Application Device Power Output Input Voltage Output Voltage Topology

Audio PKS607YN 75 W, 126 W Peak 195 - 265 VAC ±26 V, ±15 V, 5 V Flyback

DI-148 Design Idea

PeakSwitch

www.powerint.com February 2008

Multiple Output Flyback Power Supply for Audio Amplifi er

Using Magnetic Amplifi ers to Achieve Better Cross Regulation

®

Design Highlights

Effectively replaces linear transformer-based power supplies in

home audio applications

Dramatically reduces weight, allowing chassis cost reduction

Proprietary magnetic amplifi er (mag amp) approach enables

tight cross regulation of two main outputs in fl yback topology

Low component count, compact and light weight.

Energy effi ciency

>82% effi ciency at full load

<800 mW no-load power consumption at 265 VAC

Reduces heat sink requirements and eliminates need for

separate standby supply

Excellent transient response – improves audio quality

Integrated frequency jittering, together with a simple EMI fi lter,

allows for CISPR-22/EN55022B conducted EMI compliance

(see Figure 2)

Integrated safety/reliability features:

Accurate, auto-recovering, hysteretic thermal shutdown func-

tion maintains safe PCB temperatures under all conditions

Latching shutdown protects against output short circuits and

open feedback loops

•

•

•

•

•

•

•

•

•

•

•

•

•

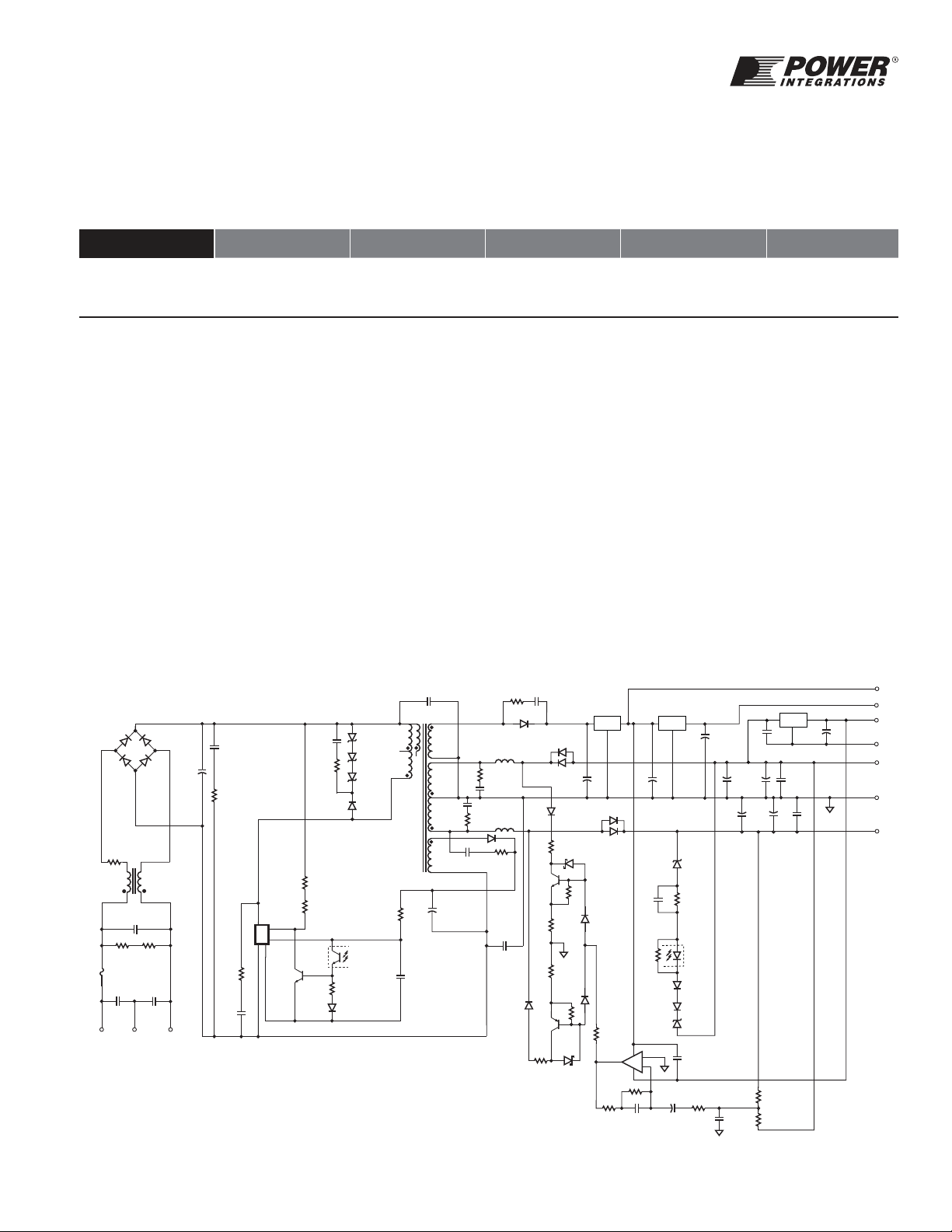

Figure 1. Schematic of a 75 W Continuous and 126 W Peak Audio Amplifi er Power Supply.

Operation

The universal input power supply shown in Figure 1 has multiple

outputs, ±26 VDC, ±15 VDC, and +5 VDC. The ±26 V outputs

can each deliver a minimum output current of 2.42 A peak (ther-

mally limited) and 1.45 A continuous. Additionally, the voltage

regulation and, importantly, transient response is excellent over the

entire load range (no-load to full load).

The controller in U1 skips switching cycles to regulate the output

voltage, based on feedback to its EN/UV pin. When the current

pulled out of this pin exceeds 240 µA, a low logic level (disable) is

generated. At the beginning of each cycle, the EN/UV pin state is

sampled, and if high, the power MOSFET is turned on for that

cycle (enabled); otherwise the power MOSFET remains off

(disabled). During start-up, switching is inhibited until the input

voltage is above the under-voltage threshold, determined when a

current >25 µA fl ows into the EN/UV pin.

D6

D3 1N4148

UF4002

C5

47 uF

C48

33 pF

1 kV

35 V

R16

68 1/2 W

C23

C26

100 F

25 V

C19

100 F

25 V

C49

470 pF

100 V

C27

47 F

10 V

C20

680 nF

50 V C28

100 F

25 V

C16

680 nF

50 V

C15

680 nF

50 V

C11

330 F

50 V

C10

330 F

50 V

R21

130 U2A

PC817D

C46

47 F

10 V

C37

10 nF

50 V

C35

220 nF

50 V

U7A

LM358P

C39

1 nF

50 V

R30

49.9 k1%

R50

10 R32

1 kR27

1 kR45

2.7 kR46

5.1 k1/8 W

R23

510 R24

510 R48

5.1 k1/8 W

R47

2.7 kR52

68 k1/2 W

R53

68 k1/2 W

R31

49.9 k1%

R43

1 kD19

1N4148

D21

1N4148

D20

SB160

D5

BYV32-

200

D9

BYV32-

200

D13

BAV20

D18

SB160

D12

BAV20

D11

1N4148

D10

1N4148

VR5

1N5254B

27 V

C34

100 nF

50 V

VR4

1N5253B

25V

C13

330 F

50 V

C14

330 F

50 V

330 pF

N.C.

T1

EER28

4

8,9

5

7

1

2,3

6

12

C47

1 nF

50 V

R5

2M

VR1

P6KE91A

R3

4.7 kR4

2M

D2

UF4005

C4

330 nF

R6

1501/2 W

C6

470 pF

1kV

C8

2.2 nF

250 VAC

U2B

PC817D

C7

4700pF

1kV

R49

10 1/2 W

R51

100 1/2 W

R7

2.2 C9

2.2 nF

250 VAC

VR2

R1

1.3 MC17

220 pF

250 VAC

C45

100

F

400 V

C1

275 VAC

330 nF

R2

1.3 M

D7-8,D16-17

1N4007

D22

1N4148

F1

C18

220 pF

250 VAC

L1

10 mH

3.15 A

NPEL

tO

P6KE91A

U1

PKS607YN

PeakSwitch

RT1

VR3

P6KE91A

10

11

3

2

L2

MP1305

PI-4884-021108

15 V, 150 mA

5 V, 150 mA

26 V, 1.45 A

195 - 265

VAC

-26 V, 1.45 A

RTN

RTN

-15 V, 150 mA

R44

100 kR26

2 kQ2

MPSA42

Q3

2N3904

U8

LM7915

U5

LM78L05

U6

UA7815

IN OUT

GND

IN OUT

GND

IN OUT

GND

Q1

2N5401

D

S

EN/UV

BP

GND

L3

MP1305

C50

470 pF

100 V

Power Integrations

5245 Hellyer Avenue

San Jose, CA 95138, USA.

Main: +1 408-414-9200

Customer Service

Phone: +1-408-414-9665

Fax: +1-408-414-9765

Email: usasales@powerint.com

On the Web

www.powerint.com

A

02/08

Power Integrations reserves the right to make changes to its products at any time to improve reliability or manufacturability. Power

Integrations does not assume any liability arising from the use of any device or circuit described herein. POWER INTEGRATIONS

MAKES NO WARRANTY HEREIN AND SPECIFICALLY DISCLAIMS ALL WARRANTIES INCLUDING, WITHOUT LIMITATION, THE IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, AND NON-INFRINGEMENT OF THIRD PARTY RIGHTS.

The products and applications illustrated herein (transformer construction and circuits external to the products) may be covered by

one or more U.S. and foreign patents or potentially by pending U.S. and foreign patent applications assigned to Power Integrations.

A complete list of Power Integrations' patents may be found at www.powerint.com. Power Integrations grants

its customers a license under certain patent rights as set forth at http://www.powerint.com/ip.htm.

The PI logo, TOPSwitch, TinySwitch, LinkSwitch, DPA-Switch, PeakSwitch, EcoSmart, Clampless, E-Shield, Filterfuse, StackFET,

PI Expert and PI FACTS are trademarks of Power Integrations, Inc. Other trademarks are property of their respective companies.

©2007, Power Integrations, Inc.

DI-148

The primary feedback circuit is closed across the ±26 V (52 V)

outputs via VR4, U2A and VR5. This ensures that the sum of

voltages across the ±26 V outputs is regulated. For improved

cross-regulation, two separate magnetic amplifi ers (mag amps)

are used on the ±26 V outputs. A mag amp is a saturable reactor

or inductor that uses a core material that has a rectangular B-H

curve. Adjusting the current (magnetic fl ux) in the mag amp

adjusts the period that it blocks current fl ow.

Here two magnetic amplifi ers (L2 and L3) are used for improved

cross regulation. This is especially relevant for audio designs as

power is drawn from the supply at audio frequencies. The highest

output power component occurs at lower frequency where current

is alternately drawn from each output but not simultaneously.

By adjusting the current in L2 and L3, the circuitry formed by U7A,

Q1 and Q2 determines the proportion of the energy stored in the

transformer that is delivered to the +26 V and -26 V outputs

during the off time of the PeakSwitch internal MOSFET. At the

extreme, with one output fully loaded and the other at no-load,

almost all the energy is delivered to the output under full load.

Importantly, both outputs cannot be simultaneously blocked,

which would cause excessive clamp dissipation. Even with very

large load transients 25%-100% that are common in audio

supplies, the output regulation is maintained within ±5% on both

outputs.

Common mode choke, L1, and the two Y-capacitors, C8 and C9,

form the common mode EMI fi lter. Common mode choke L1 also

works in conjunction with X-capacitor C1 to provide differential

mode EMI fi ltering.

Key Design Points

The high crest factor of the music source allows physically

smaller heatsinks.

The auxiliary ±15 VDC and +5 VDC outputs are obtained from

a linear regulator. To limit the power dissipation in the (5 V and

15 V) linear regulators, a second 18 V output was added to

transformer T1.

As the value of X capacitor C1 is above 0.1 μF, safety agency

requirements specify that it R1 and R2 should be used to

discharge C1. Resistors R1 and R2 are chosen such that

(R1 + R2) × C1 ≤ 1 s.

To reduce grouping of switched cycles, a high gain optocoupler,

U2, was used to drive small signal transistor Q3, which pulls

current out of the EN/UV pin. Capacitor C34 adds high

frequency gain to the feedback signal.

In a three wire system, placing Y capacitors (C17, C18) between

line/neutral and earth helps reduce common mode EMI.

•

•

•

•

•

Transformer Parameters

Core Material EER28 NC-2H or equivalent,

gapped for ALG of 139 nH/t²

Bobbin EER28, 12 pin, Vertical

Winding Details

Add 3 mm margins on both sides of bobbin

Primary: 16T × 2, AWG30, tape

Shield: 1T × 1, foil 2 mils thick, 3 layers tape

+26 V: 8T × 2, AWG23, 1 layer tape

-26 V: 8T × 2, AWG23, 1 layer tape

18 V: 6T × 2, AWG28, tape

Bias: 5T × 2, AWG30, tape

Primary: 17 T × 2, AWG30, 2 layers tape

Winding Order Primary (4–2), Shield (NC–1), +26 V (7–8), -26 V

(9-11), 18 V (12-10), Bias (5-6), Primary (2-1)

Primary Inductance 151 μH, ±20%

Primary Resonant

Frequency 2 MHz (minimum)

Leakage

Inductance 5 μH (maximum)

Table 1. Transformer Parameters.

(NC = No Connection, TIW = Triple Insulated Wire)

Figure 2. Conducted EMI at 230 VAC With Output Grounded (Worst Case).

PI-4885-110707

1.0 0.15 10.0 100.0

-20

-10

0

10

20

30

40

50

60

80

70

MHz

dB

µ

V

QP

AV

The core size and the winding wire diameter sizes (see Table 1)

were chosen based on the average of the peak and the

continuous output power.

An RC snubber (R51and C48) was added between drain and

source of U1 to reduce radiated EMI.

•

•

![Chương trình đào tạo cơ bản Năng lượng điện mặt trời mái nhà [mới nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2026/20260126/cristianoronaldo02/135x160/21211769418986.jpg)

![Chương trình đào tạo cơ bản Năng lượng gió [Tối ưu SEO]](https://cdn.tailieu.vn/images/document/thumbnail/2026/20260126/cristianoronaldo02/135x160/53881769418987.jpg)