REVIEW PAPER

A Review on PID Control System Simulation of the Active

Suspension System of a Quarter Car Model While Hitting Road

Bumps

Babak Shafiei

1

Received: 1 August 2021 / Accepted: 20 January 2022 / Published online: 21 February 2022

ÓThe Institution of Engineers (India) 2022

Abstract In recent years, car industry experts and

designers have given more attention to ensuring the safety

and comfort of the car and its passengers while traveling on

harsh road surfaces. This paper defines a simulation

approach for a quarter vehicle model with an active sus-

pension system using the SIMULINK environment in

MATLAB software. The first aim is to implement the

correct control system for an active suspension system of a

vehicle and a take closer look at the hydraulic cylinder and

servo valve concept details and its closed-loop control

system. And the second aim is to gain both ride comfort

and reliable road-holding by correctly tunning the PID

parameters for an active suspension system to reduce the

vehicle body displacement and acceleration. Furthermore,

the hydraulic pressure, hydraulic force, and total trans-

mitted force to the vehicle body are compared for active

and passive suspension systems when the car hits contin-

uous sinusoidal and random irregular bumps. The control

system is tuned via a PID controller using the Ziegler–

Nichols method via the Control System Designer app to

achieve the desired comfort traveling of passengers and

reliable ride-holding of the car. For an active suspension

system, the simulation results showed that the car’s body

displacement and acceleration have lower amplitude

compared to the passive suspension case. Hence, active

suspensions can provide the passengers more riding com-

fort and better road-holding while traveling over harsh

street surfaces for the manufacturers.

Keywords Active suspension system SIMULINK

PID controller Ziegler–Nichols method

Introduction

The importance of the control system and stability is to

control and manage the behavior of the systems. The sta-

bility of a system is highly essential and is a safety issue in

the field of engineering. Therefore, the safety of moving

vehicles in confronting impacts caused by street bumps is

necessary. Today, car companies equip their products with

control systems technology to improve the safety and

comfort of their vehicles. One of these upgrades is to

provide the car with an active suspension system equipped

with a controllable hydraulic cylinder. A hydraulic cylinder

is a reciprocating pressure-driven machine that transforms

liquid energy into kinetic energy to move the piston. In

other words, the hydraulic cylinder is a mechanism that

transforms fluid energy under pressure into mechanical

force. Hence, the force obtained via the hydraulic cylinder

can control the displacement of a mass subjected to the

cylinder. Accordingly, the hydraulic cylinder can apply a

necessary independent force on the suspension to improve

the riding comfort.

The earliest model was issued in 1954, with the

hydropneumatic suspension developed by Paul Mage

`sat

Citroe

¨n. However, Colin Chapman introduced the original

theory of computer control of hydraulic suspension in the

1980s to enhance cornering in racing cars. Lotus fitted an

archetype system to a 1985 Excel with electro-hydraulic

active suspension, yet never offered it for sale to the public.

However, several demonstration vehicles were made for

other manufacturers. After many developments in the

&Babak Shafiei

babakshafiyi.1994@yahoo.com

1

Department of Civil, Chemical, Environmental, and

Materials Engineering - DICAM, University of Bologna, Via

Zamboni, 33, 40126 Bologna, Italy

123

J. Inst. Eng. India Ser. C (August 2022) 103(4):1001–1011

https://doi.org/10.1007/s40032-022-00821-z

concept of the active suspension system, in 1992, Williams

Grand Prix Engineering prepared an active suspension for

F1 cars, producing such successful vehicles that the

Fe

´de

´ration Internationale de l’Automobile voted to halt the

technology [1]. Later, the 1999 Mercedes-Benz CL-Class

(C215) launched active body control, where high-pressure

hydraulic servos are controlled via electronic computing;

moreover, this characteristic is yet usable. Vehicles can be

produced to actively tend to curves to enhance passenger

comfort [2].

Active suspensions have been widely studied for more

than 20 years due to their promising characteristics. The

actuator in the suspension can apply the required energy to

lower the chassis independently at each wheel. This action

will give a smooth driving experience which is important to

car manufacturers. In contrast, passive suspensions are

provided by large springs where the movement is assessed

totally by the road profile. Hence, the passive suspensions

cannot give perfect desired comfort driving, while the

vehicle is subjected to harsh damps. In the studies of

Gadade [3], an experimental model of a car suspension

system was fabricated in the laboratory to assess the dif-

ference in the dynamic behavior of passive and active

suspension systems in action. Gadade and his colleague

modeled the 2-DOF quarter vehicle model, assuming that

this model is stationary and the earth is moving. A rotary

motion to a plate with a sinusoidal bump was given by a

gearbox causing the wheel to move in the vertical direc-

tion. The results showed that the active suspension gives a

better handling performance than the passive one.

Given that the methods used in experimental studies

should be close to the actual state as much as possible,

Kararsiz and his colleagues [4] opt for using the HILS

method in their studies. The study investigates the semi-

active suspension system where the road disturbance is

represented with the sum of sinusoidal with unknown

coefficients. Using the HILS method by Kararsiz was to

examine the system performance without a mathematical

model of MR damper and obtain more realistic results than

pure numerical simulation.

As the use of the control system in the car suspension

system becomes more important, many researchers and

authors have begun to simulate the behavior of the active

suspension system for cars subjected to road disturbances

such as bumps. For instance, Wei Hu and Shan Lin [5]

proposed nonlinear backstepping tactics to promote the

fundamental tradeoff within the drive comfort of riders and

suspension travel. The innovation was in applying a non-

linear filter whose adequate bandwidth relies on the amount

of suspension travel. Other works listed earlier [6,7] used

SIMULINK in the MATLAB software to implement the

dynamic equations and obtain body displacement solutions

via numerical methods. Other control methods, such as

Meng and his colleague [8], propose a different control

method based on a homogenous domination approach to

construct an active suspension homogenous controller

(ASHC). Meng stated in his work that the ASHC could

stabilize the system within 2 s, but the sliding mode control

(SMC) stabilizes the system within 2.5 s. However, to see

the dynamic equations of the hydraulic cylinder and servo

valve plus the control system properties like the bode

diagram, it is advisable to use the PID controller via the

SIMULINK environment in MATLAB since the PID block

provides a complete characterization of the control system.

PID control is the most common preferred industrial con-

troller due to its manageable structure and comparative

ease of tuning intuitively or with possible tuning methods

[9–12]. Regarding industrial actuators, the investiga-

tor [13] gives complete information regarding the servo

valves and different kinds of hydraulic cylinders with their

dynamic equations, valve coefficients, and bode diagram of

the open-loop and closed-loop of the servo valve.

According to the previously mentioned methods, this

paper prefers to implement a control system with a PID

controller in the SIMULINK to design the considered

active suspension system. The SIMULINK environment is

appropriate for modeling a system and simulating its

response to the desired input [14,15]. Furthermore, the

output signal can be analyzed well by this method to verify

the system’s stability. SIMULINK has a collection of block

libraries that each one represents equations and modeling

concepts. With these blocks, it is possible to model an

actuator in a closed-loop system. The quarter vehicle

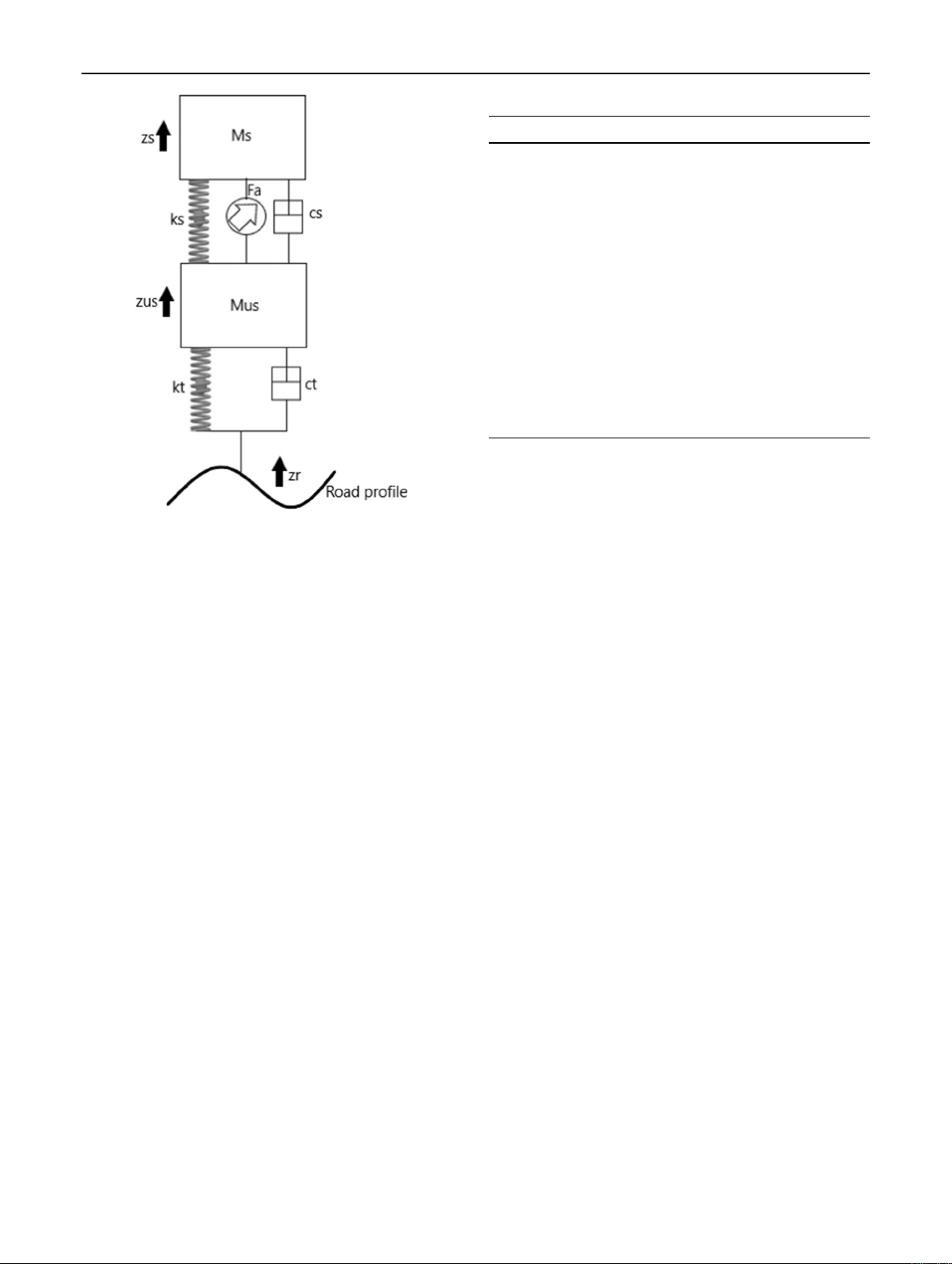

having an active suspension system is considered to model

the design, as shown in Fig. 1. The mass sprung model is

the most suitable [16]. To account for the bouncing or

suspension movement. Later, the vehicle model was sub-

jected to sinusoidal and more realistic street profiles such

as random irregular-shaped road bumps. Then, SIMULINK

was used to see the performance of the active suspension

system affected by road disturbances and compare the

riding comfort between active and passive suspensions.

The numerical solution used to run the control system in

the SIMULINK is Runge–Kutta numerical method

(ode45). Furthermore, to tune the output voltage of the PID

controller to the desired value and obtain the PID gains,

Ziegler–Nichols method is used via the Control System

Designer app inside the SIMULINK environment.

One exception to this paper is implementing the correct

control system based on the dynamic equations and going

deeper into the details of the hydraulic cylinder and servo

valve concept and its closed-loop control system. This

paper also compares the active suspension total transmitted

force to the vehicle body with the passive suspension total

transmitted force when the car hits sinusoidal and more

realistic road profile as an irregular bump. However,

123

1002 J. Inst. Eng. India Ser. C (August 2022) 103(4):1001–1011

finding the actual gain values for a hydraulic cylinder

subsystem is complex, such as flow gain, flow pressure

coefficient, and pressure sensitivity inside the control sys-

tem. Hence, this paper uses some assumptions to solve this

problem, which is mentioned during the calculations of the

gains. To this end, the author suggests that researchers ask

car manufacturers for accurate design information and the

active suspension system parameters to ensure that the

control system results in any theoretical work are close to

the actual state.

Active Suspension System

Data and Assumptions

The 2-DOF quarter vehicle model with an active suspen-

sion system is shown in Fig. 1. The definitions of the

coefficients and their values are given in Table 1. The

model is subjected to road bumps, which are modeled in

further sections. Plus, all the stiffness coefficients and

damping constants are linear. According to Iftikhar [17],

the linear suspension system has lower sprung mass and

unsprung mass maximum displacement and setting time

when the step input is used as a road profile. Iftikhar

concluded that the sprung mass and unsprung mass maxi-

mum displacement show lower magnitudes in the nonlinear

system than the linear one when the vehicle hits a non-

continuous sinusoidal road profile. However, according to

the Iftikhar’s results, in the noncontinuous sinusoidal

bump, the setting times for both masses in the linear system

are less than nonlinear ones. Assuming that the road is

perfectly flat after five seconds and to gain a low setting

time after the vehicle goes over bumps, the author opted for

a linear system based on the details mentioned earlier.

Table 1shows the quarter car model’s data and its

actuator in the suspension system [18,19]. Another

assumption which is made in this problem is as below:

Maximum suspension travel: 10cm

Vehicle’s constant speed: 12:5m=s

The maximum output voltage of the PID controller:

20volt

Maximum spool valve displacement: 2cm

Servo valve time constant: 4:50 103second

The top speed of the hydraulic cylinder: 0:6255m=s

Voltage to ampere conversion gain:

KVA ¼1:00 103A=V

Meter to voltage conversion gain: KMV ¼100V=M

Equations governing the problem

The problem to be studied is shown in Fig. 1. The goal is to

apply the desired value of force or pressure trajectory to the

system when the vehicle is subjected to a road bump. The

desired force will be applied to both the car’s wheel and

body, and this action will cause movement of the vehicle

body to the desired amount. This force is produced via a

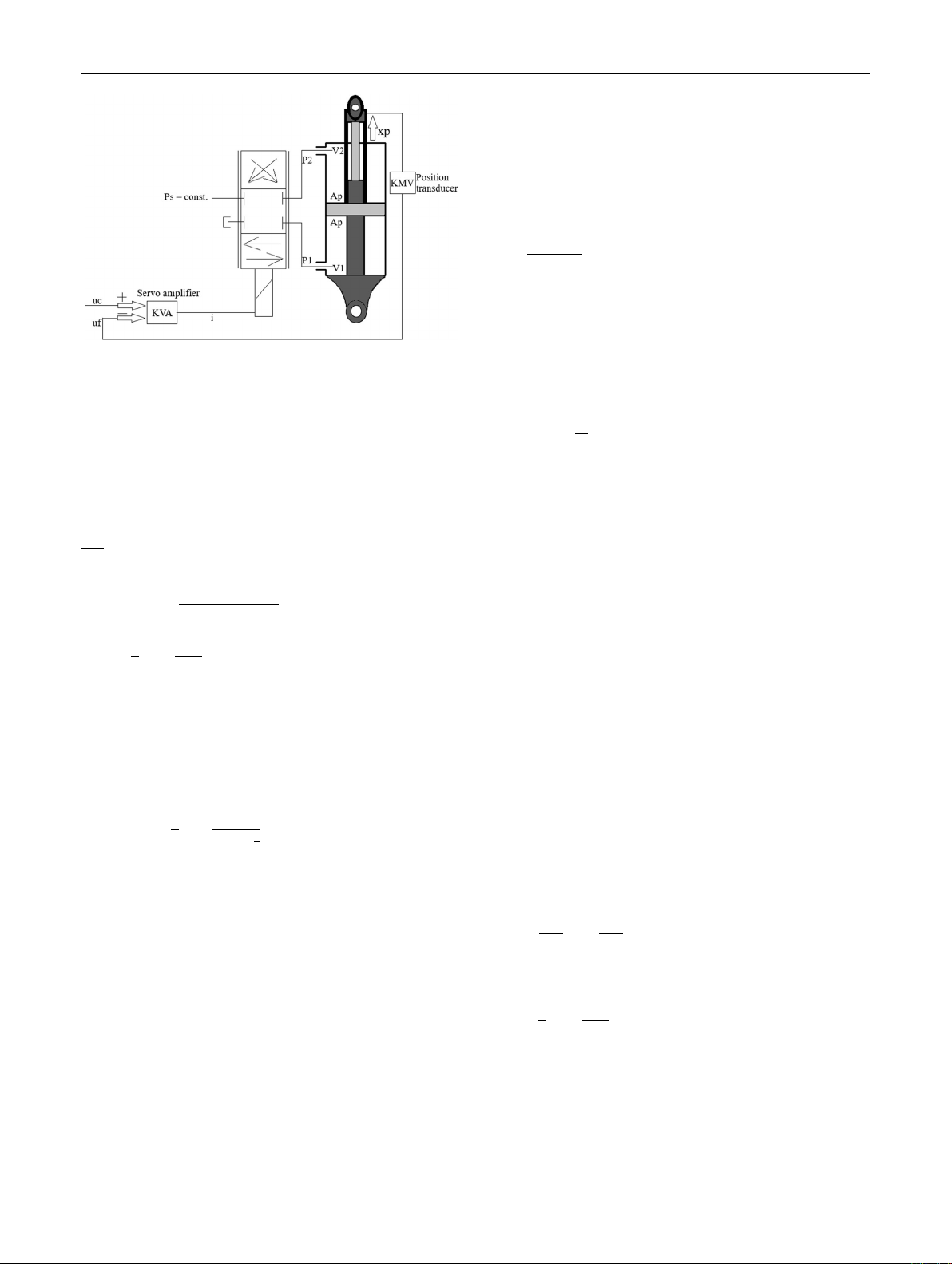

double-acting hydraulic cylinder driven by a four-way

spool valve shown in Fig. 2. The servo valve has its closed-

loop control system, and it acts as a subsystem in the

overall control system. In Fig. 2, the position of the piston

is measured by a position transducer, which further gives a

voltage signal (uf) as an input to the servo amplifier. Then,

Fig. 1 Quarter car active suspension system

Table 1 Data for quarter car model with an active suspension system

Coefficient Definition Value Unit

mus Unsprung mass 41.5 kg

msSprung mass 241.5 kg

ksSpring stiffness 6:0103N=m

ktTire stiffness 1:4104N=m

csSpring damping 300 N:s=m

ctTire damping 1500 N:s=m

zus Unsprung mass displacement m

zsSprung mass displacement m

zrRoad profile m

ApActuator piston area 1:1103m2

VtThe total volume of the chamber 1:1104m3

Ctp Total leakage coefficient 1:01011 m5=N

beEffective bulk modulus 8:0108N=m2

PsSupply pressure 2:10 107N=m2

123

J. Inst. Eng. India Ser. C (August 2022) 103(4):1001–1011 1003

the servo amplifier will compare the command signal (uc)

with the feedback signal (uf), and the resultant error is

gained with the factor (KVA). However, with having a PID

controller in the system, the resulting error signal gains

with PID parameters.

The differential equations governing the actuator

dynamics are given as follows [20]:

Vt

4be

_

PL¼Ap

_

xpCtpPLþQL;ð1Þ

QL¼Cdwxvffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi

Pssgn xv

ðÞPL

q

s;ð2Þ

_

xv¼1

sxvþKVA

su;ð3Þ

where xpis the actuator piston displacement, QLis the

load flow, Cdis the discharge coefficient, wis the spool

valve area gradient, xvis the spool valve position, qis the

fluid density, sis the servo valve time constant, KVA is the

voltage to ampere conversion gain, and uis the voltage

signal. The PID controller has the transfer function as:

UsðÞ¼PþI1

sþDN

1þN1

s

;ð4Þ

where Pis the proportional gain, Iis integral gain, D is

derivative gain, and Nis filter coefficient.

According to Ref. [13], the nominal load flow gives a

valve efficiency of gsv ¼0:67, where gsv is equal to PL=Ps.

Hence, in this problem, the maximum load pressure is

PLmax ¼1:407 107N=m2. However, in practice, the valve

efficiency will be lower when the valve leakage flow is

considered. Referring to the approach to force control for

electro-hydraulic systems studied by Alleyne [21], the

expression ffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi

Pssgn xv

ðÞPL

pis seldom to zero when the

system operates smoothly since load pressure is seldom

close to zero. Alleyne’s claim is in contrast to the Rydberg

[9] state, which proves that the maximum load pressure is

2=3Psfrom the efficiency / load pressure derivative equal

to zero. Hence, by opting to PLmax ¼2=3Ps, the DPv¼

PsPL

ðÞ¼6:93 106N=m2the servo valve nominal flow

for mentioned pressure difference is defined as below:

QL¼QN¼Kqxv¼Apvmax;ð5Þ

where the valve flow gain can be written as Eq. (6)

which is written as:

Kq¼Apvmax

xv

;ð6Þ

where Eq. (2) is not used to obtain flow gain since the top

speed of the piston was given. Plus, the maximum actuator

speed value is an assumption given in this paper since the

values for the discharge coefficient, the spool valve area

gradient, and the exact maximum magnitude of load

pressure are not clear. Finally, by referring to the data,

assumptions, and Eq. (6), the valve flow gain becomes

Kq¼0:0344 m2

s.

The active suspension system applies a certain amount

of force to the wheel (unsprung mass) and body (sprung

mass), which the overall control system needs to reach the

desired input. The equations of motion based on Newton’s

law are given as:

Ms

€zsþkszszus

ðÞþcs

_zs_zus

ðÞFa¼0;ð7Þ

Mus

€zus þct

_zus _zr

ðÞþkszus zs

ðÞþcs

_zus _zs

ðÞ

þktzus zr

ðÞþFa

¼0;ð8Þ

where zris road profile, and Fais actuator force

(Fa¼ApPL).

Further, by assuming zs¼x1,zus ¼x3,zr¼xr,PL¼x5

and xv¼x6, Eq. (1), Eq. (3), Eq. (7), and Eq. (8) can be

rewritten in the form of first-order differential equations as

below:

_

x1¼x2;

_

x2¼ks

Ms

x1cs

Ms

x2þks

Ms

x3þcs

Ms

x4þAp

Ms

x5;

_

x3¼x4;ð9Þ

_

x4¼ctþcs

Mus

x4þct

Mus

_

xrþks

Mus

x1þcs

Mus

x2ksþkt

Mus

x3

Ap

Mus

x5þkt

Mus

xr;

_

x5¼ax2x4

ðÞbx5þcffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi

Pssgn x6

ðÞx5

p

x6;

_

x6¼1

sx6þKVA

su;

where a¼4Abe=Vt;b¼4Ctpbe=Vt;and c¼

4Cdbew=Vtffiffiffi

q

p

:

Equation (9) is the simplified representation of actuator

dynamics and is modeled in the next section. Before

Fig. 2 Symbol circuit of a position servo

123

1004 J. Inst. Eng. India Ser. C (August 2022) 103(4):1001–1011

modeling the system, it is also necessary to define road

profile xraccording to Eq. (9). This paper describes road

profiles as the street bumps assumed to be continuous

sinusoidal and random irregular shape bumps. Therefore,

besides this study’s ideal sinusoidal street profile, a random

irregular road profile is also used, representing a more

realistic street bump.

Active Suspension Control System Design

In this section, the design of the active suspension control

system is studied. Many methods exist to design an active

suspension system, such as nonlinear modeling a vehicle

suspension using the LPV technique reviewed by Gaspar [22].

The goal of using the LPV method by Gaspar was to compose

a nonlinear suspension controller that can highlight a distinct

performance objective, depending on the size of the suspen-

sion deflection. While the suspension deflection is small, the

controller should concentrate on passenger comfort. When the

displacement limit is approached, the controller should stop

the suspension deflection from passing this limit. The LPV

method is an excellent approach to control nonlinear systems

using a family of linear controllers. However, a significant

shortcoming of the classical gain scheduling method is that

satisfactory performance, and in some matters, yet stability is

not insured at operating states other than the design points

[23]. Considering that the system presented in this paper is

linear, it is more promising to use a numerical simulation

method using SIMULINK in MATLAB to design and control

the active suspension system.

The SIMULINK environment provides a large range of

designing and controlling tools and apps, which are helpful

to satisfy the system’s stability and performance. Regard-

ing controlling an active suspension system, recent works

such as Mudduluru [12] conclude that active suspension

controlled by the PID controller provides a better response

than a passive system. The application of the PID con-

troller for a quarter and full car model, which is studied by

the researchers [12], shows a significant reduction in mass

sprung displacement.

Actuator Modeling

The actuator in the active suspension system is considered

double-acting by a four-way spool valve. Figure 3shows

the subsystem of the hydraulic cylinder with its valve

inside the overall control system. The dynamic models of

the valve and hydraulic cylinder are obtained via consid-

ering Eq. 8and data and assumption. The force that is

obtained by the actuator is applied on both sprung mass and

unsprung mass, which can affect the vehicle’s body

displacement.

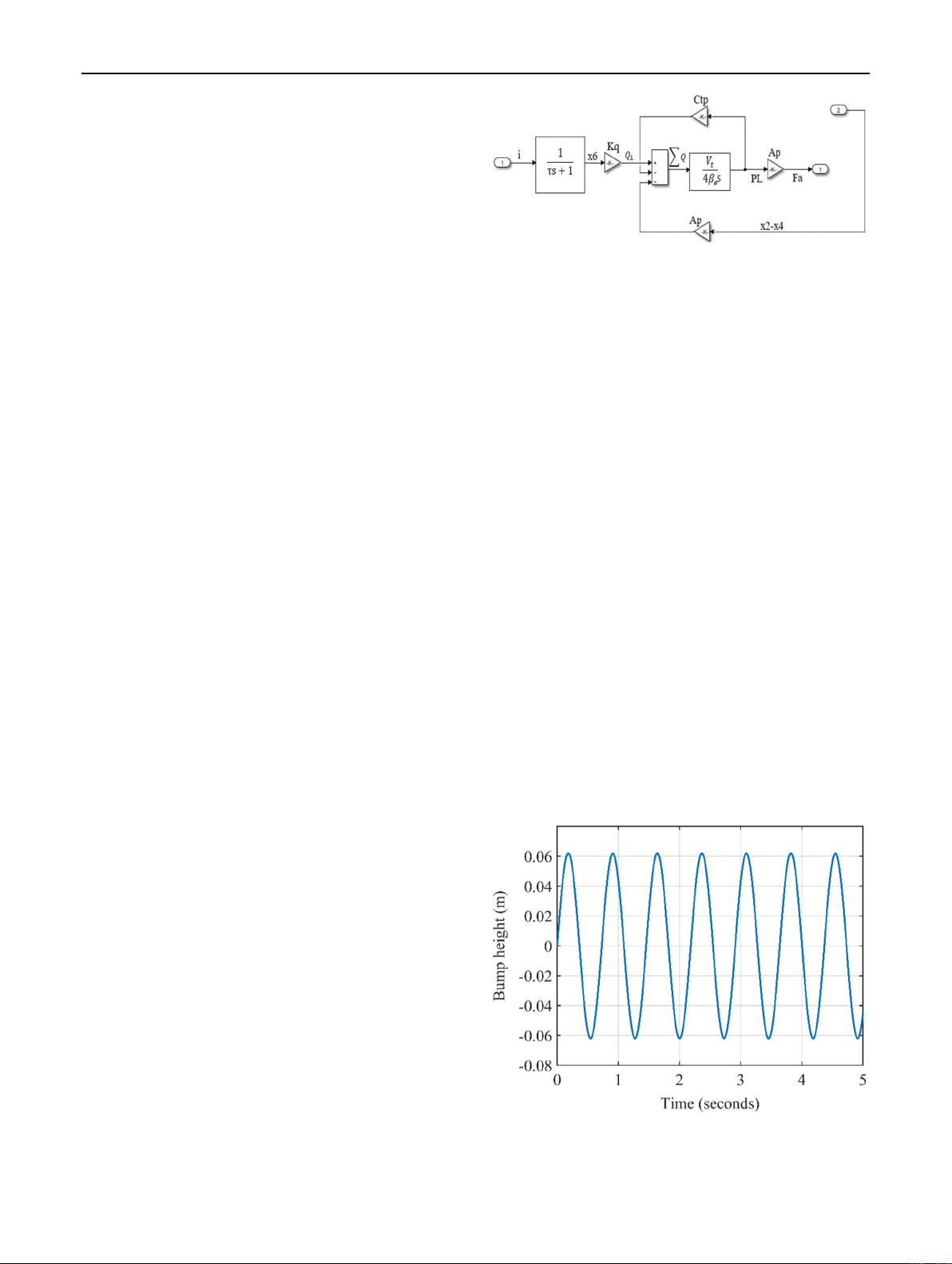

Road Profile Modeling

Figures 4and 5indicate the road profiles xrdesigned for

this study using SIMULINK. The shape of the bump is

sinusoidal with a 0.062 m amplitude. The assumed bumps

maximum heights prevent the suspension deflection from

approaching its limit, which is 10 cm.

General Modeling of the Control System

Considering the overall dynamic equations of the active

suspension system given in Eq. (8) and the road profiles xr,

shown in Figs. 4and 5, the final model of the system is

shown in Fig. 6. In this control system, the road profile

signal acts as a disturbance signal. The actuator itself is a

subsystem inside the overall system, and it aims to generate

the necessary force to apply to the vehicle body and the

wheel. The actuator force is obtained via a PID controller,

which commands the valve by a current signal. Further, the

displacement of the spool valve caused by the current

signal gives a certain amount of oil rate inside the cylinder.

Then, the hydraulic cylinder converts fluid energy to

kinetic energy with the movement of the piston. Finally, a

shaft connected to the piston moves upward and down-

ward, leading to the vehicle’s body movement.

Fig. 3 Block diagram for a valve-controlled cylinder

Fig. 4 Continuous sinusoidal road profile xr

123

J. Inst. Eng. India Ser. C (August 2022) 103(4):1001–1011 1005

![Đề thi Kỹ thuật lập trình PLC: Tổng hợp [Năm]](https://cdn.tailieu.vn/images/document/thumbnail/2026/20260121/lionelmessi01/135x160/85491768986870.jpg)

![Đề thi cuối học kì 1 môn Máy và hệ thống điều khiển số năm 2025-2026 [Kèm đáp án chi tiết]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20251117/dangnhuy09/135x160/4401768640586.jpg)

![Tự Động Hóa Thủy Khí: Nguyên Lý và Ứng Dụng [Chi Tiết]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20250702/kexauxi10/135x160/27411767988161.jpg)