Journal of Science and Technique - ISSN 1859-0209

185

EXPERIMENTAL STUDY ON THE FLEXURAL BEHAVIOR

OF TRC-STRENGTHENED REINFORCED CONCRETE BEAMS

Thi Thu Nga Nguyen1, Ngoc Quang Vu1, Viet Chinh Mai1,*, Trung Kien Nguyen2

1Institute of Techniques for Special Construction, Le Quy Don Technical University

2Ministry's Office, Ministry of Construction

Abstract

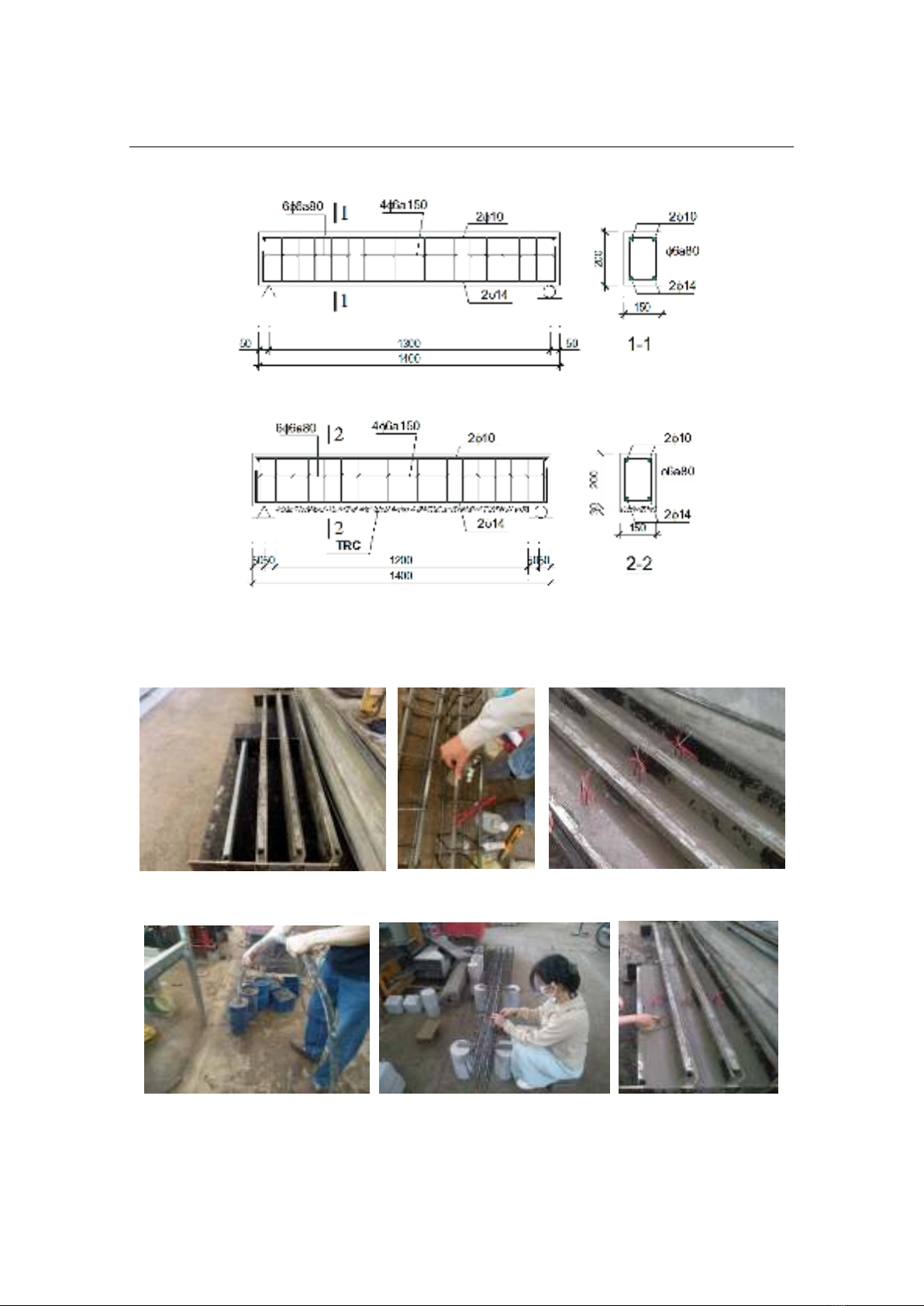

This article presents the experimental results on the flexural behavior of reinforced concrete

(RC) beams strengthened with textile-reinforced concrete (TRC). Four RC beams were made

of B22.5 grade concrete, and the TRC strengthening layer utilized Sigratex Grid 350 textile,

with fine-grained concrete Sikagrout 214-11 serving as the binder. The reinforcement layer was

applied using a grooving technique. The four-point bending test was conducted to evaluate the

improvements in load-bearing capacity and deformation of the beams after strengthening. The

results indicated that the strengthened beams exhibited a 36.2% higher load-bearing capacity

and a 13.5% increase in mid-span deflection compared to un-strengthened beams. However,

the occurrence of debonding in the reinforcing layer reduced the strengthening effectiveness.

To ensure the efficiency of flexural strengthening with TRC, attention should be given to the

adhesion of the fine-grained concrete layer and additional reinforcement of the compression

zone. These findings provide a basis for the practical application of TRC in enhancing RC

structures, ensuring both safety and performance.

Keywords: Textile reinforced concrete; strengthened reinforced concrete beam; four-point bending

test; grooving technique.

1. Introduction

Textile Reinforced Concrete (TRC) primarily consists of fine-grained concrete and

high-strength textile reinforcement, such as carbon or glass fiber. TRC exhibits superior

mechanical properties, high durability, and better corrosion resistance compared to

conventional concrete. TRC is used as a structural material and as a reinforcement to

enhance load-bearing capacity and extend the service life of structures [1, 2]. It is an

effective solution for improving the load-carrying capacity of reinforced concrete (RC)

beams, significantly increasing strength, initial cracking load, and ultimate load capacity,

enhancing ductility, and reducing environmental deterioration [3-5].

Experimental and numerical studies on flexural-strengthened beams have shown that

ensuring proper bonding between the TRC layer and the existing concrete is critical for

effective reinforcement. The adhesion between the fine-grained concrete layer and the old

* Corresponding author, email: maivietchinh@lqdtu.edu.vn

DOI: 10.56651/lqdtu.jst.v7.n02.885.sce