TẠP CHÍ KHOA HỌC VÀ CÔNG NGHỆ, Trường Đại học Khoa học, ĐH Huế

Tập 24, Số 1 (2024)

13

REAR-SIDE INTERFACIAL MODIFICATION OF µC-SI:H(N+) BACK SURFACE

FIELD LAYERBY CONTROLLING ITS CRYSTALINE FOR SILICON

HETEROJUNCTION SOLAR CELL APPLICATIONS

Chi-Hieu Nguyen1, Truong-Tho Nguyen2, Ngoc-Toan Dang3,4,

Thanh-Thuy Trinh5,6,*, Vinh-Ai Dao7,*

1 Power Engineering Consulting Company, Southern Power Corporation,

Ho Chi Minh City, Vietnam

2 Faculty of Electronics, Electrical Engineering and Material Technology,

University of Sciences, Hue University, Vietnam

3 Institute of Research and Development, Duy Tan University,Danang, Vietnam

4 Faculty of Environmental and Natural Sciences, Duy Tan University, Danang, Vietnam

5 Department of Physics, International University, Ho Chi Minh City, Vietnam

6 VietnamNational University, Ho Chi Minh City, Vietnam

7 Department of Physics, Faculty of Applied Sciences,

HCMC University of Technology and Education, Ho Chi Minh City, Vietnam

*Email: daovinhai@hcmute.edu.vn, tttrinh@hcmiu.edu.vn

Received: 12/6/2024; Received in revised form: 13/6/2024; Accepted: 24/6/2024

ABSTRACT

In hydrogenated amorphous silicon/crystalline silicon (a-Si:H/c-Si) heterojunction

(HJ) solar cell, the high contact resistance or high Schottky barrier at the back-surface

field (BSF)/Indium Tin Oxide (ITO) is prejudicial to the majority carrier collections

process, as it degrades the fill factor (FF), which in turn, cell efficiency. To minimize

the contact resistance or Schottky barrier, high conductivity of the BSF layer is thus

required. In this study, to preserve high BSF conductivity, while without prompting

silicon dehydrate-related structural defects within the films, the high conductivity

n-type hydrogenated microcrystalline Si layer (c-Si:H(n+)), instead of standard n-

type hydrogenated amorphous silicon, was employed as a BSF layer. The film

conductivity (

d) of the c-Si:H(n+) layer was improved from 0.16 (S/cm) to 4.16

(S/cm), as the crystalline fraction (Xc) increased from 6% to 89%. It was found that

the FF tends depend on the contact resistance at the c-Si:H(n+)/ITO interface, in

defiance of Schottky contact behavior. Thus, series contact resistance dominates the

FF of the device; this finding is opposite to previous report. Using a moderated

Rear-side interfacial modification of µc-Si:H(n+) back surface field layerby controlling its crystaline…

14

crystalline fraction of 60% c-Si:H(n+)-BSF, the photovoltaic parameter of the a-

Si:H/c-Si HJ solar cells yielded an open-circuit voltage of up to 700 mV, in turn giving

an efficiency >20%.

Keywords: passivation, back-surface field, heterojunction, silicon solar cell, µc-

Si:H(n+).

1. INTRODUCTION

Currently, industrial solar cell technology tends toward thinner wafers, thus,

hydrogenated amorphous silicon/crystal silicon (a-Si:H/c-Si) heterojunction (HJ) solar

cells are a focus of interest due to their low-temperature production process (~200C)

and high efficiency of 25.1% [1]. This low-temperature process enables use of

inexpensive, low-quality wafers and reduces the probability of wafer bowing and

breakage [2]. One of the well-known criterion factors for the high performances of a-Si:H/c-

Si HJ solar cells is an excellent surface passivation at the a-Si:H/c-Si heterointerface by

using an intrinsic hydrogenated amorphous silicon (a-Si:H(i)) passivated layer [3].

In addition, to produce high-performance a-Si:H/c-Si HJ devices, the front- and

back-inverted Schottky junction and/or contact resistance should also be minimized [4].

At the back-surface field (BSF)/Indium Tin Oxide (ITO), to promote carrier collections,

an inverted Schottky junction, which is formed due to the work-function discrepancy between

the ITO and the BSF layer must be minimized [5]. To reduce this inverted Schottky junction,

the conductivity of the BSF must be sufficient high to preserve a flat band at the BSF/ITO

interface [6]. Generally, high conductivity is realized by using the high doping

concentration. This increased dopant, however, leads to structural defects within the

film, as a result the open-circuit voltage (Voc) and the fill factor (FF) of the devices are

reduced, as mentioned elsewhere [7]. To compromise between the structural defects and

the conductivity within the films, the stacked-configuration was implementation for the

emitter [8] and also for the BSF layer [7]. This realization shown potential high Voc and

FF as well, compared to standard-configuration. The improvement in Voc and FF was

ascribed to not only the improved a-Si:H/c-Si interface passivation, owing to low doped

layer, which served as a passivated layer, in the stacked-configuration, but also high

conductivity, owing to the high doped layer, which served as a contacted layer to the

ITO, in the stacked-configuration [8]. On the other hand, Ghafarokhi et al., suggested to

improve the electrical conductivity of the emitter via the evolution of the film

crystallinity, which obtained by increasing film thickness. This advance could lead to a

lower Schottky barrier [9]. The lower Schottky barrier height may promote carrier

collection more efficienctly, hence, FF will be improved; nevertheless, this thicker emitter

(p-type c-Si) could cause higher photon absorption, and consequently lower short-circuit

current density (Jsc). Thus, although there has been research studying the optimization of

TẠP CHÍ KHOA HỌC VÀ CÔNG NGHỆ, Trường Đại học Khoa học, ĐH Huế

Tập 24, Số 1 (2024)

15

the emitter layer to achieve low contact resistance and/or Schottky barrier, similar work

for ITO/BSF interface has not been extensively carried out, beside S. Martín de Nicolás

et al. [7] and T. Watahiki et al. [10].

For the aim of obtaining a high conductivity of the film, less detrimental influence

of the a-Si:H/c-Si heterointerface, while without introducing structural defects, within

the film, especially, without detrimental influence influence of the Jsc of the devices, an

approach that is similar to Ghafarokhi et al., was realized in this study, except the doped

layer we used in our study is of n-type c-Si, which is used as a BSF in the BSF/ITO

heterointerface. With this advancement, the Voc and FF of the device showed

improvement, while it did not adversely affect the Jsc.

2. EXPERIMENTAL DETAILS

Czochralski-grown n-type c-Si [CZ c-Si(n)] wafers (1 – 10 cm, 525 m thick,

<100> oriented) were used as an absorber material. To remove organic and inorganic

residues, the wafers were first treated in sequentially with acetone, methanol, de-ionized

water, and RCA (1, 2). Immediately before loading into the chamber, the wafers were

immersed in 1% hydrofluoric acid for 1 min to remove natural native oxide. At the front-

surface of the wafers, the a-Si:H(i) and then p-type a-Si:H (a-Si:H(p)) layers were

deposited in sequence. At the rear-surface, the a-Si:H(i) layer and c-Si:H(n+)-BSF, have

different crystallinity, were deposited. The thickness of the a-Si:H(i), a-Si:H(p) layers

were fixed at 5 and 7 nm, respectively, while the thickness of the c-Si:H(n+)-BSF was

varied to alter film crystallinity. A sputtered ITO layer, 80 5 nm thick and 0.6 0.6 cm

in dimensions, was formed by placing a metal mask directly on the a-Si:H(p) surface.

Finally, Al/Ag electrodes were formed as fingers by thermal evaporation, while the

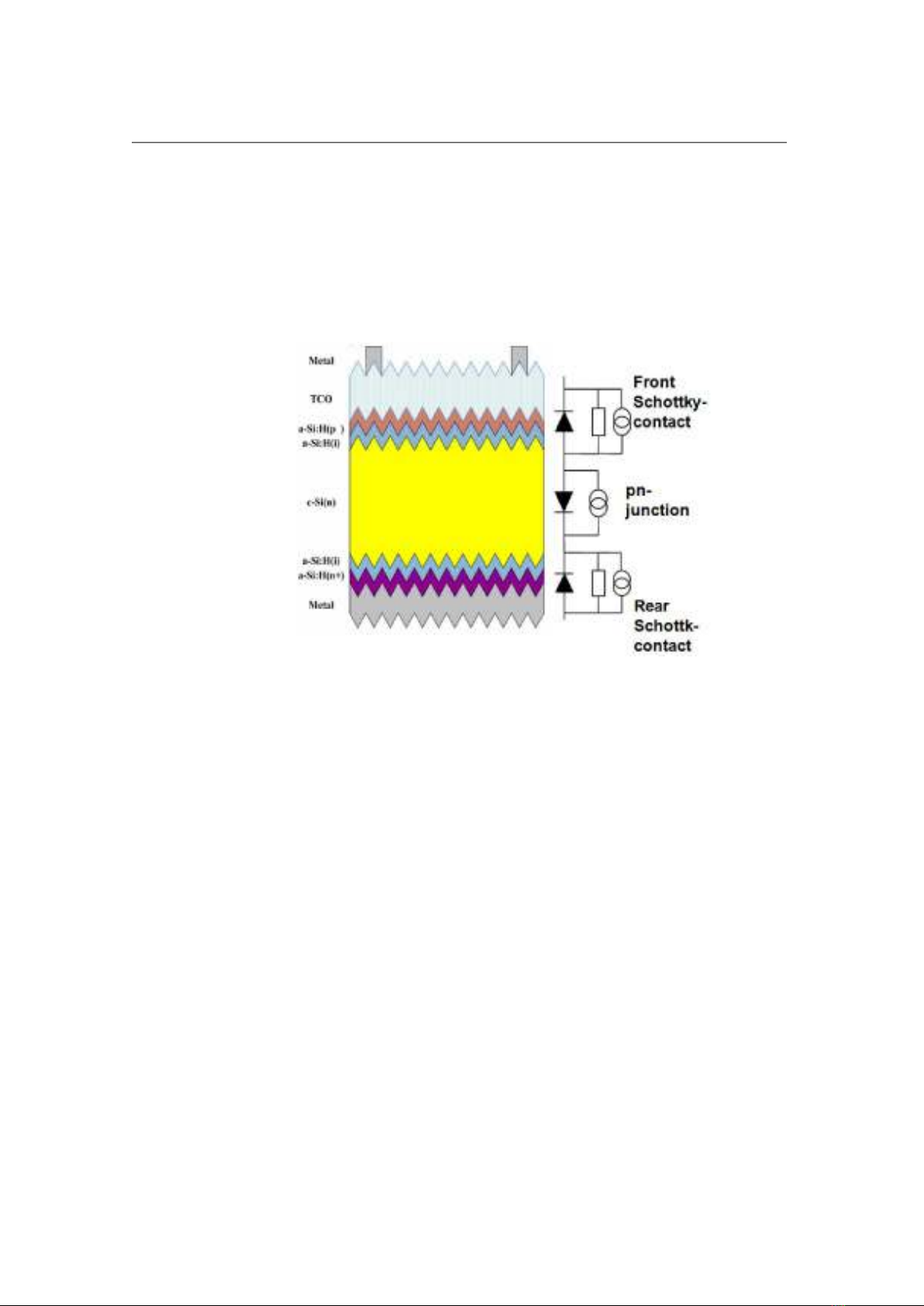

entire rear-surface was covered with ITO/Al as a back-contact. A schematic diagram of

the a-Si:H/c-Si heterojunction solar cell is shown in Fig. 1.

Film thickness was measured using spectroscopic ellipsometry (VASE, J. A.

Woollam, 240 nm < < 1700 nm) at room temperature. Then, the optical constant of each

layer was deduced using the Tauc-Lorentz equation combined with the Bruggemen

effective medium approximation (BEMA) model by comparing the ellipsometry of tan

and cos between the empirical and the theoretical models. To estimate the film

crystallinity, Raman spectroscopy (Ramboss 500i, Dongwoo optron, 514.5 nm laser line)

was performed at room temperature. A programmable Keithley 617 electrometer was

employed to measure the dark conductivities (d) of the films deposited on glass with

co-planar contact geometry. The passivation properties of the ITO/a-Si:H(p)/a-Si:H(i)/c-

Si(n)/a-Si:H(i)/c-Si:H(n+)/ITO HJ structures, such as minority carrier lifetime (

eff) and

implied voltage (iVoc), were measured using the characteristic quasi-steady state photo

conductance decay (QSSPC) method (WCT-120). The external voltage value (extVoc) and

Rear-side interfacial modification of µc-Si:H(n+) back surface field layerby controlling its crystaline…

16

pseudo-FF (pFF) of the completed devices were extracted from the series resistance-free

I-V characteristic using the Sinton Instruments Suns-Voc. The device characteristics, such

as Voc, Jsc, FF, and conversion efficiency, were determined based on current-voltage

measurements under Air Mass 1.5 Global (100 mW/cm2, AM 1.5 G) at 25C. The

equilibrium schematic band diagram of the c-Si(n)/c-Si:H(n+)/ITO heterojunction was

realized using the automat for the simulation of heterostructure (AFORS-HET)

simulation software [11].

Figure 1. Schematic diagram of the a-Si:H/c-Si HJ solar cell.

3. RESULTS AND DISCUSSION

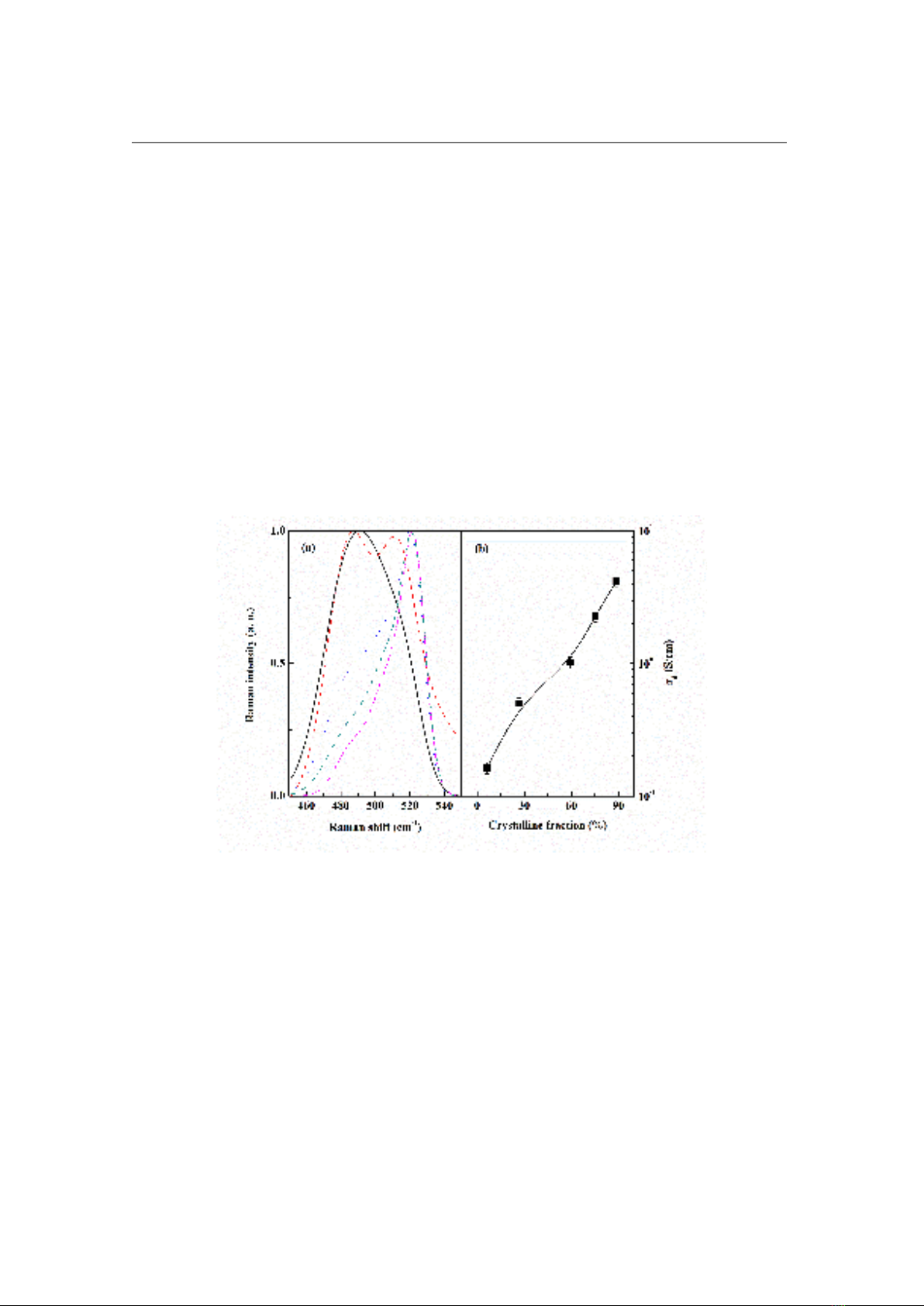

The normalized Raman spectra of the µc-Si:H(n+) layers, having a thickness in

the range 10 to 120 nm, deposited on a glass substrate are shown in Fig. 2(a). As can be

seen in Fig. 2(a), the peak intensity variation at 520 cm-1 becomes more pronounced with

increasing layer thickness. The variation in peak intensity could, hence, be related to a

higher crystalline fraction (Xc) within the films, as seen in Table 1; here, Xc was estimated

from normalized Raman spectra as described in [12]. The d respective to film

crystallinity of the µc-Si:H(n+) films was measured and shown in Fig. 2(b). It can be seen

that d increases by 26 orders of magnitude with increasing µc-Si:H(n+) crystallinity

fraction, where, the d of the c-Si:H(n+) increased from 0.16 (S/cm) to 4.16 (S/cm), with

the increases in the Xc from 6% to 89%. This result can be ascribed to the improvement

in the crystallinity fraction within the films, resulting in an evolution grain size, which,

in turn, improves carrier transportation [9].

Fig. 3 depicts the

eff of an ITO/a-Si:H(p+)/a-Si:H(i)/c-Si(n)/a-Si:H(i)/µc-

Si:H(n+)/ITO HJ structure, which the µc-Si:H(n+) properties were shown in Fig. 2. Our a-

Si:H/c-Si HJ structure showed decreasing

eff in the entire range of injection-levels of the

TẠP CHÍ KHOA HỌC VÀ CÔNG NGHỆ, Trường Đại học Khoa học, ĐH Huế

Tập 24, Số 1 (2024)

17

excess carrier density with increasing crystallinity fraction. Generally, two types of

surface passivation mechanism are suggested to be the roles: field-effect passivation,

which is indicated by excess carrier lifetime at low injection level and neutralization of

the defects of interface states, which is indicated by excess carrier lifetime at high

injection level [13]. As is well-known, at low level of carrier injection, the high film

conductivity can produce more electron concentrations within the film, resulting in

reducing Schottky-contact at the c-Si:H(n+)/ITO interface, which induced improve field-

effect passivation, as in turn, increasing

eff . It is observed that our data is in contrast to

those reported elsewhere [14], and also, contrary to our expectations, as aforementioned.

In this study,

eff shown decreased with increasing film conductivity in a low level of

injected excess carrier density. Thus, the field-effect passivation was not contributed to

the c-Si surface passivation in this investigation. Hence, only one passivation mechanism

was observed; i.e., reduction of interface defect density due to neutralization of the

defects of interface states.

Figure 2. a) Normalized Raman spectra of c-Si:H(n+) layers. Black-solid: 10 nm, red-dash: 20

nm, blue-dot: 40 nm, dark cyan-dash-dot: 70 nm, and magenta-dash-dot-dot: 120 nm. b)

Variation in room temperature dark conductivity of c-Si:H(n+) layers due to variation in the

thickness.

Film microstructure was performed to gain insight into the passivation

mechanism. The empirical spectroscopic ellipsometric data concerning the optical

constant were fitted based on the Tauc-Lorentz equation combined with the BEMA

model. The fitted results are shown in Table 1. With decreasing film crystallinity, the

values of A show a decrease, while the values of C show an increase, leading to low

density, high disorder and high hydrogen content within the films [14], where A and C

is the amplitude and the broadening parameter of the imaginary part of the dielectric

![Ảnh hưởng của chiều dày lớp Cu lên tương tác trao đổi và tính chất từ trong van spin dị hướng vuông góc [Co/Pd]: Nghiên cứu màng mỏng đa lớp](https://cdn.tailieu.vn/images/document/thumbnail/2024/20241011/vifilm/135x160/2791728643263.jpg)

![Bộ câu hỏi lý thuyết Vật lý đại cương 2 [chuẩn nhất/mới nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20251003/kimphuong1001/135x160/74511759476041.jpg)

![Bài giảng Vật lý đại cương Chương 4 Học viện Kỹ thuật mật mã [Chuẩn SEO]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20250925/kimphuong1001/135x160/46461758790667.jpg)