Journal of Water Resources & Environmental Engineering - No. 87 (12/2023)

25

Tire-road separation: Problem and solving method

Nguyen Dang Quy

1

, Vu Ngoc Tuan

1*

, Nguyen Truong Sinh

1

, Vu Van Tan

2

Abstract: The paper discusses the movement of a quarter-

car concerning whether the tires are in contact

with the road or not. A set of equations is formulated to highlight the two different states, and a new

approach is p

resented to solve these equations while also considering the separation of the tires. A

comparison between the new and old models shows that previous studies lacking this consideration

must be reevaluated. A simulation is conducted to demonstrate how the c

haracteristics of the road and

suspension affect vertical displacement. Ultimately, this research provides more accurate outcomes that

can be used to inform future suspension design.

Keywords: Quarter-car vibrations, vehicle vibrations, vibration dynamics, tire-road separation, v

ehicle

safety, ride comfort.

1. Introduction

*

Previous research on vehicle vibrations has

traditionally assumed that the vehicle remains in

contact with the road (Jazar, 2017). However, in

real-world scenarios, cars can experience instances

where they lose contact with the road due to

various factors (Jazar, 2023). Recent studies in

separation dynamics have demonstrated that

accounting for the possibility of separation between

the wheel and the ground leads to a more realistic

representation of the system (Nguyen, 2022a),

(Nguyen, 2021), (Nguyen, 2021a), (Nguyen,

2021b), (Nguyen, 2022b), (Khazaie, 2018).

To observe the normal vibration dynamics,

researchers have employed vibrating half-car

models or more comprehensive models such as

the full-car model (Gillespie, 1992). However,

solving the governing equations for these

models, particularly in their discontinuous states

due to wheel and suspension constraints, can be

more complex (Nguyen, 2021b). A quarter-car

model, which focuses on studying the vertical

1

Le Quy Don Technical University, Hanoi, Vietnam

2

University of Transport and Communications, Hanoi,

Vietnam

*

Corresponding author; Email: tuan.vungoc@lqdtu.edu.vn

Received 20

th

Sep. 2023

Accepted 23

rd

Oct. 2023

Available online 31

st

Dec. 2023

responses and investigates a single corner of the

vehicle with body bounce, is widely used and

popular (Jazar, 2017). Moreover, the quarter-car

model is also suitable for vibration optimization

purposes (Wong, 2008).

Therefore, this paper aims to investigate how

the progress of separation affects the vertical

dynamics of a 2-degree-of-freedom (2DOF)

quarter-car model and validates the ride comfort

of the system under specific conditions. By

focusing on the tire-road separation with 2DOF,

this study provides a solid foundation for

understanding the basics of vibration dynamics

and serves as a valuable resource for gaining

insights into ride comfort.

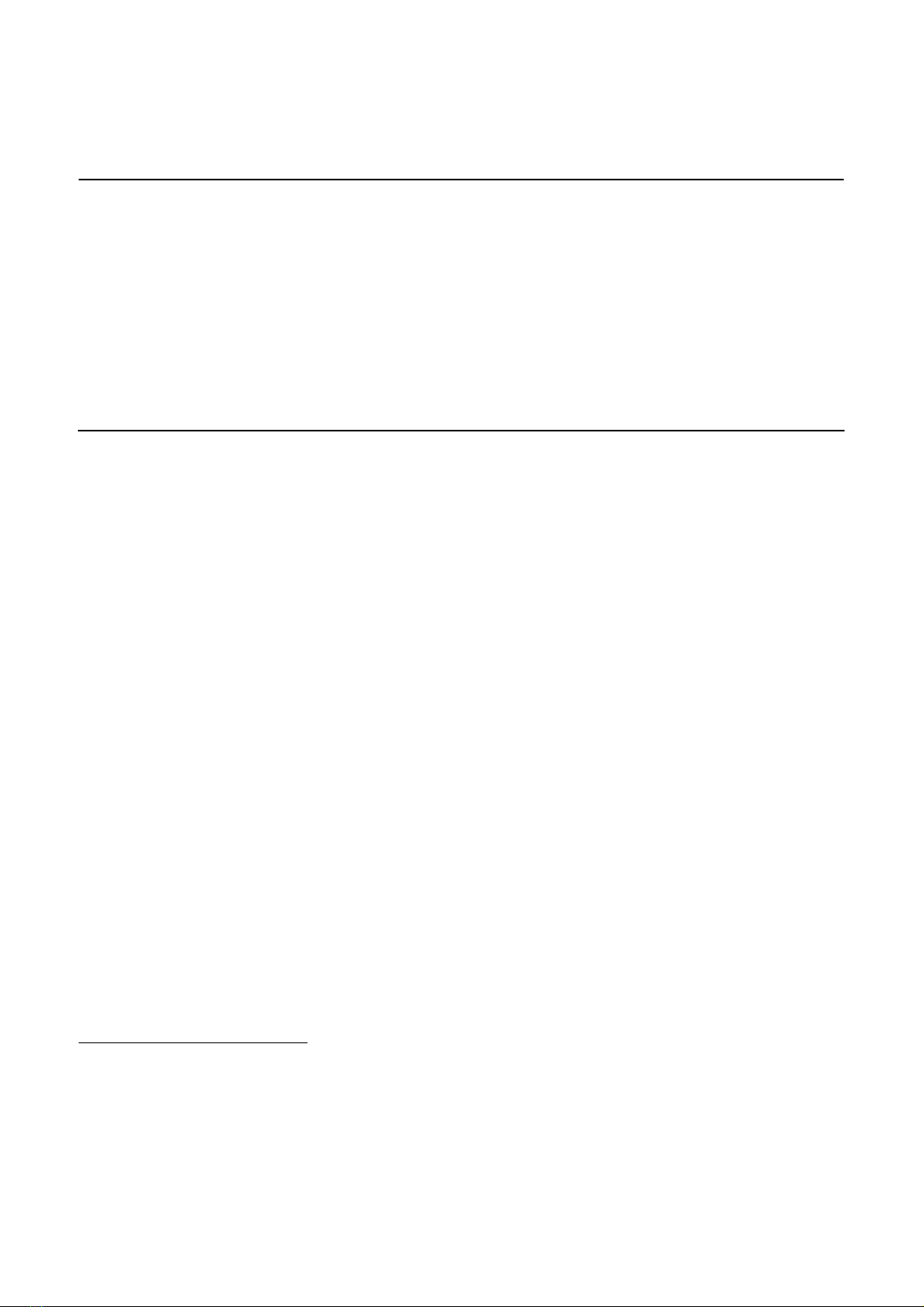

2. Vehicle modeling

This section, the focuses on modeling the

progress of separation in a quarter-car system

and the numerical method employed to solve the

dynamic equation system. The separation

phenomenon is incorporated into the model to

capture its effects on the system's behavior.

2.1. Dynamic Equations of Motion

In order to obtain the dynamic equations of

motion, we analyze the free-body diagram of

the masses at a particular moment, as shown in

Figure 1. Note that the forces from the gravity

of the masses cancel with the static spring

Journal of Water Resources & Environmental Engineering - No. 87 (12/2023)

26

forces. Next, we will examine the free-body

representation to derive the equations of motion

for each component.

m

s

m

u

x

s

x

u

y

c

s

k

s

k

u

m

s

m

u

F

s

F

c

F

u

F

st

W

s

W

u

F

Ts

Figure 1. Quarter-car model and free body

diagram

Applying Newton’s second law of motion,

the vertical response of sprung mass may be

expressed in equation form as follows:

s s C S ST S

m x F F F W

(1)

where, the component forces acting upon the

sprung mass as known:

( )

c s u s

F c x x

is the damping force.

( )

s s u s

F k x x

is the spring force.

st s

F m g

is the static spring

compressive force.

s s

W m g

is the sprung mass’s weight.

Substituting the existing force into equation

(1), the equation of motion of the sprung might

be written as:

( ) ( ) 0

s s s s u s s u

m x c x x k x x

(2)

For the in-contact state, application of the

second law to the unsprung mass leads to:

u u C S U ST U Ts

m x F F F F W F

(3)

Again, the component forces acting inversely

upon the unsprung mass can be obtained:

( )

u u u

F k y x

is the tire spring force.

u u

W m g

is the unsprung mass’s weight.

( )

T s u ST s u

F k x m m g

is the static

compressive force of the tire, where,

ST

x

is the

static tire deflection.

Thus, the equation of motion of unsprung

massin the contact state:

( ) ( )

u u s u s u s u s s u

m x c x x k k x k x k y

(4)

Separation condition is:

u ST

x y x

no contact (5)

u ST

x y x

in contact (6)

When the tire looses contact with the road,

0

T s

F

,

0

U

F

(Khazaie, 2018), thereby, the

equation of the unsprung mass will be:

( ) ( ) ( ) 0

u u s u s s u s u s

m x c x x k x x m m g

(7)

One of the major limitations of quarter-car

models without separation assumption is the

linearity. However, the differential equations

governing the system here are switched from (2)

and (4) to (2) and (7) for the sprung and

unsprung masses respectively when the

separation condition (5) and (6) happens.

Therefore, the system would be nonlinear and

more complicated.

To investigate vertical vibrations in the

dimensional field, assuming that a periodically

varying ground excitation with period

2 /

and the system vibrates harmonically with a

function

0

sin( )y y t

, where

0

y

is the road

amplitude,

is the input frequency.

2.2. Solving method

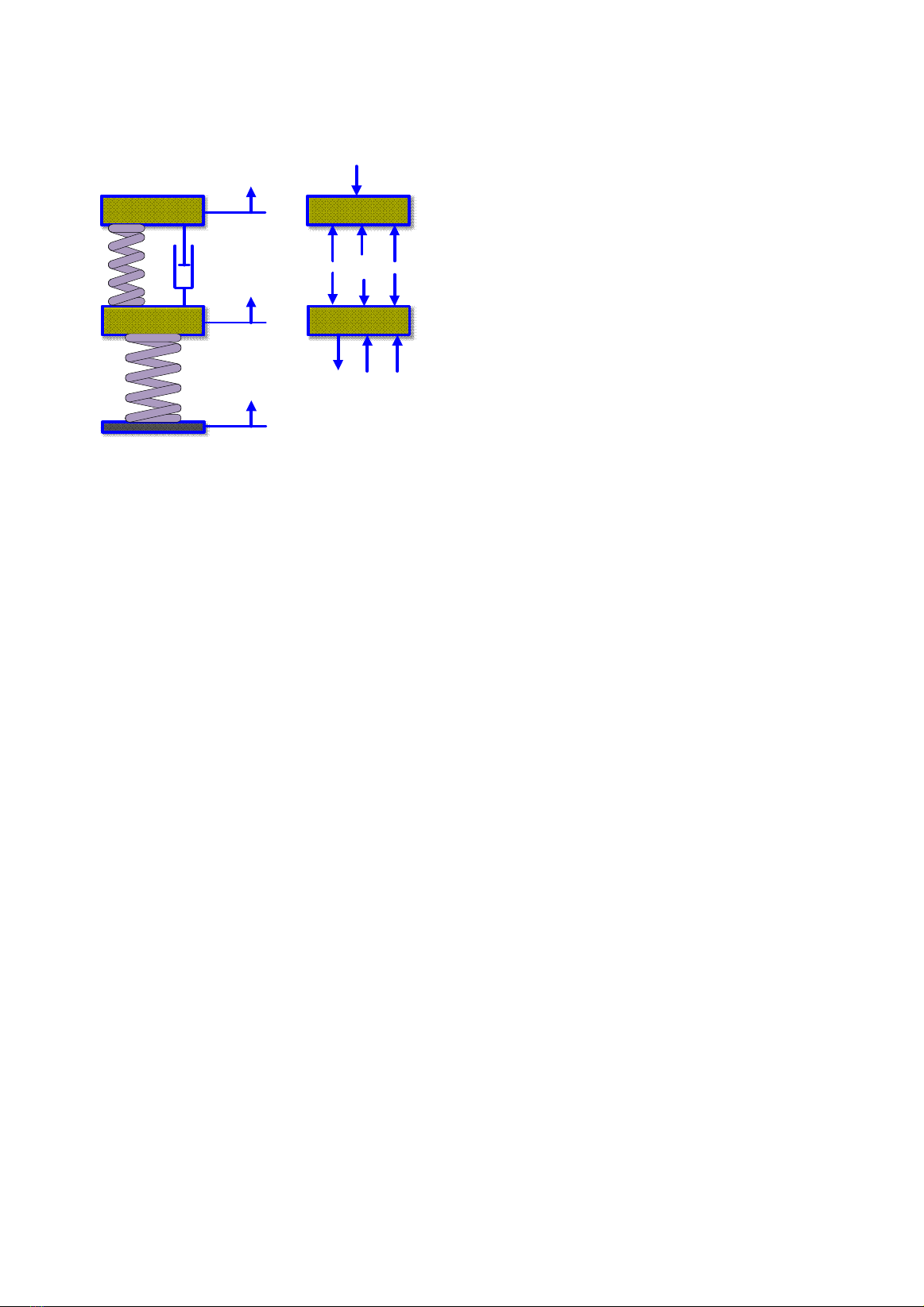

By employing these numerical methods, the

dynamic equation system is solved iteratively

over time, capturing the progress of separation

and its impact on the overall system response.

To solve the governing equation system of

motion, this study uses a loop in MATLAB

software throughout the complete interval. The

ode45 method is utilized, which automatically

adjusts the resolution across the investigation

time by dividing the time interval into smaller,

adequately spaced steps to generate evaluation

points. Using the provided input data, the solver

examines the separation condition for each

Journal of Water Resources & Environmental Engineering - No. 87 (12/2023)

27

interval instance and assigns a value of 0.02 to

an indicator variable when there is no contact

and a value of 0 when there is contact. The

program follows the flow chart presented below

during execution.

Start

Initial Condition

End

Evaluate Equations No

Yes

Separation

Condition

Data

Figure 2. Flow chart for Time Response Program

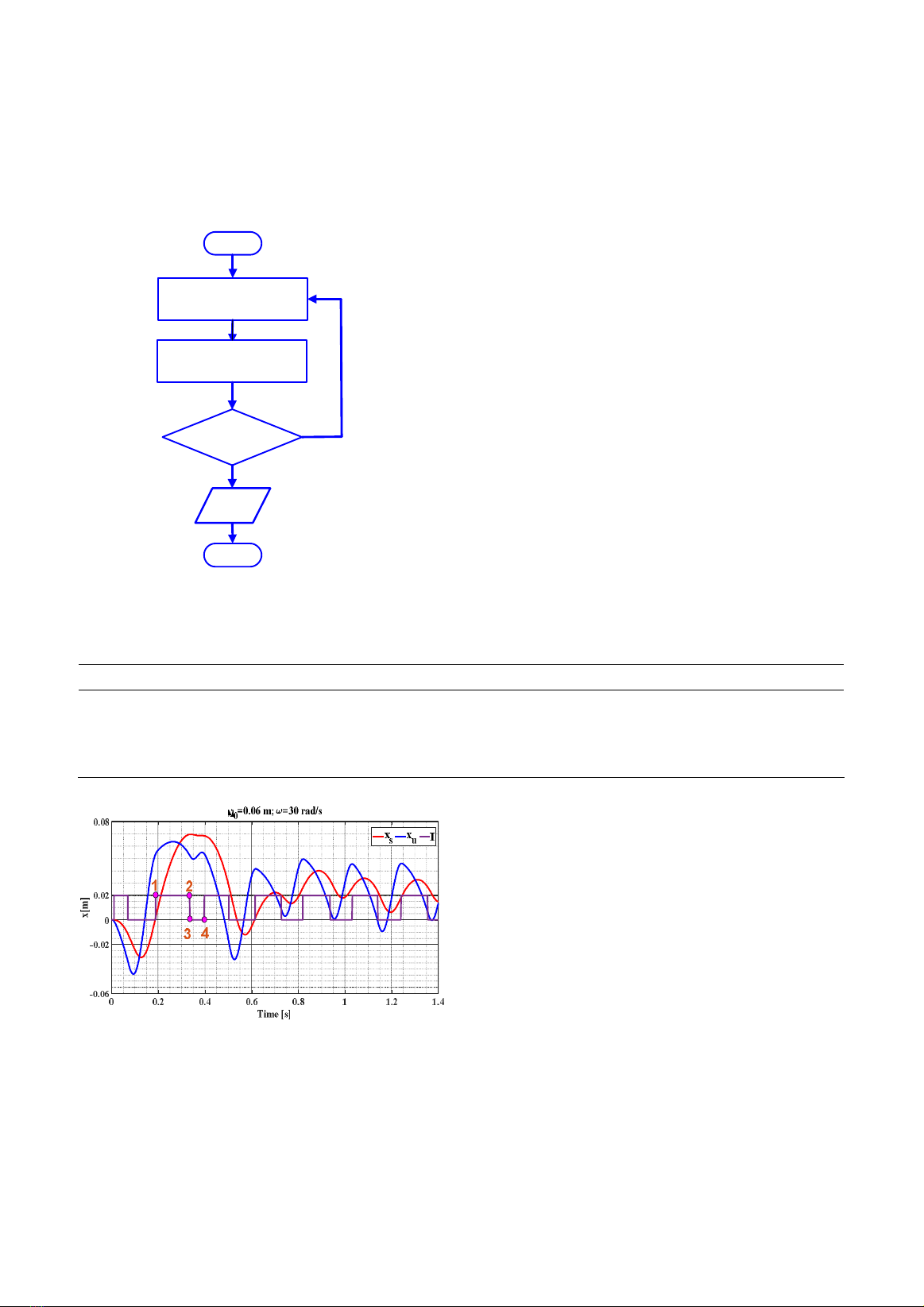

3. Results and discussion

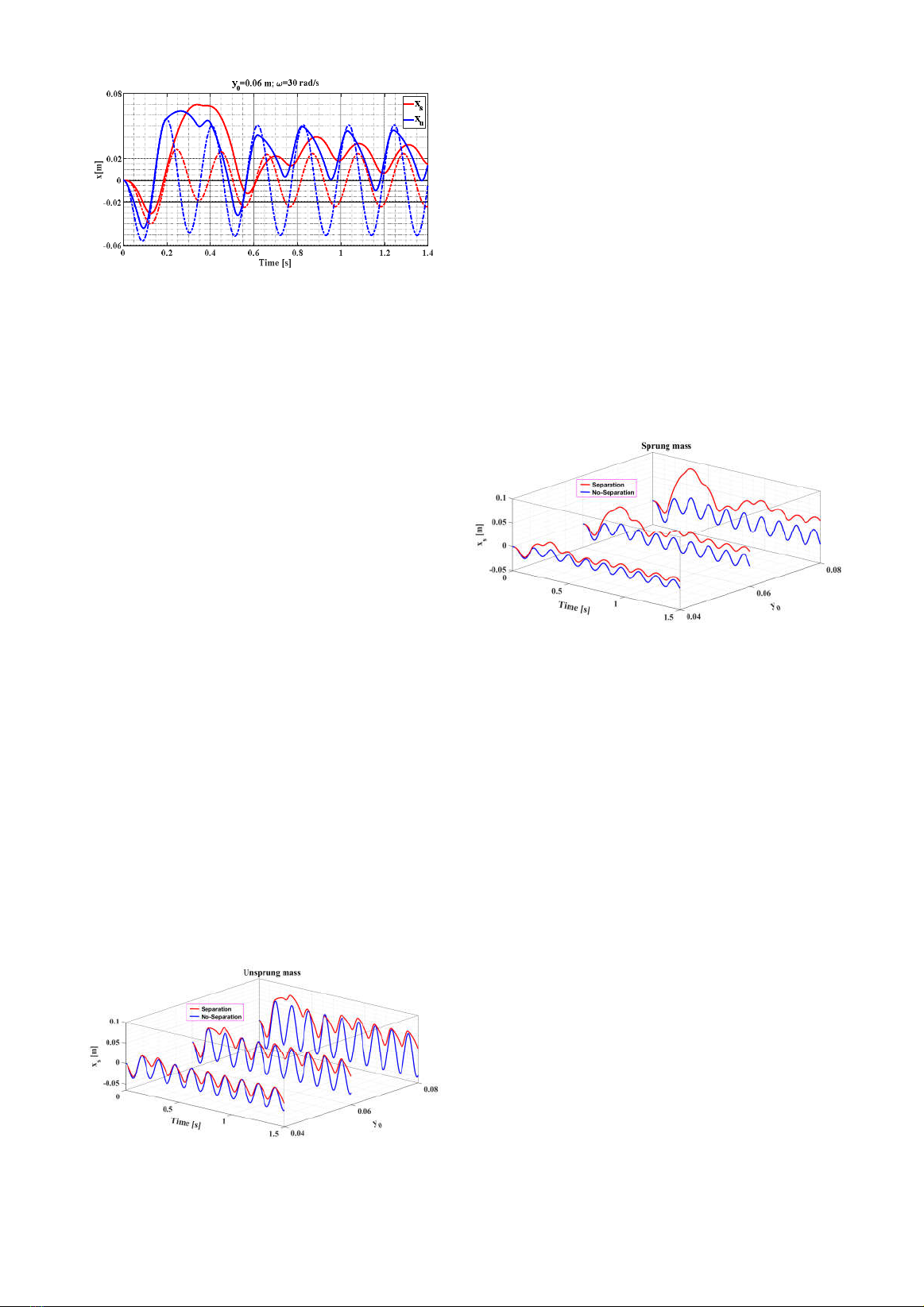

By utilizing the parametric inputs provided

for a practical quarter-car model in Table 1

(Alvarez-Sánchez, 2013), the simulation

program generates a time response considering

the assumption of no contact, as depicted in

Figure 3. The separation dynamics are observed

in response to a sinusoidal input with an

amplitude of 0.06m and a frequency of 30rad/s.

Two distinct curves can be seen for the

unsprung and sprung masses. Initially, the

vertical displacements experience a sudden

jump, reaching approximately 0.08m, then

stabilize to a steady-state separation. To observe

a no-contact period, the study employs an

indicator variable, denoted as I. In this case, the

indicator takes a value of 0.02 during the

interval from point 1 to point 2, indicating the

presence of separation, while the tire makes

contact with the road profile (I=0) from point 3

until point 4.

Table 1. The parameters of a quarter-car model.

Parameter Value [Unit] Parameter Value [Unit]

s

m

208 [kg]

s

k

18709 [N/m]

u

m

28 [kg]

u

k

127200 [N/m]

s

c

3000 [Ns/m]

ST

x

2.7 [mm]

Figure 3. Time response with tire-road

separation

When the tire loses contact with the road, the

displacements of the sprung and unsprung

masses (

s

x

and

u

x

) behave unpredictably in a

linear system. Using the input data in Figure 3,

Figure 4 illustrates an example of the changes in

s

x

and

u

x

. The solid curves represent the

displacements of the actual system, while the

dotted curves show the displacements without

considering the separation assumption. These

curves only coincide during each contact period

(I = 0), indicating that the assumptions of

contact and no-contact align at those points.

However, outside of those periods, the

displacements of the real system and the system

without the separation assumption differ

significantly.

Journal of Water Resources & Environmental Engineering - No. 87 (12/2023)

28

Figure 4. Comparison of displacements

between contact and no-contact consideration.

Furthermore, the research conducted

simulations to study the separation phenomenon

across a wide range of road amplitudes. A series

of time responses of the unsprung mass

s

x

can

be seen from Figure 5 which exhibit multiple

displacements simultaneously in response to a

high-frequency excitation of ω = 40rad/s. These

displacements are depicted in three planes

denoted by

0

y

. The value of the road amplitude

0

y

has a significant impact on the deflection of

the unsprung mass, causing it to increase from

0

0.04y m

to

0

0.08y m

. During tire contact

with the road surface, all dynamic behaviors

appear to exhibit harmonic responses. However,

there are notable differences between the real

systems with separation consideration and those

without. Unexpected effects on vertical ride

comfort have been greatly reduced at high

amplitudes of road excitation when separation is

taken into account. This highlights the

importance of accounting for separation when

analyzing the phase portraits and understanding

the true behavior of the system.

Figure 5. Series of time response for unsprung mass

Among all the factors influencing passenger

comfort, the vibrations of the sprung mass play

a vital attention as they generate vertical forces

on the human body. Thus, the dynamic response

of the sprung mass has been analyzed for

different road excitations, as depicted in Figure

6. It is observed that the vertical displacement of

the sprung mass, taking into account the

separation assumption, is significantly greater

than the original displacement. This emphasizes

the importance of incorporating the effects of

tire-road separation when analyzing the

behavior of such systems.

Figure 6. Series of time response for sprung mass

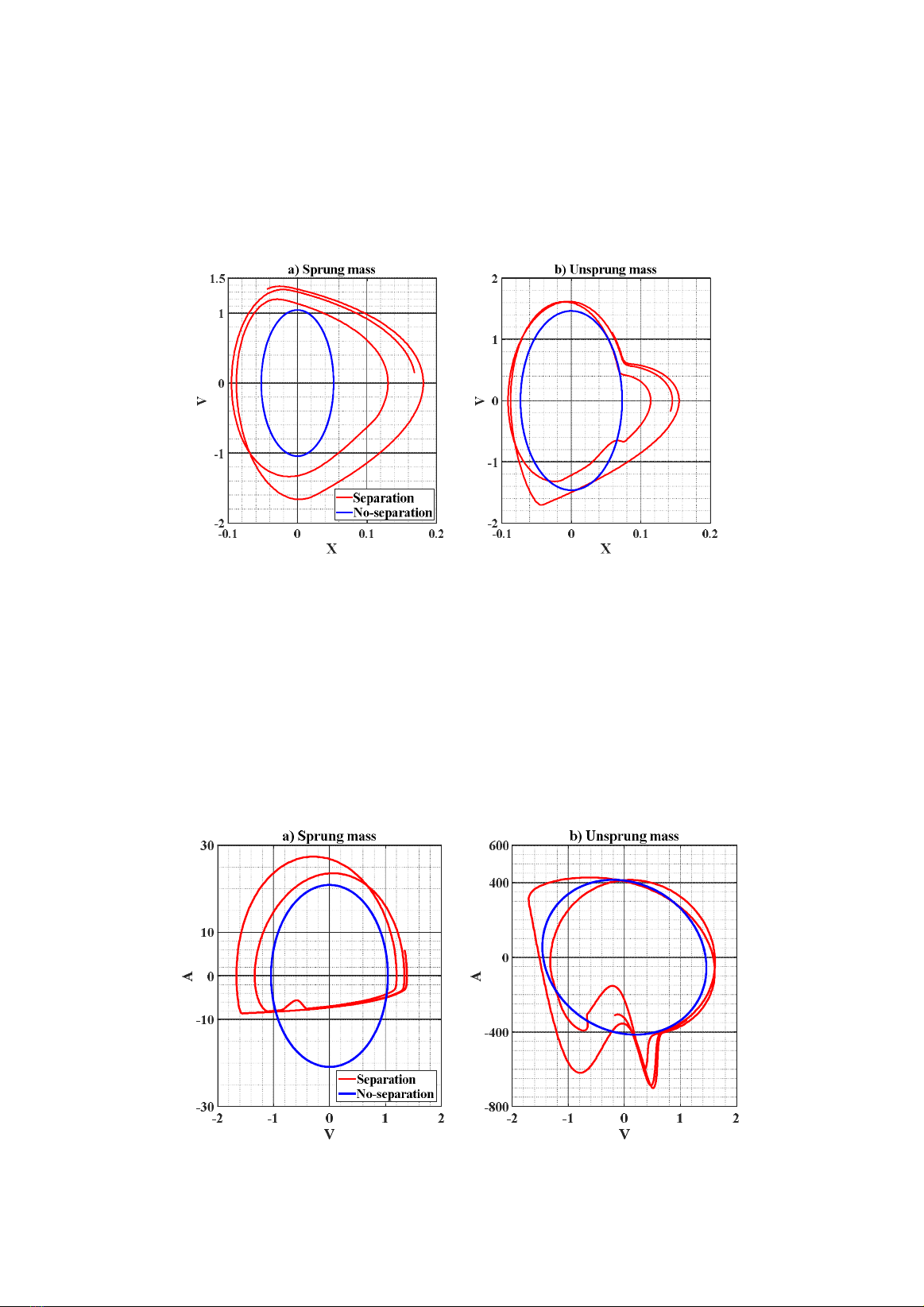

Phase plane analysis is a highly useful and

widely adopted method for studying the

behaviors of nonlinear systems. It involves

creating a phase portrait, which is typically a

two-dimensional plot in the configuration space

of the dynamic system. This plot illustrates the

trajectories of the system in terms of two

systemic state variables when the model is

initialized with various initial conditions. In the

case of tire-road separation, the nonlinearity of

the system causes the trajectories of the

dynamic response to deviate from those of the

linear system that does not consider the

separation assumption.

Figure 7 presents phase portrait graphs in

the dimensional field, excluding the transient

period. The phase portraits illustrate the

relationship between the vertical

displacement X and vertical velocity V.

Journal of Water Resources & Environmental Engineering - No. 87 (12/2023)

29

Figures 7a and 7b precisely depict the phase

portraits for the sprung and unsprung masses,

respectively. Without of the separation

assumption, the displacement and velocity

exhibit harmonic outputs, resulting in an

elliptic relationship in the phase portraits.

However, in a real system that considers the

effects of separation, this relationship

undergoes changes. The presence of tire-road

separation introduces nonlinear dynamics

that can alter the shape and characteristics of

the phase portraits.

Figure 7. Phase portraits in a no-contact zone.

Acceleration plays a significant role in

assessing vehicle ride comfort. Figure 8 displays

two phase portraits depicting the relationship

between velocity and acceleration of the sprung

and unsprung masses. In a similar fashion to the

previous analysis, when considering the

separation phenomenon, the dynamic response

exhibits chaotic behavior and deviates

substantially from the elliptical trajectories

observed in the absence of separation. This

highlights the impact of separation on the

acceleration patterns and emphasizes the need to

account for it when evaluating vehicle ride

comfort.

Figure 8. Phase portraits between acceleration and velocity