http://www.iaeme.com/IJMET/index.asp 1210 editor@iaeme.com

International Journal of Mechanical Engineering and Technology (IJMET)

Volume 10, Issue 03, March 2019, pp. 1210–1216, Article ID: IJMET_10_03_123

Available online at http://www.iaeme.com/ijmet/issues.asp?JType=IJMET&VType=10&IType=3

ISSN Print: 0976-6340 and ISSN Online: 0976-6359

© IAEME Publication Scopus Indexed

THE INFLUENCE OF THE CATHODE SHAPE

ON THE PHASE COMPOSITION AND

STRUCTURE DURING OXIDATION

N. F. Kolenchin

Chief Researcher of Technopolis, Doctor of Engineering, Associate Professor, Industrial

University of Tyumen, Volodarskogo, 38, Tyumen, Russia, 652000

ABSTRACT

The process of anodizing aluminium alloys in an ozone-containing electrolyte when

a flat cathode is replaced with a needle shape was studied. The microstructure of the

oxide layer and the density distribution of the phases in the volume of the film in two

positions of the cathode — stationary and during its rotation — were investigated. The

mechanical properties of the surface layer were determined.

Key words: anodizing, needle-shaped cathode, ozonation, pore microgeometry, phase

distribution, surface hardness, activation.

Cite this Article: N. F. Kolenchin, The Influence of the Cathode Shape on the Phase

Composition and Structure During Oxidation, International Journal of Mechanical

Engineering and Technology 10(3), 2019, pp. 1210–1216.

http://www.iaeme.com/IJMET/issues.asp?JType=IJMET&VType=10&IType=3

1. INTRODUCTION

The search for ways to activate the interelectrode gap during oxidation is one of the promising

areas in the technology of hardening the surface layer of aluminium alloys. For most

researchers, the range of factorial variability is determined by the boundaries of the electrolytic

cell and, as a rule, is associated with changes in the chemical composition of the electrolyte and

the conditions of energy excitation. The performance is estimated by the degree of activity of

the main participants of the process - aluminium and oxygen under the conditions of the

necessary and sufficient influence of the working environment.

Non-traditional is the technology of external activation of oxygen and its transfer into the

interelectrode space. This is achieved through the introduction of ozone into the electrolyte [1].

Being the strongest oxidizer, ozone itself or atomic oxygen formed during its decomposition

acts, contributing to the intensification of the process, changing the structure and phase

composition of the oxide. Questions of the effectiveness of oxide formation in the ozonized

electrolyte are the motive for finding ways to activation, including changing the shape of the

cathode.

N. F. Kolenchin

http://www.iaeme.com/IJMET/index.asp 1211 editor@iaeme.com

With traditional anodizing, a flat-shaped cathode is used [2,3]. This ensures a uniform

distribution of the electric field strength in the electrolytic cell. To change the density of

discharges on the surface of the anode, the amperage or voltage of forming increases.

Study of the influence of the cathode shape on the near-anode space is prompted by the

results of processes of the same nature in which a pointed cathode was used. According to the

authors of [4], the scientific and practical aspects of electrochemical processes in process gases

between the needle-shaped cathode and the liquid anode, when the pores of the oxide layer are

filled with steam, confirm the identity of the processes for anodizing aluminium and its alloys.

During plasma-electrolytic anodizing [5], passing a pulsed current of high density, a thin

cathode is placed over the surface of the electrolyte, and the anode is immersed to a depth of 1

mm. At the time of the breakdown, a vapour-gas funnel with oxygen donors is formed. The rate

of oxidation increases and the phase composition of alumina changes.

Studying the effect of electrode geometry on the distribution of electric fields in a discharge

of a high-current low-inductance vacuum spark type [6], when the cathode was the pointed tip

and the anode was the plane, it was found that the field strength is maximum at the anode

surface at a distance of approximately 1/4 of the radius from the centre, Figure 1.

Figure 1 Distribution of the electric field in the "tip-plane" geometry

During electrospark processing [7], to increase the magnitude of the electric field at one of

the electrodes, the diameter of the second electrode is reduced or sharpened to a radius of

curvature of about 1 micron. This significantly increases the emission of electrons due to the

tunnel effect, which allows you to make high-current installations more reliable and compact,

without the presence of hot electrodes in them.

As a result of the use of filament-like inclusions of titanium and zirconium oriented along

the axis of the needle and facing the emitting surface, the authors of [8] achieved stability of

electron emission.

Needle-shaped cathodes are also used in a vacuum-arc evaporator [9] for surface

metallization due to the evaporation of droplets flying from the cathode, which contributes to

improved adhesion and increased corrosion resistance of surface oxides.

The Influence of the Cathode Shape on the Phase Composition and Structure During Oxidation

http://www.iaeme.com/IJMET/index.asp 1212 editor@iaeme.com

2. MATERIALS AND METHODS

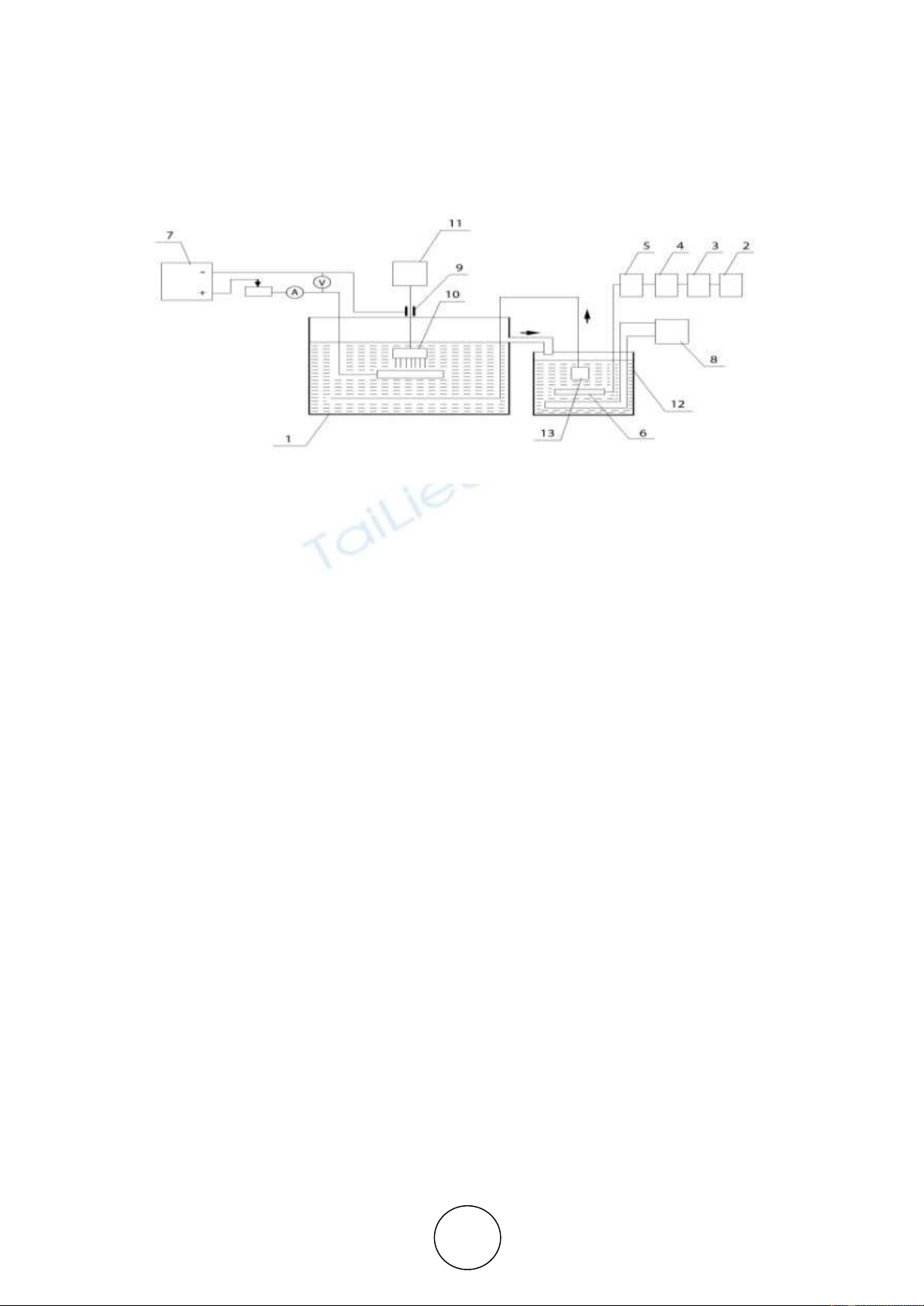

The anodizing scheme is shown in Figure 2.

The anodizing process was carried out in a bath tank (1), made of corrosion-resistant steel

12Kh18N10T with a capacity of 20 litres. Air was injected into the supply system by a SO-45A

grade compressor (2), passing through an air absorption dryer (3) HLS-R012-HL0030 entered

an ozoniser (4) "OZON-5PV1" with a power capacity not more than 150 W and a maximum

productivity of 16g/m3. Ozone-resistant PVC hoses and glass tubes were used as a pipeline for

transporting the ozone-air mixture. The ozone content in the air was determined using Medozon

254/5 with a measurement range from 0 to 150 mg/l. The ozone content in the liquid was

measured by Medozon-254/5Zh with a range of measured concentrations from 0.1 to 25 mg/l.

Adjustment of the flow rate of the gas-air mixture was carried out using a rotameter (5) Emis

Meta 210-R-008V-G. As a current source (7), a VSA-5K selenium rectifier was used which

allows adjusting the current in the range from 0 to 20 A at voltages up to 90 V. Contact with

the cathode was carried out using a sliding contact (9). The current strength was monitored with

a high-precision desktop digital multi-meter MS8050. Cooling and mixing were carried out in

a storage tank (12) with the help of a refrigeration unit (8) VS 0.7-3 and a bubbler (6). The

electrolyte with dissolved ozone was fed into the electrolytic bath by a pump (13).

A needle-shaped cathode (10), which is a cylindrical structure with a 40- mm outer diameter

and a 20-mm inner diameter, is made of thin, corrosion-resistant wire with a diameter of 0.1

mm. To ensure uniform contact with the anode plane, the working, end surface of the needle-

shaped cathode was sanded. The rotation speed was provided by an adjustable electric motor

(11). The distance between the electrodes varied in the interval of 0.1-0.5 mm.

Tests were conducted on the D16T alloy. The size of the anode was 60x40x3 mm. The study

of the structure of the samples was carried out using a JEOLJ5M-6150 scanning electron

microscope with an attachment module for X-ray spectral analysis and an Integra Aura atomic-

power probe microscope using the semi-contact method with scanning the sample previously

purified from organic pollutants with ethyl alcohol. Samples were scanned with a resolution of

1024 points per side. When scanning, the relief of the sample and the distribution of the

Figure 2 Scheme of anodizing with a needle-shaped cathode:

1- bath tank; 2- compressor; 3- ozone dryer; 4- ozone generator; 5- rotameter; 6- bubbler; 7-

current source; 8- refrigeration unit; 9- sliding current lead; 10- needle-shaped cathode; 11-

electric motor; 12- storage tank; 13- pump

N. F. Kolenchin

http://www.iaeme.com/IJMET/index.asp 1213 editor@iaeme.com

amplitude and phase of the probe oscillations over the scan area were recorded. The lateral

scanning resolution of the microscope is at least 3 nm, the height resolution is at least 0.5 nm.

Hardness was measured using an ultrasonic contact thickness gauge "Konstanta-K5". This

device allows measuring oxide coatings up to 2 mm thick, excluding preliminary sample

preparation. Hardness was determined by a multifunctional ultrasonic device "Konstanta-

K5U". Measurement limits were from 20 to 80 HRC, error was +/-2. The concentration of

transmitted ozone in the air mixture corresponded to 3 mg/l.

3. RESULTS AND DISCUSSION

The oxidation process was carried out in a 10% aqueous solution of sulfuric acid in the mode

of falling power. Two options were considered — static, when the cathode is stationary, and

mobile, when the cathode is rotating.

When the cathode is stationary, the anode surface located inside the needle-shaped electrode

is partially etched due to insufficient cooling in the domed zone and an increased etching rate

due to the heating of the electrolyte.

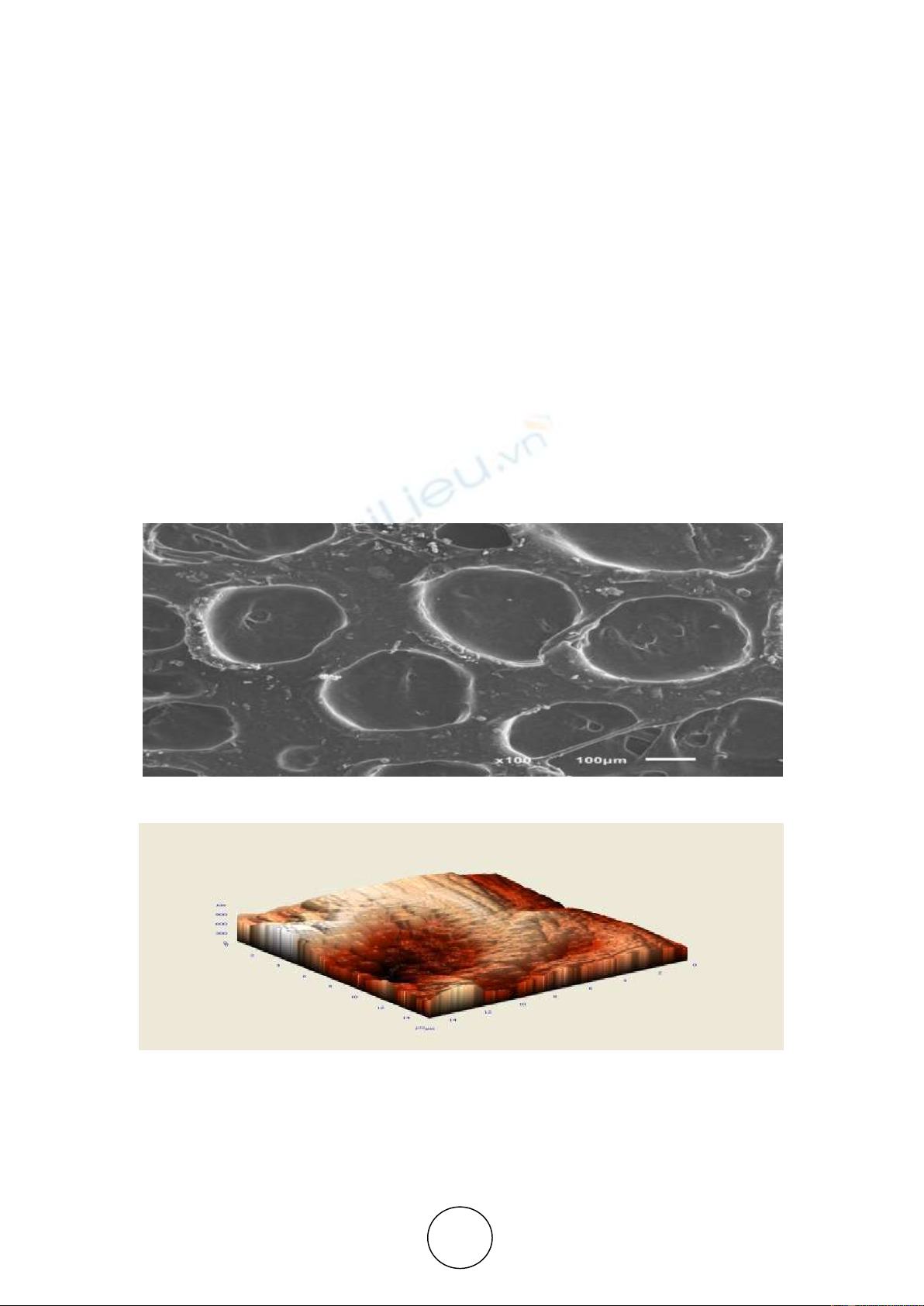

The surface of the anode located opposite the needles was formed with the original texture

presented in Figure 3. a

b

Figure 3 The oxide surface formed with a stationary cathode. Voltage of forming - 25V. Electrolyte - a 10%

solution of sulfuric acid cooled to 0 °C:

а - microgeometry of the flat part of the surface;

b - microgeometry of the surface in 3D

The crater-shaped surface is the result of the concentration of current density on the edges

of the cathode — the centre of elevated temperature and, accordingly, the zone of elevated

The Influence of the Cathode Shape on the Phase Composition and Structure During Oxidation

http://www.iaeme.com/IJMET/index.asp 1214 editor@iaeme.com

etching rates. The film was formed diametrically unevenly in thickness with a decrease in the

direction of the axis of the stationary electrode. Over 60 minutes, the average oxide thickness

turned out to be insignificant and amounted to 15 µm.

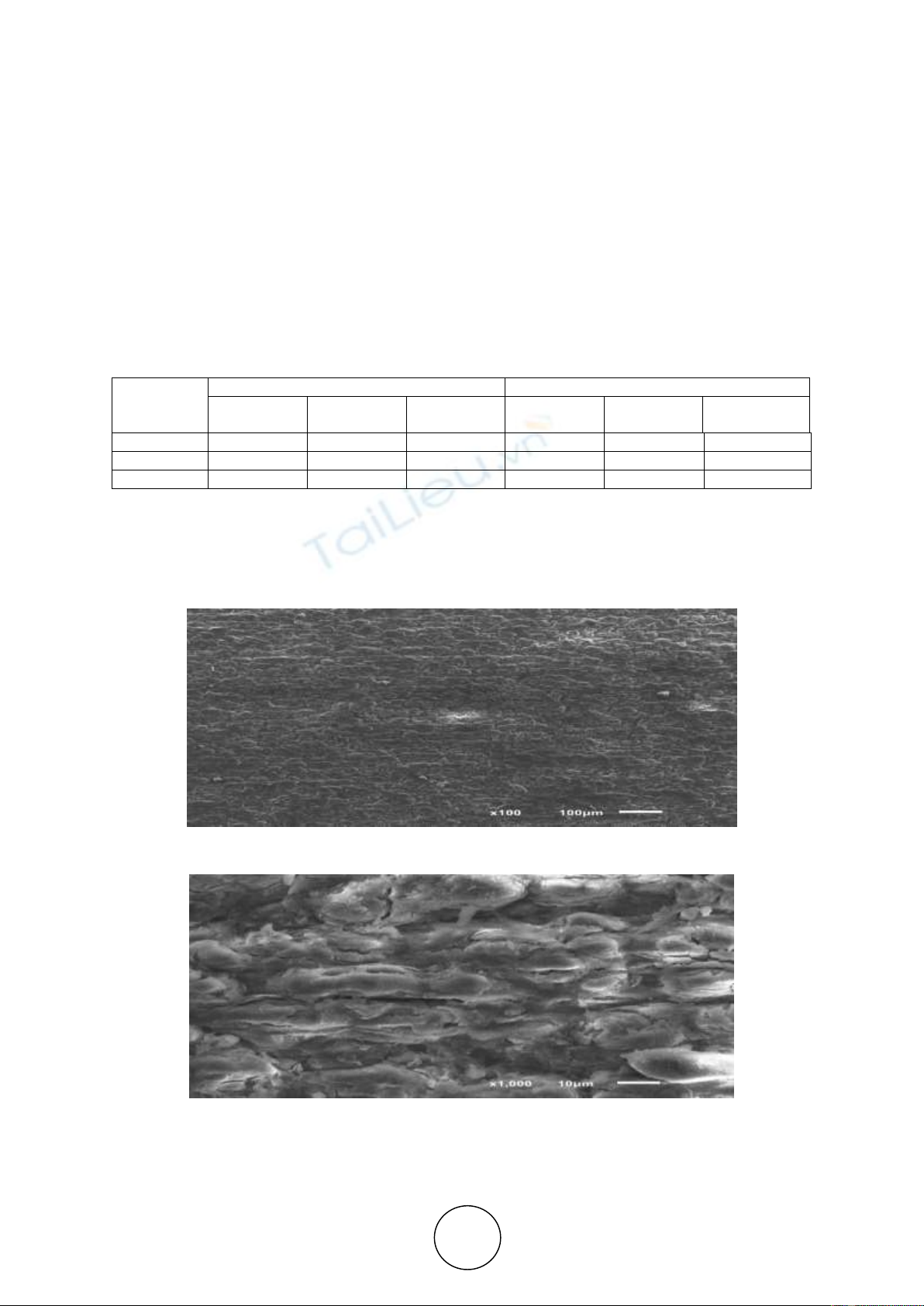

By imparting rotation to the cathode at a speed of 150 rpm, the electrolyte bubbling in the

contact zone was improved. The maximum convergence of two electrodes, with intensive

homogenization, provides an increase in current density at the tip, which contributes to the

dissolution of ozone in the interelectrode gap and, accordingly, increases the likelihood of its

participation in oxide formation. The results of measurements of the thickness and hardness of

the oxide layer over 30 minutes of the process are shown in Table 1. The oxide formed on the

inner surface of the sample has low hardness and thickness.

Table 1 Properties of the formed layer with different modes of anodizing

Initial current

density,

A/dm2

Hardness, НRC

Thickness, µm

Along the

contact line

Inside the

contact line

Outside the

contact line

Along the

contact line

Before the

contact line

Outside the

contact line

1

62

41

60

54

32

51

5

66

43

63

57

36

53

10

72

48

68

64

39

57

A set of needles is a definite obstacle to the ozonized electrolyte in the inner zone. The strip

under the needle electrode has some advantages in terms of the parameters under study over

anodizing with a flat electrode. On average, the thickness and hardness of the oxide layer were

10% greater.

а

b

Figure 4 Geometry of the pores formed during the rotation of the cathode at a speed of 150 rpm with a

magnification: a-100 times; b-1000 times

![Bài tập tối ưu trong gia công cắt gọt [kèm lời giải chi tiết]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20251129/dinhd8055/135x160/26351764558606.jpg)