TRƯỜNG ĐẠI HỌC ĐIỆN LỰC

KHOA QUẢN LÝ CÔNG NGHIỆP VÀ NĂNG LƯỢNG

---------***---------

BÁO CÁO

ĐỀ TÀI

Các giải pháp tiết kiệm năng lượng theo công nghệ mới cho

toà nhà

……………………………………………………………

Giáo viên hướng dẫn: Nguyễn Đình Tuấn Phong

Sinh viên thực hiện: Nguyễn Trung Kiên

Lớp: D17QLNL1

Hà Nội .07./.09./.2025.

Hà Nội … - ….

1.Introduction: The Energy Context and the Need for

Digitization

1.1. Global Energy Challenges from the Construction Secto

The construction sector and its buildings are playing a central role in the global energy

consumption and emission landscape. Specifically, buildings in the European Union consume

nearly 40% of the total energy consumption, and the sector is responsible for approximately

36% of total global emissions. To achieve the ambitious energy and environmental targets for

2030 and 2050, mitigating energy consumption in buildings is an urgent necessity.

The core issue lies with the existing building stock. Over 97% of the building stock consists of

older buildings. For instance, more than 220 million units of housing in the EU, with 85% built

before 2001, remain inefficient. These buildings often rely on fossil fuels for heating and cooling

and utilize outdated and inefficient technologies.

1.2. The Opportunity Lies in the Operational Stage

The majority of construction assets are currently in their operational life cycle stage. Intervening

at this stage, through the installation of digital technologies, can contribute significantly to

reducing energy demand and enhancing occupant comfort. The digitalization of building data

is a crucial catalyst, allowing buildings to adapt to changes in the power grid and user behavior,

while also supporting strategic maintenance activities.

1.3. Digital Twin (DT) as the Solution

The Digital Twin emerges as a key technology to realize this potential. Unlike traditional

Building Information Modeling (BIM), which provides only a static analysis during the design

and construction phases, DT integrates real-time sensor data and a two-way data exchange

between the digital model and the physical asset. This combination of the BIM model (providing

detailed component-level description) and IoT data (providing near real-time operational data)

forms the foundation for a comprehensive Digital Twin.

However, DT implementation in the built environment still faces major challenges, particularly

with older buildings that lack digital records or BIM models. This article aims to systematically

evaluate the applications, benefits, and challenges of DT in optimizing energy efficiency during

the operational stage of buildings.

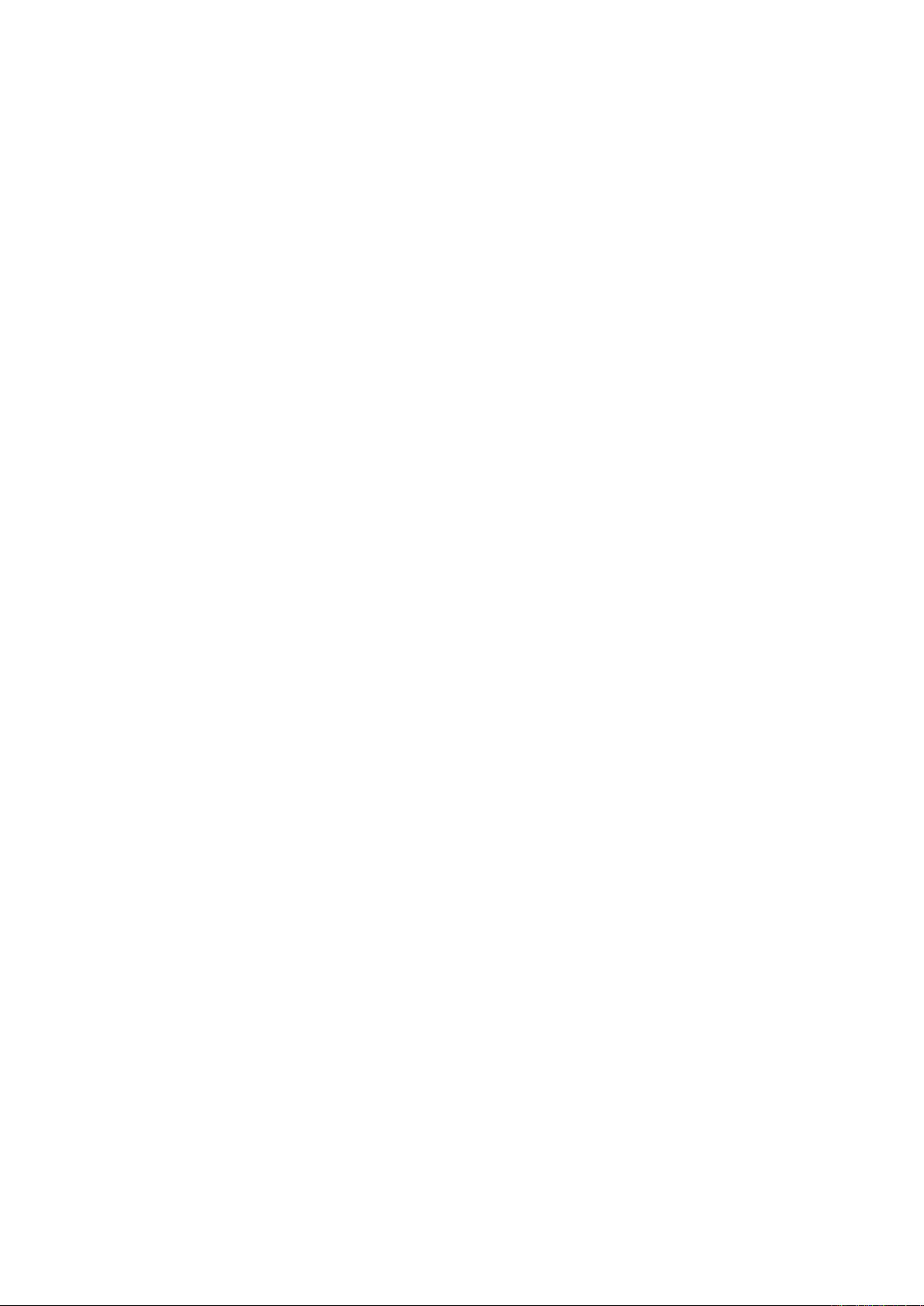

2.3. Main Thematic Classification

Through the analysis of 21 case studies, recurring themes were identified based on the specific

benefits achieved from DT implementation. Five primary applications were found, all related to

improvements in the building's operational phase:

1. Component Monitoring: Focuses on creating a detailed model of a specific component

to monitor its status and collect data about the surrounding environment.

2. Anomaly Detection: Uses the DT to identify operational faults or improper procedure

execution (e.g., cooling coil not working correctly).

3. Operational Optimization: Applies advanced control algorithms (such as Model

Predictive Control - MPC) to adjust system settings to reduce energy consumption.

4. Predictive Maintenance: Uses DT and Machine Learning (ML) to forecast the time of

equipment failure or need for maintenance, extending lifespan and reducing costs.

5. Simulation of Alternative Scenarios: The ability to simulate changes (e.g., renovation

strategies or renewable energy integration) before physical implementation.

Table 1: Summary of the Main Application Classification of Digital Twin in Building Operations

3. In-depth Analysis of DT Applications and

Quantitative Results

3.1. Component Monitoring and Optimization: The 40% COP Story

Initial DT studies often focused on creating detailed component-level models. For example, one

study described the creation of a limited DT for a specific office building facade element,

collecting over 25,000 sensor readings to monitor light, temperature, and humidity. The goal was

to enable more subtle control over temperature and lighting, thereby reducing facility

management and operational costs.

A typical case illustrating quantitative benefits in component optimization is the study on the

chiller DT. By creating a DT model integrating static information, physical models, and

interactive mapping, the system manipulated the chiller setpoints more intelligently. When the

optimization feature was activated, the chiller's Coefficient of Performance (COP) increased by

approximately 40%. This is an impressive figure, demonstrating the immense potential of DT in

optimizing energy-intensive Mechanical, Electrical, and Plumbing (MEP) systems.

3.2. Fault Detection and Diagnostics (FDD) and Optimal Operation

Fault Detection and Diagnostics (FDD) is another crucial application. DT provides real-time

diagnostic capability by comparing actual performance against its modeled standard.

One study introduced a systematic retro-commissioning method, using a dynamic model to

identify operational problems in a hospital in Denmark. This technique successfully detected

issues such as malfunctioning cooling coils, providing a better baseline for future energy

efficiency measurement and warning of inadequate operation.

In the area of Operational Optimization, DT often serves as the backbone for advanced control

systems, such as Model Predictive Control (MPC). MPC uses the DT model to forecast energy

loads and building behavior, allowing the system to automatically adjust HVAC and lighting

settings to minimize energy consumption without compromising user comfort. For example, a

centralized energy operations center (EOC), utilizing a BIM-based DT, was reported to achieve a

17% energy reduction in a South Korean building.

3.3. Predictive Maintenance (PdM) and Retrofitting Simulation

Predictive Maintenance leverages DT's data analysis and machine learning capabilities. Instead

of performing maintenance based on a fixed schedule (whether needed or not) or after a failure,

DT helps pinpoint the exact time components are at risk of failure.

AI Application for AHUs: Various machine learning techniques, such as Artificial

Neural Networks (ANN) and Support Vector Machines (SVM), are employed to

predict the state of components in Air Handling Units (AHUs), extending their lifespan

and significantly reducing maintenance costs.

Simulation of Alternative Scenarios is a unique DT application for decision-making support.

This capability allows stakeholders to evaluate the potential impact of renovation strategies or the

integration of renewable energy sources (RES) before physical investment. This function is

especially critical for the existing building stock in the EU. DT assists in forecasting

electrical/thermal loads, optimizing energy production systems, and minimizing risks and costs

associated with the trial-and-error process.

![Liệu pháp nội tiết trong mãn kinh: Báo cáo [Mới nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2024/20240705/sanhobien01/135x160/4731720150416.jpg)