TRU'CJNG DAI HOC SU- PHAM KY THUAT

THANH PHO HO CHI MINH

KHOA CO KHI CHE TAO MAY

BO MON CO BIEN Tf f

BE THI CUOI HOC KY 2 NAM HOC 2022-2023

Mon: Tu dong hoa qua trinh san xuat

Ma mon hoc: MPAU220729

De so/Ma de: 001 Be thi co 3 trang.

Thai gian: 75 phut.

Dugc phep su dung tai lieu. Sinh vien nop lai de.

Cau 1: (1.5 diem)

PLC da va dang dugc su dung rong rai trong cong nghiep va dan dung.

a. Neu cac uu diem chinh cua PLC (it nhat 4 uu dilm). (0.5d)

b. Ke ten toi thieu 3 thiet bi dau vao (input) va 3 thiSt bi ddu ra (output). (0.5d)

c. Ve so do noi day cam bien NPN va cam bien PNP vai PLC. (0.5d)

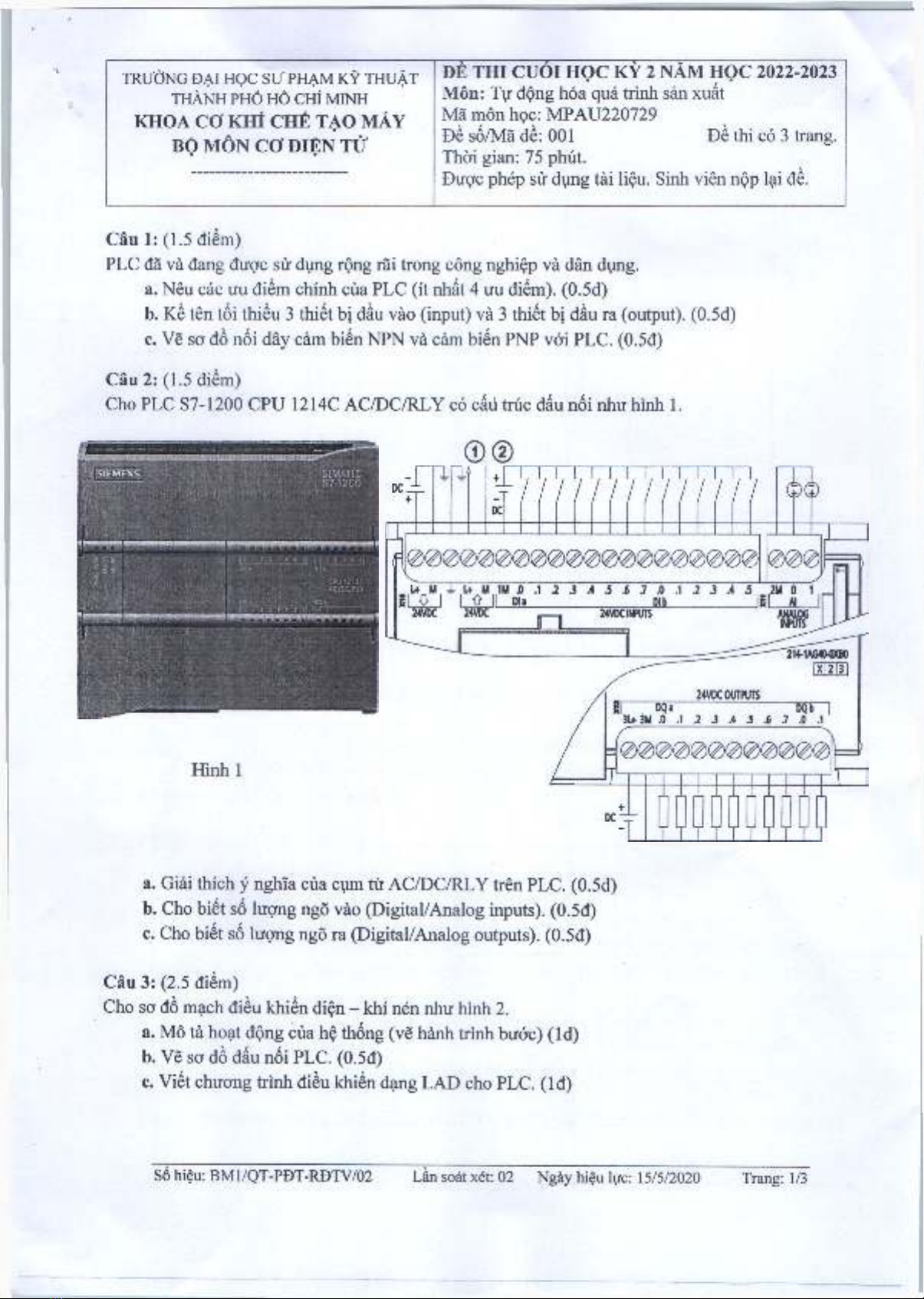

Cau 2: (1.5 diem)

Cho PLC S7-1200 CPU 1214C AC/DC/RLY co c iu true ddu n6i nhu hinh 1.

Hinh 1

©@

a. Giai thich y nghTa cua cum tu AC/DC/RLY tren PLC. (0.5d)

b. Cho bi6t s6 lugng ngo vao (Digital/Analog inputs). (0.5d)

c. Cho bmt s6 lugng ngo ra (Digital/Analog outputs). (0.5d)

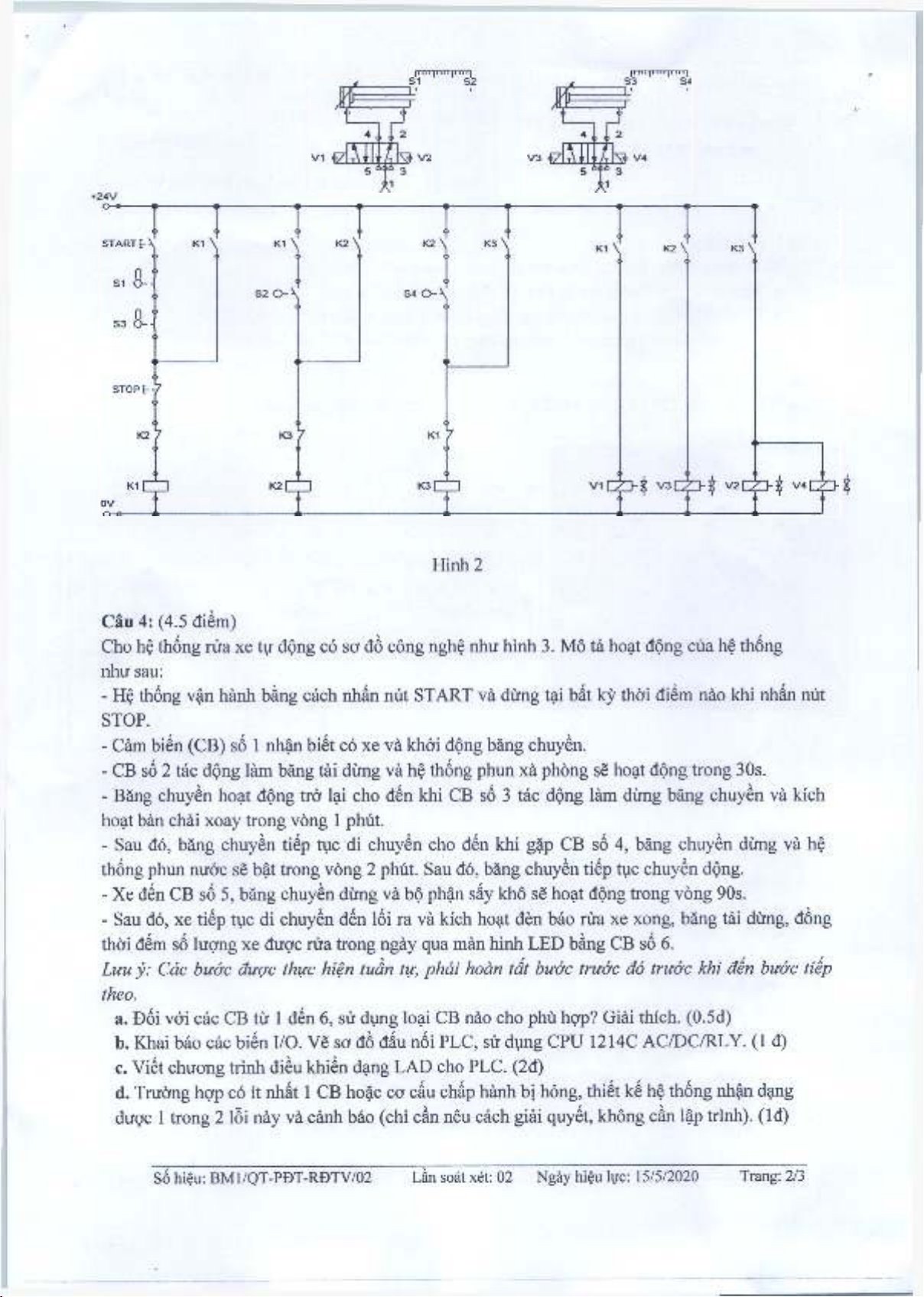

Cau 3: (2.5 diSm)

Cho so do mach dieu khien dien — khi nen nhu hinh 2.

a. Mo ta hoat dong cua he thong (ve hanh trinh buac) (Id)

b. Ve sa do dau noi PLC. (0.5d)

c. Vilt chuang trinh di6u khien dang LAD cho PLC. (Id)

S6 hieu: BM1/QT-PDT-RDTV/02 Lan soat xet: 02 Ngay hieu luc: 15/5/2020 Trang: 1/3

111111" 111" " I

S2

Hinh 2

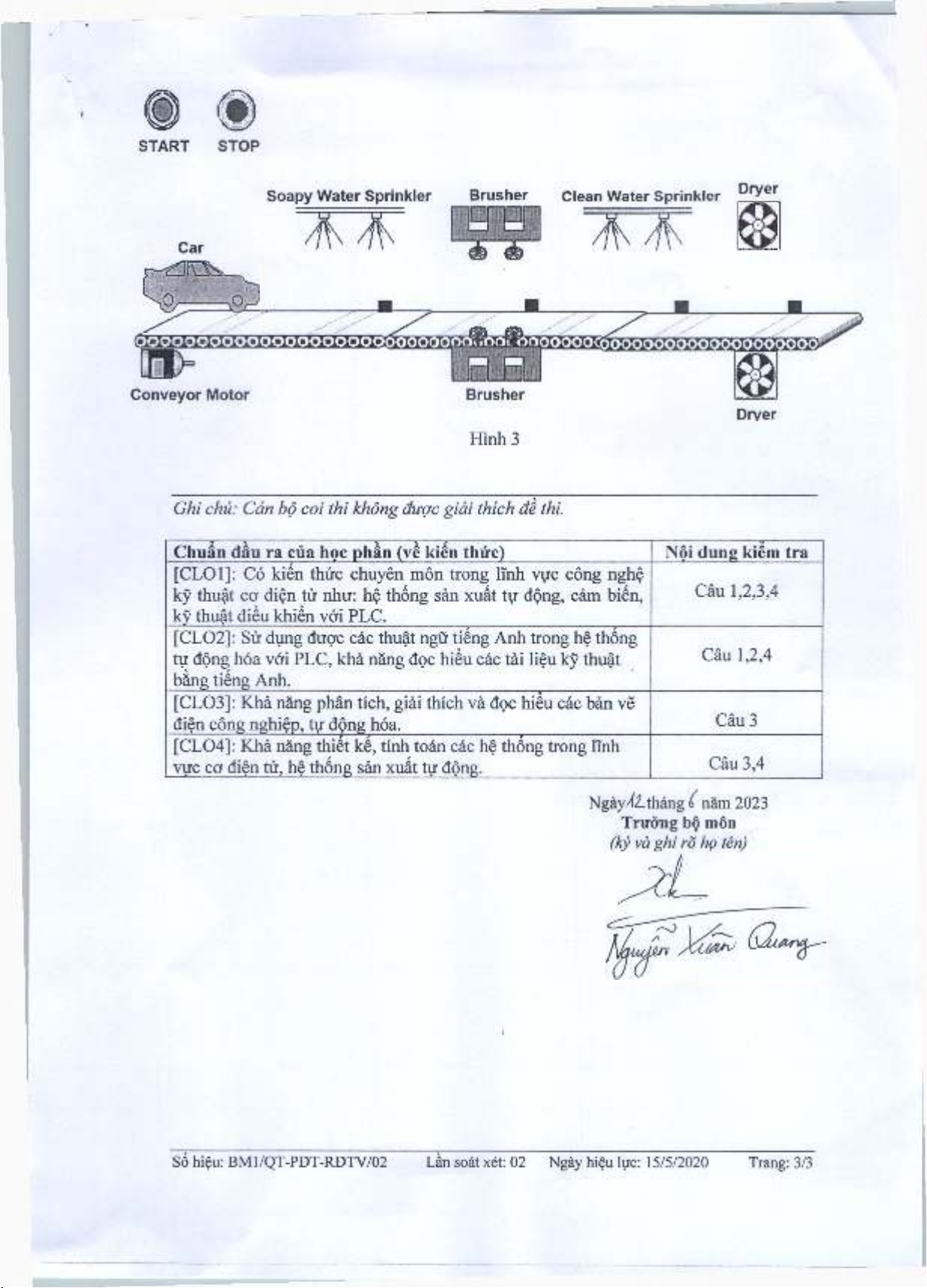

Cau 4: (4.5 diem)

Cho he thdng rua xe tu dong co so do cong nghe nhu hinh 3. Mo ta hoat dong cua he thong

nhu sau:

- He thdng van hanh bang each nhan nut START va dung tai b§t ky thdi diem nao khi nhin nut

STOP.

- Cam bidn (CB) so 1 nhan biet co xe va khdi dong bang chuyen.

- CB sd 2 tac dgng lam bang tai dung va he thong phun xa phong se hoat dong trong 30s.

- Bang chuyen hoat dong trd lai cho den khi CB so 3 tac dong lam dung bang chuyen va kich

hoat ban chai xoay trong vong 1 phut.

- Sau do, bang chuydn tidp tuc di chuydn cho den khi gap CB so 4, bang chuyen dung va he

thdng phun nuoc se bat trong vong 2 phut. Sau do, bang chuyen tiep tuc chuy€n dong.

- Xe den CB so 5, bang chuyen dimg va bo phan say kho se hoat dong trong vong 90s.

- Sau do, xe ti£p tuc di chuyen den 16i ra va kich hoat den bao rira xe xong, bang tai dung, dong

thdi d£m s6 luong xe dugc rua trong ngay qua man hinh LED bang CB so 6.

> r f r

Lieu y: Cac buoc dugc thuc hien tuan tu, phai hoan tat bu&c truac do truoc khi den buac tiep

theo.

a. B6i vdi cac CB tu 1 den 6, su dung loai CB nao cho phu hop? Giai thich. (0.5d)

b. Khai bao cac bien I/O. Ve so do dau noi PLC, su dung CPU 1214C AC/DC/RLY. (1 d)

c. Viet chuong trinh dieu khien dang LAD cho PLC. (2d)

d. Truong hop co it nhdt 1 CB hoac co c4u chap hanh bi hong, thiet ke he thong nhan dang

dugc 1 trong 2 16i nay va canh bao (chi can neu each giai quyet, khong can lap trinh). (Id)

S6 hieu: BM1/QT-PDT-RDTV/02 LSn soat xet: 02 Ngay hieu lye: 15/5/2020 Trang: 2/3

START STOP

Soapy Water Sprinkler Brusher Clean Water Sprinkler Dryer

Car

□

;

H

E>ooooooooooooooooooo:oooooooo^»ooLiooooooocoooooooooooooooooooo'

in>

Conveyor Motor lJrusher■

Dryer

Hinh 3

Ghi chu: Can bo coi thi khong duoc giai thick de thi.

Chuan dau ra cua hoc phan (ve kien thu’c) Noi dung kiem tra

m r

[CLOl]: Co kien thuc chuyen mon trong lmh vuc cong nghe

ky thuat co dien tu* nhu: he thong san xuat tur dong, cam bien,

ky thuat dieu khiln voi PLC.

Cau 1,2,3,4

[CL02]: Su dung duoc cac thuat ngu tieng Anh trong he thdng

tur dong hoa voi PLC, kha nang doc hilu cac tai lieu ky thuat

bang tieng Anh.

Cau 1,2,4

[CL03]: Kha nang phan tich, giai thich va doc hilu cac ban ve

dien cong nghiep, tur dong hoa. Cau 3

[CL04]: Kha nang thiet ke, tinh toan cac he thong trong ltnh

virc co dien tu, he thong san xuat tu dong. Cau 3,4

Ngay'/Z.thang £ niim 2023

Trird’ng bo mon

(ky va ghi ro ho ten)

S6 hi?u: B M 1 /QT-PBT-RDTV/02 L in so&t x6t: 02 Ngay hieu lire: 15/5/2020 Trang: 3/3

![Đề kiểm tra cuối kỳ Tự động hóa công nghiệp [năm học] mới nhất](https://cdn.tailieu.vn/images/document/thumbnail/2020/20200906/tamynhan4/135x160/9951599383224.jpg)

![Đề thi Kỹ thuật lập trình PLC: Tổng hợp [Năm]](https://cdn.tailieu.vn/images/document/thumbnail/2026/20260121/lionelmessi01/135x160/85491768986870.jpg)

![Đề thi cuối học kì 1 môn Máy và hệ thống điều khiển số năm 2025-2026 [Kèm đáp án chi tiết]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20251117/dangnhuy09/135x160/4401768640586.jpg)

![Tự Động Hóa Thủy Khí: Nguyên Lý và Ứng Dụng [Chi Tiết]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20250702/kexauxi10/135x160/27411767988161.jpg)