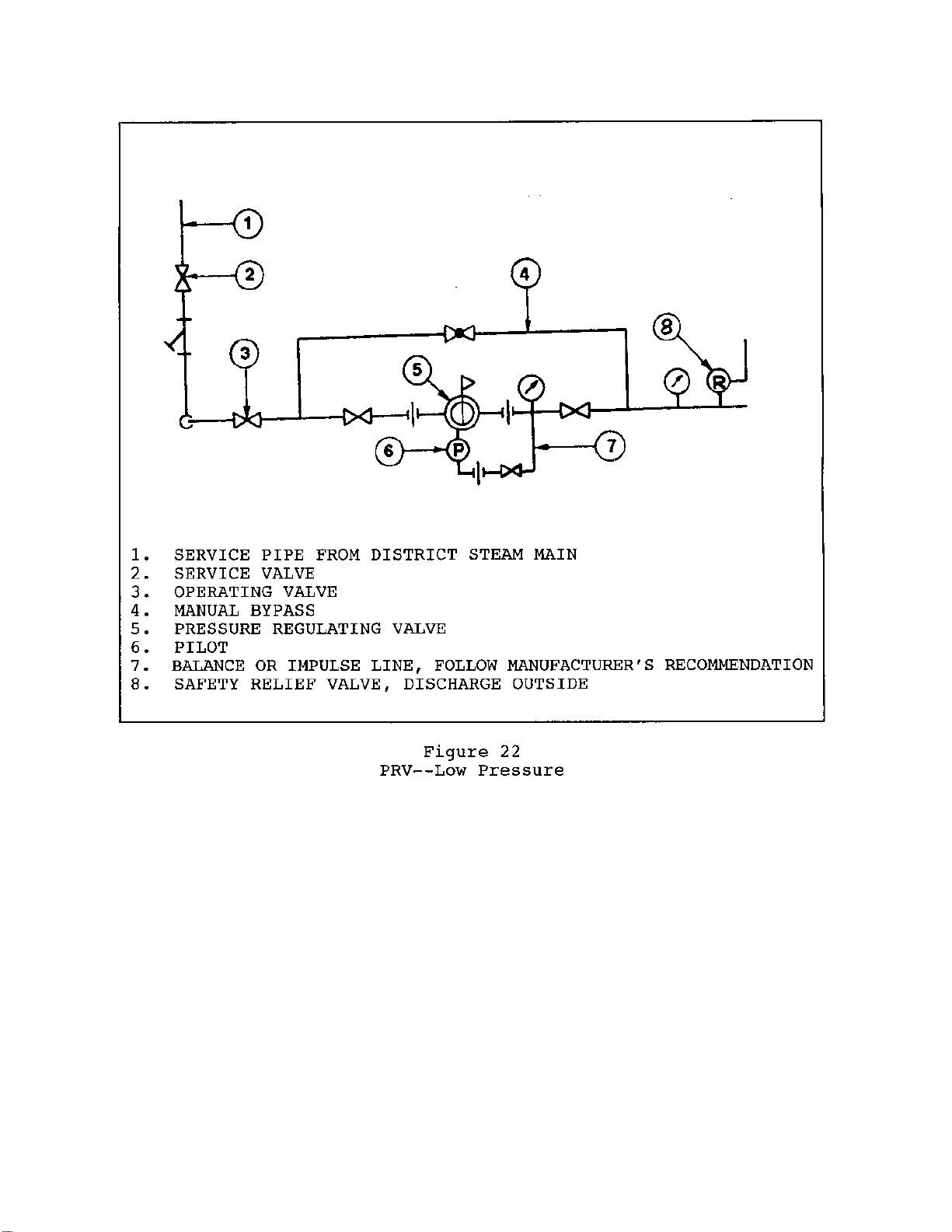

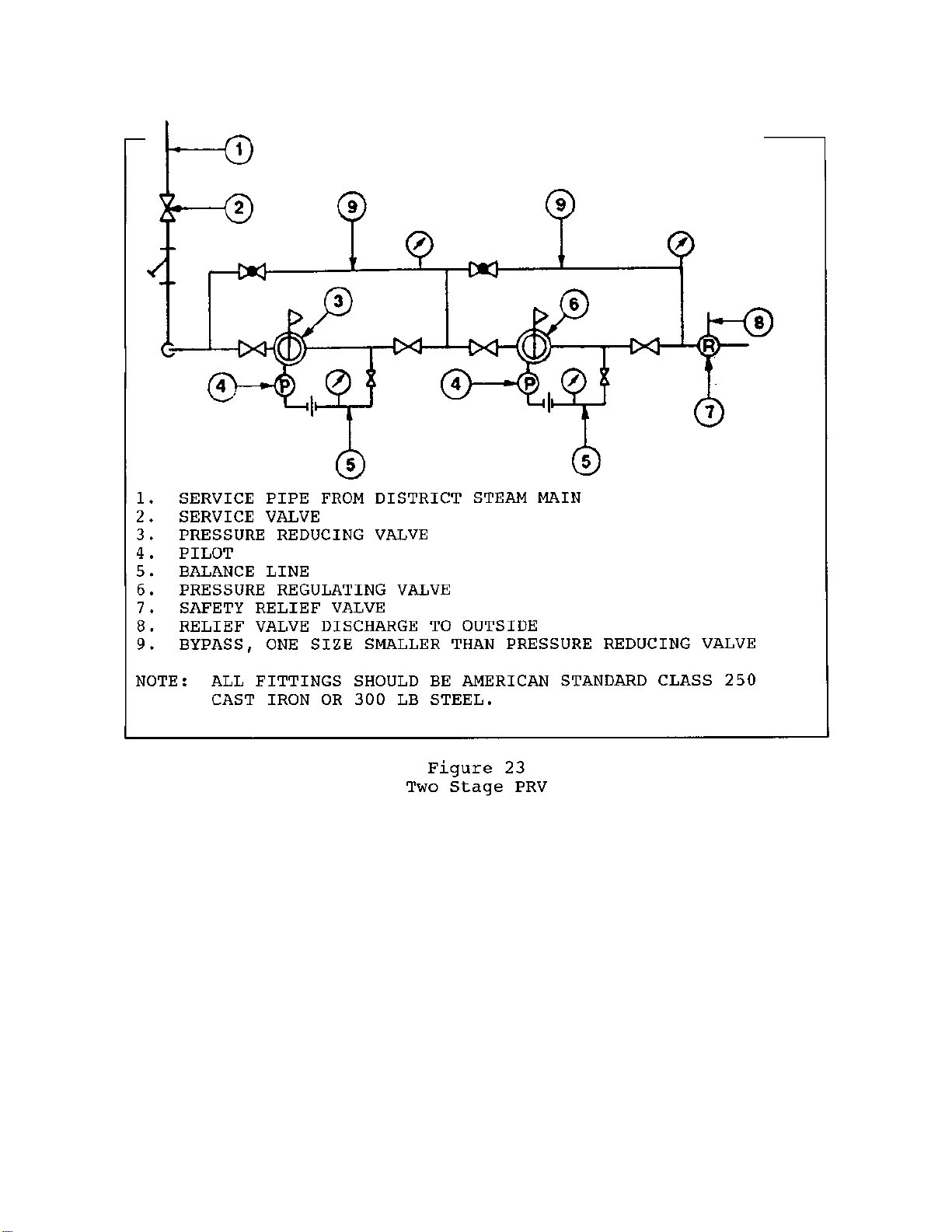

7.3.3.4 Steam Pressure Regulating Valves. See Figures 22 and 23 for piping

of steam pressure regulating assemblies, and note the following:

a) Sizing Pressure Regulating Valves

(1) Analyze flow required for maximum and minimum demand.

(2) Size the pressure regulating valve to handle peak flow.

This will generally result in a valve body that is smaller than inlet supply

line size.

(3) If there is a big turndown ratio between minimum and

maximum flow, consider using two regulator valves in parallel, perhaps sized

for 30 percent and 70 percent of the flow. Consider to flip the settings so

that the small regulator pilot maintains optimum downstream pressure in the

summer and the big regulator pilot is the lead controller in the winter.

(4) Look at the manufacturer's tables to see whether a two

stage assembly should be used with two regulators in series. Sometimes this

is done anyway for redundancy in low pressure installations; with the

downstream regulator controlling to 5 psi, and a upstream regulator set at 7

psi in case the downstream regulator cannot handle a flow surge.

b) Piping Pressure Regulating Valves

(1) Provide a bypass around the regulator with a globe valve

that has a tight shutoff seat. Size bypass to flow less than wide open

failure flow of the regulator, but not less than regulator design flow.

89

Simpo PDF Merge and Split Unregistered Version - http://www.simpopdf.com

MIL-HDBK-1003/3

90

Simpo PDF Merge and Split Unregistered Version - http://www.simpopdf.com

MIL-HDBK-1003/3

91

Simpo PDF Merge and Split Unregistered Version - http://www.simpopdf.com

MIL-HDBK-1003/3

(2) Put a pressure gage immediately downstream of

the regulator pilot tap. The pressure gage range should include

the upstream inlet pressure.

(3) Provide a relief valve on the downstream side

that will handle 150 percent of the wide open failure flow rating

of the regulator. Set the relief valve higher than the

downstream operating pressure, and pipe the relief valve

discharge to a safe place.

(4) Provide shutoff valves on each side of the

regulator assembly; with the low side shutoff valve downstream of

the pilot tap.

(5) Locate the entire regulator assembly in an

accessible place.

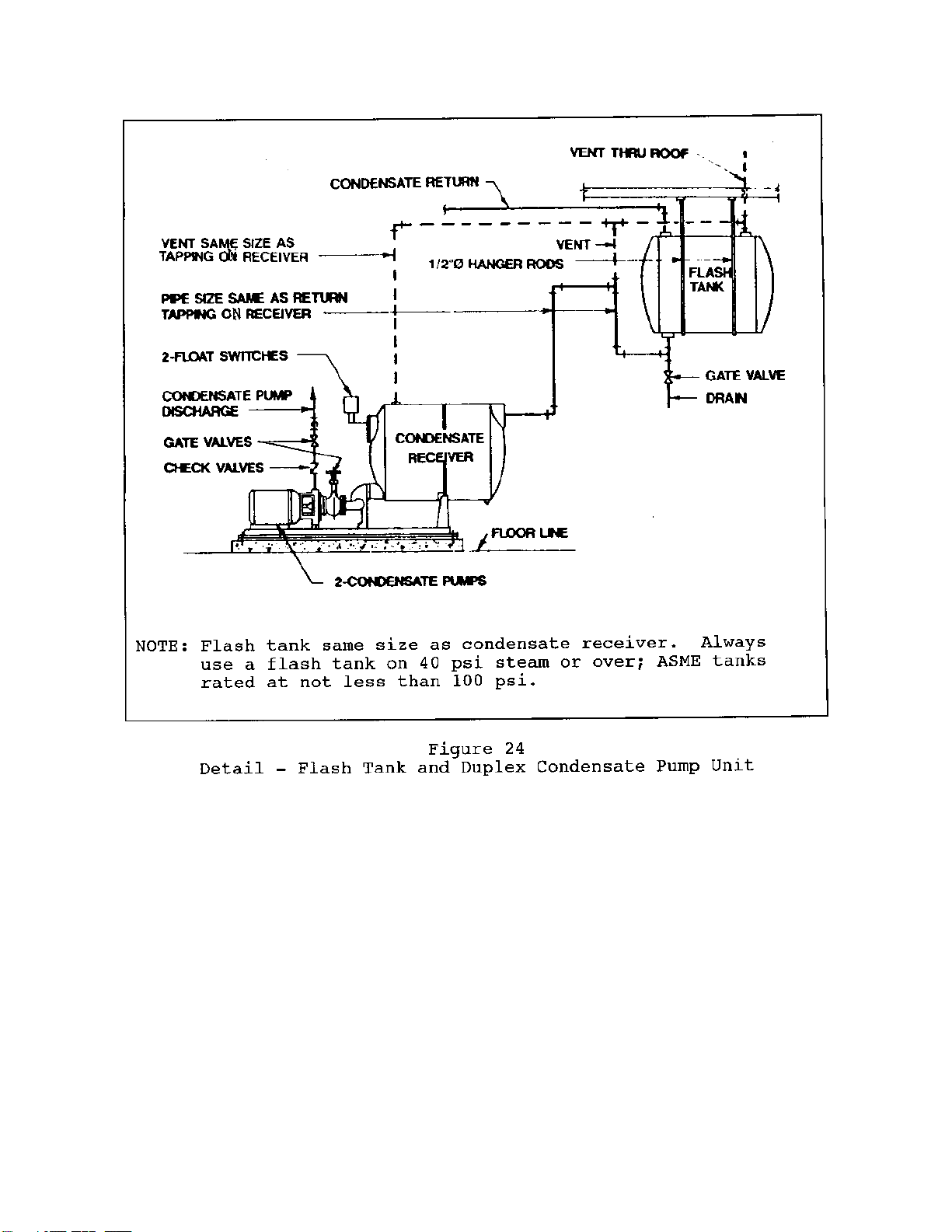

7.3.3.5 Condensate Pumps and Flash Tank. Higher pressure steam

condensate is hotter than low pressure steam condensate. If the

system is over 40 psi steam, always run the condensate through a

flash tank before entering the receiver of the condensate pump

set. This prevents the condensate flashing to steam in the

pumps. See Figure 24.

7.3.3.6 Steam Coils - General. Refer to par. 7.2.2.2 and the

manufacturer's capacity tables for selection. See Figures 25 and

26 for piping steam coils. Always provide steam traps for each

coil section. Steam distributing coils feature a perforated

distributing header inside the main coil construction.

7.3.3.7 Steam Traps. In a steam system, steam traps should be

provided to remove condensate and gas from the steam supply as

soon as it forms. Unless this is done:

a) A slug of condensate can harm the system.

b) Accumulation of CO gas can cause corrosion.

2

See Table 14 for common types of steam traps and Figure 27 for

piping of a low pressure drip.

7.3.4 Boilers. Size the steam boiler in accordance with the

ASHRAE Equipment Handbook, and include building heating, process

steam, domestic water heating, and pickup loads. See Figure 28

for piping a low pressure steam boiler.

92

Simpo PDF Merge and Split Unregistered Version - http://www.simpopdf.com

MIL-HDBK-1003/3

93

Simpo PDF Merge and Split Unregistered Version - http://www.simpopdf.com

![Hệ thống HVAC và Dehumidifying: Tổng quan [Năm hiện tại]](https://cdn.tailieu.vn/images/document/thumbnail/2012/20120202/luly_meo1/135x160/hvac_and_dehumidifiying_systems_b_split_14_8134.jpg)

![Hệ thống HVAC và Dehumidifying: Tổng quan [Năm hiện tại]](https://cdn.tailieu.vn/images/document/thumbnail/2012/20120202/luly_meo1/135x160/hvac_and_dehumidifiying_systems_b_split_13_3651.jpg)

![Hệ thống HVAC và Dehumidifying: [Thêm từ mô tả/định tính để tăng CTR]](https://cdn.tailieu.vn/images/document/thumbnail/2012/20120202/luly_meo1/135x160/hvac_and_dehumidifiying_systems_b_split_12_8041.jpg)

![Hệ thống HVAC và Dehumidifying: [Thông tin chi tiết/Hướng dẫn/Lựa chọn]](https://cdn.tailieu.vn/images/document/thumbnail/2012/20120202/luly_meo1/135x160/hvac_and_dehumidifiying_systems_b_split_11_4149.jpg)

![Hệ thống HVAC và hệ thống hút ẩm: [Thông tin chi tiết/Hướng dẫn/Lựa chọn tốt nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2012/20120202/luly_meo1/135x160/hvac_and_dehumidifiying_systems_b_split_10_7992.jpg)

![HVAC và Hệ thống Hút Ẩm: [Thêm thông tin chi tiết để tối ưu SEO]](https://cdn.tailieu.vn/images/document/thumbnail/2012/20120202/luly_meo1/135x160/hvac_and_dehumidifiying_systems_b_split_9_3668.jpg)

![HVAC và Dehumidifying Systems: [Mô tả chi tiết/Hướng dẫn/Đánh giá]](https://cdn.tailieu.vn/images/document/thumbnail/2012/20120202/luly_meo1/135x160/hvac_and_dehumidifiying_systems_b_split_6_8164.jpg)

![Hệ thống HVAC và Dehumidifying: [Thông tin chi tiết/Hướng dẫn/Lựa chọn]](https://cdn.tailieu.vn/images/document/thumbnail/2012/20120202/luly_meo1/135x160/hvac_and_dehumidifiying_systems_b_split_5_3816.jpg)

![HVAC và Dehumidifying Systems: [Thêm thông tin chi tiết để tối ưu SEO]](https://cdn.tailieu.vn/images/document/thumbnail/2012/20120202/luly_meo1/135x160/hvac_and_dehumidifiying_systems_b_split_4_7836.jpg)

![Ngân hàng trắc nghiệm Kỹ thuật lạnh ứng dụng: Đề cương [chuẩn nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20251007/kimphuong1001/135x160/25391759827353.jpg)