http://www.iaeme.com/IJMET/index.asp 555 editor@iaeme.com

International Journal of Mechanical Engineering and Technology (IJMET)

Volume 10, Issue 03, March 2019, pp. 555-566. Article ID: IJMET_10_03_057

Available online at http://www.iaeme.com/ijmet/issues.asp?JType=IJMET&VType=10&IType=3

ISSN Print: 0976-6340 and ISSN Online: 0976-6359

© IAEME Publication Scopus Indexed

EFFECT OF BAFFLES GEOMETRY ON HEAT

TRANSFER ENHANCEMENT INSIDE

CORRUGATED DUCT

Jaafar Jaber Abdulhameed, Dhamiaa Saad and Muna S. Kassim

Department of Mechanical Engineering, Faculty of Engineering,

Almustansiriyah University, Iraq.

ABSTRACT

The turbulent heat transfer and friction inside a corrugated square duct inserted

with various baffles geometries have been studied experimentally. Five types of baffles

(flat, rectangular, semicircular, triangular and trapezoidal) are attached on top and

bottom walls of the duct. The effects of duct wavy surface, baffle geometry, baffle

position and flow Reynolds number are examined. Air is used as the working fluid

with Reynolds number ranged from 3442.6 to 17213.19 under constant wall heat flux.

Experimental results show obtained for average Nusselt numbers and friction factor.

The results indicate that the trapezoidal baffled geometry provides a higher thermal

performance than the other type baffled one. The present work showed that the highest

thermal performance factor under the same pumping power obtained from the

experiments, is about 2.26 times more than that of plain duct. Also, it is found that the

thermal performance of the baffles attach on the bottom wall of the duct is higher than

the other baffles attach on the top.

Key words: Square duct, Nusselt number, Friction factor, inclined baffles.

Cite this Article Jaafar Jaber Abdulhameed, Dhamiaa Saad and Muna S. Kassim,

Effect of Baffles Geometry on Heat Transfer Enhancement inside Corrugated Duct,

International Journal of Mechanical Engineering and Technology, 10(3), 2019, pp.

555-566.

http://www.iaeme.com/IJMET/issues.asp?JType=IJMET&VType=10&IType=3

1. INTRODUCTION

One of the passive heat transfer augmentation techniques is using of baffle used in many

industrial applications such as heat exchangers, internal cooling for turbines-blade, solar-

collectors and used in electronic-devices cooling system. Baffles making a role in enhance

heat-transfer enhancement by enlarge the area of the effective-surface and residence of time-

period for the fluid heat transfer. Some parameters influence on the transferring heat and

pressure-drop involves pitch ratio, orientation, blockage-ratio, baffles geometry and Reynolds

number.

Jaafar Jaber Abdulhameed, Dhamiaa Saad and Muna S. Kassim

http://www.iaeme.com/IJMET/index.asp 556 editor@iaeme.com

Heat transfer enhancement by baffles have been studied by various authors. Researcher

[1] studied experimentally heat transfer and frictional losses in channel of rectangular section

with two inclined solid and perforated baffles of the similar overall size on. The upstream

baffle is mounted on the top surface (heated), while the orientation, shape and location of the

other baffles was varied to attain the optimum geometry for augment transferring heat. The

results of experimentation proved that the distribution of Nusselt-number depending on the

orientation, location and second plate baffles geometry. Researcher [2] numerical study was

conducted for laminar flow (periodic) of transferring heat and losing pressure in a channel

that fitted with a staggered-baffles of diamond shaped. They found that the baffle-diamond

with half-apex angle of 5◦ –10◦ provided thermal performance slightly better than the flat

baffle. Researcher [3] experimentally studied the effect of 60°-V-type turbulator-baffle on

transferring heat and pressure-drop. Three types of various baffles-shape had e/H value of 0.1,

0.2 and 0.3 and PR values of 1, 2 and 3 are used a range of Reynold's number about 5000-

25000, researcher [4].The results show that the maximum improvement thermal factor of 1.87

was achieved when used V-type baffle and PR=1.0 and e/H= 0.10 at lower Reynolds number.

Researcher [5] studied experimentally transferring heat in a-channel with Z-ribs-shaped for

various pitches at Re range of 4400-20400. Zigzag-shape baffles are placed in a series-aligned

on the top-wall fluxed isothermally. The Z-type baffles are 45°-inclined relative to the main

flow direction are characterized at three baffle pitch ratios (P/H=1.5, 2 and 3) and the ratio of

baffle- to channel-height (e/H=0.1, 0.2 and 0.3) .The results show a significant effect of the

presence on the transferring heat rate for Z-type baffle and friction loss over the plain channel

with no baffle, Researchers [6 - 7].

This work aims to realize the effects of baffle's geometry and position of baffle on fluid

characteristic, such as pressure drops, friction factor and heat transfer in corrugated square

duct .Five types of baffles (flat, rectangular, semicircular, triangular and trapezoidal) inserts in

the duct which are manufactured locally and experimentally realized. Finally, a performance

differentiation of all inserts shall be made to obtain the optimum geometry.

2. EXPERIMENTAL SETUP

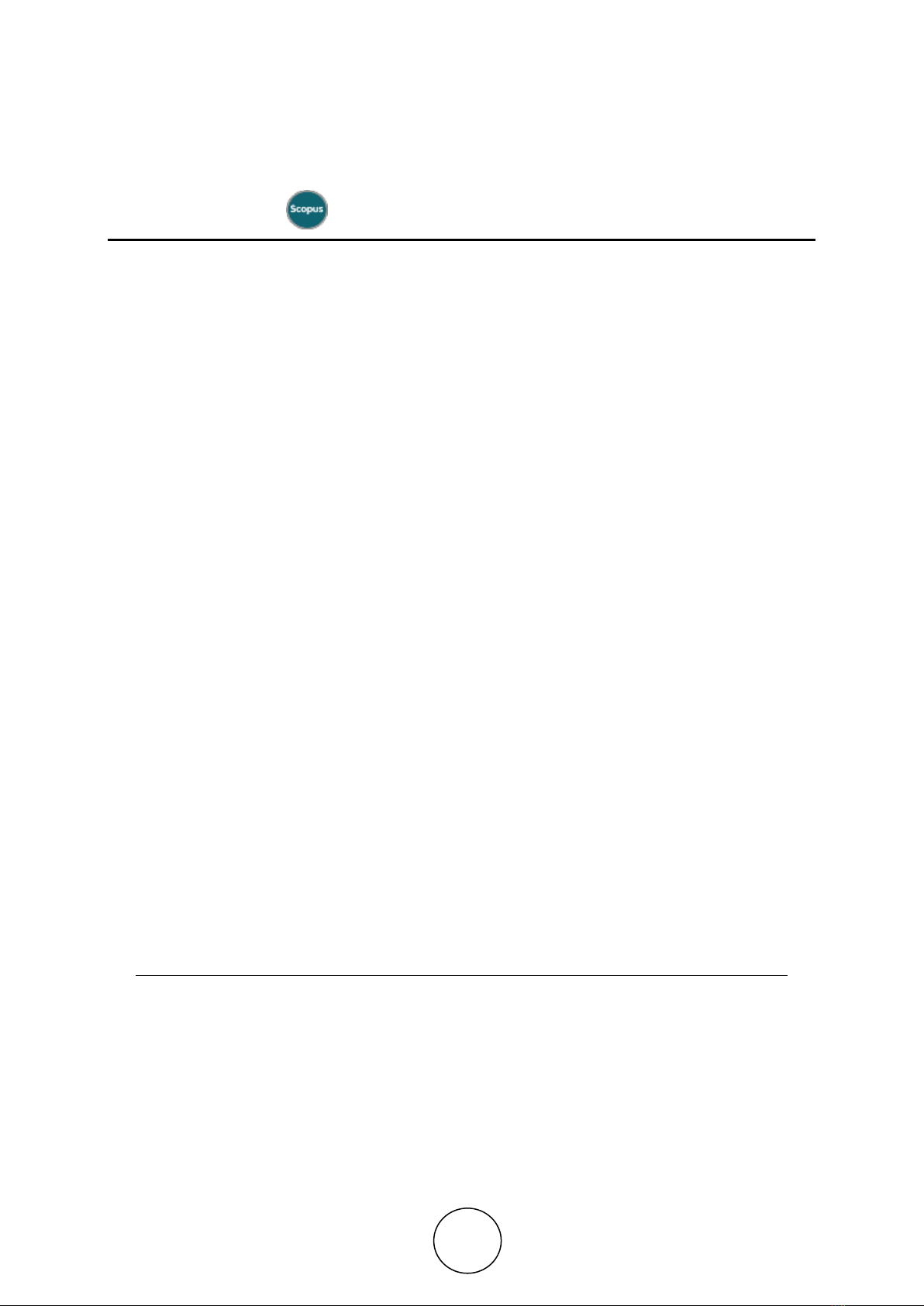

The experimental apparatus illustrates in Figure 1 that used in this study. It consists of a

blower, inlet section, a test-section, exit section and instrumentations to measure

temperatures, air velocity, pressure drop and electrical power input. The details of the

apparatus are depicted as follows:

(a) Air blower: An air blower of centrifugal kind, operates by an electrically-motor of 0.8

kW capacity and 2840 rpm, was used to supply the system with air at the required flow rate.

Flow rate of an air can be controlled by manual control valve which is connected with blower.

(b) Test section: The test section is a horizontal corrugated square duct has an internal

size of 60*60 mm, the duct is manufactured from copper, 0.5 mm in thickness. The wavy

surface of duct are manufactured locally by bending. The test section has 600 mm length, and

an additional 600 mm (10 dh), Researcher [8] hydrodynamic entry length so that flow would

be fully developed as it enters the baffles section.

The plate-type heater with rating (1000W, resistivity 4.9 Ohm/meter) is applied for

heating the walls. To attain a constant heat flux boundary condition along the tested duct the

heater is connected to a variac voltage transformer that supply an electric AC power to

regulate the input voltage across it. To minimize the heat losses the test section is insulated

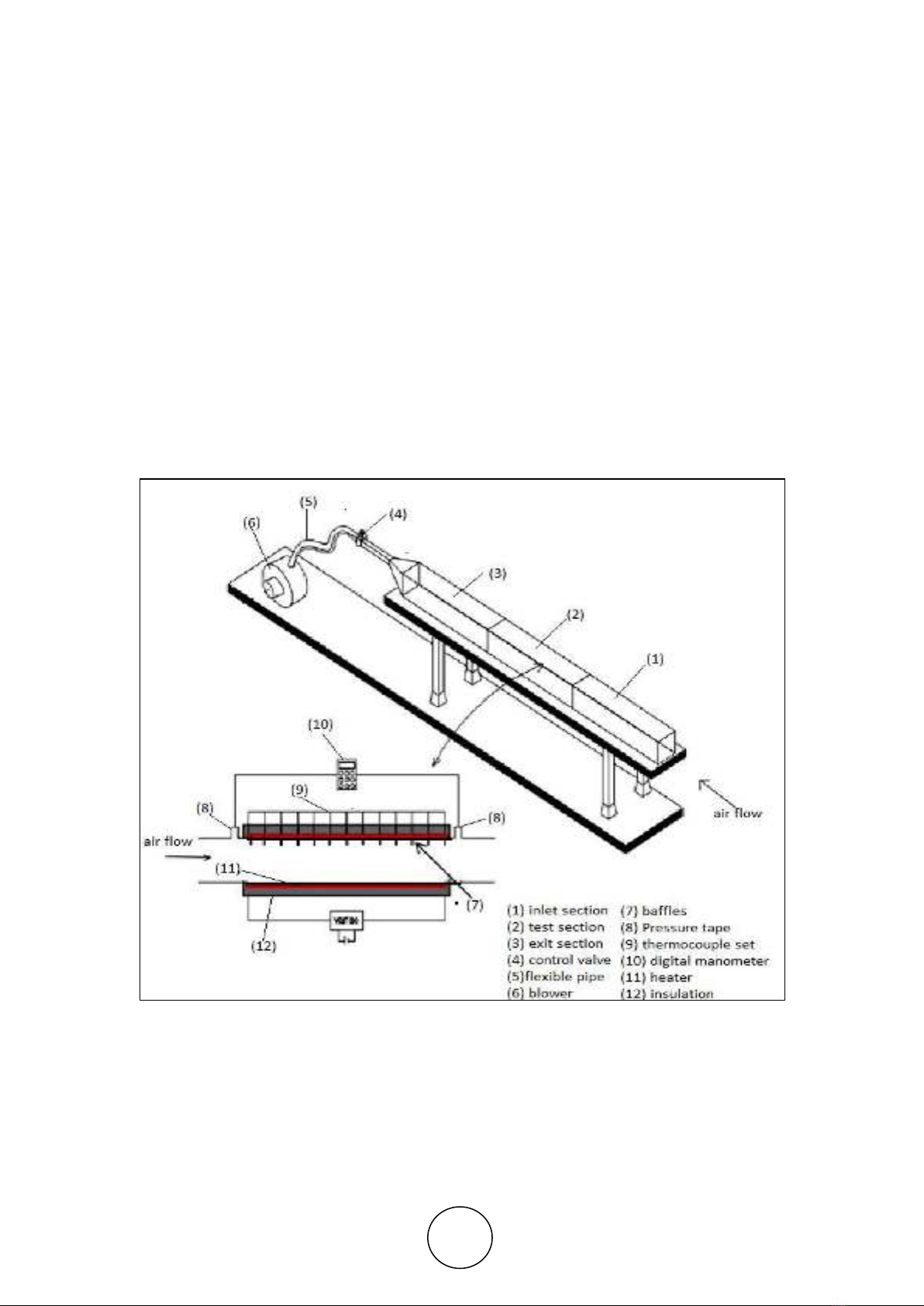

with 50 mm-thick glass wool. Figures 2 & 3 show, a surface profiles of the duct wall, and the

tested duct respectively.

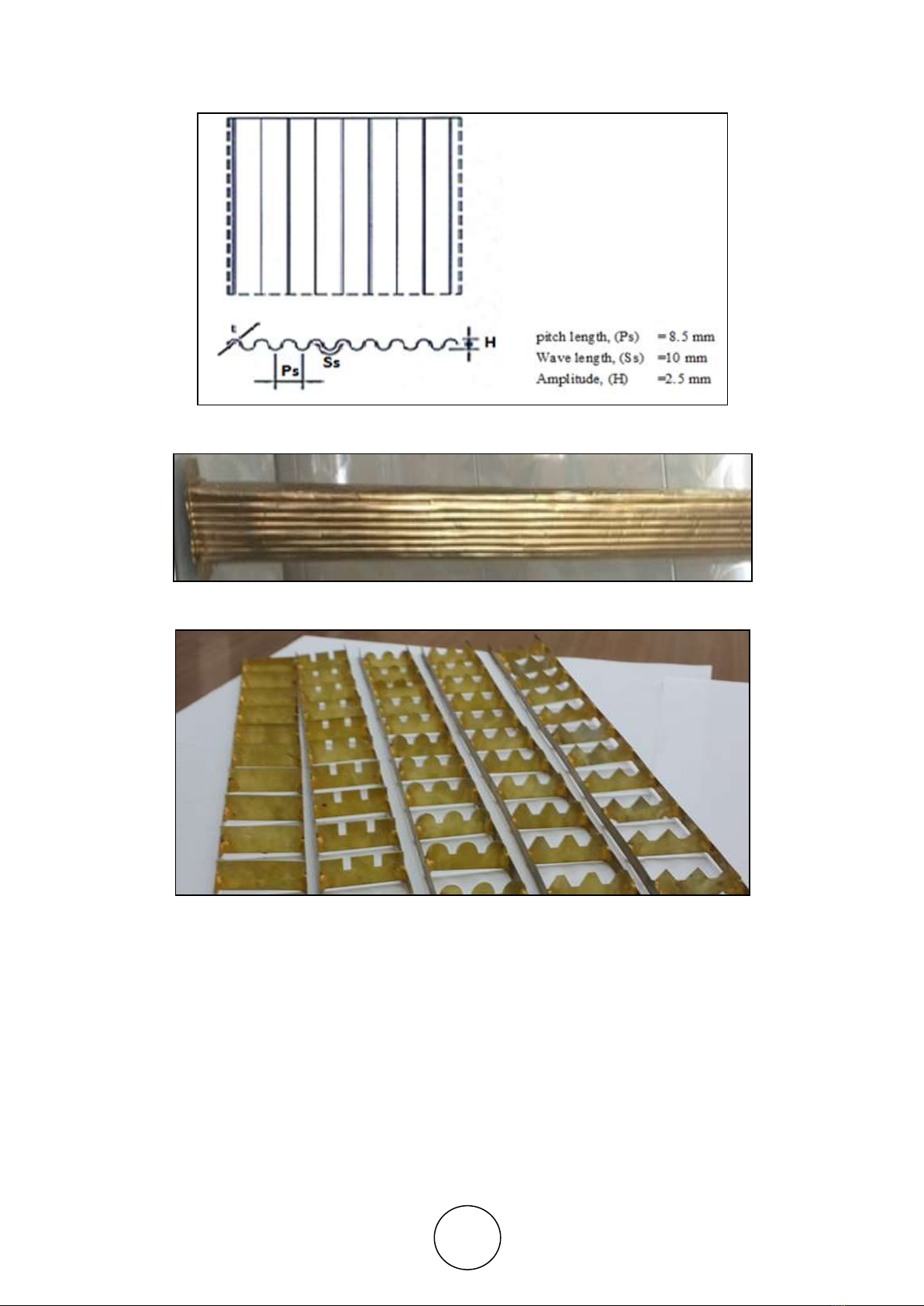

(c) Baffles: Flat, rectangular, semicircular, triangular and trapezoidal baffles are used in

the present study as shown in Figure 4. The copper baffles are attached on the upper and then

Effect of Baffles Geometry on Heat Transfer Enhancement inside Corrugated Duct

http://www.iaeme.com/IJMET/index.asp 557 editor@iaeme.com

to the lower wall of the duct with height of 175 mm, width of each baffles is about 2 mm less

than the width of the duct .The distance between two successive baffles (pitch,Bp) is (50

mm). All details of baffles are demonstrated in Figure 5.

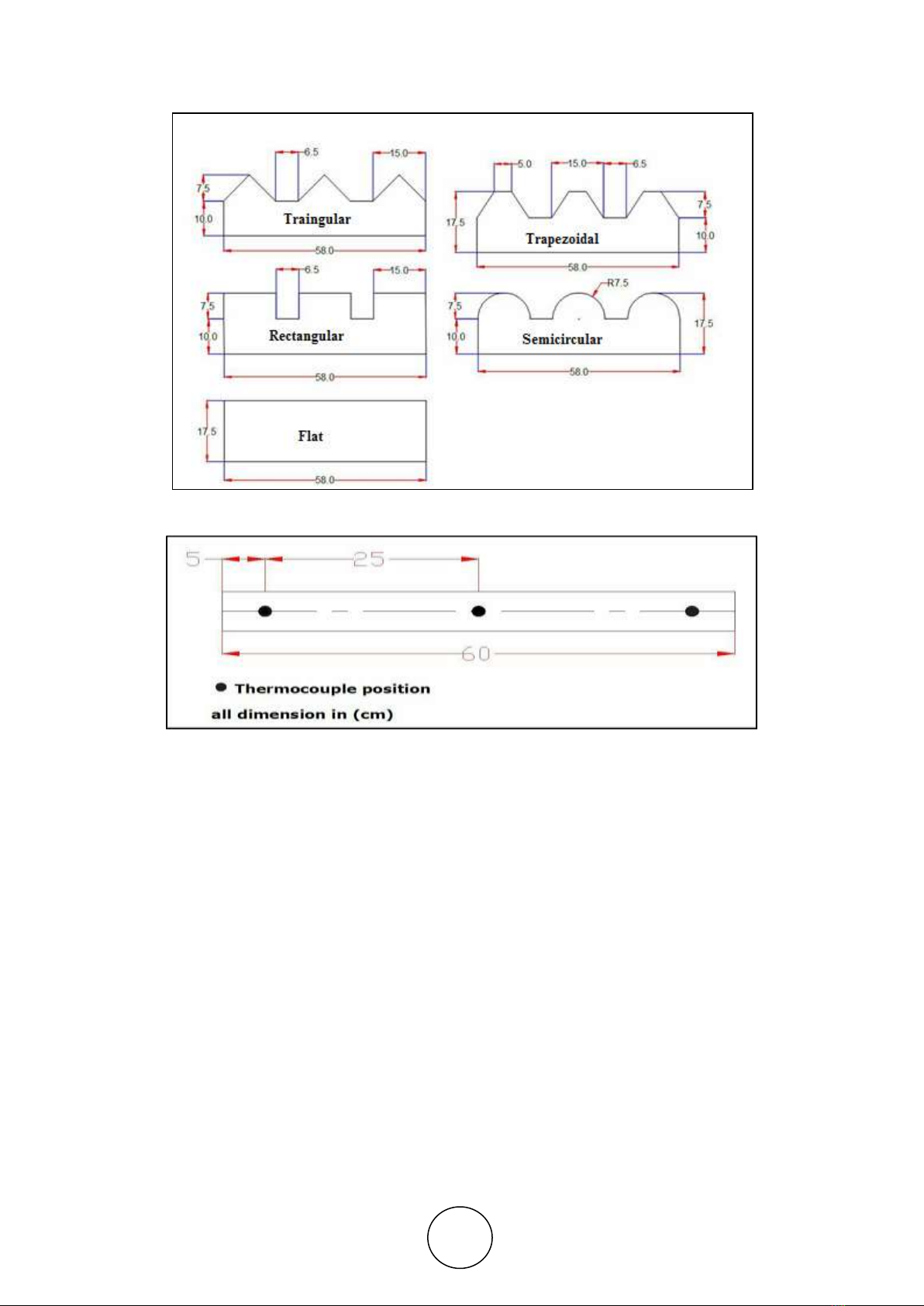

d) Instrumentation: The temperatures of duct surface (Ts) on the upper, lower and side

walls are measured by 12 thermocouples (K-,Type, range: 0°C ,to 800°C) of 1 mm diameter

located along the test section as shown in Figure 6 . And another two thermocouples are

positioned upstream and downstream of the test duct to measure the inlet and outlet air

temperatures. These thermocouples are connected to a Bench type 12 channels temperature

recorder SD card time data logger model BTM-4208SD digital recorder.

To measure the axial pressure drops across the test section two static pressure taps are

located at the top of the duct wall, which used to evaluate average friction factor. The pressure

drop is measured by digital manometer (±2000 mbar, range differential, input Model PM-

9100). Digital vane-type anemometer is used to measure the air velocities. Reynolds number

of range of 3442.6 - 17312.19 is adopted.

The data of electric power input, the surfaces temperature, inlet and outlet air flow

temperatures, and the manometers readings are recorded when the steady state is attained.

Figure 1 Schematic diagram of apparatus

Jaafar Jaber Abdulhameed, Dhamiaa Saad and Muna S. Kassim

http://www.iaeme.com/IJMET/index.asp 558 editor@iaeme.com

Figure 2 Surface profiles of the duct wall

Figure 3 The tested duct

Figure 4 The tested baffles

Effect of Baffles Geometry on Heat Transfer Enhancement inside Corrugated Duct

http://www.iaeme.com/IJMET/index.asp 559 editor@iaeme.com

Figure 5 Schematic diagram of baffles

Figure 6 Positions of the thermocouples on the test sectio

3. THEORETICAL ANALYSIS

The aims of current work is to inquiry the Nusselt number, friction factor and thermal

enhancement factor. Reynold's number is an independent parameter. The Reynolds number

based on the hydraulic diameter of the square duct which is given by Researcher [9]:

Re= (1)

Where

dh: is the hydraulic diameter of square duct ,(m)

dh=4Ac/p (2)

u : is the average velocity, (m/s).

Heat carried by air is given by Researcher [9]:

Qhc= cp(

– ) (3)

Where = mass flow rate, (kg/s) is given by

= (4)

Assumption: steady-state conditions of transferring heat transfer equals to losing heat loss

in test section is given by:

![Bài tập trắc nghiệm Kỹ thuật nhiệt [mới nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20250613/laphong0906/135x160/72191768292573.jpg)

![Bài tập Kỹ thuật nhiệt [Tổng hợp]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20250613/laphong0906/135x160/64951768292574.jpg)

![Bài giảng Năng lượng mới và tái tạo cơ sở [Chuẩn SEO]](https://cdn.tailieu.vn/images/document/thumbnail/2024/20240108/elysale10/135x160/16861767857074.jpg)