http://www.iaeme.com/IJMET/index.asp 1025 editor@iaeme.com

International Journal of Mechanical Engineering and Technology (IJMET)

Volume 10, Issue 03, March 2019, pp.1025-1037. Article ID: IJMET_10_03_103

Available online at http://www.iaeme.com/ijmet/issues.asp?JType=IJMET&VType=10&IType=3

ISSN Print: 0976-6340 and ISSN Online: 0976-6359

© IAEME Publication Scopus Indexed

OPERATIONAL IMPROVEMENT BY LEAGILE

APPROACH

Krishnamoorthy S

Department of Mechanical Engineering, Sri Krishna College of Engineering and Technology

Coimbatore, Tamilnadu, India.

Ben Ruben R

Department of Mechanical Engineering, Sri Krishna College of Engineering and Technology

Coimbatore, Tamilnadu, India.

ABSTRACT

This research work is carried out in a air compressor manufacturing company

which produces different models of air compressors. The work aim was to improve the

productivity by reducing the total operating cycle time, unnecessary motions, material

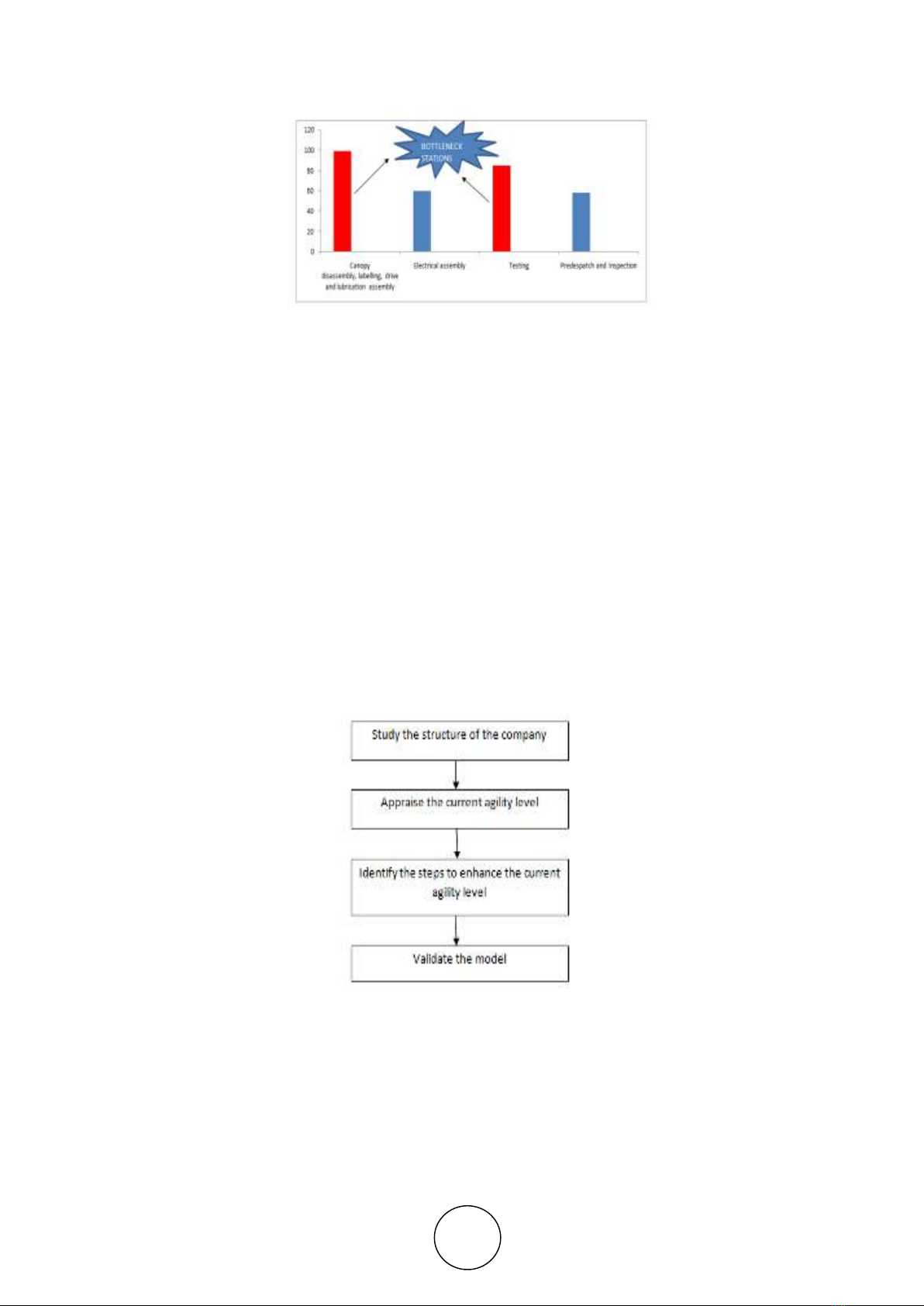

handling, and to create a standardized working environment. Two stations namely drive

and lubrication assembly and testing were found out to be the bottleneck stations, and

efforts are taken to improve its productivity. Kaizen’s were planned for improvement

activities and were implemented subsequently. These improvement actions were based

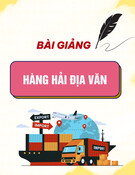

on Lean production organizational model and application of Lean tools. The current

agility level of the firm was calculated and suggestions were given to improve the agility

level of the firm.

Keywords: Leagile, Testing, Kaizen, Agility Assessment, New Product Development.

Cite this Article: Krishnamoorthy S and Ben Ruben R, Operational Improvement by

Leagile Approach, International Journal of Mechanical Engineering and Technology,

10(3), 2019, pp. 1025-1037.

http://www.iaeme.com/IJMET/issues.asp?JType=IJMET&VType=10&IType=3

1. INTRODUCTION

Lean manufacturing is focused on eliminating wastes in the entire manufacturing process. It

deals with minimizing work -in progress, eliminating processes that do not add value to the

product, making the process more flexible to make products of different design without

changing the value of the product. Many manufacturing companies, historically, have been able

to maintain bloated or inefficient methods because of a protected market, strong brand strength

or huge profit margins. The global competition is forcing these manufactures to quickly change

their methods to be less wasteful, and provide value to their customers through customization

and reduced cycle or delivery times. There are five-key principles that must be followed to

implement lean manufacturing successfully. They are,