Comparative study of degumming of silk varieties by different techniques

Shweta K. Vyas and Sanjeev R. Shukla*

Department of Fibres & Textile Processing Technology, Institute of Chemical Technology (University under Section 3 of UGC Act

1956), Mumbai, India

(Received 15 September 2014; accepted 26 January 2015)

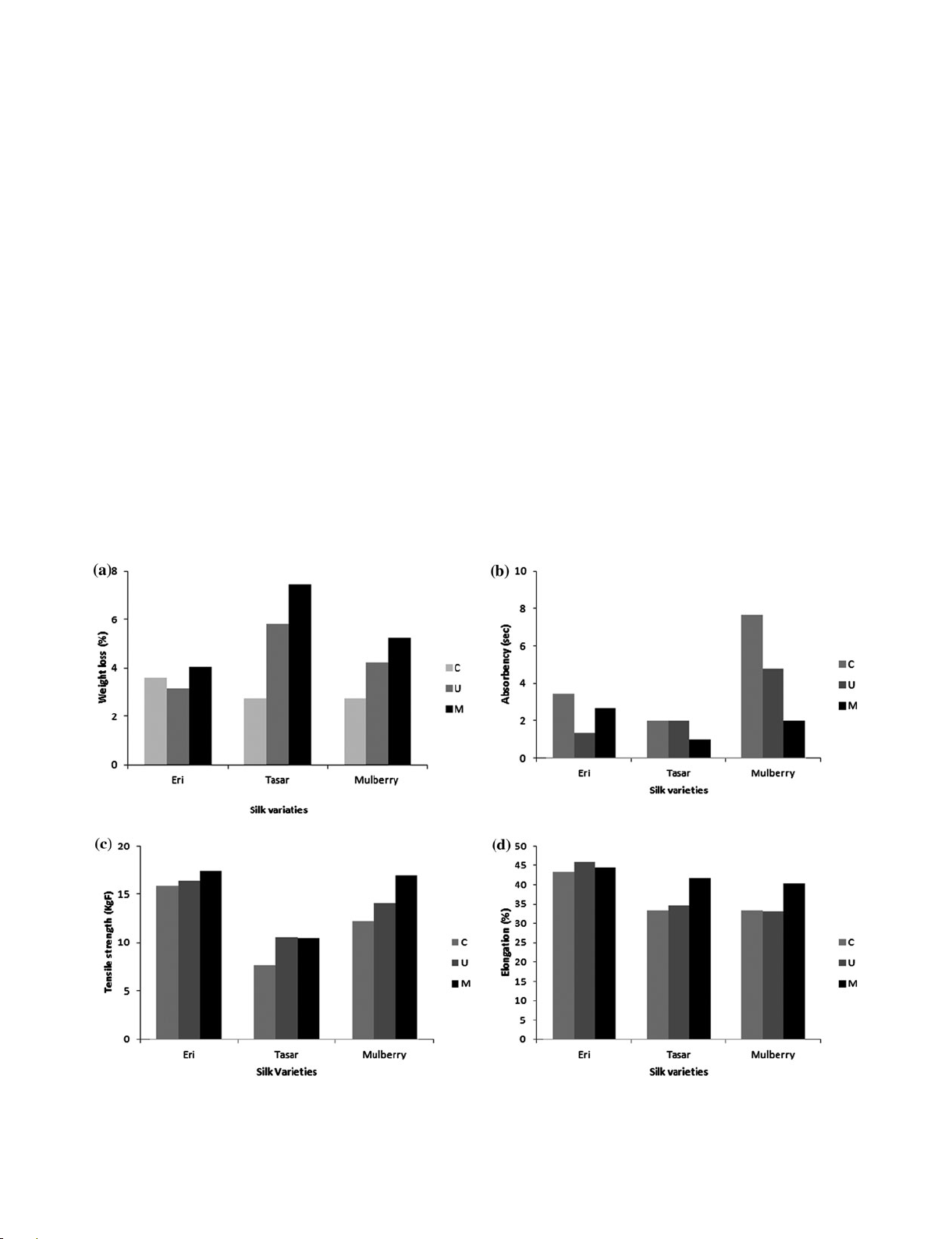

Different varieties of silk differ from each other in their chemical composition as well as the physical, chemical and

mechanical properties. Silk degumming is a primary important process, which needs to be carried out uniformly to a

sufficient level to get good quality in further processes such as dyeing. In the present study, we have compared the

efficiencies of five different degumming treatments for eri, tasar and mulberry silk fabrics using conventional, ultrasonic

and microwave techniques. Among the various treatments, soda ash plus hydrogen peroxide and enzyme (papain)

degumming recipies gave the best results in terms of weight loss and absorbency. As compared to the conventional

technique, the treatments under ultrasonication and microwave enhanced the efficiency. The microwave technique was

found to be superior, with the advantage of drastic reduction in treatment time, better retention of tensile strength and

smooth appearance of silk. The dye uptake also increased after degumming. The molecular conformation of the different

silk varieties, as estimated by FTIR spectroscopy, and the crystalline structure, as elucidated by X-ray diffraction,

remained unchanged. SEM showed distinct morphological changes on degumming.

Keywords: silk varieties; degumming processes; ultrasonication; microwave; FTIR; XRD; SEM

Introduction

Silk is a unique natural protein filament fibre produced

by sericigenous insects. It is one of the world’s most

exclusive and luxurious fibres. Silk is categorized into

mulberry or domesticated silk and non-mulberry or wild

silk like muga, eri and tasar. Eri silk, also known as

‘Ahimsa Silk’in India and produced by the worm

Philosamia ricini, is a secretion of a lepidopteran insect

Samia ricini and it is available in the north-east region

of India, particularly Assam. Tasar silk is produced by

the worm Antheraea mylitta, whereas mulberry silk is

produced by the worm Bombyx Mori and it is available

in Andhra Pradesh, Karnataka, Tamil Nadu and West

Bengal (Kariyappa, 2008). Although labelled as ‘silk’,

their characteristic properties differ widely, and hence a

comparison of their processing is necessary for obtaining

desired optimum performance.

The silk fibre is composed of two cores of fibroin

surrounded by a layer of sericin in a structure known as

a bave (each individual fibroin core is known as a brin)

(Pérez-Rigueiro, Viney, Lorca, & Elices, 2000). Fibroin

is the structural protein of silk fibre, whereas sericin is

the water-soluble proteinaceous glue that serves to bond

the fibres together. The majority of fibroin’s composition

contains amino acids with bulkier side chains. The

sericin content of mulberry is 20–30%, tasar of 7–15%

and that of eri silk is as low as 7–12%, since most of it

gets removed during the cooking of cocoons (Srisuwan,

Narkkong, & Srihanam, 2009). The composition of the

fibroin is glycine, alanine and serine; and that of sericin

is serine, aspartic acid and glycine, with threonine

present in significant amounts.

Degumming and bleaching are the important

treatments of silk processing. The presence of gum

sericin makes the silk harsh and stiff, and masks its

natural lustre. Degumming is a process of cleavage of

peptide bonds of sericin by hydrolysis or enzyme action

(Chopra, Chattopadhyay, & Gulrajani, 1996). The

recommended standard method of degumming is based

on Marseilles soap, which is prepared from olive oil.

However, degumming of silk has been carried out

conventionally by soap–soda ash method and it is

considered the best, although it has the drawback of

some fibre degradation leading to dull appearance and

loss in tensile strength. Furthermore, studies have been

reported on the removal of sericin by different types of

enzymes (Freddi, Mossotti, & Innocenti, 2003; Gulrajani,

Gupta, Gupta, & Suri, 1996). Organic acids have been

attempted as alternative agents due to their milder action

to overcome the problems present in traditional

degumming process. Degumming of silk fabric with

tartaric acid showed excellent performance, in terms of

silk sericin-removal efficiency (Freddi, Allara, &

Candiani, 1996; Khan et al., 2010).

The work reported here aims to compare the

efficiencies of degumming, bleaching and dyeing

*Corresponding author. Email: srshukla19@gmail.com

© 2015 The Textile Institute

The Journal of The Textile Institute, 2015

http://dx.doi.org/10.1080/00405000.2015.1020670

Downloaded by [Florida Atlantic University] at 00:52 10 September 2015