Automatica,

Vol. 12, pp. 211-224. Pergamon Press, 1976. Printed in Great Britain

The Design of a Multivariable Control

System for a Ship Boiler*

ARNE TYSS~,? J. CHR. BREMBO~ and KJELL LIND§

An application of linear regulator theory in the design of multivariable control

systems/or nonlinear processes

Summary--A multivariable control system is designed for a

large scale ship boiler. The design is based on concepts of

modern control theory and extensive use of all-digital

real-time simulation.

This paper describes in particular how it is possible to

verify the multivariable control system without having the

real process operating.

1. INTRODUCTION

THE SOtLER studied in this paper is a Foster

Wheeler ESD III with a normal steam production

of 21.9 kg/sec. The boiler is operated on the basis

of natural circulation. The control system is

designed to maintain the drum level, drum

pressure and the steam temperature at pre-

scribed reference values given by the load

condition. A Kalman filter for the estimation of

the process state as well as the environmental

state vector is included. The environment is

supposed to produce slowly varying distur-

bances to the process.

The integral control action (reset) is provided

by an external decoupled integrator loop, and the

integral action in the estimation loop follows

from the assumptions about the disturbance

model.

The external integrator structure also gives a

simple solution to the 'bumpless transfer' prob-

lem, that is a soft transfer from conventional

back up system mode to multivariable mode.

By means of simulation facilities it is possible

to examine the behaviour of the control system

for all kinds of manoeuvres and disturbances.

Examples of such tests will be presented.

*Received August 14, 1975; revised May 19, 1975; revised

December 2, 1975. The original version of this paper was

presented at the IFAC/IFIP Symposium on Ship-Operation-

Automation which was held in Oslo, Norway during July

1973. The published Proceedings of this IFAC Meeting may

be ordered from: IFAC/IFIP Conference, Gloriastrasse 35,

CH-8006, Zurich. This paper was recommended for publica-

tion

in revised form by associate editor K. J. ~strfm.

?The

University of Trondheim, The Norwegian Institute of

Technology, Division of Engineering Cybernetics.

~The Ship Research Institute of Norway, Trondheim,

Norway.

§Sonnico Pan Electric Contracting A/S, Oslo, Norway.

The integrity of the control system will be

discussed, and the digital real time simulation

system which consists of two process control

type computers, will be described in some detail.

Important works in the field of boiler models

and boiler control systems are given by

Eldund[5], Anderson[16], Kwan and Ander-

son[19], Nicholson[17], [18], Waiters and

Williams[20], McDonald and Kwatny [21],

McDonald, Kwatny and Spaare [22].

The paper is divided into two parts:

1. The theoretical work necessary for the

control system's design.

2. The application of the all digital real time

simulation in evaluating the control system.

2. THEORETICAL WORK

2.1

The boiler model

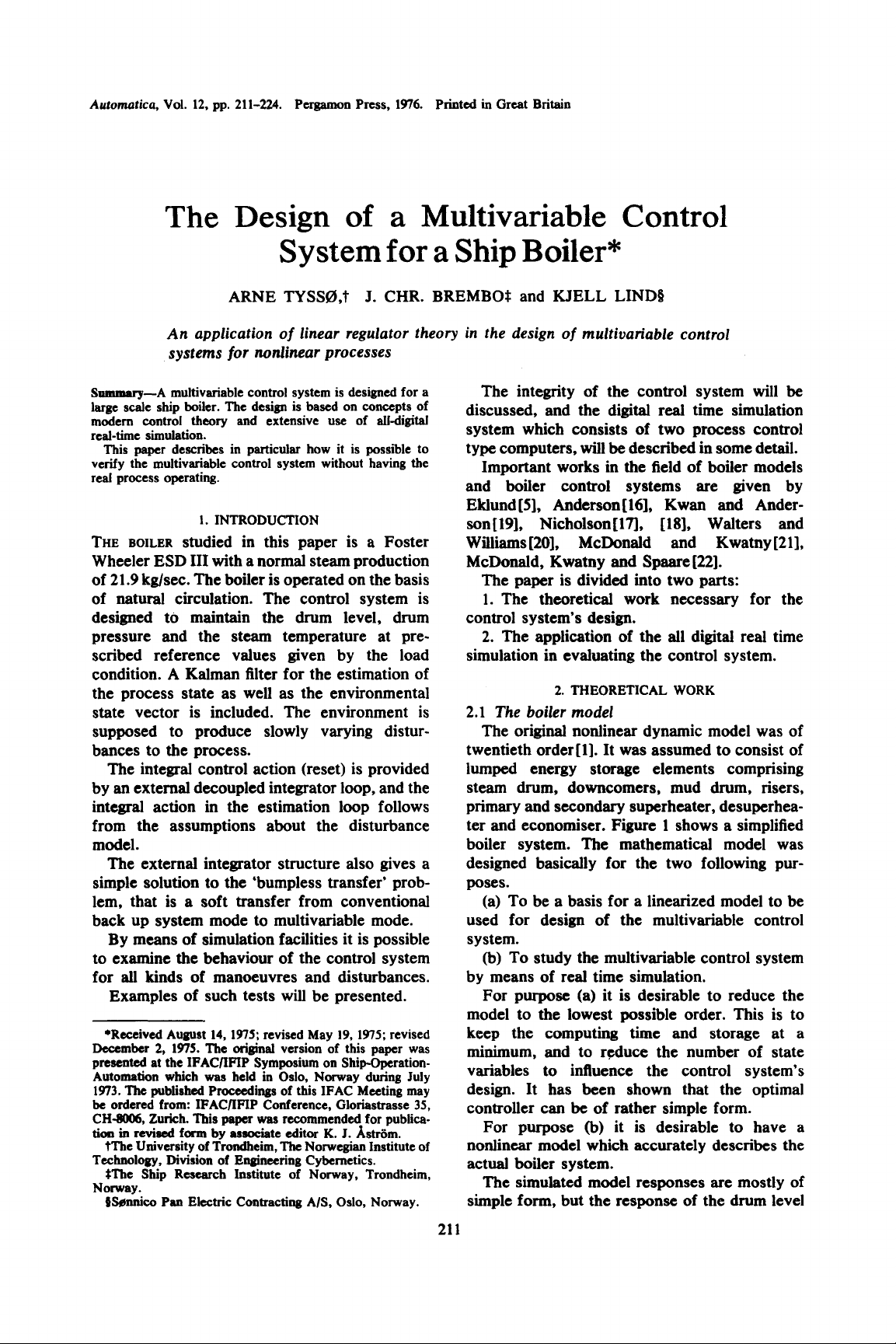

The original nonlinear dynamic model was of

twentieth order[l]. It was assumed to consist of

lumped energy storage elements comprising

steam drum, downcomers, mud drum, risers,

primary and secondary superheater, desuperhea-

ter and economiser. Figure 1 shows a simplified

boiler system. The mathematical model was

designed basically for the two following pur-

poses.

(a) To be a basis for a linearized model to be

used for design of the multivariable control

system.

(b) To study the multivariable control system

by means of real time simulation.

For purpose (a) it is desirable to reduce the

model to the lowest possible order. This is to

keep the computing time and storage at a

minimum, and to r,educe the number of state

variables to influence the control system's

design. It has been shown that the optimal

controller can be of rather simple form.

For purpose Co) it is desirable to have a

nonlinear model which accurately describes the

actual boiler system.

The simulated model responses are mostly of

simple form, but the response of the drum level

211

212 A. TYsso

et al.

By-pass-valve

/ "

Feedwoter

'

_ I~;C~

II |

',,Th,o*.e-

Feedwater ~:.I '~,_~

Air

temp. ~ -

_. ;-

FIG. I. A simplified boiler system.

to a change in steam load is of the expected

non-minimum phase form. We also have an

unstable model. The zero in the right half of the

complex frequency plane qualitatively accounts

for the effects of bubble formation and evapora-

tion in the riser tubes and steam drum with

dynamically decreasing pressure. This is also

known as 'shrink and swell'.

The nonlinear model equations were linearized

by considering small perturbations about a

steady state operating point[2]. The resulting

equations were manipulated by means of a large

digital computer into state space form.

The appropriateness of the model has been

verified by comparing model responses with

responses of the actual ship boiler in operation.

The measurements and the equations are pre-

sented in the references [14] and [15].

2.2

Reduction of the system order

The aim for the model reduction was to

achieve a reduced model, sufficiently accurate

for the synthesis of the control system. The

reduction was based on a modal method,

described in [31 and [4]. By neglecting the

dynamic effects associated with the small time

constants of the system, a reduced model was

obtained.

It was found that several variables could be

removed, without introducing serious errors in

the total system response. Primarily the fast

responses and variables of similar character

were removed. In this way, it was possible to

obtain a satisfactory 8th- and 10th-order reduced

system. The results obtained from the model

reduction were utilized in the nonlinear model,

and we thus succeeded in reducing the original

20th-order nonfinear model to a 12th-order

nonlinear model[15]. The real time simulation

was based on the latter one.

As the response of the 10th-order system was

very close to the original system response, the

multivariable control system was based on this

description. In state space form the boiler is

described by the vector matrix differential

equation

i,(t)=Ax,(t)+Bu(t)+C,v,(t)+C2v2(t)

(1)

where

x,(t): the deviation of the process state from

steady state (dim = n)

u(t): control vector (dim = r)

v,(t): measurable process disturbances (dim=

q)

V2(t),

unmeasurable process disturbances

(dim = p)

The measurement vector (dim = m):

y(t)=Dx2(t)+DBu(t)+Dcvt(t)+w(t) (2)

where

w(t):

measurement noise (dim = m)

The noise is assumed to be of white character

and Gaussian.

A, B, C,, C2, D,/)8 and

Dc are

matrices of

dimension compatible with the dimensions of the

associated vectors. The system description of

the 12th order linearized model is given in

Appendices A1 and A2.

For the original 12th order linearized model

the eigenvalues are:

Ai = -- 1.141 ,t2 = --0.758 a3= --0.590

A4 = --0.384 A5 -- --0.339 ?,6= --0.146

;t7 = - 0.020

As

= - 0.009 ~,9 = - 0.007

Ai0 = --0.006 All =0 An = 0.00016

Notice the eigenvalue at the origin and the

positive one.

The unstable mode depends on how the ratio

between mass of steam and water in drum

system and how the masses of iron are taken into

account. If the steam mass flow is not considered

to be an input variable, the unstable mode is

changed into a stable model5]. The zero eigen-

value is obviously associated with the drum

liquid level.

Discrete-time-model.

In a digital control sys-

tem the process outputs are measured at discrete

intervals of time

t = 0, T,

2T... where T is the

sampling period, and the control inputs are held

constant between sampling instants. Equation (1)

may conveniently be expressed in the discrete

time form:

x,((k + 1)T) =

~(T)x,(kT) + A(T)u(kT)

+ fl,(T)v,(kT) + l'h(T)v2(kT)

(3)

The design of a multivariable control system for a ship boiler 213

The choice of sampling rate depends on the

process and valves dynamics and the noise

characteristics.

By removing the two fastest eigenvalues from

the 12th-order model the fastest eigenvalue in the

new 10th order model is given by ?,3 ffi -0.59.

This indicates theoretically a sampling rate not

lower than 0.9 sec. Simulations, however, have

shown that a sampling rate T ffi 2 sec is sufficient.

The 10th order model is given in Appendix A3.

2.3

Control philosophy

The optimal control with state variable feed-

back is determined from the minimization of the

quadratic objective functional given a unit

sampling interval

J = 2(x(N) - x~)Ts (x(N) - x~)

N--I

(4)

where x~ is the desired state. S and Q are

positive, semideflnite symmetric, constant mat-

rices which penalize the final state offsets and the

deviation in the state variables, respectively. P is

a symmetric matrix of constants which penalize

use of control action and must be positive

definite.

The solution of this problem can be separated

into two independent problems

(a) a deterministic control problem.

Co) an estimation problem.

The deterministic control strategy is known to

be

u(k) - Gx,(k)

= - P-' A T~P-T(R (k )

-

Q)x,(k)

(5)

It is difficult

a priori

to choose the parameters

in the loss functional. As a rule of thumb we use

i= l,2,...,n

j--1,2 ..... r

as initial guess of Q and P. Through a simulation

it is possible to see if the feedback controller is

satisfactory. The constraints and dynamic limita-

tions in the control variables are not taken into

account explicitly. Therefore we have to balance

a fast response against a realistic magnitude of

the control variables. The final answer to this

question will be given by the real time simulation

in the data laboratory. It is important that the

feedforward terms, discussed below, are in-

cluded in the simulation.

To implement an optimal control it is neces-

sary that every element in the state vector be

available for measurement. In our case only two

components of the state vector are measured

directly, so it is necessary to estimate the others.

The estimator is based on a reduced, linear

model of the process. The solution will therefore

be sub-optimal.

It is known that the least squares estimator is

described by

il(k

+ 1) = ~,(k) + An(k) + flv,(k)

+ ~K,(y(k) - ~(k))

(8)

where ^ denotes estimates. In equation (8) KI is

given by

K, = AX(k)DT(DAX(k) +

W(k))-' (9)

where

AX(k ) = E(~,(k )Ax,T(k ))

= E ((x,(k) -

i,(k)Xx,(k) - ~,(k)) 'r)

where R is determined from the discrete matrix

Riccati equation

R(k)ffi Q

+~pT(R-'(k +

I)+AP-'AT)-'~ (6)

with boundary condition

R(N) = S (7)

For the boiler application we will use the

stationary value of the feedback matrix

G(k).

The terminal time can be regarded as plus

infinity. This also means that S can be set equal

to zero.

and

W(k) ffi= E(w(k)wr(k))

are the covariance matrices of the state estima-

tion error and the measurement noise, respec-

tively.

AX(k)

can be determined as the solution

of a discrete matrix Riccati equation.

The main objective for the multivariable

controller is to keep three variables at prescribed

reference values given by the load condition.

The prescribed reference vector

r~(k) ffi f(v,(k)) (10)

214 A. Tvsso et al.

The reference variables are:

y, = drum pressure

y~ = steam outlet temperature

y3 = drum level

or expressed in an equation:

where

r(k)

=

Ty(k)

r(k) = reference vector, (dim = 1).

In the stationary state we require:

(11)

both the process and the environment is de-

scribed by

r,,.)1

=LU I U

J

,(t)

L~--~J

+ [-~]v,(t)+ [O]n(t) (17)

and can be written

,(t) = Ax(t)

+/]u(t)+

~v,(t)+ #n(t) (18)

and in the discrete-time form

x((k + I)T) = ~(T)x(kT) + f~(T)u(kT)

+

~(T)v,(RT)

+

O(T)n(RT)

(19)

r(k) - r,a(k) = 0 (12) The gain in the extended estimator is now

2.4 Elimination of steady state errors

If the control law given by equations (5) and

(8) is used without any additional features, there

will be two kinds of stationary errors in the

multivariable control system; one in the estima-

tion loop and one in the control loop.

This is due to the fact that we use an

approximated model in the estimator, and that

the process is influenced by disturbances (equa-

tion 1).

The difference between the actual measure-

ment and the estimated one can be expressed

Lim

{y(t) - S,(t)}

=

Ay (13)

t--~z

The steady state offset error in the control loop

can be expressed

Lim

{r(t) - r~,r(t)}

-- Ar

(14)

f~

In [6] it is shown that this special choice of

dynamics of the environment leads to an integral

action in the estimation loop.

The assumed covariance of the environment

excitation determines the way in which i~(k) will

track x2(k), since K2 determines the reset time

for tracking x2(k) in the estimator. It is always

difficult to assume reasonable values for the

environment excitations, and therefore we have

used a modal method to determine K,. Thus we

specify in advance the desirable reset time in the

estimation loop. It is reasonable to assume that

the process estimator is considerably faster than

the environment estimator. If H is the specified

eigenvalue matrix (with diagonal elements only)

for the environment, we find that

K2 = (I-H)(D(I-O+OK,D)O)-' (20)

The estimation loop. The estimation loop

problem can be solved by regarding the error as a

slowly varying process disturbance and estimate

this in an estimator.

The environment which generates the distur-

bances is described by a Wiener process

i~(t) =Fn(t)

(15)

v,(t) = Hx2(t) (16)

where

x2(t):

environment state vector (dim = 1)

n(t): white noise, zero mean vector.

The state of the "supersystem' encompassing

K, is determined from the equation for optimal

estimation. A necessary condition for (D(I - • +

OK,D)O)-' to exist is that the number of

environmental states is assumed to be equal to

the number of measurements (m ffi p). If m < p,

the environment model is not observable.

The control loop. Depending on whether the

disturbance can be measured or not, we will have

the following solutions:

(a) When the disturbance vector can be

measured directly, a feedforward vector can be

produced from the disturbance vector.

(b) When the disturbance vector cannot be

measured, a control strategy which performs

integral action in the control loop will be used.

If the prescribed reference vector is regarded

as a measurable disturbance, the control law

The design of a multivariable control system for a ship boiler 215

including the feedforward then is: Now let

u(k) =

Gi,(k)+ G,r.~(k)+

G4v,(k) (21)

The feedforward matrices can be determined as

follows:

In the stationary state we have:

i,(k

+

I) = t,(k) (22)

From equation (2) and (11) we then have

r(k) =

T(D + DBG)i,(k ) + TD.G3r..-(k )

+ T(DuG4 + Dc)v,(k)

(23)

G is found from equation (5) and from the

condition r(k)= r,~(k) we have:

G, = ((TD. - T(D + DBG)(O - I +

AG)-'A)-' (24)

G4 = Gs(T(D + DsGX~ - I + AG)~ - TDc)

(25)

A condition for G3 to exist is that T have the

dimension r x m.

The integral action in the control loop is very

important. From a theoretical point of view it is

possible to obtain this in different ways. In [6] it

is proposed to use a feedback from the estimated

environmental state, and in [7] and [8] it is

proposed an external integrator loop by aug-

menting the state vector with an integration

vector (equation 27). It is also possible to obtain

integral action by weighting higher order time

derivatives of u in the performance index.

Regarding a practical implementation of the

integral action, attention must be paid to the

'wind up' problem, which seriously occur when

control variables are temporarily or permanently

in the saturated state.

The implemented solution is based on use of

an external decoupled integrator structure[13]

controlled by a computer program. The number

of integrators must be less or equal the number

of control variables. Thus the process is output

controllable with respect to r if l <- r.

The complete control law will be

z = (28)

and the performance index could now be

1

], = (x(k)- +

o(k)Tpu(k)

+ (r(k) - r,,dk))TQ~(r(k) - r~(k)) (29)

Expressions for the feedback-feedforward

matrices are given in Appendix A4. G2 will now

not be in diagonal form, and will thus only give

the initial values for a final solution.

The weighting elements for the augmented

states must be carefully chosen, so that their

dynamics do not influence the main dynamic

behaviour. This can be examined by studying the

eigenvalues in the closed feedback loop with and

without the integration vector included.

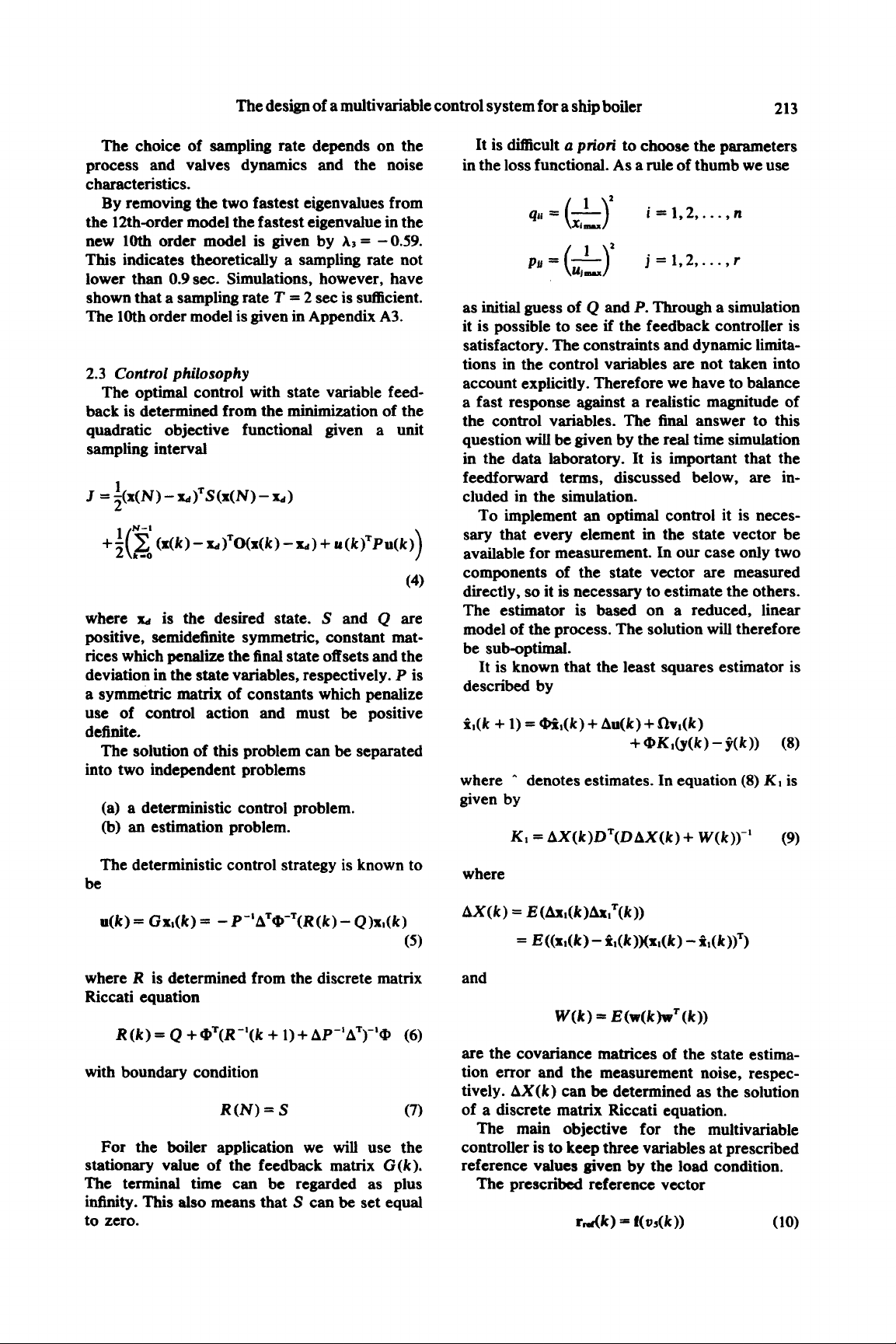

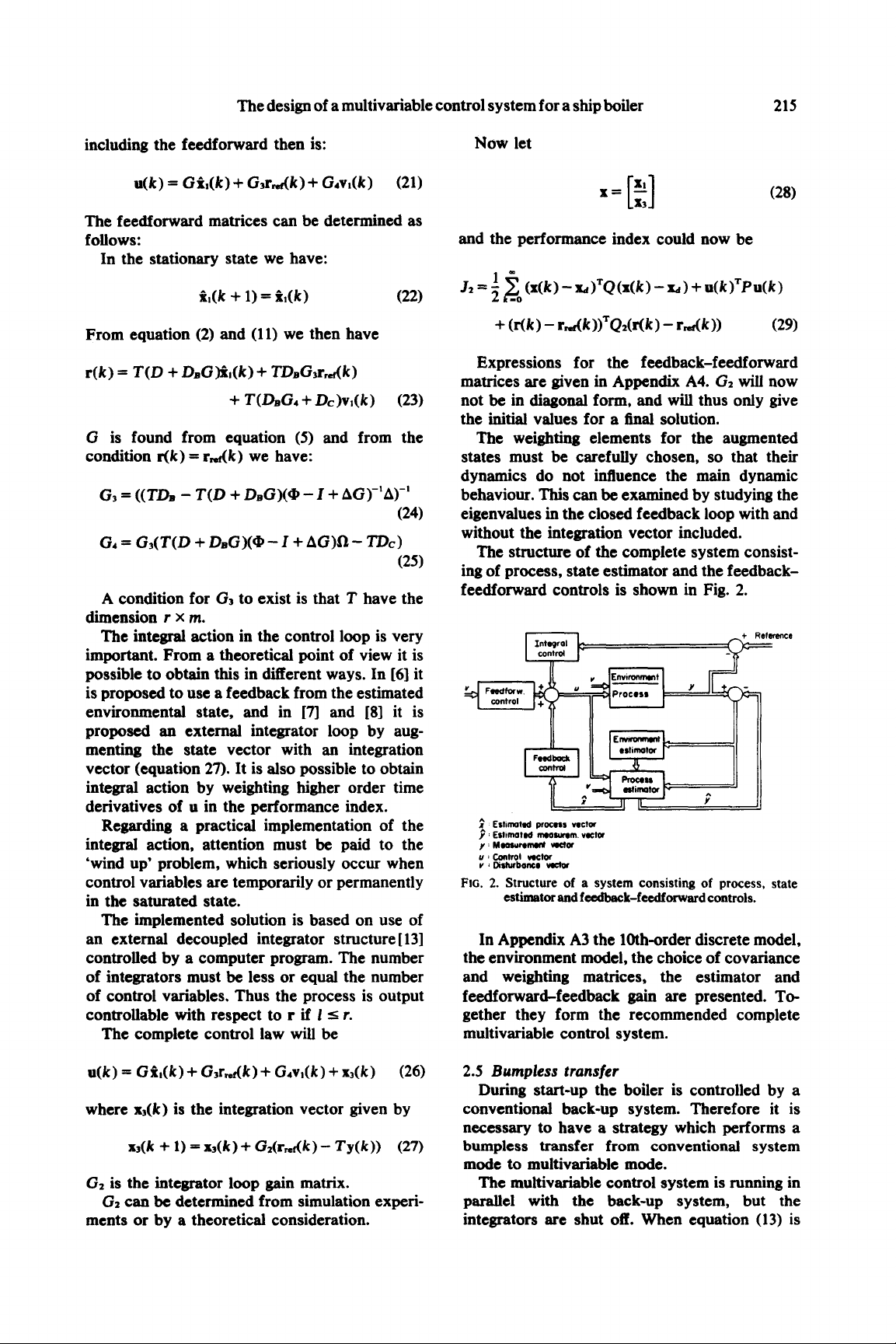

The structure of the complete system consist-

ing of process, state estimator and the feedback-

feedforward controls is shown in Fig. 2.

~: Estimated process vector

: Estimated meosurem vect~'

¥ : Measuremenl vector

u : Control voctor

v , Dislwbonce voct~

+ Reference

FIG. 2. Structure of a system consisting of process, state

estimator and feedback-feedforward controls.

In Appendix A3 the 10th-order discrete model,

the environment model, the choice of covariance

and weighting matrices, the estimator and

feedforward-feedback gain are presented. To-

gether they form the recommended complete

muitivariable control system.

u(k) = G/,(k) + G3r,,,(k) + G,v,(k) + x3(k) (26)

where x3(k) is the integration vector given by

x~(k + 1) = x3(k) + G2(r,.f(k)- Ty(k)) (27)

G2 is the integrator loop gain matrix.

G2 can be determined from simulation experi-

ments or by a theoretical consideration.

2.5

Bumpless transfer

During start-up the boiler is controlled by a

conventional back-up system. Therefore it is

necessary to have a strategy which performs a

bumpless transfer from conventional system

mode to muitivariable mode.

The multivariable control system is running in

parallel with the back-up system, but the

integrators are shut off. When equation (13) is

![Đề thi Kỹ thuật lập trình PLC: Tổng hợp [Năm]](https://cdn.tailieu.vn/images/document/thumbnail/2026/20260121/lionelmessi01/135x160/85491768986870.jpg)

![Đề thi cuối học kì 1 môn Máy và hệ thống điều khiển số năm 2025-2026 [Kèm đáp án chi tiết]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20251117/dangnhuy09/135x160/4401768640586.jpg)

![Tự Động Hóa Thủy Khí: Nguyên Lý và Ứng Dụng [Chi Tiết]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20250702/kexauxi10/135x160/27411767988161.jpg)