http://buihongquan.com

Chương 3. Đng hc phn ng to sinh khi

3.1. Cac khai niê m cơ ban

3.2. Qua t rinh tao sinh kho i vi sinh va t

3.3. Ky thua t nuo i ca y thêo mê

3.4. Ky thu a t nuo i ca y thêo mê co bo sungcơ cha t

3.5. Phương trinh Monod va Đo ng hoc tao sinh kho i vi

sinh va t

12/23/2018 152 Bioreaction engineering.

http://buihongquan.com

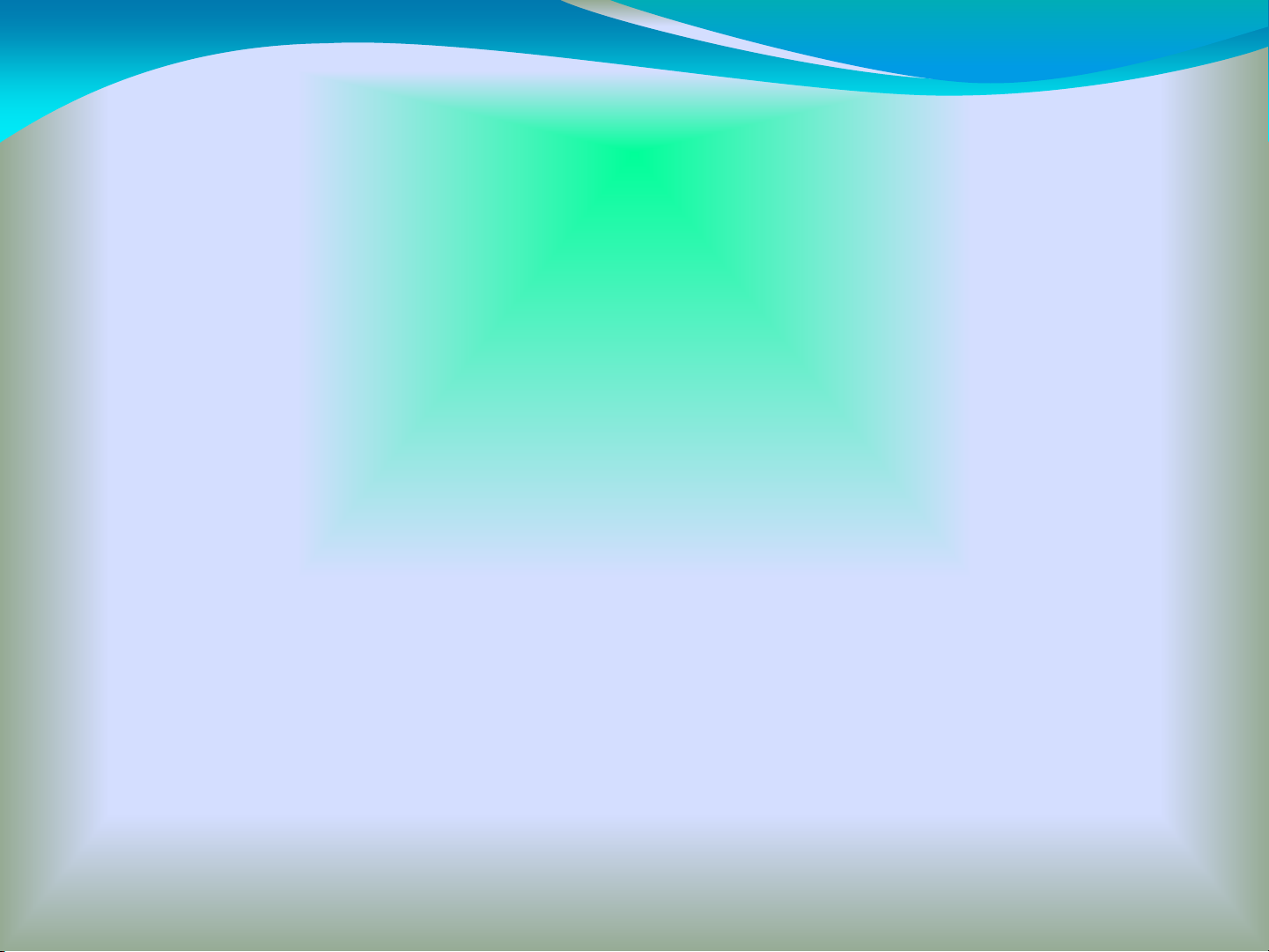

Fermentation Process

12/23/2018 154 Bioreaction engineering.

http://buihongquan.com

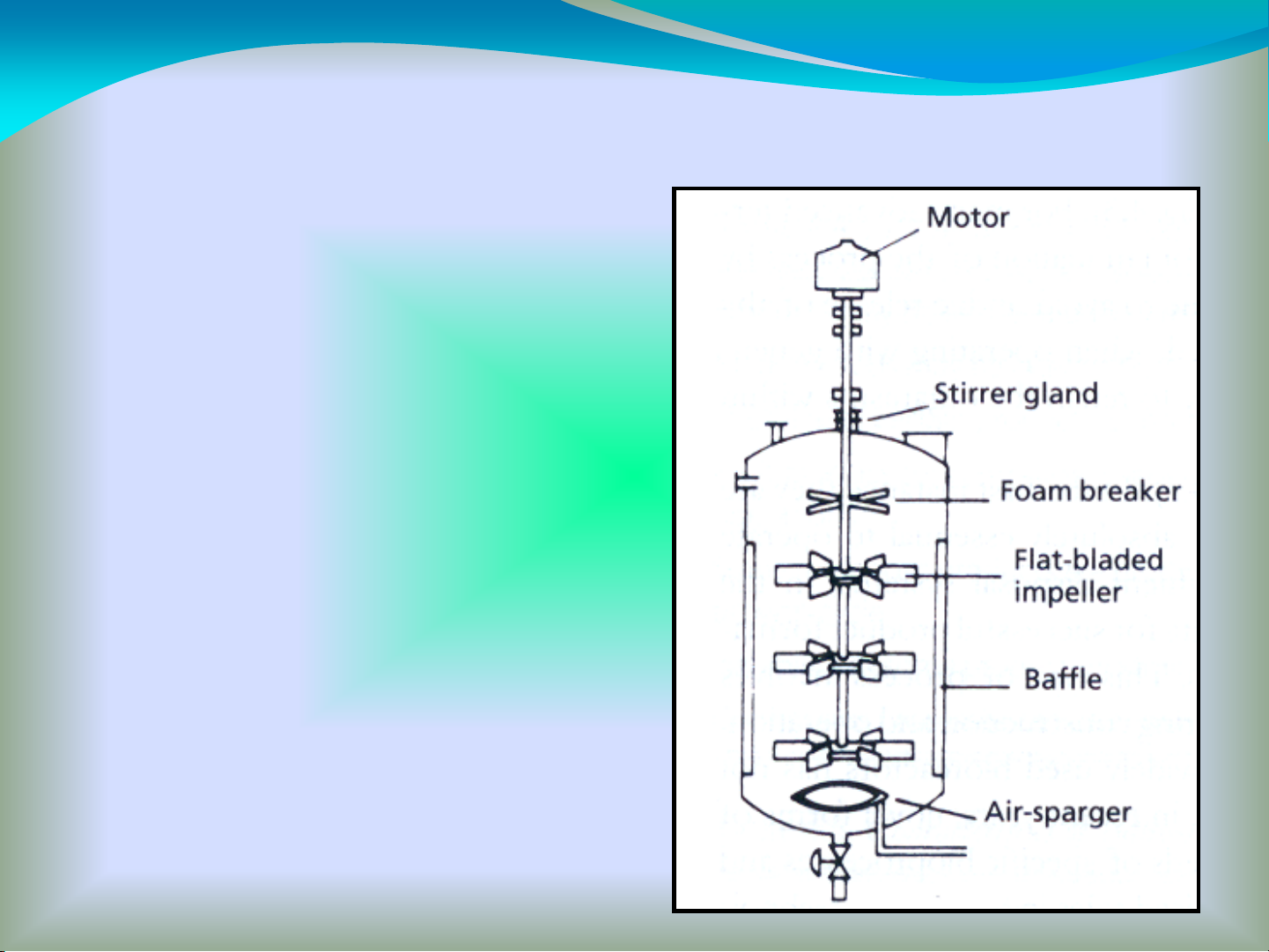

Major Functions of a Bioreactor

1) Provide operation free from

contamination;

2) Maintain a specific temperature;

3) Provide adequate mixing and aeration;

4) Control the pH of the culture;

5) Allow monitoring and/or control of

dissolved oxygen;

6) Allow feeding of nutrient solutions and

reagents;

7) Provide access points for inoculation

and sampling;

8) Minimize liquid loss from the vessel;

9) Facilitate the growth of a wide range of

organisms.

Ref;(Allman A.R., 1999: Fermentation

Microbiology and Biotechnology)

12/23/2018 155 Bioreaction engineering.

http://buihongquan.com

Biotechnological Processes Of Growing

Microorganisms In A Bioreactor

1) Batch culture: microorganisms are inoculated into a fixed

volume of medium and as growth takes place nutrients are

consumed and products of growth (biomass, metabolites)

accumulate.

2) Semi-continuous:

fed batch

-gradual addition of concentrated

nutrients so that the culture volume and product amount are

increased (e.g. industrial production of baker’s yeast);

Perfusion

-addition of medium to the culture and withdrawal of an

equal volume of used cell-free medium (e.g. animal cell

cultivations).

3) Continuous: fresh medium is added to the bioreactor at the

exponential phase of growth with a corresponding withdrawal of

medium and cells. Cells will grow at a constant rate under a

constant condition.

12/23/2018 156 Bioreaction engineering.

![Giáo trình Vi sinh vật học môi trường Phần 1: [Thêm thông tin chi tiết nếu có để tối ưu SEO]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20251015/khanhchi0906/135x160/45461768548101.jpg)

![Bài giảng Sinh học đại cương: Sinh thái học [mới nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20250812/oursky02/135x160/99371768295754.jpg)

![Đề cương ôn tập cuối kì môn Sinh học tế bào [Năm học mới nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2026/20260106/hoang52006/135x160/1251767755234.jpg)

![Cẩm Nang An Toàn Sinh Học Phòng Xét Nghiệm (Ấn Bản 4) [Mới Nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20251225/tangtuy08/135x160/61761766722917.jpg)