Journal of Water Resources & Environmental Engineering - No. 87 (12/2023)

2

Mechanical behavior of functionally-Graded concrete beam

under flexural loading

Nguyen Viet Duc

1

Abstract: This paper presents the mechanical behavior of functionally-

graded concrete (FGC) beam

under flexural bending. The FGC beam was made of conventional concrete of strength class 30MPa

with a thickness of 45mm and high performance glass fiber reinforced concrete (HPGFRC) of st

rength

class 60MPa with thickness of 15mm. While the reference beam is composed of entirely conventional

concrete of strength class 30MPa with thickness of 60mm. Both of the beams were reinforced by using

two steel bars at the bottom with a concrete cover of 25 mm. Based on the third-

point bending test,

both the reference and FGC beam behaved in a similar manner, even though the latter consists of two

layers of conventional concrete and HPGFRC. Their mechanical behavior is represented in four stages

including the first crack propagation, the second crack appearance, reinforcement load-

carrying

capacity, and finally failure. Cracking and ultimate strength obtained from the FGC beam were 19% and

28% higher than those from the reference beam. The better per

formance of the FGC beam was mainly

due to the functionality of HPGFRC with higher strength and glass fiber inclusion. By observing the

failure of the FGC beam, there is no crack or delamination between the conventional concrete and

HPGFRC layers on this beam.

Keywords: Functionally-

graded concrete, flexural loading, glass fiber, high performance glass fiber

reinforced concrete.

1. Introduction

*

The application of functionally graded

material in concrete has attracted more and

more attention over the last years. Ma et al. (Ma

et al., 2009) proposed a functionally graded

concrete segment in shield tunnel. The segments

used in shield tunneling lining structures should

have high durability and long service life. Based

on the principle of functionally graded materials

(FGMs), the FGMs for reinforced concrete

segments were designed and optimized. By the

method of multi-layer vibrating formation, the

segments with characteristics such as high

impermeability of the covering layer, high

strength of the main structural layer, and fire-

resistance of an inner layer, were prepared.

1

Division of Construction Materials, Faculty of Civil

Engineering, Thuyloi University

Received 13

th

Jul. 2023

Accepted 10

th

Aug. 2023

Available online 31

st

Dec. 2023

Furthermore, a good manufacturing technique

for the interface was adopted to ensure the

homogeneous transition of different material

layers, and the integrated design effects of

function and structure were achieved.

On the other hand, Maalej et al. (Maalej et

al., 2003) reported the results of an experimental

program on the effectiveness of a ductile fiber

reinforced cementitious composite (DFRCC)

material, which exhibit strain-hardening and

multiple-cracking behavior under flexural

loadings, in retarding the corrosion of steel in

reinforced concrete (RC) beams. Based on the

collective findings from theoretically-estimated

steel losses, rapid chloride permeability tests,

pH value tests, as well as structural tests, it was

concluded that functionally-graded concrete

(FGC) beams, where a layer of DFRCC material

was used around the main longitudinal

reinforcement, had noticeably higher resistance

Journal of Water Resources & Environmental Engineering - No. 87 (12/2023)

3

against reinforcement corrosion compared to a

conventional RC beam. Besides, Maalej &

Leong (Maalej & Leong, 2005) investigated the

corrosion resistance and failure characteristic of

functionally graded concrete beam and ordinary

concrete beam. The experiment reveals that,

compared to ordinary concrete beams,

functionally graded reinforced concrete beams

have better resistance to corrosion, and thus

more durable. B

In this study, the author intends to present the

mechanical behavior of functionally-graded

concrete (FGC) beam under flexural loading. The

FGC beam consists of the layer of conventional

concrete of strength class 30MPa with a thickness

of 45mm and the layer of high performance glass

fiber reinforced concrete (HPGFRC) of strength

class 60MPa with a thickness of 15mm. The FGC

beam is studied in comparison with the reference

beam, which consists of the entire layer of

conventional concrete of strength class 30MPa

with a thickness of 60mm.

2. Specimen preparation and experimental

program

2.1. Material used

This study used ordinary Portland cement

PC40, conforming to the European cement

standard EN 197-1. Silica fume was used as a

supplementary cementitious material. Fine and

coarse aggregates for concrete production are

manufactured sand and crushed stone

respectively. Alkali resistant glass fibers,

conforming to ASTM C1666, were used for the

HPGFRC mix. Besides, a third generation

polycarboxylate superplasticizer was involved.

Lastly, tap water at Hanoi area was used for the

proportion mix. Details of the material used in this

study in term of physical and mechanical

characteristics of cement and silica fume, sieve

analysis and characteristics of coarse and fine

aggregates, as well as characteristic of glass fibre

fiber, superplasticizer, and water can be found in

the previous publications (Nguyen, 2020).

2.2. Mix proportion of conventional

concrete and HPGFRC

In this study, two types of concrete mix

proportions were designed. The first one was

conventional concrete of strength class 30 MPa.

This type of concrete was used for the

preparation of the reference beam. While the

second is HPGFRC mix of strength class 60

MPa that is used in combination of the

abovementioned conventional concrete to form

FGC beam. Taking into account that HPGFRC

is also a high strength self-compacting mortar.

Some “trial-and-error” were involved to adjust

the dosage of water and superplasticizer content.

Eventually, the mix proportion and properties of

conventional concrete and HPGFRC used in this

study were obtained and they can be found in

details in Refs (Ngo, 2020; Nguyen, 2020).

2.3. Specimen preparation

Both the reference beam and FGC beam

have a similar size of 400mm length, 100mm

width, and 60mm height. There are two steel

bars of diameter 6mm playing a role as

reinforcement to avoid an abrupt failure of the

beam. The concrete cover is 25mm. The

reference beam was cast by placement of

conventional concrete and a subsequent

adequate vibration for the entire layer of 60mm.

While the FGC beam was cast in two steps;

firstly, conventional concrete was placed and

vibrated properly, then HPGFRC was poured

above the conventional concrete at the fresh

state in the same mold to form the FGC beam.

Since HPGFRC is a self-compacting mix, it

does not need vibration to compact. The only

difference between the reference and FGC

beams is the latter consists of conventional

concrete and HPGFRC, in which the beam

height thickness of the HPGFRC layer is 15mm

and the rest of conventional concrete is 45mm.

After casting, the beams were cured at the

standard conditions and then used for the

experimental tests at 28 days. The detailed

Journal of Water Resources & Environmental Engineering - No. 87 (12/2023)

4

process of the specimen preparation is presented

elsewhere in References (Nguyen, 2020).

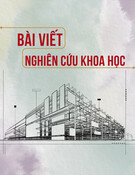

2.4. Experimental program

The reference and FGC beams were subjected

to third-point loading. The bending test was used

with a span length of 300 mm and the distance

between load application points is 100 mm.

Besides, an extensometer was mounted in the

middle of the beam to capture the displacement

during the test, as can be seen in Figure 1.

Figure 1. Experimental test set-up

During the bending test, there is a sagging and

hogging moment exerting on the beam, where the

bottom layer is under tension and the top layer is

under compression. Since HPGFRC owns high

tensile strength thanks to fiber inclusion, during

the test the FGC beam was placed so that the

HPGFRC layer is at the bottom in order to take

advantage of HPGFRC functionality.

The test was performed using a hydraulic

testing machine, and the load rate was 1kN per

minute. The test was conducted up to beam

failure to acquire its maximum loading capacity.

3. Results and discussion

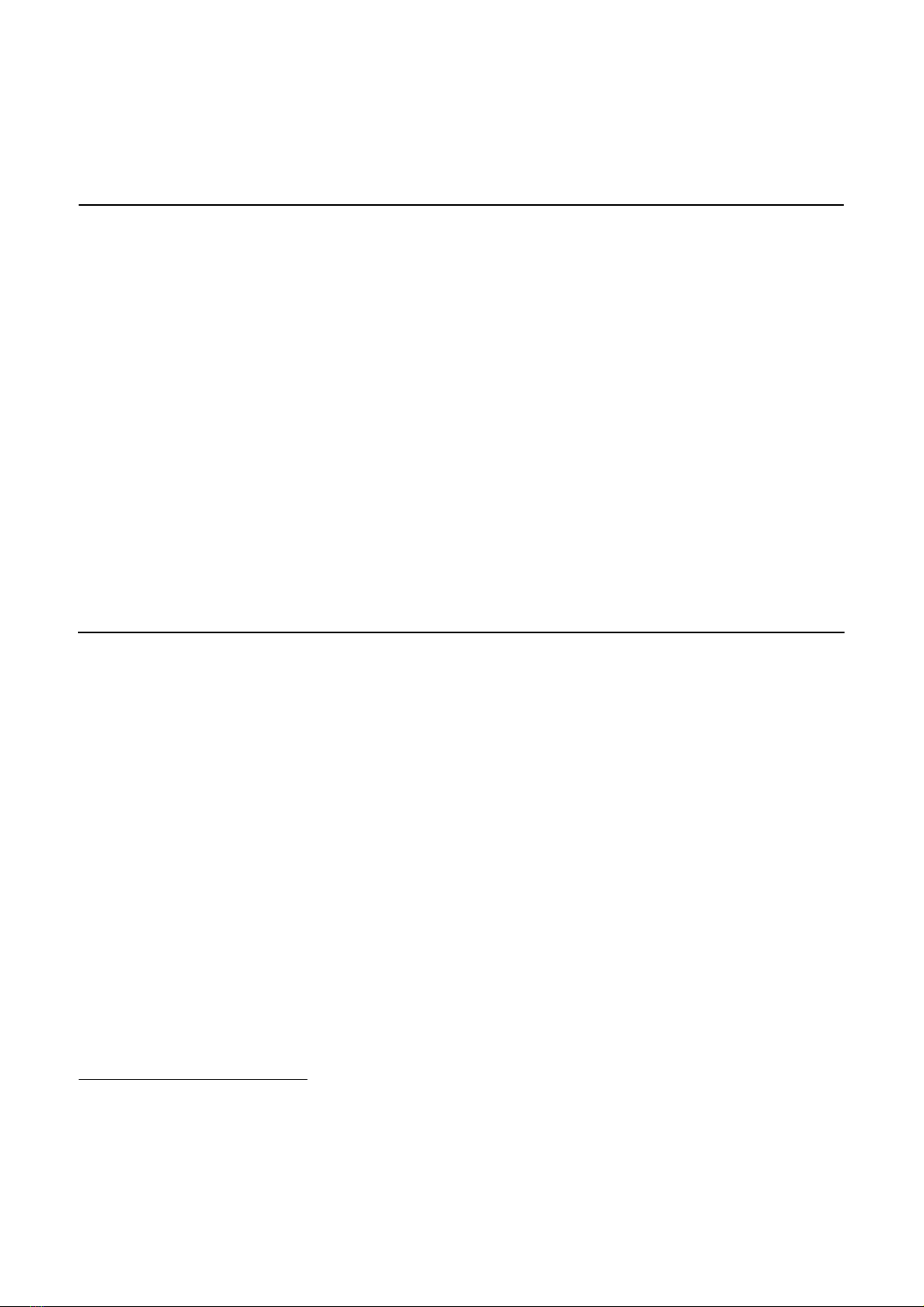

3.1. Reference beam behavior

The flexural strength versus displacement

relationship of the reference beam is shown in

Figure 2. It can be seen that there are four

principal stages during the flexural test on the

reference beam. The first one (point 1 in Figure

2) is the moment when the first visible crack

appeared at about 3MPa. The illustration of the

first crack appearance can be observed in Figure

3. The crack is propagated in the middle third of

the beam, where it commonly receives the

maximum bending moment.

Figure 2. Flexural strength versus displacement

relationship of the reference beam

Figure 3. Crack propagation at the first stage

(point 1 in Figure 2)

Figure 4. Crack propagation at the second stage

(point 2 in Figure 2)

Journal of Water Resources & Environmental Engineering - No. 87 (12/2023)

5

After that, the beam is still able to carry more

loads, and the second crack appears on the left

third of the beam at about 8MPa (point 2 in

Figure 2), as noted in Figure 4. In the meantime,

the first crack still develops wider and wider. At

this moment, steel bar reinforcement is the main

component to carry the load (point 3 in Figure

2) and the second crack develops much more

than the first one, as can be seen in Figure 5.

The beam is considered to be failed when there

is a big displacement, which excelscapacity of the

extensormeter and the testing machine (point 4 in

Figure 2), and the beam no longer carries more

load. It is noted that from the second crack

appearance up to the failure, the increment of

load-carrying capacity is much lower than the

increment of displacement. As shown in Figure 6,

the beam fails at the second crack on the left third

of the beam, where it receives maximum shear

loading during the test.

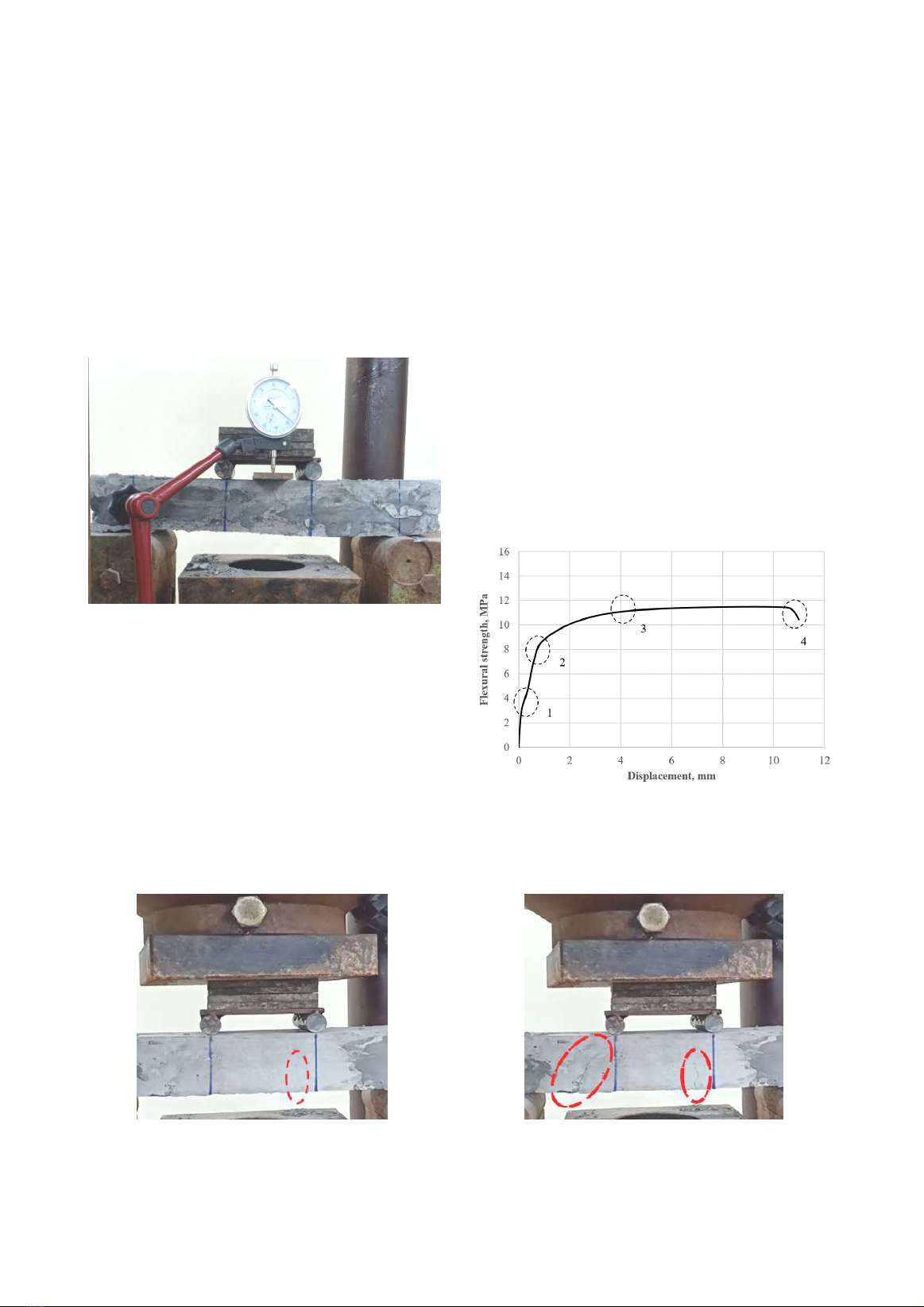

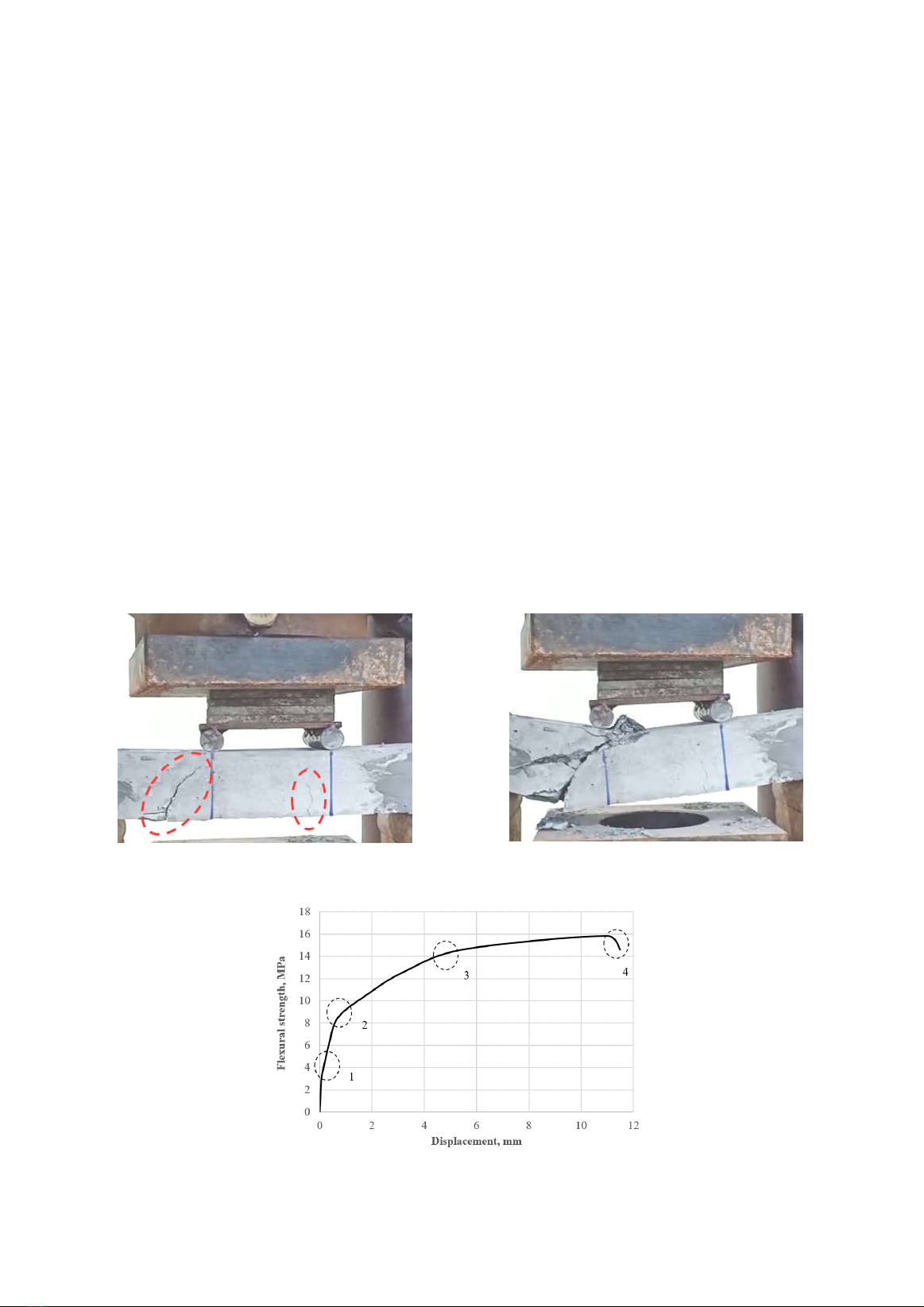

3.2. FGC beam behavior

Similar to the case of the abovementioned

reference beam, there are also four principal

stages during the flexural test on the FGC beam,

as can be observed in Figure 7 representing the

relationship of flexural strength versus

displacement. The first crack (point 1 in Figure

7) appears in the middle third at about 3.6MPa,

as can be seen in Figure 8. The second crack

appears on the right third, as shown in Figure 9,

at about 9MPa (point 2 in Figure 7).

After that, the FGC beam carries more load

(point 3 in Figure 7), but at this moment the load is

transferred mostly to the steel bar reinforcement.

The first crack seems to be opened wider than the

second one, as shown in Figure 10, and the beam

continues to be bent. Up to the moment, the beam

does not carry more loads, it is considered to be

failed (point 4 in Figure 7). The beam fails at the

first crack, as can be seen in Figure 11.

Figure 5. Crack propagation at the third stage

(point 3 in Figure 2)

Figure 6. Failure development at the final stage

(point 4 in Figure 2)

Figure 7. Flexural strength versus displacement relationship of the FGC beam

Journal of Water Resources & Environmental Engineering - No. 87 (12/2023)

6

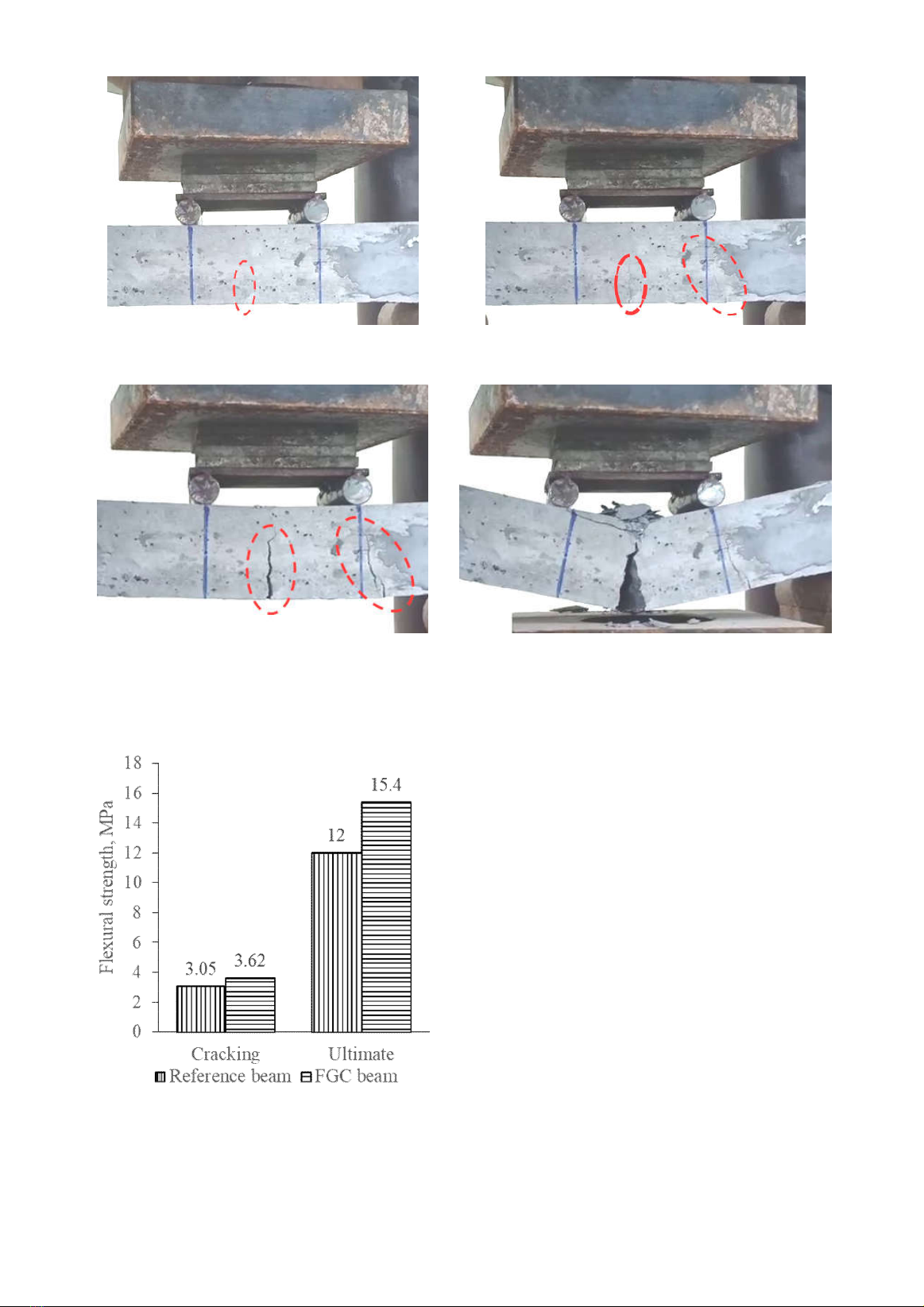

Figure 8. Crack propagation at the first stage

(point 1 in Figure 7)

Figure 9. Crack propagation at the second stage

(point 2 in Figure 7)

Figure 10. Crack propagation at the third

stage (point 3 in Figure 7)

Figure 11. Failure development at the final stage

(point 4 in Figure 7)

3.3. Flexural strength and failure mode

Figure 12. Cracking and ultimate

flexural strength of the reference and

FGC beam (mean value)

The mean values of cracking and ultimate

flexural strength obtained from the reference

and FGC beam are plotted in Figure 12. It can

be observed that cracking and ultimate strength

obtained from the latter is 19% and 28%

respectively higher than those from the former.

It indicates that the FGC beam performs better

than the reference beam under bending load

thanks to the application of the HPGFRC layer.

The FGC beam was scrutinized after the test.

The pull-out of glass fiber in the HPGFRC layer

was witnessed, as shown in Figure 13. The FGC

beam fails as same as the reference one. There is

no crack or delamination between the two layers

of conventional concrete and HPGFRC on the

FGC beam, as can be observed in Figure 14.

This point out that this kind of beam is viable and

applicable to many kinds of structures in