http://www.iaeme.com/IJMET/index.asp 487 editor@iaeme.com

International Journal of Mechanical Engineering and Technology (IJMET)

Volume 10, Issue 03, March 2019, pp. 487-495. Article ID: IJMET_10_03_051

Available online at http://www.iaeme.com/ijmet/issues.asp?JType=IJMET&VType=10&IType=3

ISSN Print: 0976-6340 and ISSN Online: 0976-6359

© IAEME Publication Scopus Indexed

APPLICATION OF GREY RELATIONAL

ANALYSIS FOR MULTI VARIABLE

OPTIMIZATION OF PROCESS PARAMETERS

IN DRILLING OF POLYMER BASED GLASS

FIBER REINFORCED COMPOSITE

Dr. Murthy BRN and Dr. Rajendra Beedu*

1Department of Mechanical and Manufacturing, Manipal Institute of Technology, Manipal.

Karnataka, India.

*Corresponding Author

ABSTRACT

The present work deals with a simple approach which predicts the optimum setting

of process parameters of drilling operation on Polymer Based Glass Fiber (PBGF)

composite. The process parameters selected are drill angle (DA), Drill diameter (DD),

Material Thickness (MT), Speed (N) and Feed (f). The output parameters are Thrust,

Torque, Surface Roughness and Delamination. Three levels of each input parameters

are considered. Taguchi’s L27 array is used to set the process parameters. Gray

relational analysis (GRA) is used to find the optimum value of process parameters.

Conduction of ANOVA on GRA shown the significance of each factor on the process

output. A conformation test conducted revealed that the setting of parameters ensures

optimum output.

Keywords: Drilling, PBGF composite, orthogonal array, Gray relational analysis.

Cite this Article: Dr. Murthy BRN and Dr. Rajendra Beedu, Application of Grey

Relational Analysis for Multi Variable Optimization of Process Parameters in Drilling

of Polymer Based Glass Fiber Reinforced Composite, International Journal of

Mechanical Engineering and Technology, 10(3), 2019, pp. 487-495

http://www.iaeme.com/IJMET/issues.asp?JType=IJMET&VType=10&IType=3

1. INTRODUCTION

The use of Polymer based glass fiber (PBGF) is extending beyond the initial applications in

aerospace and military fields, driven by the advances in manufacturing technologies which

has made the production process more cost effective. PBGF composite materials offer

excellent mechanical properties, while being much more lightweight than the metallic alloys.

As PBGF composite parts are usually integrated in a mechanical assembly, drilling is the

most common encountered machining process in the production of such parts. Drilling is

Dr. Murthy BRN and Dr. Rajendra Beedu

http://www.iaeme.com/IJMET/index.asp 488 editor@iaeme.com

carried out during the final stages of the manufacturing process in order to create holes for

fabrication.

Excessive tool wear and delamination are the two major problems highlighted in the

drilling process of the PBGF composites. The excessive tool wear makes the drilling process

of the fiber reinforced composites very expensive, only a limited number of holes can be

drilled with one particular drill. Delamination is the one of the main reasons which is leading

rejection of composite parts in the larger quantity.

Most of the researchers are focusing on characterization of PBGF composite. But the main

problem occurs in drilling holes for the purpose of assembly. The components made by PBGF

may fail due to delamination and rough surface, excess thrust force and torque associated with

speed. Hence optimization of process parameters is essential to reduce the damage occurs

during drilling process in order to reduce the rejection of composite components. Literature

review reveals that many researchers are made attempts to optimize the process parameters to

achieve the good quality holes by minimizing the thrust force, torque, surface roughness and

delamination factor. Palanikumar [1] used Taguchi and response surface methodology to

optimese the process parameters to achieve the minimum surface roughness. Enemuoh et al.

[2] proposed an approach of combining Taguchi’s technique and multi-objective optimization

criterion to select cutting parameter for damage-free drilling in carbon fiber-reinforced epoxy

composite materials. Ghani et al. [3] developed a new approach using Taguchi’s method to

optimize the cutting parameters in end milling of AISI H1312. K. Karthik et al. [4] optimized

the process parameters to minimize the delamination on the drilling of GFRP composites

using HSS drill bits. Lewlyn L. R. Rodrigues et al. [5] optimized the process parameters in the

drilling of CFRP composites to reduce the surface roughness using Taguchi and RSM

methods. S Aril et al. [6] did the optimization in drilling of GFRP composites using HSS

drills to achieve the lower delamination. They used an optimization algorithm using simulated

annealing with a performance index for this purpose. In this way numerous numbers of

researchers used various methods to optimize the process parameters to obtain the desired

outputs [7-9]. In the literature review we noticed that they did optimization for one output

parameter at a time. But in this present work we tried to develop the optimization for four

output parameters at a time. Production of acceptable components with minimum failure is

the main purpose of setting proper process parameters.

2. FABRICATION OF COMPOSITE

The glass fiber reinforced resin composite required for testing was manufactured through

hand layup method. The glass fibers are reinforced in general purpose resin matrix. Chopped

glass mat is used for reinforcement which is presented in Figure 1a and the prepared

composite sheet in Figure 1b.

Figure 1a Chopped glass mat Figure 1b Prepared composite specimen

2.1. Selection of Levels of Drilling Parameters

Application of Grey Relational Analysis for Multi Variable Optimization of Process Parameters in

Drilling of Polymer Based Glass Fiber Reinforced Composite

http://www.iaeme.com/IJMET/index.asp 489 editor@iaeme.com

The input drilling parameters are selected as per the available literature survey information,

solid carbide drill bits are used because of their low wear characteristics. All five parameters

and their levels chosen for the present work are shown in Table1.

Table 1 Levels of process parameters

Parameters

Drill angle

(DA) degrees

(A)

Drill Diameter

(DD) mm

(B)

Material

Thickness (MT

mm) (C)

Speed (N) RPM

(D)

Feed (f) m/min

(E)

Level 1

90

6

8

900

75

Level 2

103

8

10

1200

110

Level 3

118

10

12

1500

150

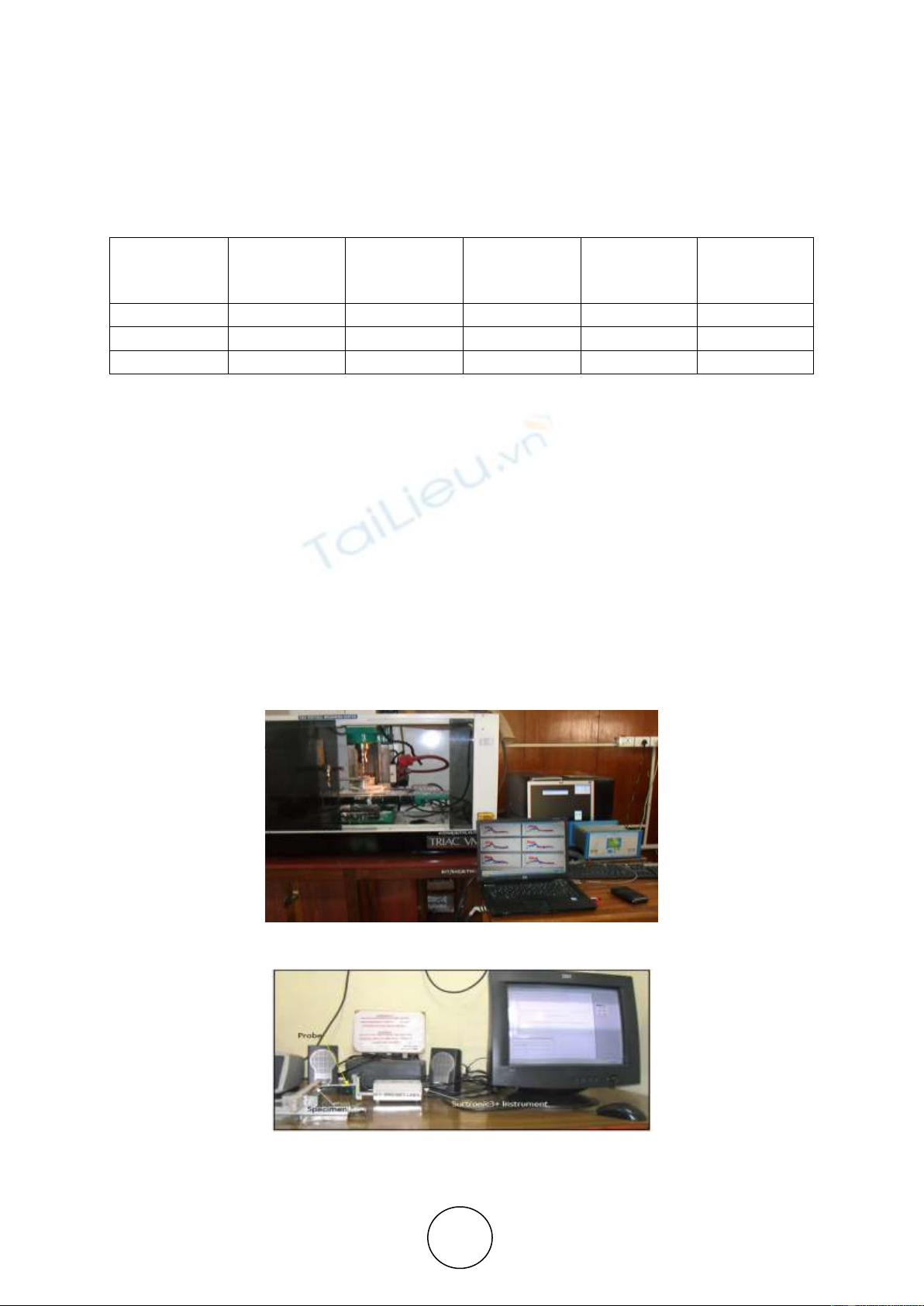

2.2. Selection of process parameters for each trial and measurement of output

parameters

The process parameters are selected according to Taguchi’s L27 orthogonal array. This array

ensures minimum number of experiments to be conducted with nearly accurate solution. The

drilling experiments were conducted on a CNC machine which is capable of drilling accurate

and precise holes. WC tool is used. The experimentation set up to drill the holes and to

measure the thrust and torque produced during the machining is process is shown in Figure 2.

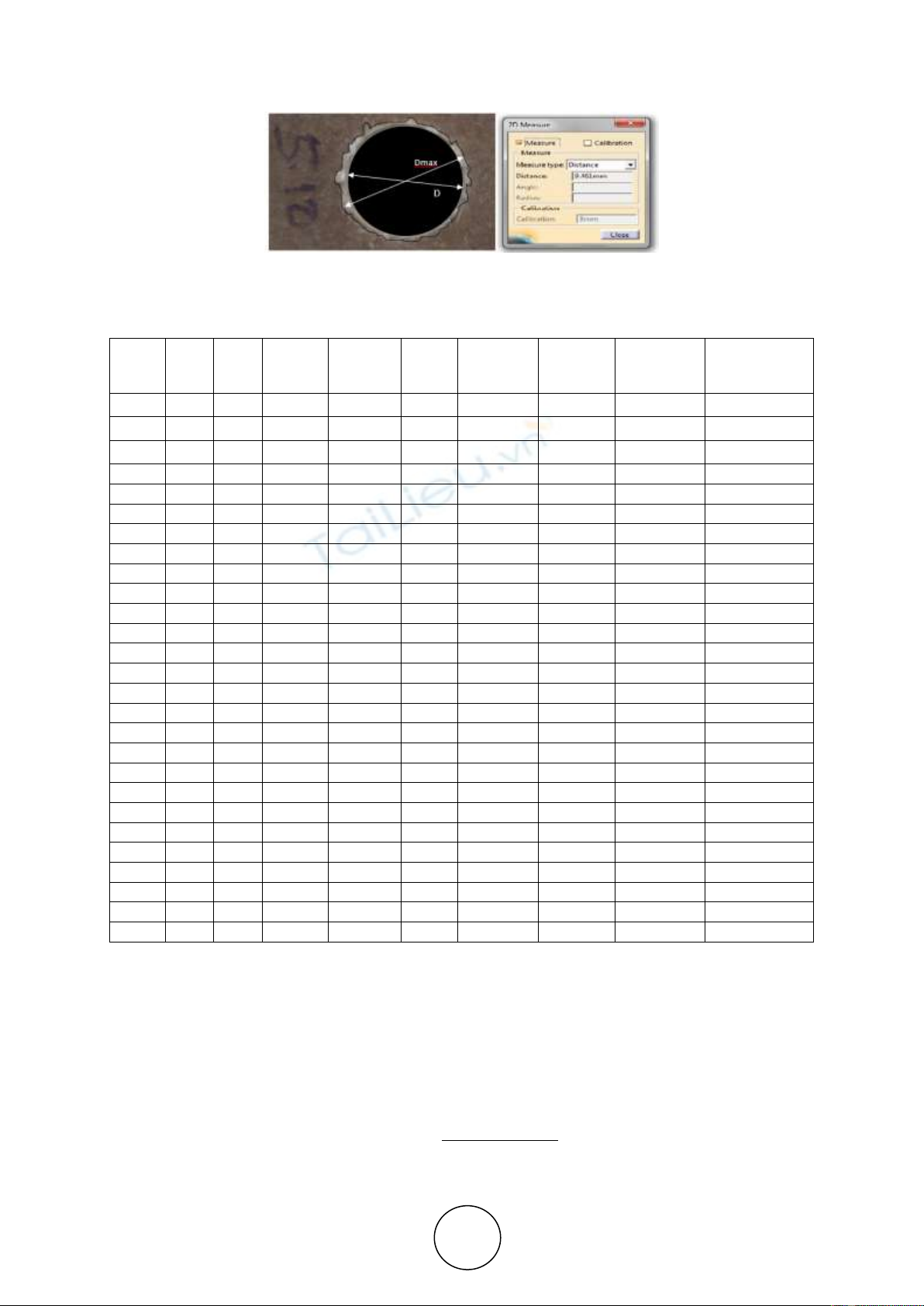

The output parameters are measured and listed as shown in table 2. The thrust force and

torque are measured using Kistler dynamometer, surface roughness using Taylor Hobson

Surtronic 3+ roughness measurement instrument and delamination factor was estimated by

taking the images of the drilled with the help of high resolution scanner and measuring the

dimensions of scanned images by using CATIA software. Arrangement made to measure

surface roughness and delamination is presented in figures 3 and 4. The measured data is

illustrated in Table 2.

Figure 2 Experimental set-up to drill the holes and to measure thrust and torque.

Figure 3 Measurement of surface roughness

Dr. Murthy BRN and Dr. Rajendra Beedu

http://www.iaeme.com/IJMET/index.asp 490 editor@iaeme.com

Figure 4 Measurement of delamination factor

Table 2 L27 orthogonal array with factors and responses

Trial

No

A

B

C

D

E

Thrust (N)

Torque

(N-mm)

Surface

Roughness

µm

Delamination

1

1

1

1

1

1

29.67

16.32

2.99

1.06

2

1

1

1

1

2

36.20

18.04

3.11

1.07

3

1

1

1

1

3

38.20

20.46

3.29

1.08

4

1

2

2

2

1

31.65

30.04

3.20

1.09

5

1

2

2

2

2

33.99

30.23

3.23

1.10

6

1

2

2

2

3

34.16

24.66

3.24

1.11

7

1

3

3

3

1

36.04

27.64

3.35

1.11

8

1

3

3

3

2

37.86

28.45

3.37

1.12

9

1

3

3

3

3

38.04

34.23

3.40

1.13

10

2

1

2

3

1

34.98

14.66

3.20

1.09

11

2

1

2

3

2

36.38

14.02

3.30

1.10

12

2

1

2

3

3

36.77

14.34

3.33

1.16

13

2

2

3

1

1

44.27

26.98

3.40

1.11

14

2

2

3

1

2

45.83

27.09

3.42

1.12

15

2

2

3

1

3

46.98

30.65

3.48

1.13

16

2

3

1

2

1

40.71

26.92

3.20

1.07

17

2

3

1

2

2

40.29

29.98

3.30

1.10

18

2

3

1

2

3

40.46

24.97

3.31

1.10

19

3

1

3

2

1

42.98

17.46

3.57

1.11

20

3

1

3

2

2

43.36

18.02

3.58

1.12

21

3

1

3

2

3

45.36

19.18

3.59

1.13

22

3

2

1

3

1

40.46

17.70

3.25

1.09

23

3

2

1

3

2

41.32

17.39

3.30

1.11

24

3

2

1

3

3

42.56

17.67

3.11

1.14

25

3

3

2

1

1

58.36

41.01

3.37

1.10

26

3

3

2

1

2

59.38

41.46

3.38

1.11

27

3

3

2

1

3

59.98

41.96

3.39

1.11

Number of replication of each factor is 1 (k=1). The responses are measured in different

units and has different ranges. For multi-response optimization, the results are brought in the

range 0 to 1 by the process called normalization. Normalisation scales down the responses in

an acceptable range for further operation.

2.3. Normalisation

The response parameter is of two types i.e, beneficiary (maximum the better) and non-

benificiery (minimum the better). For beneficiary attribute j, the normalized parameter of the

trial i and replication k is given by

and for non beneficiary attribute

Application of Grey Relational Analysis for Multi Variable Optimization of Process Parameters in

Drilling of Polymer Based Glass Fiber Reinforced Composite

http://www.iaeme.com/IJMET/index.asp 491 editor@iaeme.com

where k is the replication. In this paper all response parameters are

non beneficiary type. The actual response X ijk is modified to X’ijk which ranges from 0 to 1.

The maximum value of normalized response, irrespective of response parameter is taken as

reference value R.

R = 1.

2.4. Calculation of difference value

The difference value is calculated by, | |. The difference values arrange the

output response in the ascending order for non-beneficiary attribute. These value is used to

calculate Gray relational Coefficient

2.5. Calculation of Grey Relational Coefficient GRCijk

The Grey Relational Coefficient is calculated by the formula,

where ξ is the distinguishing coefficient ranging from 0 to 1. Generally, ξ is taken as 0.5.

2.6. Calculation of Grey Relational Grade

The average of GRC in each row is known as Grey Relational Grade . The Grey

relational grade is given by the formula, ∑ ∑

where m is the number of

response parameters and n is the number of replications (n=1).

The calculated GRG is shown in Table 3

Table 3 Orthogonal Array with Gray Relational Grades.

Trial No

A

B

C

D

E

GRG

1

1

1

1

1

1

0.67

2

1

1

1

1

2

0.58

3

1

1

1

1

3

0.50

4

1

2

2

2

1

0.53

5

1

2

2

2

2

0.51

6

1

2

2

2

3

0.47

7

1

3

3

3

1

0.46

8

1

3

3

3

2

0.45

9

1

3

3

3

3

0.47

10

2

1

2

3

1

0.48

11

2

1

2

3

2

0.44

12

2

1

2

3

3

0.38

13

2

2

3

1

1

0.48

14

2

2

3

1

2

0.47

15

2

2

3

1

3

0.47

16

2

3

1

2

1

0.58

17

2

3

1

2

2

0.51

18

2

3

1

2

3

0.48

19

3

1

3

2

1

0.42

20

3

1

3

2

2

0.41

![Bài tập tối ưu trong gia công cắt gọt [kèm lời giải chi tiết]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20251129/dinhd8055/135x160/26351764558606.jpg)