http://www.iaeme.com/IJM/index.as 16 editor@iaeme.com

International Journal of Management (IJM)

Volume 8, Issue 4, July– August 2017, pp.16–22, Article ID: IJM_08_04_003

Available online at

http://www.iaeme.com/ijm/issues.asp?JType=IJM&VType=8&IType=4

Journal Impact Factor (2016): 8.1920 (Calculated by GISI) www.jifactor.com

ISSN Print: 0976-6502 and ISSN Online: 0976-6510

© IAEME Publication

MAINTENANCE MODELLING OF SHIPBOARD

MACHINERY BY DELAY TIME ANALYSIS

Rahul Ramachandran

KunjaliMarakkar School of Marine Engineering,

Cochin University of Science and Technology, Cochin, India

Dr. K. Sunil Kumar

Model Engineering College, Institute of Human Resource Development, Cochin, India

Roy V. Paul

KunjaliMarakkar School of Marine Engineering,

Cochin University of Science and Technology, Cochin, India

ABSTRACT

Shipping Companies are looking for an optimised Maintenance Model to be

incorporated into the Safety Management System of the Ships operated by them. Coming

into terms with what the best maintenance practise for each of the shipboard machinery

is the need of the hour. Optimisation of Maintenance actions will enhance the safety

and reliability of the machinery. It is believed that both over maintenance and under

maintenance are to be avoided to enhance the efficiency of the concerned machinery.

This paper attempts to develop a numerical maintenance model to determine the optimal

inspection regime to be followed for shipboard machinery. The maintenance modelling

is carried out by Delay Time Analysis using a down time estimation model. The model

is validated using operational data, original equipment manufacturer recommendations

and historical failure data collected from Wartsila A6L20C auxpac system.

Key words: Maintenance Models For Engines In Ships; Safety Management System;

Delay Time Analysis

Cite this Article: Rahul Ramachandran, Dr. K. Sunil Kumar and Roy V. Paul,

Maintenance Modelling of Shipboard Machinery by Delay Time Analysis.

International Journal of Management, 8 (4), 2017, pp. 16–22.

http://www.iaeme.com/ijm/issues.asp?JType=IJM&VType=8&IType=4

Rahul Ramachandran, Dr. K. Sunil Kumar and Roy V. Paul

http://www.iaeme.com/IJM/index.as 17 editor@iaeme.com

1. INTRODUCTION

In the marine shipping industry, maintenance planning is very significant due to its complexity

and the obligations on shipping organisations to comply with certain regulations and

requirements. Moreover, improper planning can reduce the ship‘s availability, which may in

turn, be reflected in the revenue of the company. Every hour of intermission brings high

expenses to the ship-owner and the maintenance expert’s task is to do their best to avoid the

unplanned intermission or to reduce its duration (Buksa, et al., 2005).

In shipping industry, most of the maintenance actions are performed based on the operation

manual provided by the original equipment manufacturer (OEM). However studies have

revealed that maintenance activities should be based on the current state of the machine because

each machine may operate in a different environment and failure of the machine (due to

component failure) may not have similar occurrence as OEM predicted. Inspections can be

carried out on the machinery at any interval of time which will help identify the faults that have

cropped up during operation of the machinery. Each inspection carried out on the machinery is

associated with a certain amount of down time. Carrying out inspections at very small intervals

of time is considered to be a case of over maintenance which is not a favourable situation both

in terms of the time spent for inspection and also the cost incurred as part of the inspection

process. Similarly, when machinery inspections are scheduled at very lengthy intervals; faults

may arise which may lead to a machinery failure prior to the inspection being carried out

thereby reducing the effectiveness of the inspection carried out.

Alhouli, 2011 in his PhD thesis has developed a new methodology to measure the

maintenance performance in marine shipping organisations using Ship Maintenance

Performance Measurement (SMPM) Framework. Pillay et al. (2001) studied the maintenance

of fishing vessels ‘equipment by using time-delay analysis. In the study, a model was proposed

to optimise the inspection period of the vessels ‘equipment.

The IMO ISM Code states that “development, implementation and maintenance of all

instructions and procedures to ensure safe operation of the ship and protection of the

environment in compliance with relevant international and Flag state legislation shall be a part

of the ship’s safety management system (SMS)” (ISM Code Section 1.4). Furthermore, it states

that the ship owner is responsible for “establishing procedures to ensure that the ship is

maintained in conformity of the provisions of the relevant rules and regulations and with any

additional requirements which may be established by the company” (ISM Code Section 10).

The Significance of Planning and control of maintenance systems including the role of

modelling and validation has been recognised by several workers (White. 1973; White 1975

and Duffuaa, et al., 1999). Lee, 2013; in his thesis demonstrates the application of predictive

analytics to ship machinery maintenance to aid in the reduction of operational downtime and

increase the overall effectiveness of a ship maintenance programme.

This paper aims to develop a framework that can help the decision maker to identify and

choose optimum decisions regarding ship maintenance. The idea is to construct an optimised

maintenance model for the routine maintenance of the ship under study, by using a Delay time

estimation model which will help determine the optimal time/interval to carry out inspections

on the machinery under study with a view to maximise the ship‘s availability within the

company fleet. The model is to be defined by the down time that is associated with a failure

mode.

Maintenance Modelling of Shipboard Machinery by Delay Time Analysis

http://www.iaeme.com/IJM/index.as 18 editor@iaeme.com

2. MODEL FORMULATION

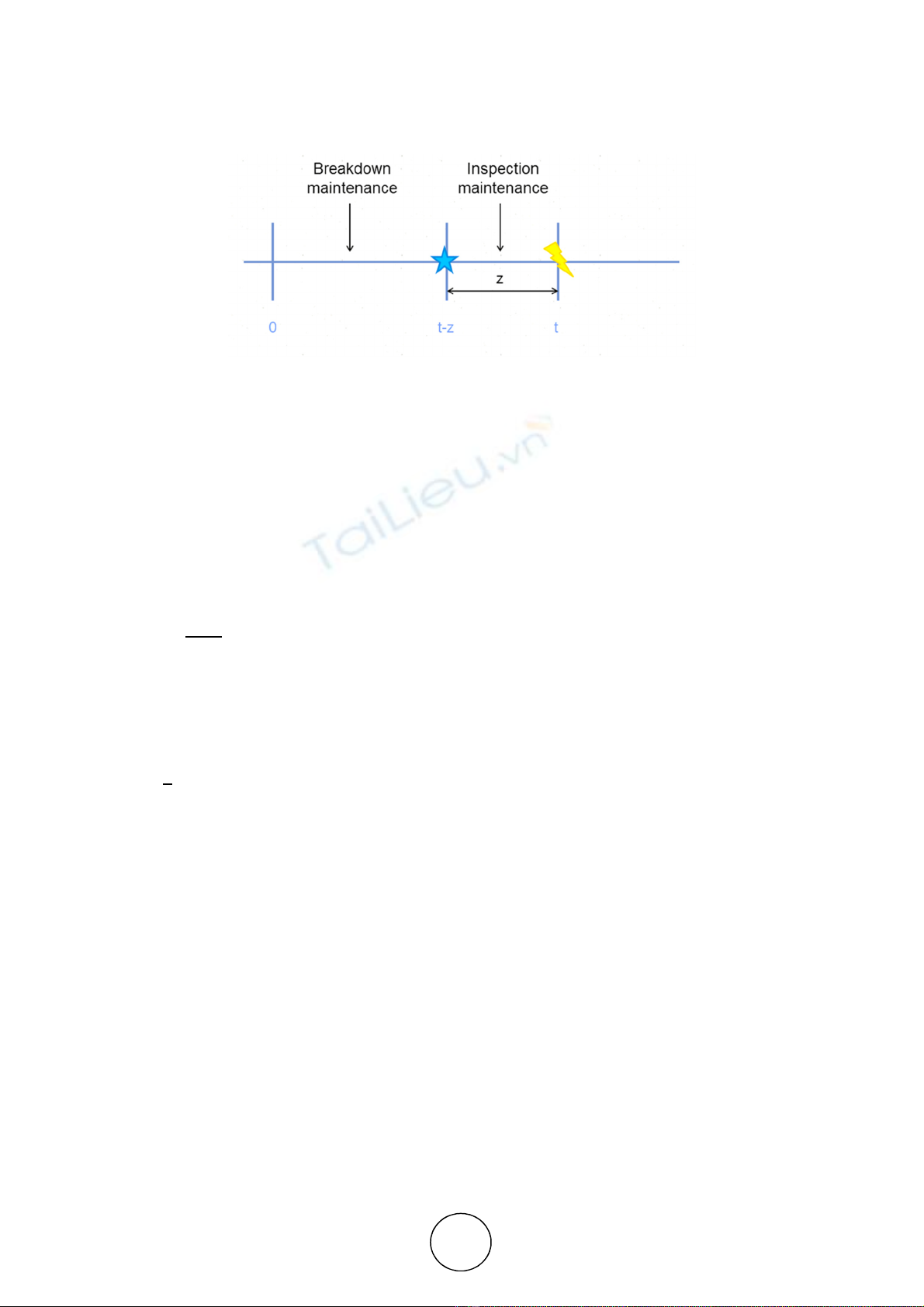

Figure 1 Breakdown and Inspection Maintenance

As can be seen from figure 1, a fault arising within a time period (0,t) is associated with a

delay time z, the probability of occurrence of the event being ∆. is the probability

density function of the delay time z. A fault arising within the time duration (0, t-z) will undergo

a breakdown maintenance whereas a fault arising within the time duration (t-z, t) will undergo

an inspection maintenance.

Summing up all possible values of z, the probability of a breakdown defect occurring, b(t)

can be expressed as follows;

Eqn 1

Assuming that the inspections are carried out at fixed intervals of t hours and the duration

of each inspection is constant. That implies;

Eqn 2

1

It is to be noted here that the probability of a breakdown defect occurring is independent of

the arrival rate of the defect per unit time but dependant on the delay time. The delay time can

be estimated only when a fault has occurred and it has led to a breakdown failure. Hence if a

breakdown failure can exist when a fault has arisen, then it can be said that the probability of

the failure being a breakdown failure, b (t) is a conditional probability (excluding the case of a

sudden failure without any delay time).

2.1. Assumptions made in downtime model formation

• A fault arising within (0,t) has a delay time z

• Probability of occurrence of this event is f(z)dz

• f(z) is the pdf of z

• Inspections are carried out at fixed intervals of t hours.

• The duration of each inspection is constant.

• System downtime during inspection is j hours

• Downtime for carrying out breakdown maintenance is J hours

• Inspection period is of t hours

Rahul Ramachandran, Dr. K. Sunil Kumar and Roy V. Paul

http://www.iaeme.com/IJM/index.as 19 editor@iaeme.com

• Q is the frequency of arrival of defects

• Machinery faults are assumed to be repaired immediately; J<<t

• A good inspection standard is assumed to be present.

• All defects are assumed to be detected.

• An identified defect is assumed to be repaired and the system put back into service within the

inspection period.

• The delay time, z is independent of its time of origin.

• Faults are assumed to be originated at uniform time intervals over the time between inspections.

As a consequence of the above assumptions, the expected downtime per unit time, D(t) can

be expressed as follows;

Eqn 3

{

+ ! " ∗

∗ " $ ∗ $ }

/ ! "+

That implies,

Eqn 4

[(+)∗∗*

+( ]

Substituting value for b(t) obtained from Eqn. 2 in Eqn. 4;

Eqn 5

[(+)∗∗{

,

-}*

+( ]

During literature survey, it came to light that the probability density function was more

close to following a Weibull distribution or a Normal distribution. Similar studies carried out

in the field of maintenance and reliability had used either a Weibull distribution or a Normal

distribution. Due to the simplicity associated with the Normal distribution, the probability

density function of the delay time is assumed to follow a Normal distribution.

That implies;

Eqn 6

1

√201

2

345

6766

Where 8 is the mean of the delay time and 9

:

stands for the standard deviation of the delay

time. The delay time associated with a failure is normally a positive value. Also in cases where

a sudden failure occurs as soon as a fault develops the value of delay time will be zero. It is to

be noted that the delay time is never a negative value due to the fact that a fault could be

followed by a failure but a failure is never followed by a fault.

Maintenance Modelling of Shipboard Machinery by Delay Time Analysis

http://www.iaeme.com/IJM/index.as 20 editor@iaeme.com

That implies;

Eqn 7

≥0

From Eqn. 7 it is very evident that there exists a positive chance for the observation depicted

in Eqn6 being a negative value. This is not considered to be a favourable observation. Hence it

is assumed that the probability density function of delay time follows a truncated standard

normal distribution, truncated at 0 with mean of the delay times, 80 and standard deviation

of the delay time, 9

:

1

Thus the probability density function of delay time is as follows;

Eqn 8

2

√20

2

3

66

Substituting the value of probability density function obtained from Eqn. 8 into the equation

for the expected down time per unit time, Eqn. 5;

That implies;

Eqn 9

[(+)∗∗{

,

-

:

√:=

436

6

}*

+( ]

Eqn. 9 depicts the estimated down time per unit time of the equipment. This is the final

form of the down time model that we have formulated.

2.2. Model Validation

As an example, the maintenance requirements of fuel valves used in Wartsila A6L20C are

considered. It should be noted here that the following information was gathered from logged

historical records, real time operating data and are complimented by expert judgements where

data was not readily available.

The down time due to inspection, j = 30 minutes = 0.5 hours

Down time for breakdown maintenance, J = 12 hours

Arrival rate of defects, Q = 0.00048 per hour

From Eqn. 9,

[(+)∗∗{

,

-

:

√:=

436

6

}*

+( ]

Substituting the values of j, J and Q into Eqn9,

Eqn. 10,

[0.5+0.00048∗∗{

,

-B

:

√:=

436

6

C∗12

+0.5 ]

![Tài liệu học tập Hệ thống điều khiển điện - khí nén và thủy lực [mới nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2021/20211005/conbongungoc09/135x160/811633401135.jpg)

![Tính chọn lắp ghép tiêu chuẩn giữa áo trục và trục chân vịt tàu thủy [chuẩn nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2021/20210219/caygaocaolon10/135x160/5291613732560.jpg)

![Đề thi Kỹ thuật lập trình PLC: Tổng hợp [Năm]](https://cdn.tailieu.vn/images/document/thumbnail/2026/20260121/lionelmessi01/135x160/85491768986870.jpg)

![Đề thi cuối học kì 1 môn Máy và hệ thống điều khiển số năm 2025-2026 [Kèm đáp án chi tiết]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20251117/dangnhuy09/135x160/4401768640586.jpg)

![Tự Động Hóa Thủy Khí: Nguyên Lý và Ứng Dụng [Chi Tiết]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20250702/kexauxi10/135x160/27411767988161.jpg)