TRƯỜNG ĐẠI HỌC BÁCH KHOA ĐÀNẴNG

KHOA HOÁ

PHÂN TÍCH POLYME

(POLYMER ANALYSIS)

TS. ĐoànThịThu Loan

♣♣♣

Is a branch of polymer science dealing with analysis and characterisation of

polymers.

The complication of macromolecular chains, the dispersion in molecular

weight, tacticity, crystallinity, orientation, composition of polymers etc. and

complex morphological systems

⇒analysis of polymer ≠the small organic materials

⇒Focus on viscoelasticproperties, dynamic mechanical testing.

Polymer analysis

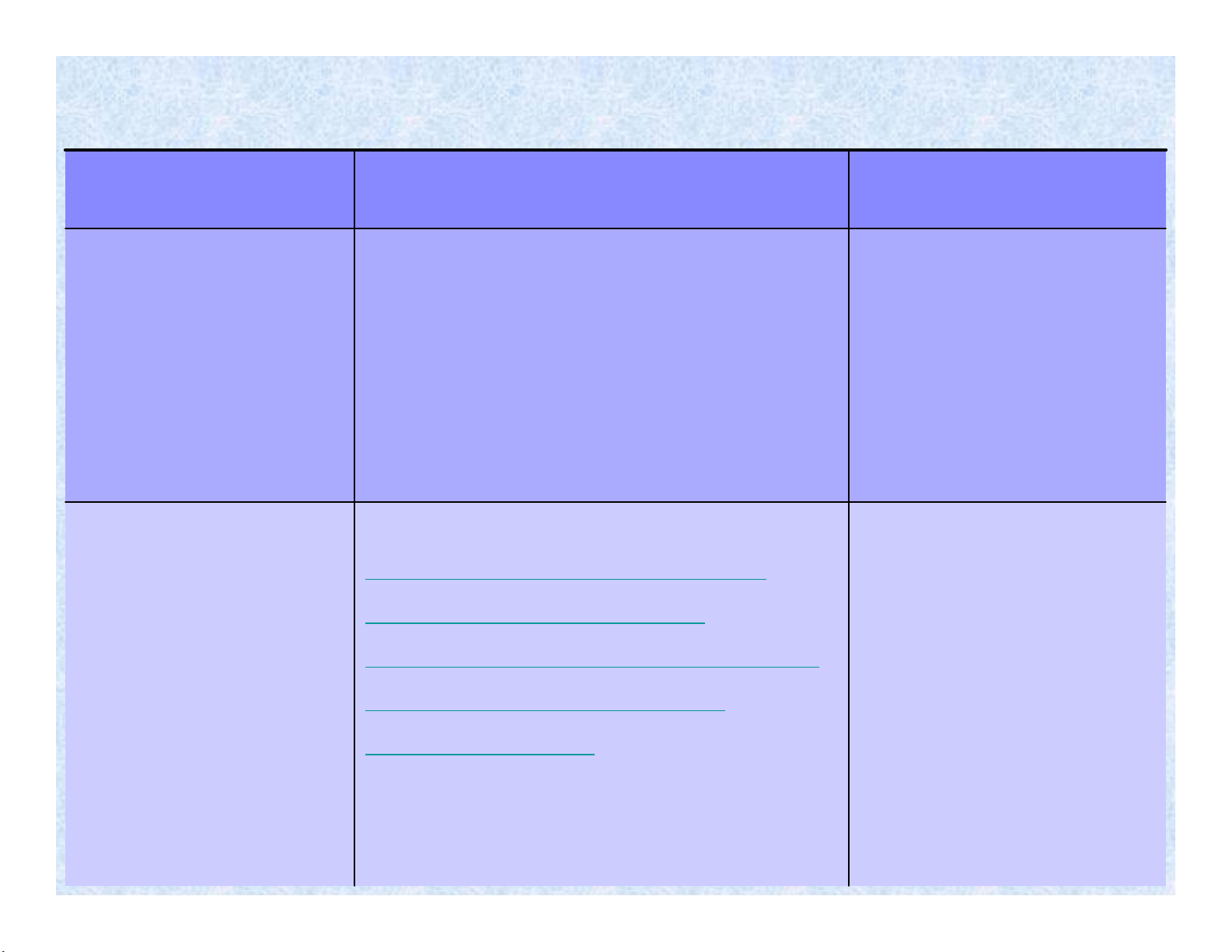

•Instronmechanical tester

•Vickerhardness tester

•DMA

•Melt flow indexer

•Torsions Rheometer

•

•-AFM, SEM

•-FT-IR

•-Pull-out test

Instruments

•FT-IR

•IR-microscope

•GPC ( size exclusion chromatography

SEC)

•-Viscosimetry

•-X-ray (WAXS and SAXS)

•-EM, SEM, TEM, AFM

•-Dynamic and static methods for contact

angle measurements.

-Tensile, flexural, impact,

compression, hardness tests,

-Rheologicaland viscoelastic

properties, stiffness and

modulus, surface tension,

permeation and diffusion in

polymers, adhesion tests,

density

-Surface roughness,

-Chemical

composition,

-Interface

characetrisation

-Molecular weight determination,

-Microstructuralcharacterisation and

compositional analysis,

-Crystallinity,

-Investigation of polymer morphology,

particle size,

-Contact angle and wettability

measurements

Mechanical and Physical

Properties

Surface

Characterisation

Chemical, Molecular and Structural

Characterisation

Methods of polymer analysis

•GC

•pH meter

•HPLC

•Karl-Fischer titration

•Thermogravimetricanalyser (TGA)

•TGA-FTIR coupled technique

•Differential scanning calorimetry(DSC)

•Modulated differential scanning

calorimetry(ADSC)

•Dynamic thermomechanicalanalyser

(DMTA)

•Dielectric relaxation

Instruments

Inolabconductivity

meter

•

Purity and molecular

weight of small

molecules, water content

in organic solvents,

surface tension

measurement, pH

-Melting point, glass transition

temperature, free rotation temperature,

-Degradation and stability behaviour of

polymers

Conductivity, electric

current in solution,

light emitting and

electromagnetic

properties

Miscellaneous (hontap)Thermal Behaviour

Electrical and Optical

Properties

Methods of polymer analysis

-For quality control

-For predicting service performance

-To generate design data

-To investigate failures

Purpose of polymer analysis

Essential to identify the purpose of testing, because the requirements for each

of the purposes are different.

-Precision

-Reproducibility

-Rapidity

Balance of these attributes,

according to the purpose of

the test

-Complexity

-Automated test

-Nondestructive test

-Cost

![Bài giảng Tính chất cơ lý của vật liệu polymer [chi tiết]](https://cdn.tailieu.vn/images/document/thumbnail/2016/20160304/phamvanphat1891995/135x160/5961457069939.jpg)

![Bài giảng Chế biến khoáng sản vô cơ [Mới nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20251025/thanhvan173002/135x160/21521761538638.jpg)