Journal of Water Resources & Environmental Engineering - No. 87 (12/2023)

9

Mechanical-microstructural characteristics

of concrete containing high volumes of coal bottom ash

Nguyen Van Dung

1*

, Mai Thi Hong

1

, Nguyen Thi Thanh

1

, Nguyen Vu Linh

1

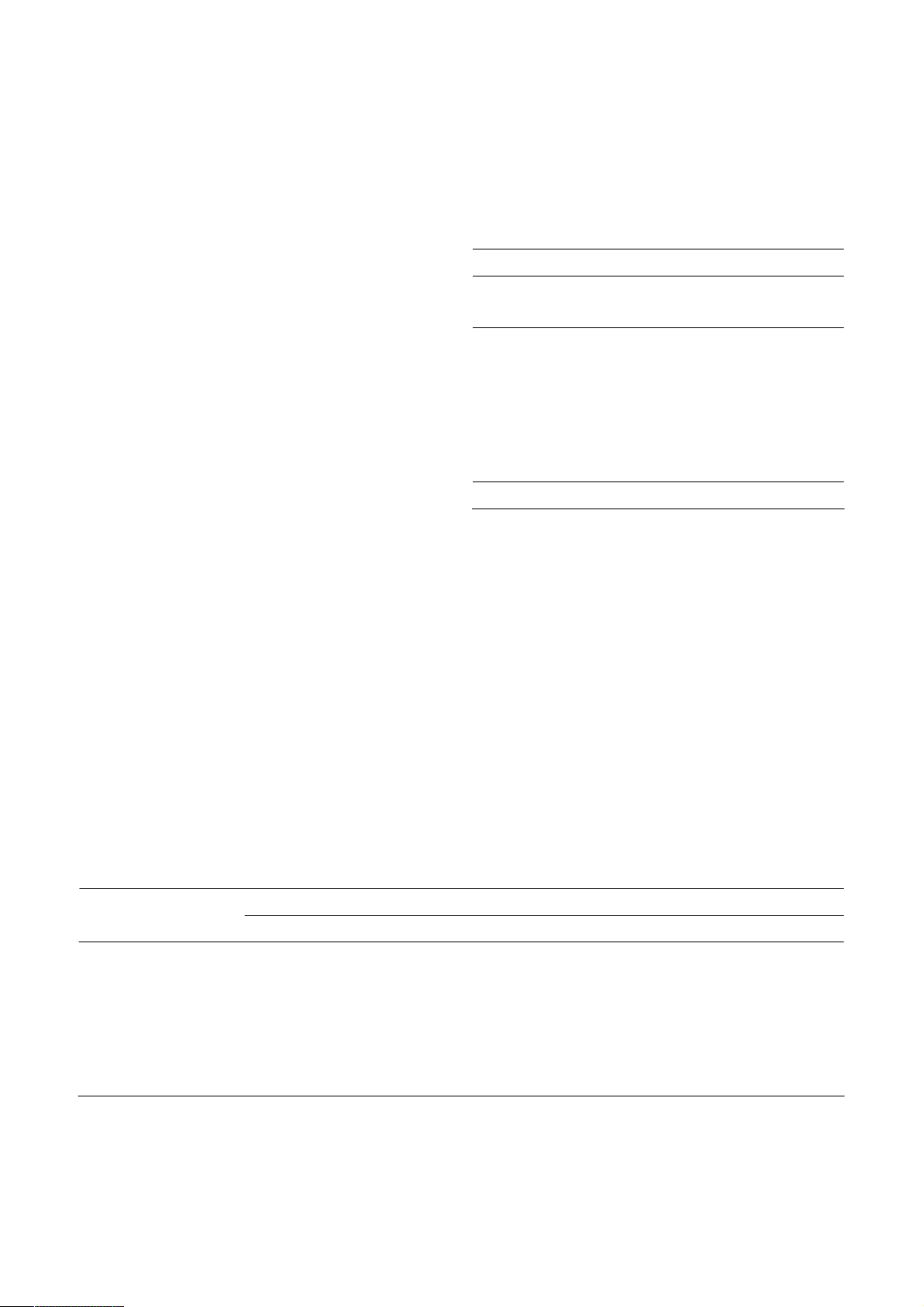

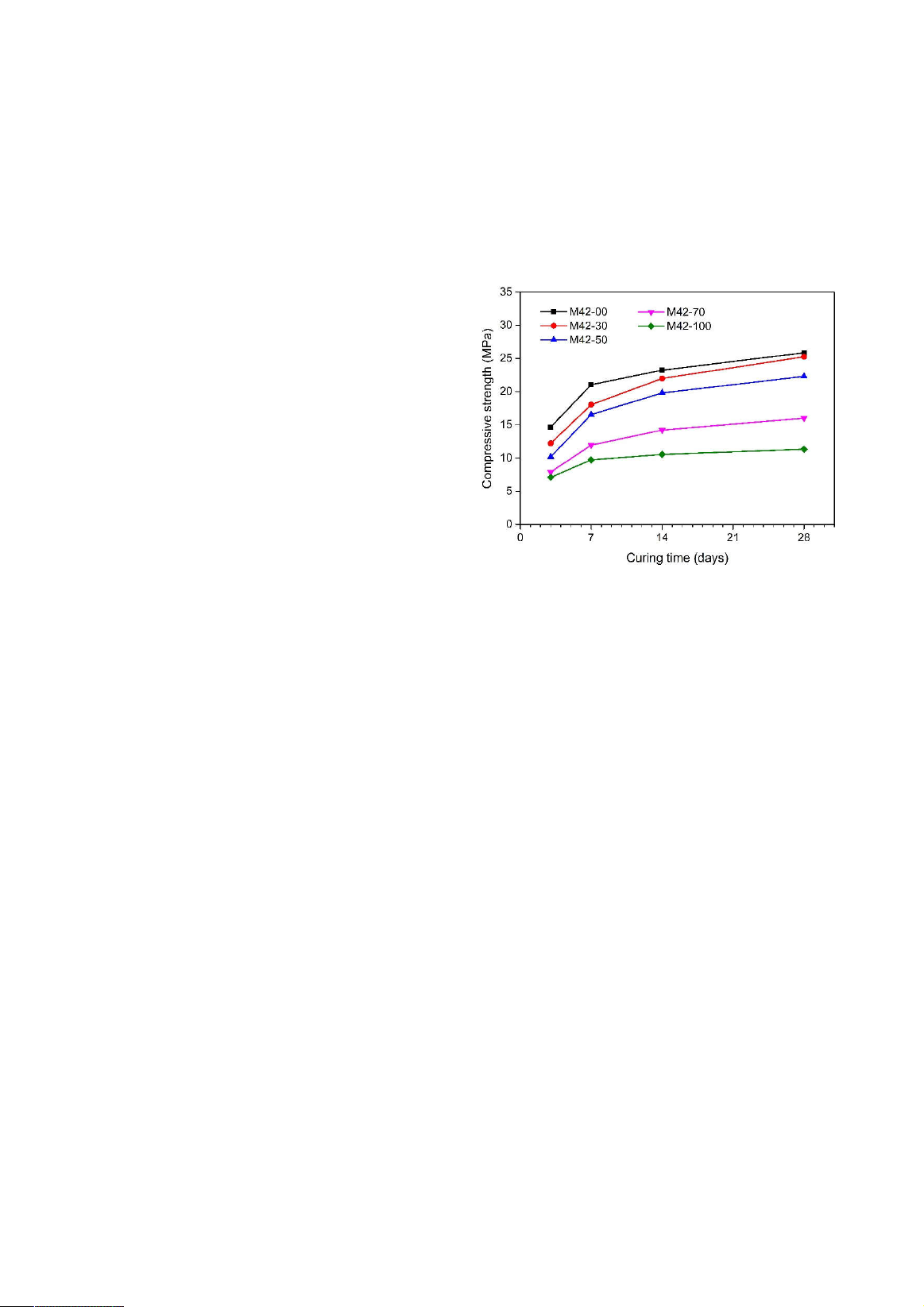

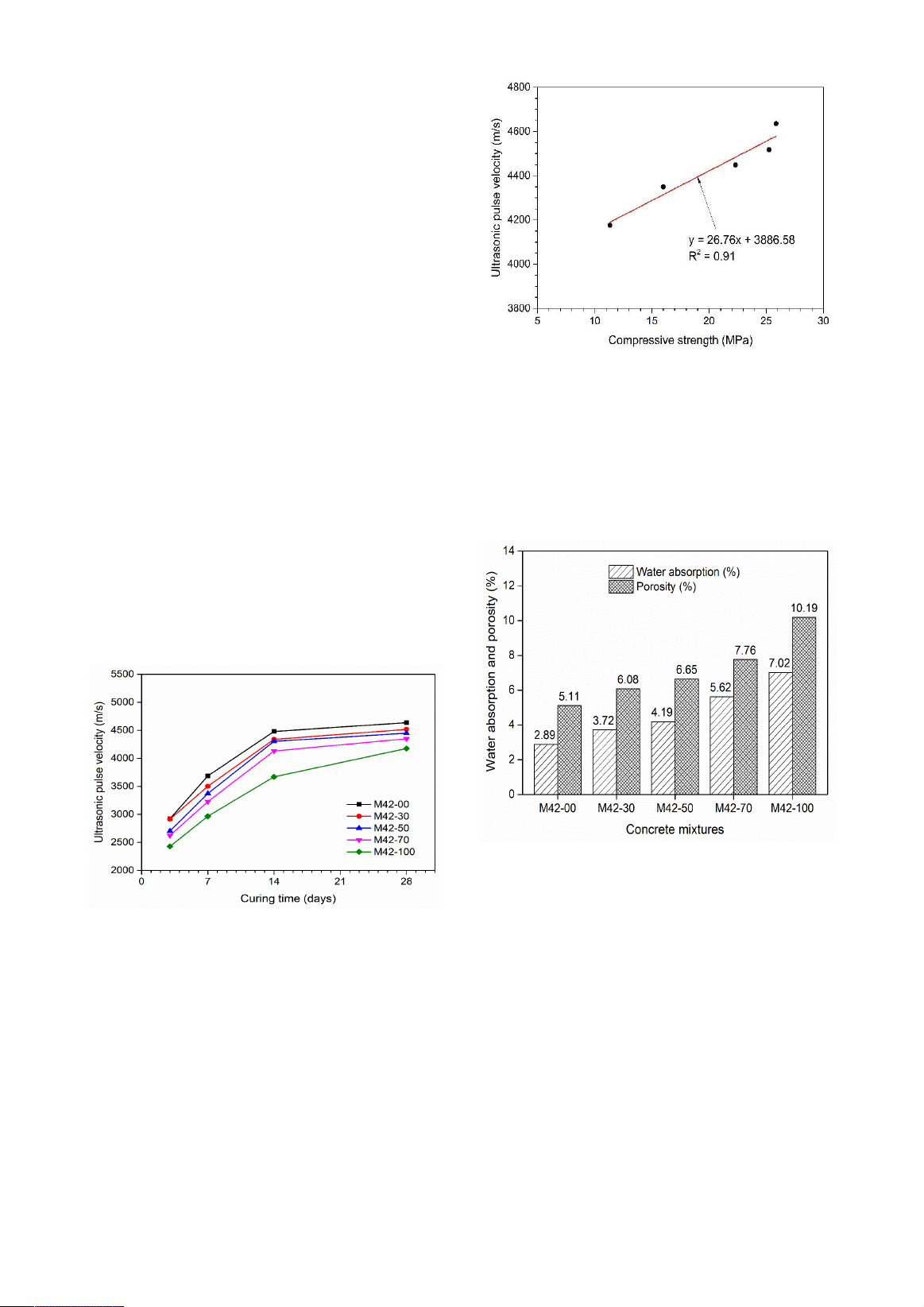

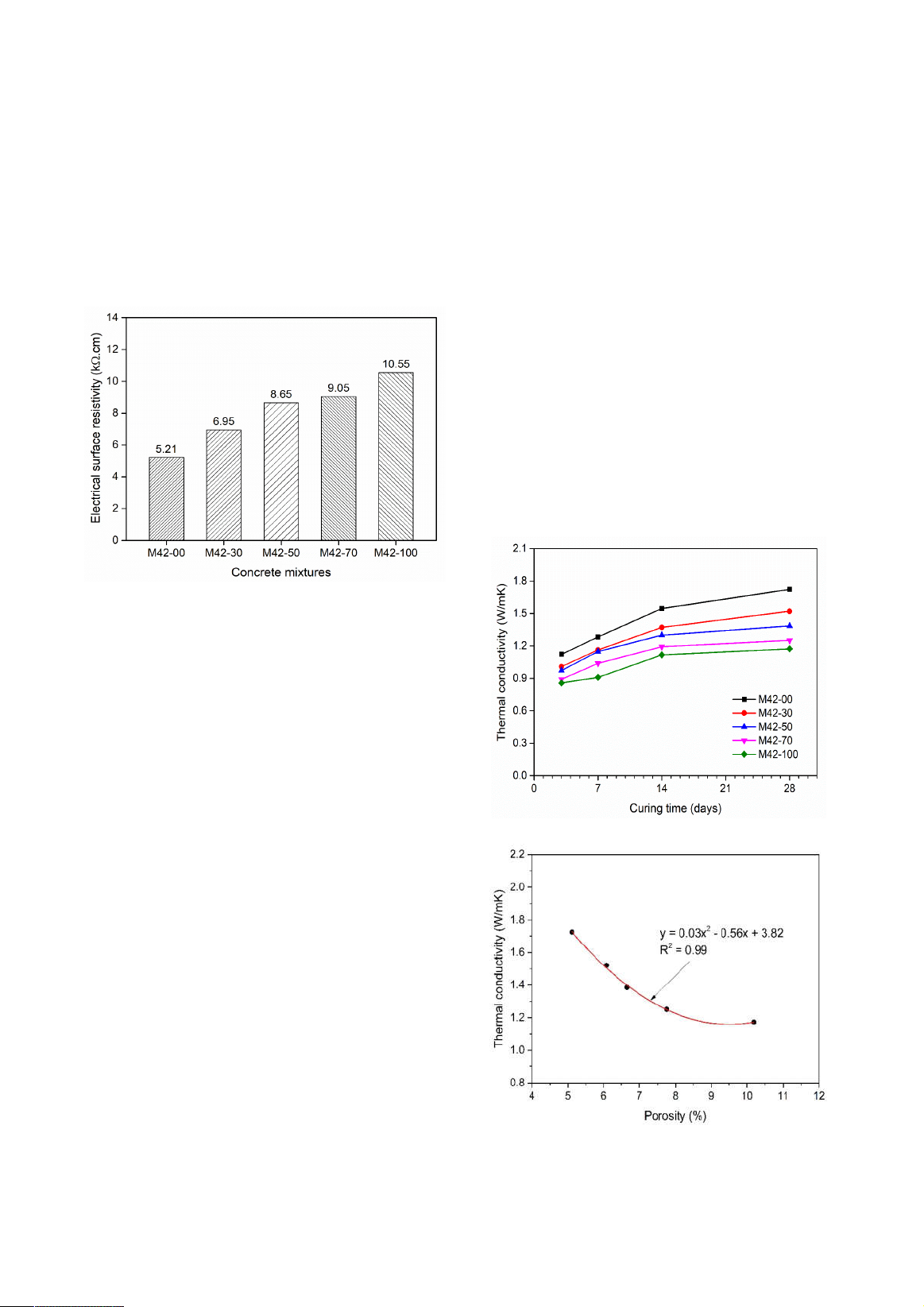

Abstract: This paper aims

to study the effect of coal bottom ash (CBA) as a fine aggregate substitution

at high levels on the mechanical properties and microstructure characteristics of concrete. CBA that

sourced from a local coal-fired power plant in Vietnam was used to replace t

he natural sand (NS) in the

concrete mixtures at different levels of 0, 30, 50, 70, and 100%. The concrete samples were prepared in

the laboratory and checked for properties through the tests of compressive strength (CS), ultrasonic

pulse velocity (UPV), w

ater absorption (WA), porosity, electrical surface resistivity (ESR), and thermal

conductivity (TC). Notably, the scanning electron microscope was also used to characterize the

microstructure of the hardened concrete. Test results show that the replacement

of NS by CBA affected

the concrete’s properties significantly. However, all of the concrete samples were classified as good

quality with the UPV, CS, WA, porosity, ESR, and TC values fell within the ranges of 4176 –

4636 m/s,

11.3 – 25.9 MPa, 2.89 – 7.02%, 5.11 – 10.19%, 5.21 – 10.55 kΩ.cm, and 1.17 –

1.72 W/mK,

respectively. Therefore, the proper quantity of CBA will be suggested depending on the requirement for

the quality of the concrete for a specific application.

Keywords: Concrete, coal bottom ash, mechanical property, durability, microstructure.

1. Introduction

*

Recently, the rapid development of the

construction industry requires a large quantity of

concrete, which is a well-known and major

construction material so far. In which, natural

aggregate such as river sand or crushed sand is one

of the main components that occupy a large

proportion of the concrete mixture. Hence, the

consumption of a large quantity of concrete requires

a considerable amount of NS every year, leading to

the depletion of this type of natural aggregate as

announcing by the local Government in Vietnam. In

addition, the over-exploitation of NS has also been

caused by many environmental issues, e.g., water

pollution, erosion, and landside, etc.

Besides, the rapid development of other

industrial activities generates a large number of

1

Hong Duc University

* Corresponding author; Email: nguyenvandung@hdu.edu.vn

Received 20

th

Jun. 2023

Accepted 28

th

Aug. 2023

Available online 31

st

Dec. 2023

different types of solid waste. In which, CBA is

one of the solid wastes that generated with a

considerable quantity by the coal-fired power

plants. In Vietnam, the Government statistic

points out that about 15 million tons of CBA are

generated in 2020. The CBA quantity will be

jumped to about 17 and 21 million tons in 2025

and 2030, respectively. It is important to remark

that the generation of such a large quantity of

CBA will cause serious pollution to the

environment if there are no sufficient treatment

methods. Thus, one of the possible ways to treat

the CBA is by turning it into construction

materials. By the way, more CBA is consumed

sufficiently.

Therefore, this paper is conducted with the

purpose of using CBA sourced from a local coal-

fired power plant in Vietnam as fine aggregate to

partially and fully replace NS in the production of

concrete. The potential of utilization and

application of CBA in concrete is evaluated

through the study of the effect of CBA on both the