ISA Transactions 51 (2012) 550–558

Contents lists available at SciVerse ScienceDirect

ISA Transactions

journal homepage: www.elsevier.com/locate/isatrans

Decentralized PI/PID controllers based on gain and phase margin specifications

for TITO processes

D.K. Maghadea, B.M. Patreb,∗

aDepartment of Instrumentation and Control Engineering, Vishwakarma Institute of Technology, Pune-411037, India

bDepartment of Instrumentation Engineering, Shri Guru Gobind Singhji Institute of Engineering and Technology, Vishnupuri, Nanded-431602, India

article info

Article history:

Received 5 January 2011

Received in revised form

2 January 2012

Accepted 21 February 2012

Available online 23 March 2012

Keywords:

Decentralized controller

Decoupled system

Empirical modeling

Interactive processes

Model order reduction

Real time application

abstract

In this paper, a decentralized PI/PID controller design method based on gain and phase margin

specifications for two-input–two-output (TITO) interactive processes is proposed. The decouplers are

designed for systems to minimize the interaction between the loops, and the first order plus dead time

(FOPDT) model is achieved for each decoupled subsystem based on the frequency response fitting. An

independent PI/PID controller is designed for each reduced order decoupled subsystem to obtain the

desired gain and phase margins, and the performance is verified on the original interactive system to

show the effectiveness of the proposed design method for the general class of TITO systems. Simulation

examples are incorporated to validate the usefulness of the presented algorithm. An experimentation is

performed on the Level–Temperature reactor process to show the practical applicability of the proposed

method for the interactive system.

©2012 ISA. Published by Elsevier Ltd. All rights reserved.

1. Introduction

Many of the industrial processes have multi-input–multi-

output (MIMO) dynamics with interaction among the input–output

variables. In most of the industrial processes, decentralized con-

trol is used instead of multivariable centralized control since the

decentralized controller is simple to design, easy to tune, imple-

ment and maintain [1]. In the literature, the multi-loop PI/PID

control using multiple single-input–single-output (SISO) PI/PID

controllers is commonly used for controlling MIMO systems with

interaction [2]. The reason for using SISO PI/PID controllers for

multi-loop control is its simple structure, easy tuning and an abil-

ity to meet most of the control objectives [3–7]. However, due to

interactions, the design and tuning of centralized multi-loop con-

trollers is much more difficult compared with that of single-loop

controllers [8]. In centralized multi-loop controllers, since the con-

trollers interact with each other, the tuning of one loop cannot be

done independently. An extension of the controller design meth-

ods for a SISO system to multi-loop systems often affects the per-

formance and stability of the systems. Many methods have been

proposed, including the detuning method [9,10], sequential loop

closing method [11,12], relay auto-tuning method [13–17], and

∗Corresponding author. Tel.: +91 2462 269324; fax: +91 2462 229236.

E-mail addresses: bmpatre@yahoo.com,bmpatre@sggs.ac.in (B.M. Patre).

independent loop method [18,19] to take loop interactions into

account in the multi-loop controller design. In detuning big log

modulus method, first introduced by Luyben [9], each controller in

the system is designed based on the corresponding diagonal ele-

ment and ignore the interactions from other loops. The controllers

are then detuned considering interactions until some prescribed

limit is attained. The detuning methods are simple, but the loop

performance and stability of the system cannot be clearly defined

through the detuning procedures. In the sequential loop closing

method, the loops are closed usually from the fastest loop, one after

the other. The dynamic interaction of closed loop is taken into ac-

count while closing of next loop, and so on. However, the final con-

troller design may depend on the order by which the controllers

are designed, and iteration procedures are essential because clos-

ing the subsequent loops may alter the response of the previously

designed loops [18]. In the relay auto-tuning method, the relay

feedback technique is applied to the design of each correspond-

ing SISO controller [13]. The control loops are tuned sequentially

and the multi-loop control system is designed in a sequence of

SISO design problems. These methods considered the interaction

in a sequential, require minimum process information, but tuning

sequence has to be repeated for the correct sequence if the de-

sign sequence is not appropriate. In independent design methods,

SISO controllers are designed independently by using the defined

bounds to guarantee stability and performance. But, the detailed

information about the controller dynamics in other loops is not

used, the resulting performance may be poor [12].

0019-0578/$ – see front matter ©2012 ISA. Published by Elsevier Ltd. All rights reserved.

doi:10.1016/j.isatra.2012.02.006

D.K. Maghade, B.M. Patre / ISA Transactions 51 (2012) 550–558 551

The TITO systems are one of the most prevalent categories

of multivariable systems, because there are real processes of

this nature or because a complex process has been decomposed

into TITO process with nonnegligible interactions between its

inputs and outputs [20–23]. Decentralized PID controllers with

decoupler are most commonly preferred for TITO processes [21,22,

24–29]. The detail discussion on the decoupling approach for TITO

systems is given in [30]. Tavakoli et al. proposed a decentralized

PI/PID controller for TITO systems based on nondimensional

analysis [21], while an ideal decoupler for the controller design

based on exhaustive search is presented by Nordfeldt and

Hägglund under the constraints on robustness and sensitivity

to measurement noise [22]. Jevtović and Mataušek presented

decentralized controller design method with ideal decoupler [23].

In this paper, simple decoupler plus decentralized PID controller is

proposed for general class of TITO systems. The frequency response

fitting based model order reduction technique is employed to get

FOPDT model of the each higher order decoupled subsystems.

An independently PI/PID controllers are designed for specified

gain and phase margins. The designed controller together with

decoupler are used to get the desired performance of the TITO

processes. The paper is organized as follows. Decoupler design

method is discussed in Section 2. In Section 3, a decoupled

higher order subsystem model is reduced into equivalent FOPDT

model. A PI/PID controller tuning formulas for FOPDT models are

presented in Section 4. To show performance and effectiveness

of proposed method two simulation examples are included in

Section 5. In Section 6, the discussion on empirical modeling of the

Level–Temperature reactor and the performance of the proposed

PI controller is included. Conclusions are drawn in Section 7.

2. The decoupling method

Let the TITO process is as follows

G(s)=g11(s)e−τ11sg12(s)e−τ12s

g21(s)e−τ21sg22(s)e−τ22s.(1)

The given process G(s)is decoupled using decoupler matrix [21].

To design decoupler matrix following two cases considered.

Case 1: The off-diagonal elements of G(s)have no RHP poles and

diagonal elements of G(s)have no RHP zeros.

The decoupler matrix is

D(s)=v1(s)d12(s)v2(s)

d21(s)v1(s) v2(s)(2)

with v1(s), v2(s), d12(s)and d21(s)as given in Eq. (3).

v1(s)=1, τ21 ≥τ22,

e(τ21−τ22)s, τ21 < τ22,

v2(s)=1, τ12 ≥τ11,

e(τ12−τ11)s, τ12 < τ11,

d12(s)= − g12(s)

g11(s)e−(τ12−τ11)s,

d21(s)= − g21(s)

g22(s)e−(τ21−τ22)s.(3)

Case 2: The diagonal elements have no RHP poles and off-diagonal

elements have no RHP zeros of G(s).

The decoupler in the form

D(s)=d11(s)v3(s) v3(s)

v4(s)d22(s)v4(s),

where,

v3(s)=1, τ22 ≥τ21,

e(τ22−τ21)s, τ22 < τ21,

v4(s)=1, τ11 ≥τ12,

e(τ11−τ12)s, τ11 < τ12,

d11(s)= − g22(s)

g21(s)e−(τ22−τ21)s,

d22(s)= − g11(s)

g12(s)e−(τ11−τ12)s.(4)

As shown in Eq. (5),H(s)is a diagonal matrix.

H(s)=G(s)D(s)=diag {h11(s), h22(s)}.(5)

The decoupled elements hii(s)are to be controlled through

decentralized PI/PID controllers kii(s), where i=1,2.

3. Model reduction

The dynamics of the elements hii(s)of H(s)are quite

complicated. A FOPDT model often reasonably describes the

process gain, overall time constant and effective dead time of

higher order processes [31]. In this section a FOPDT model lii(s)of

each elements hii(s)of H(s)is obtained as below

lii(s)=Kiie−Liis

Tiis+1,i=1,2.(6)

Three unknown parameters (Kii,Lii and Tii) in Eq. (6), need to be

determined, in order to obtain FOPDT model of hii. In this paper,

FOPDT model is obtained based on frequency response fitting at

two points, ω=0 and ω=ωcii, where ωcii is phase crossover

frequency [32].

lii(0)=hii(0),

|lii(jωcii)|=|hii(jωcii)|,

{lii(jωcii)}={hii(jωcii)}.(7)

As a result, the parameters of the FOPDT model can be calculated

using

Kii =hii(0),

Tii =K2

ii −|hii (jωcii)|2

|hii (jωcii)|2ω2

cii

,

Lii =π+tan−1(−ωciiTii)

ωciiTii

.(8)

4. The controller design method

The gain and phase margins (GPMs) are typical loop specifi-

cations associated with the frequency response [33]. The GPMs

have always served as important measures of robustness [34]. It

is known from classical control that phase margin is related to the

damping of the system, and can therefore also serve as a perfor-

mance measure [33]. The controller design methods to satisfy GPM

criteria are not new, and thus widely used [35–37]. In this paper,

simple formulas are developed to design the PI/PID controller to

meet user-defined gain margin and phase margin specifications.

552 D.K. Maghade, B.M. Patre / ISA Transactions 51 (2012) 550–558

4.1. PI tuning formula

Using definitions of GPM, following set of equations can be

written

arg lii(jωpii)kii(jωpii)= −π, (9)

Amii =1

lii(jωpii)kii(jωpii)

,(10)

lii(jωgii)kii(jωgii)=1,(11)

φmii =arg lii(jωgii)kii(jωgii)+π, (12)

where Amii and φmii are GM and PM respectively. Also ωgii and ωpii

are gain and phase crossover frequencies. The kii(s)is PI controller

for FOPDT model lii as given in Eq. (13). The PI controller is

kii(s)=kPii 1+1

TIiis(13)

where, kPii and TIii are proportional gain and integral time

respectively.

From Eqs. (6) and (13), the open loop transfer function is

lii(s)kii(s)=kPiiKii (sTIii +1)

sTIii (sTii +1)e−Liis.(14)

For given process and GPM specifications, the PI controller

parameters and crossover frequencies can be obtained numerically

but not analytically because of the presence of the arctan function.

The arctan function is approximated to get analytical solution.

arctan x=

1

4x, (|x|≤1)

1

2π−π

4x, (|x|>1)

(15)

where, xis one of ωpiiTii, ωpiiTIii,ωgiiTii and ωgiiTIii.

Resulting PI controller parameters are given as

kPii =ωpiiTii

AmiiKii

,

TIii =2ωpii −4ω2

piiLii

π+1

Tii −1

,(16)

where

ωpii =Amiiφmii +1

2π(Amii −1)

A2

mii −1Lii

.(17)

4.2. PID tuning formula

The series form of PID controller with first order filter is given

as

kii(s)=k′

Pii sT ′

Iii +1sT ′

Dii +1

sT ′

Iii sT ′

Fii +1,(18)

where T′

Fii,k′

Pii,T′

Dii,T′

Iii are filter time constant, proportional gain,

derivative time and integral time respectively.

For parallel form PID controller, the derivative time, TDii, is

usually chosen as a fixed ratio of the integral time TIii TDii =1

4TIii

[38–40]. With this selection for parallel form PID controller,

equivalently for series form PID controller given in Eq. (18), it can

be shown that, derivative time T′

Dii is equal to integral time T′

Iii.

Hence,

T′

Dii =T′

Iii.(19)

From Eqs. (6),(18) and (19), the open loop transfer function is as

below.

lii(s)kii(s)=k′

PiiKii sT ′

Iii +1sT ′

Iii +1

sT ′

Iii (sTii +1)sT ′

Fii +1e−Liis.(20)

To simplify above equation, choose T′

Fii =T′

Iii. The Eq. (20) is now

simplified as

lii(s)kii(s)=k′

PiiKii sT ′

Iii +1

sT ′

Iii (sTii +1)e−Liis.(21)

Hence the PID controller parameters can be determined as below.

k′

Pii =ωpiiTii

AmiiKii

,

T′

Iii =2ωpii −4ω2

piiLii

π+1

Tii −1

,

T′

Dii =T′

Iii,T′

Fii =T′

Iii (22)

where ωpii is given by Eq. (17).

5. Simulation results

Simulation examples are incorporated in order to evaluate ef-

fectiveness and performance of the proposed decentralized PI/PID

controller design method. The results of proposed method are

compared with those of some prevalent techniques like IMC tun-

ing method [41], BLT method [42], NDT tuning method [21] and

Wang et al.’s auto-tuning method [20]. The recommended ranges

of gain and phase margin are between 2–5 and 30°–60°respec-

tively [43,44]. For all simulation examples, unless specified, the

gain margin Amii =3 and phase margin φmii =60°are considered

to design the controller.

5.1. Example 1

Consider the Vinate and Luyben plant [45],

G1(s)=

−2.2e−s

7s+1

1.3e−0.3s

7s+1

−2.8e−1.8s

9.5s+1

4.3e−0.35s

9.2s+1

.

The decoupler is

D1(s)=

1 0.5909

0.6467(9.2s+1)e−1.45s

9.5s+1e−0.7s

.

The resulting diagonal subsystem are

h11(s)=−2.2e−s

7s+1+0.8407(9.2s+1)e−1.75s

(9.5s+1)(7s+1)

and

h22(s)=−1.6545e−1.8s

9.5s+1+4.3e−1.05s

(9.2s+1).

The FOPDT models of h11(s)and h22(s)are

l11(s)=−1.353e−0.620s

6.419s+1

and

l22(s)=2.645e−0.531s

8.561s+1

D.K. Maghade, B.M. Patre / ISA Transactions 51 (2012) 550–558 553

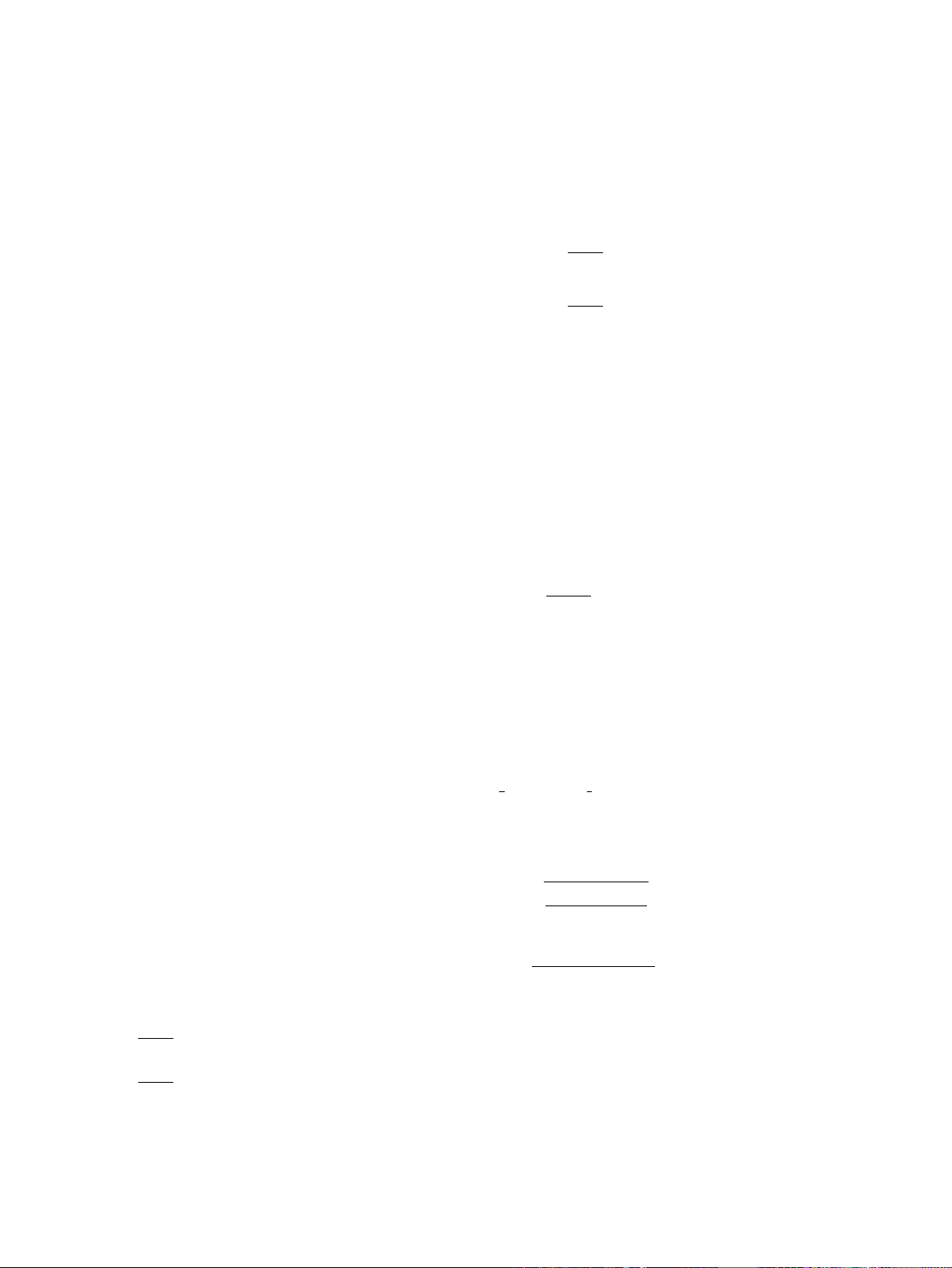

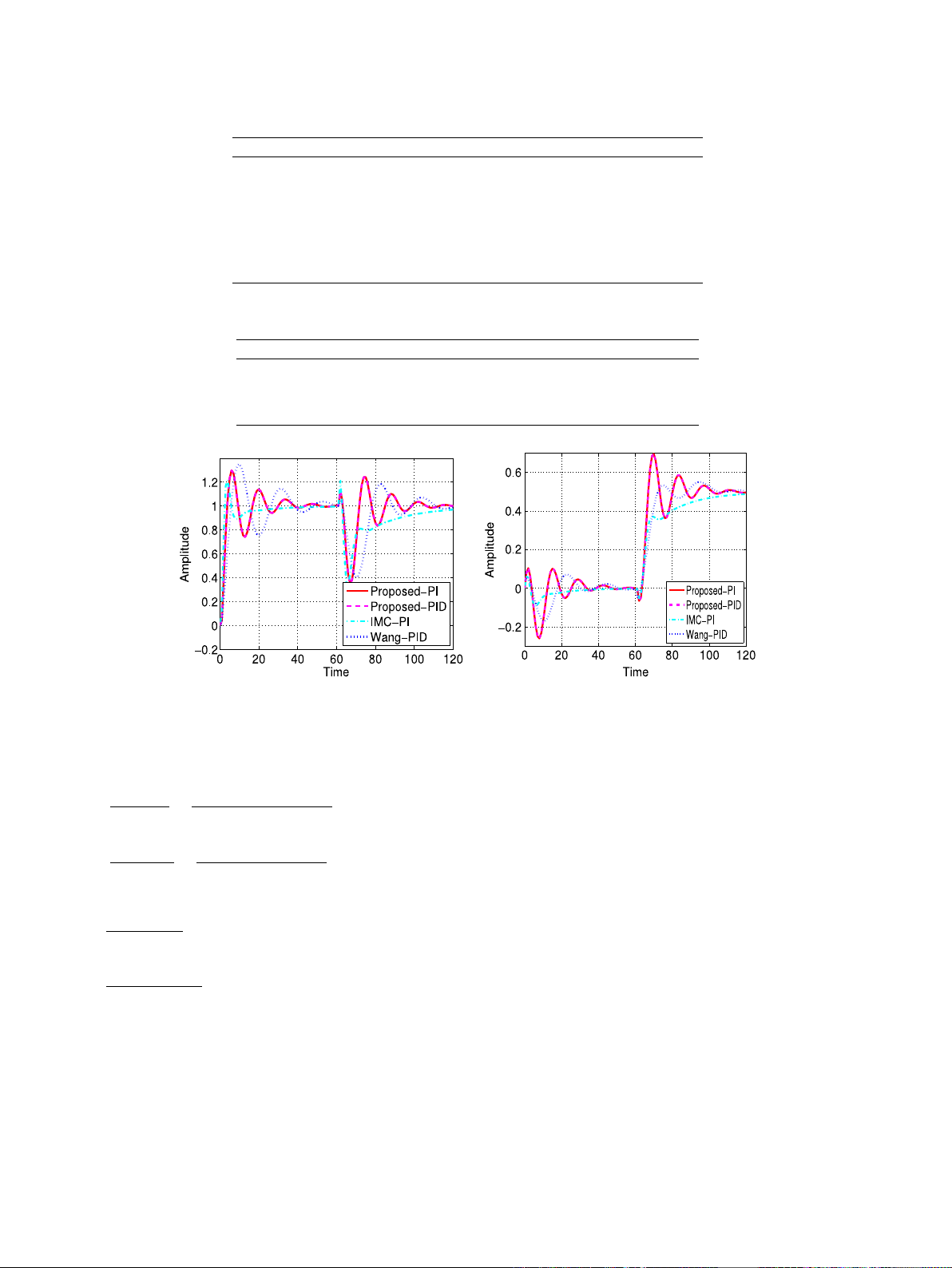

(a) First output to a unit step in the first input. (b) Second output to a unit step in the first input.

Fig. 1. First and second output to a unit step in the first input.

(a) First output to a unit step in the second input. (b) Second output to a unit step in the second input.

Fig. 2. First and second output to a unit step in the second input.

respectively. Using Eqs. (16) and (17), the proposed-PI controller is

KProposed-PI =

−4.0070 −0.6242

s0

0 3.1903 +0.3727

s

.

The NDT-PI, IMC-PI and BLT-PI controllers are given as follows

KNDT-PI =

−3.7960 −0.6671

s0

0 1.8250 +0.2137

s

,

KIMC-PI =

−2.1210 −0.3030

s0

0 3.9510 +0.4295

s

,

KBLT-PI =

−1.0700 −0.1507

s0

0 1.9700 +0.7636

s

.

First and second outputs of resultant control system to unit set-

point change in first input at t=0 and set-point change in sec-

ond input of 0.5 for 16 ≤t≤30 are shown in Fig. 1. Also first

and second outputs of resultant control system to unit set-point

change in second input at t=0 and set-point change in first in-

put of 0.5 for 16 ≤t≤30 are shown in Fig. 2. The performance

indexes such as integral absolute error (IAE), integral square error

(ISE), integral time absolute error (ITAE), peak overshoot (MP)and

rise time (TR)are given in Table 1. From Figs. 1 and 2, and Table 1,

the performance of proposed-PI controller is superior compared to

IMC-PI and BLT-PI controllers. The IAE of proposed-PI controller is

less than NDT-PI, IMC-PI and BLT-PI controllers. The NDT-PI con-

troller is designed by considering gain margin and phase margin

as the robustness constraints. For proposed-PI and NDT-PI con-

trollers, gain and phase margins are calculated. The comparative

results are given in Table 2.

5.2. Example 2

The Wood–Berry binary distillation column process is typi-

cal TITO process with strong interaction and significant time de-

lays [46]. The process has the following transfer function matrix

G2(s)=

12.8e−s

16.7s+1

−18.9e−3s

21s+1

6.6e−7s

10.9s+1

−19.4e−3s

14.4s+1

.

The decoupler matrix is computed from Eq. (2) is

D2(s)=

11.477(16.7s+1)e−2s

21s+1

0.3402(14.4s+1)e−4s

10.9s+11

.

554 D.K. Maghade, B.M. Patre / ISA Transactions 51 (2012) 550–558

Table 1

Performance indexes for example 1.

Controller Input (u)–Output (y)IAE ISE IATE MP(%)TR

Proposed-PI u1–y119.0343 13.6271 41.7848 28.30 1.16

u2–y212.8946 06.9341 32.4502 08.40 0.71

NDT-PI u1–y119.7223 13.6709 47.6276 28.10 1.19

u2–y214.1258 06.8471 47.0779 12.10 0.72

IMC-PI u1–y125.1109 15.4962 60.9464 00.60 1.87

u2–y211.7173 06.1198 32.8835 14.70 0.64

BLT-PI u1–y147.9253 26.4344 199.890 00.00 4.62

u2–y213.8729 07.7046 35.0070 11.60 1.01

Table 2

Gain and phase margins for example 1.

Controller Input (u)–Output (y)Amii % Error (Amii) φmii (°)% Error (φmii)

Proposed-PI u1–y13.0000 0.0000 60.0000 0.0000

u2–y23.0000 0.0000 60.0000 0.0000

NDT-PI u1–y13.0784 2.6134 59.2220 1.2967

u2–y23.0456 1.5200 55.3107 7.8156

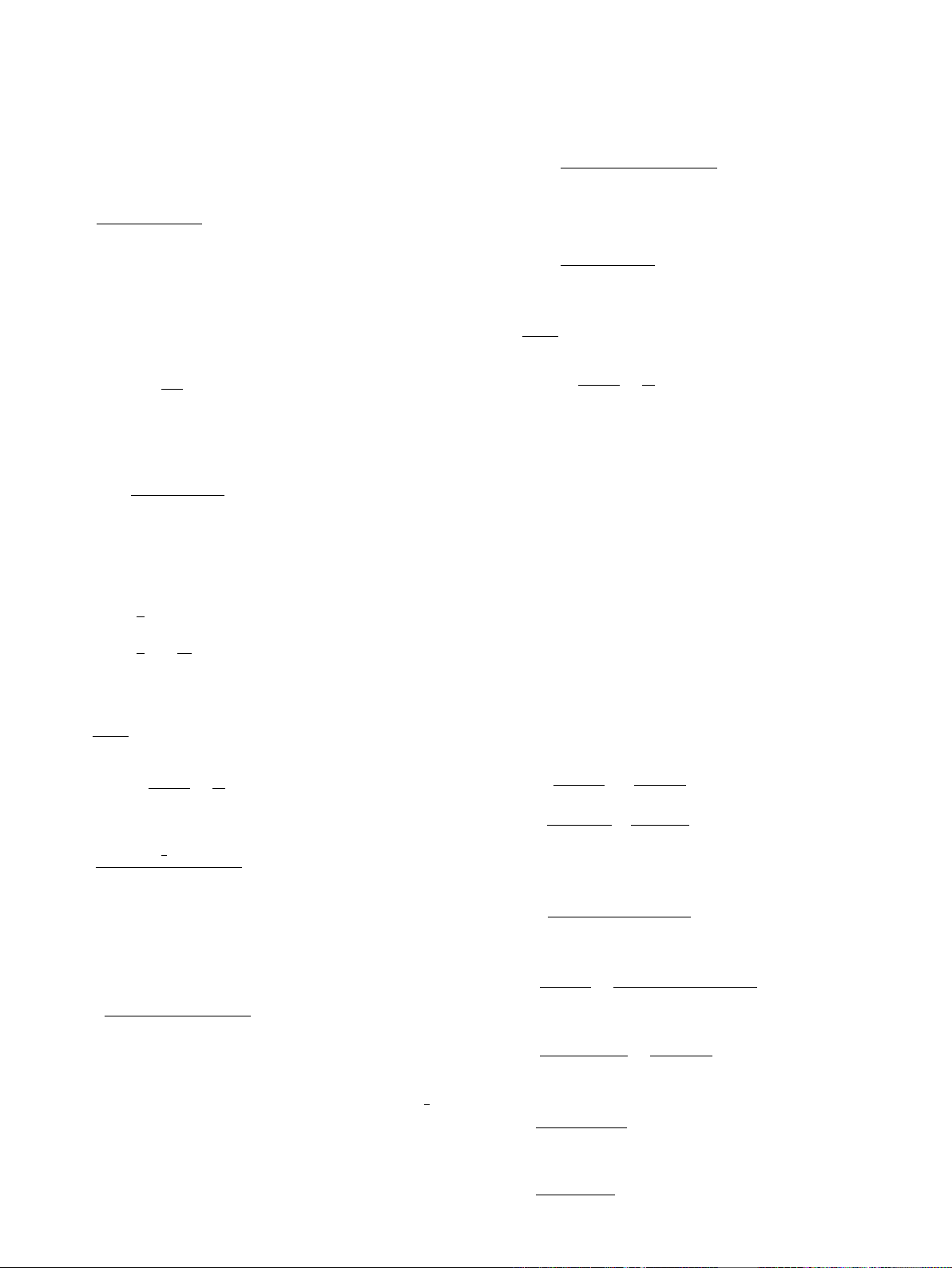

(a) First output to a unit step in the first input. (b) Second output to a unit step in the first input.

Fig. 3. First and second output to a unit step in the first input.

The resulting diagonal subsystems are

h11(s)=12.8e−s

16.7s+1−6.426(14.4s+1)e−7s

(10.9s+1)(21.0s+1),

h22(s)=−19.4e−3s

14.4s+1+9.749(16.4s+1)e−9s

(21s+1)(10.9s+1).

Using Eq. (8), the FOPDT models l11(s)and l22(s)obtained as below

l11(s)=6.37e−0.9335s

5.525s+1,

l22(s)=−9.655e−1.7823s

5.1520s+1.

Using Eqs. (16),(17) and (22), the proposed-PI and proposed-PID

controllers are as given in Box I.

For comparison purpose, two prevalent tuning methods such as

the IMC tuning method and Wang et al.’s auto-tuning method are

applied to G2(s), results in controllers given in Box II.

The IMC method do not use any decoupling method. In this ex-

ample, proposed and Wang et al.’s methods use same decouplers.

For proposed-PI decentralized controller, there are only four tun-

ing parameters, whereas, the Wang-PID controllers have to tune

six parameters.

The step responses of the resultant control system to unit set-

point changes in the first and second inputs are shown in Figs. 3 and

4. The different performance indexes, peak overshoot and rise time

are given in Table 3. Referring to Figs. 3–4and Table 3 proposed-

PID controller results better performance as compared to IMC-PI

and Wang-PID controllers in all respect.

For proposed-PI, proposed-PID and Wang-PID controllers, gain

and phase margins are calculated. The comparative results are

given in Table 4.

6. Real time application

To show the practical applicability, the decoupling method

presented in Section 2and controller design method pre-

sented in Section 4have been tested on laboratory process. A

Level–Temperature reactor process is shown in Fig. 5. The experi-

mental set-up consist of tank with heater. The process is interfaced

to personal computer through data acquisition cards and Emerson

Delta-V DCS software is used to implement the controller. The first

input is an inflow rate through solenoid valve and second input is

power control unit to heater. The first output is liquid level and

second output is liquid temperature in the reactor tank.

For the Level–Temperature reactor the parametric model is

obtained by exciting the system dynamics using PRBS (pseudo-

random-binary-sequence) input. There are numerous types of

input sequences which can provide useful information about

the process, the input is usually changed according to a PRBS

pattern [47]. A PRBS is added to the inputs of process and its effects

![Đề thi Kỹ thuật lập trình PLC: Tổng hợp [Năm]](https://cdn.tailieu.vn/images/document/thumbnail/2026/20260121/lionelmessi01/135x160/85491768986870.jpg)

![Đề thi cuối học kì 1 môn Máy và hệ thống điều khiển số năm 2025-2026 [Kèm đáp án chi tiết]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20251117/dangnhuy09/135x160/4401768640586.jpg)

![Tự Động Hóa Thủy Khí: Nguyên Lý và Ứng Dụng [Chi Tiết]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20250702/kexauxi10/135x160/27411767988161.jpg)