http://www.iaeme.com/IJMET/index.asp 576 editor@iaeme.com

International Journal of Mechanical Engineering and Technology (IJMET)

Volume 10, Issue 03, March 2019, pp. 576-584. Article ID: IJMET_10_03_059

Available online at http://www.iaeme.com/ijmet/issues.asp?JType=IJMET&VType=10&IType=3

ISSN Print: 0976-6340 and ISSN Online: 0976-6359

© IAEME Publication Scopus Indexed

ENGINE TECHNOLOGY AND RESEARCH

TRENDS OF ADVANCED BIOFUEL AS

ALTERNATIVE FUEL FOR TRANSPORTATION

VEHICLES

Byungmo Yang and Haengmuk Cho

Division of Mechanical and Automotive Engineering, Kongju National University,

Chungnam, Cheonan, Republic of Korea.

*Corresponding author

ABSTRACT

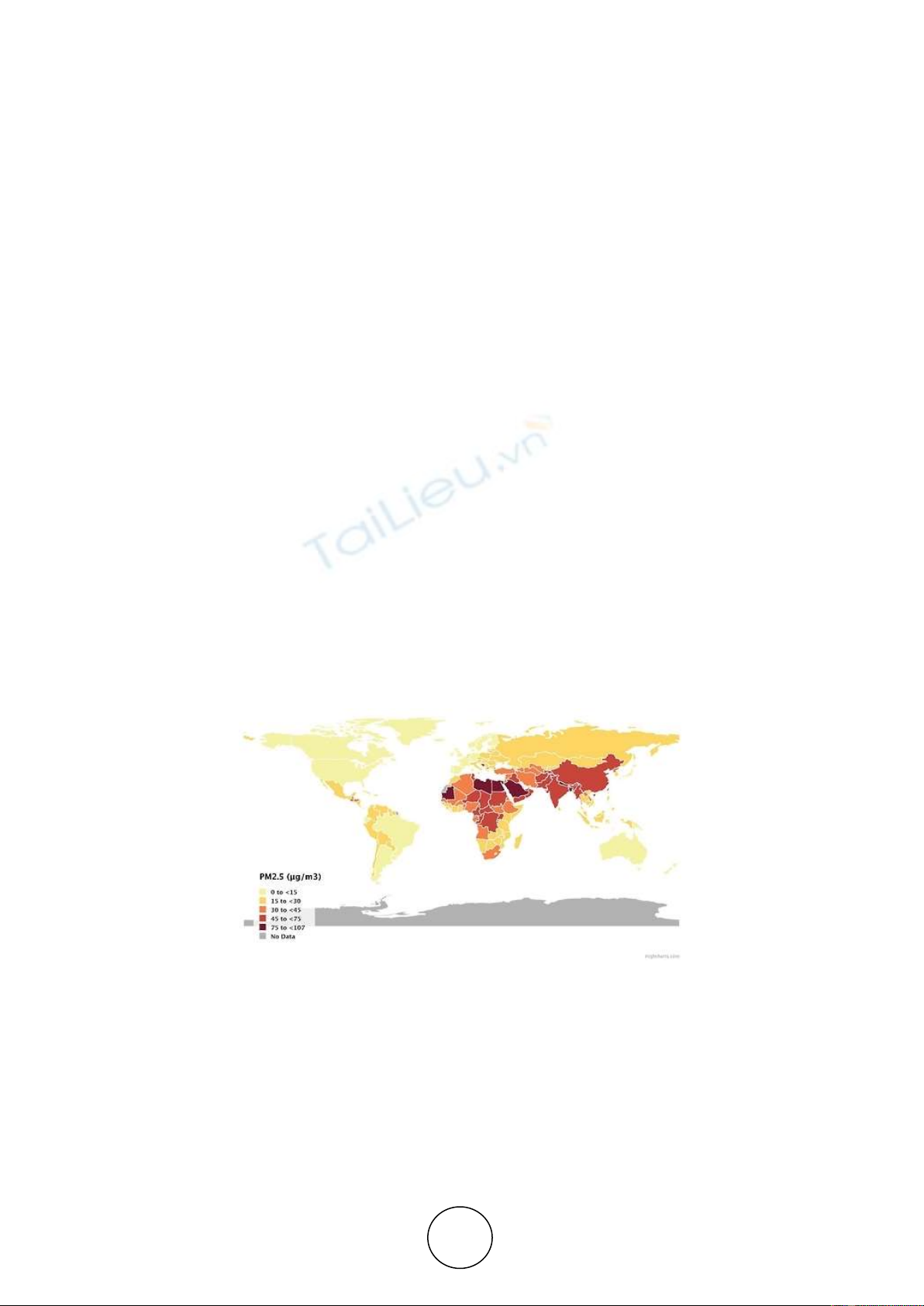

The reckless use of fossil fuels causes a lot of problems such as depletion of fossil

fuels, rising oil prices, air pollution, and fine dust. 27% of the world's major energy

sources are used for transportation, and most of the transportation fuels are used as

fossil fuels. Biofuels, which are attracting attention as a clean alternative energy

source, are most actively applied to transportation fuels because of their environment-

friendly characteristics, but they have problems in fuel production cost and engine

technology development. In order to solve these problems, research trends in domestic

and overseas researches and engine dedicated to biofuels are described. In addition,

the development of technologies that can reduce fuel production costs and the

establishment and operation of policies for more stable fuel supply are required more

flexibly to cope with sudden environmental changes.

Key words: Advanced biofuel, Engine technology, Emission characteristic, Engine

performance

Cite this Article Sutrisno, Setyawan Bekti Wibowo, Sigit Iswahyudi and Tri Agung

Rohmat, Vortex Dynamic Investigation of Wing Slotted Gap of Saab Jas Gripen C-

Like Fighter, International Journal of Mechanical Engineering and Technology, 10(3),

2019, pp. 576-584.

http://www.iaeme.com/IJMET/issues.asp?JType=IJMET&VType=10&IType=3

1. INTRODUCTION

Thoughtless use of fossil fuel is causing numerous problems such as depletion of fossil fuel,

oil price rise and air pollution. In particular, 27 % of major energy source is globally used for

transportation and fossil fuel is mostly used as transportation fuel [1,2]. The exhaust gas

emitted from fossil fuel is the key pollutant of green-house gas that causes global warming,

and the exhaust gas resulting from combustion of such fossil fuel generates substances

harmful to human health. For NOx and PM which are major exhaust gases, the emission