WELL CONTROL

Trình bày: ĐỖ QUANG KHÁNH

Bộ môn Khoan – Khai thác Dầu khí

Khoa Kỹ thuật Địa chất và Dầu khí

Đại học Bách Khoa TP. HCM

Email: dqkhanh@hcmut.edu.vn

GEOPET Well Control 2

CONTENT

1. INTRODUCTION

2. WELL CONTROL PRINCIPLES

3. WARNING SIGNS OF KICKS

4. SECONDARY CONTROL

GEOPET Well Control 3

CONTENT

5. WELL KILLING PROCEDURES

6. BOP EQUIPMENT

7. BOP STACK ARRANGEMENTS

8. EXERCISES

GEOPET Well Control 4

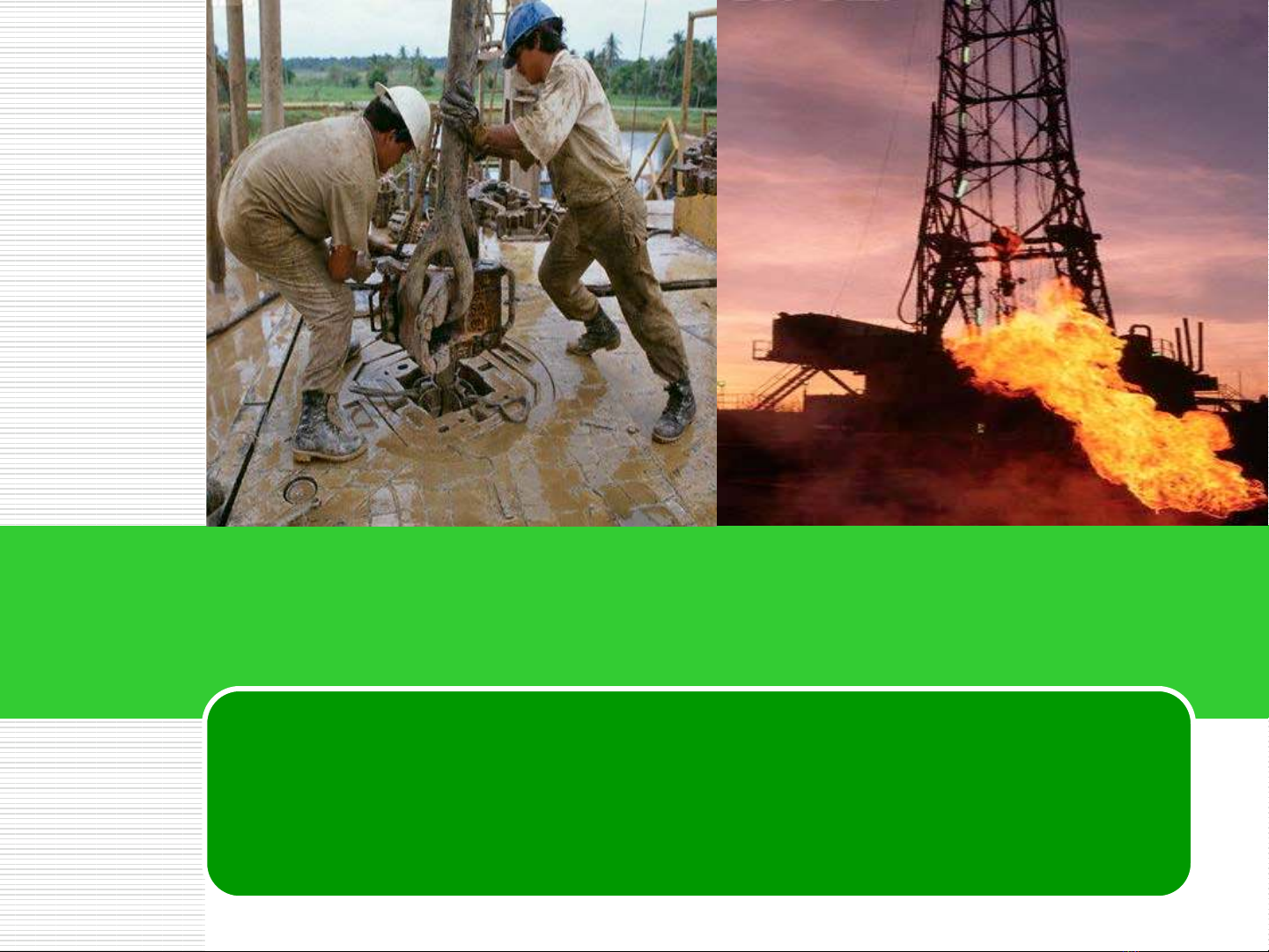

1. INTRODUCTION

GEOPET Well Control 5

![Bài giảng Công nghệ sản xuất CNG [chuẩn SEO]](https://cdn.tailieu.vn/images/document/thumbnail/2016/20160608/ntchung8894/135x160/8971465397664.jpg)

![Bài giảng Thiết bị phản ứng trong công nghiệp hóa dầu [mới nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2016/20160608/ntchung8894/135x160/8551465397592.jpg)