67

4

CHAPTER

10 Technical

Tools to Master

While on a Six

Sigma Team

In Chapter 3, we reviewed the steps a team goes through as they

attempt to improve the sigma performance of a process.

Chapter 4 addresses the 10 most important technical tools a

Six Sigma team member needs to master as they progress through

the DMAIC methodology.

While these tools are considered technical in nature, most of

them are relatively easy to learn and apply. They are covered in the

order they are used in the DMAIC methodology.

Tool #1 The Critical to Quality (CTQ) Tree

The critical to quality tree is used in the second tollgate of the De-

fine phase of DMAIC. It is used to brainstorm and validate the

needs and requirements of the customer of the process targeted

for improvement.

68 SIX SIGMA FOR EVERYONE

The steps in creating a CTQ tree are as follows:

• Identify the customer of the process targeted for improve-

ment. A customer is the recipient of the product or service

of the process.

• Identify the need of the customer, that is either the product

or service desired by the customer.

• Identify the first level of requirements of the need, that is,

some characteristic of the need that determines whether

the customer is happy with the need.

• Drill down to more detailed level(s) of the requirement if

necessary. Some requirements of the customer dictate

greater specificity. If so, the tree will need to be created in

greater detail.

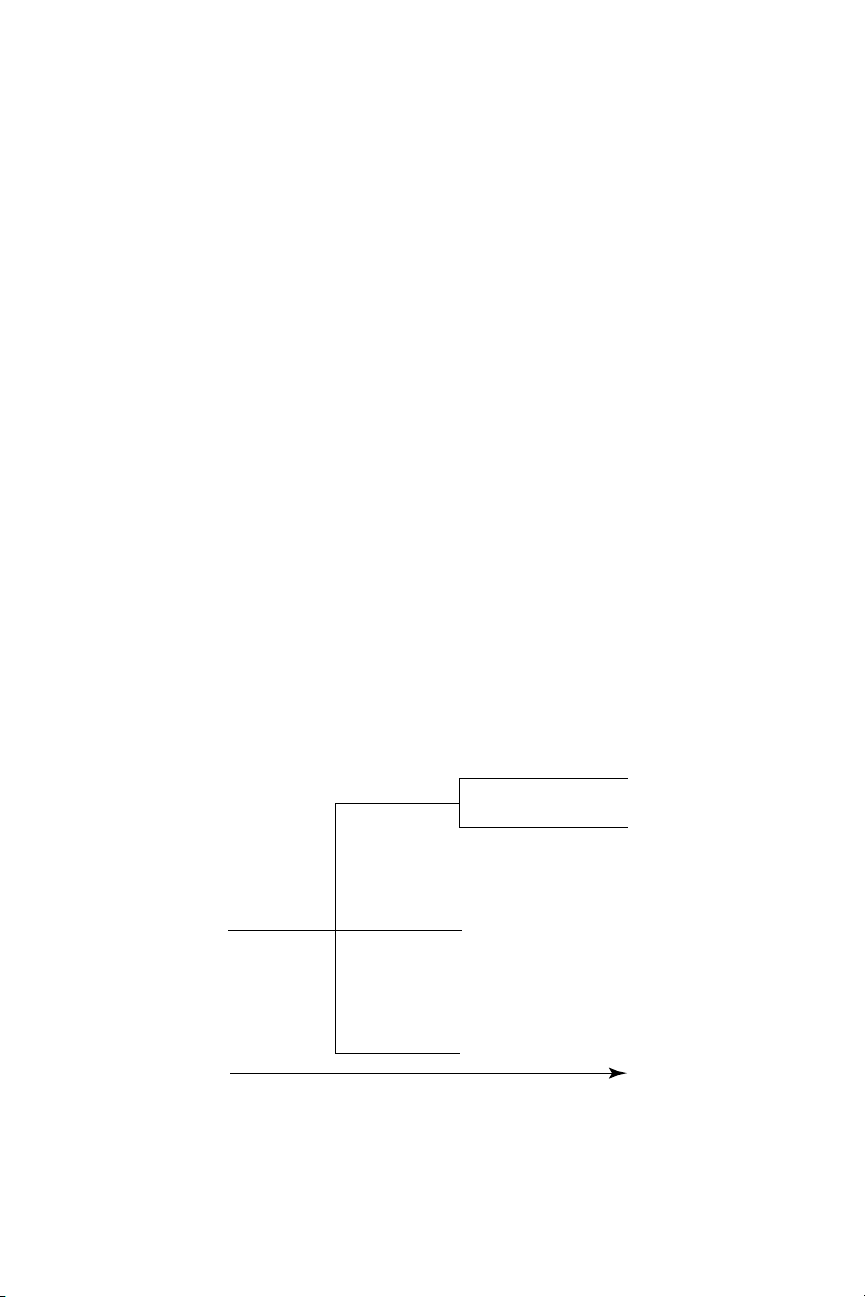

Figure 4.1 shows an example of a CTQ tree for a health care

provider where the customer of the patient registration process is

the patient. The need of the patient is to be registered. However,

you can also see that there are requirements of the patient that will

determine whether the patient has been satisfactorily registered.

Figure 4.1 Health care provider CTQ tree.

Registration

General

(need)

Behavioral

(requirement)

Accuracy

Type of room

Hospital ward

Timeliness

Courtesy

Need 1st Level 2nd Level

10 Technical Tools to Master While on a Six Sigma Team 69

Keys to Using This Tool

• Always start with the need of the customer.

• State the need as a noun with no adjectives to describe it.

• Keep moving left to right until you describe how to measure

the detailed requirements. If you have described a measure-

ment, you have gone to far (e.g., a requirement could be

speed or timeliness, but if you put it in minutes you have de-

scribed a measurement).

•

Once you have started a branch for the tree, all those

branches should be a greater detail of the preceding require-

ment, not a new requirement.

Tool #2 The Process Map

During the Define phase, the project team creates the first of sev-

eral process maps. A process map is a picture of the current steps

in the process targeted for improvement.

A process map has five major categories of work from the iden-

tification of the suppliers of the process, the inputs the suppliers

provide, the name of the process, the output of the process, and

the customers of the process. Each of these steps is summarized

as SIPOC to indicate to the team the steps that must be con-

ducted to complete a process map.

There are four stages of process mapping. The first stage is

what the project team creates during the Define stage of project

work. It is the high-level process map because the project team fo-

cuses in on the five to seven highest level steps in the current pro-

cess. Sometimes there will be less than five or more than seven

but most teams should strive to have five to seven.

The second step in process mapping occurs during the Analysis

stage. Here, the original high-level process map is created in more

detail. This second type of process map is called the subprocess

map. The third type of process map is created during the Improve

stage of DMAIC. This map is the improved map of what the new

process should be. Ergo, it is called the should-be map. Finally, the

fourth type of process map is the could-be map, usu

ally generated

70 SIX SIGMA FOR EVERYONE

in the Design for Six Sigma application. (Design for Six Sigma is

not addressed in this book.)

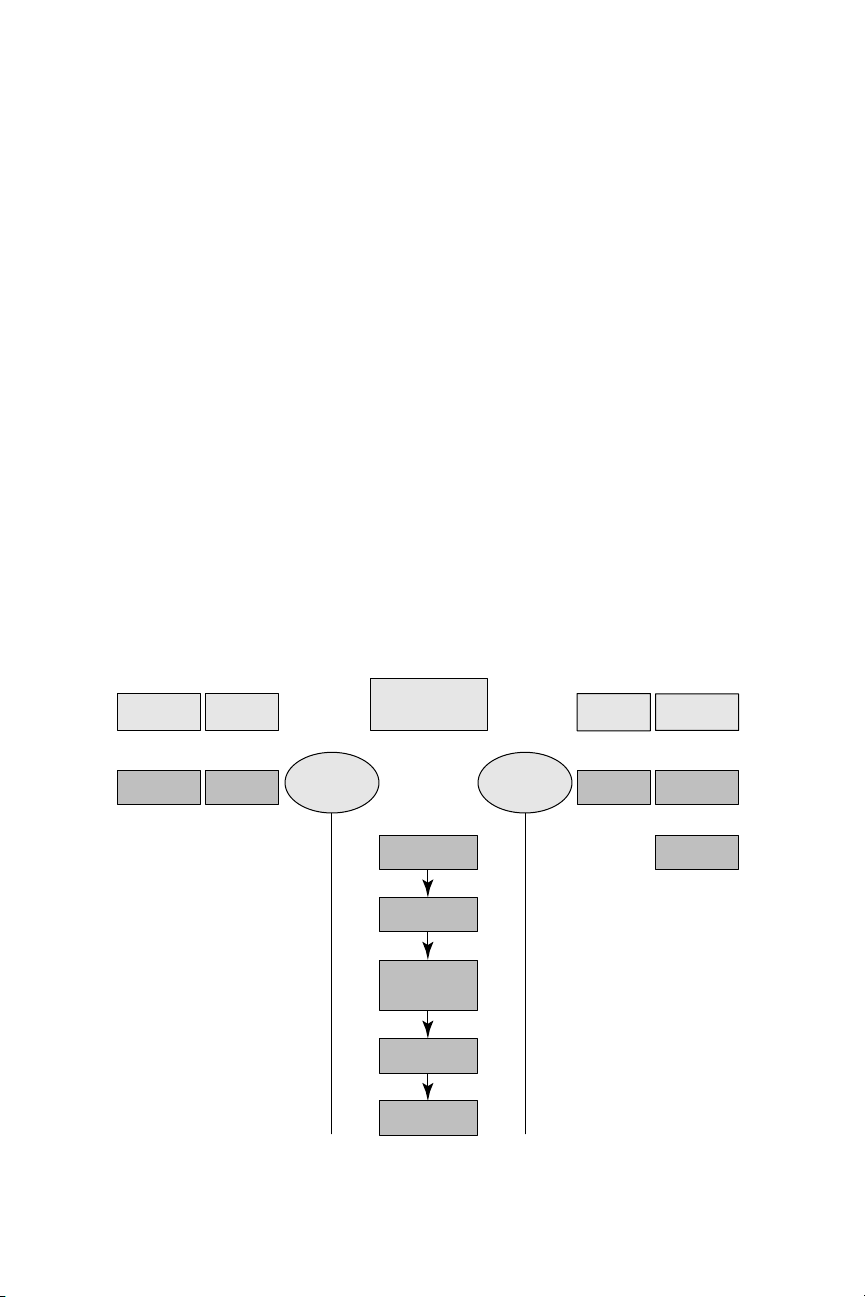

Figure 4.2 shows an example of a high-level process map for a

hospital lab test ordering process. In addition, we have also talked

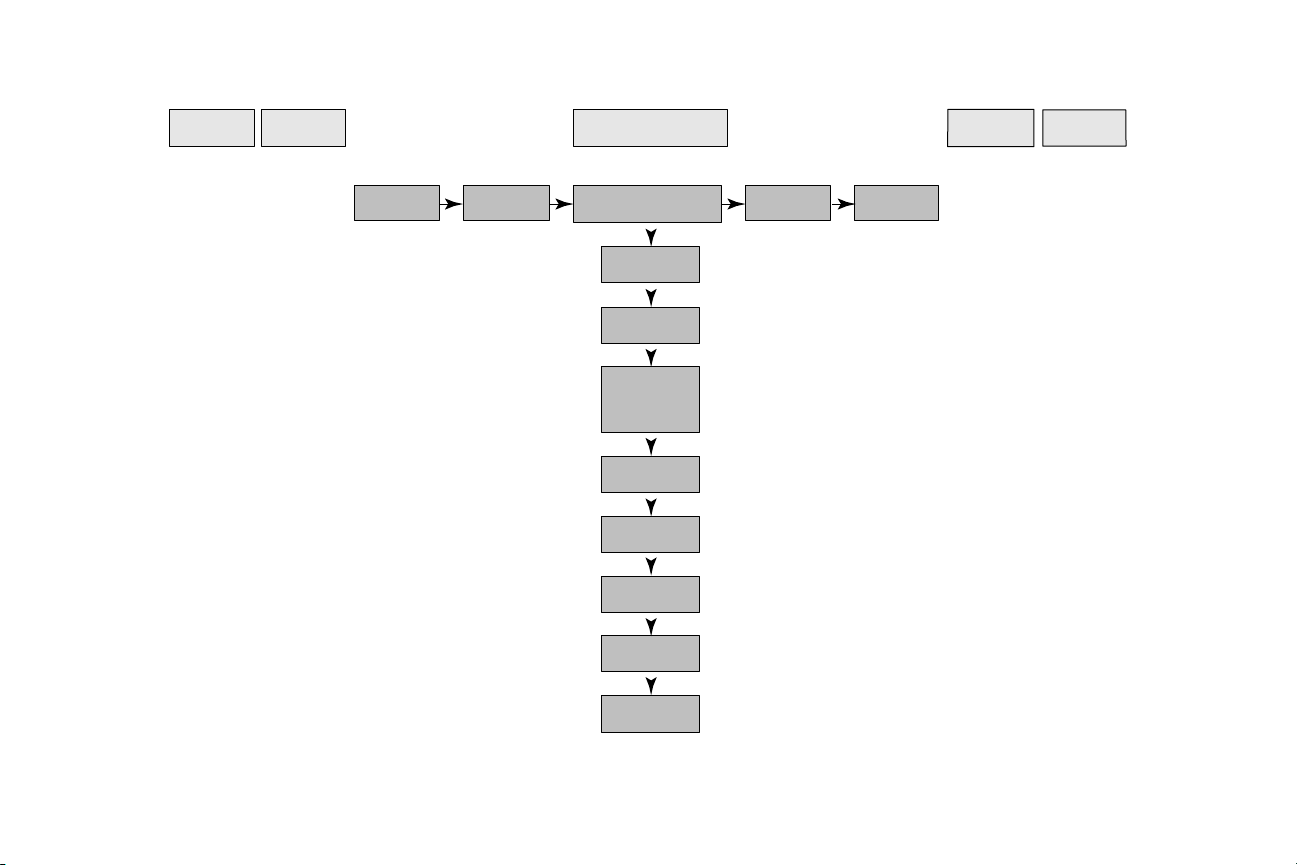

about the subprocess map created in the Analysis stage of DMAIC.

Figure 4.3 shows the same hospital lab test ordering process with

one of the high-level steps drilled down in greater detail showing

the hospital lab test subprocess map.

Keys to Using This Tool

• Don’t rush to the creation of the should-be map, this occurs

in the Improve stage of DMAIC.

•

Capture all of the steps as they actually occur in the process,

not the way you would like to see the steps in the process.

• Use verbs or adjectives to describe steps in the process.

• Use unqualified nouns to describe the output and inputs of

the process.

Figure 4.2 Hospital lab test ordering—high-level process map.

CustomersOutputs

Hospital lab

test ordering

Process

InputsSuppliers

Phlebotomy

department Order

Doctor

orders

lab

Doctor

receives lab

report

Place

order

Lab

result Patient

Care

Team

Obtain

specifications

Specifications

are compared

to lab order

Test

Report

71

Figure 4.3 Subprocess map—hospital lab test ordering process.

CO

CustomersOutputs

P

Process

IS

InputsSuppliers

Specifications

compared to lab order

Spin specimen

for test

Test

Place

order

Obtain

specifications Test Report

Wait for

order

Review

specification

Wait for

results

Prepare

report

Review

report

Verify

specification

with care

specialist

![Bài giảng Quản lý sản xuất cho kỹ sư: Chương 3 - Đường Võ Hùng [Chuẩn Nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20250812/oursky02/135x160/10441768298495.jpg)