Proceedings of Mechanical Engineering Research Day 2018, pp. 268-269, May 2018

__________

© Centre for Advanced Research on Energy

Optimization of diesel, palm oil biodiesel and ethanol blend in a diesel

engine

Md Isa Ali1,2,*, Hikneshwaran Seathuraman1

1)Faculty of Mechanical Engineering, UniversitiTeknikal Malaysia Melaka,

Hang Tuah Jaya, 76100 Durian Tunggal, Melaka, Malaysia.

2)Centre for Advanced Research on Energy, Universiti Teknikal Malaysia Melaka,

Hang Tuah Jaya, 76100 Durian Tunggal, Melaka, Malaysia.

*Corresponding e-mail: mdisa@utem.edu.my

Keywords: Palm oil biodiesel; power; fuel consumption; emission; optimization

ABSTRACT – A Kipor KM 170F engine was operated

on different fuels produced by blending palm oil

biodiesel and ethanol with diesel fuel. Four fuel blends,

namely: neat diesel fuel and 85:10:5, 80:10:10 and

70:25:5 (% v/v) blends of diesel:palm oil

biodiesel:ethanol, were prepared and tested for engine

performance and emission analyses. Engine

performance and emission data were used to optimize

the blend of diesel fuel:palm oil biodiesel:ethanol for

reducing engine emissions. The emissions were found to

be minimum with a 70:25:5 blend of diesel fuel:palm oil

biodiesel:ethanol without a significant drop in engine

power output.

1.0 INTRODUCTION

The use of vegetable oils as alternate fuel sources

or fuel extenders has been studied extensively. Many

researches have been done in the past three decades on

the use of oils from plant as alternative diesel fuel. The

major problem associated with the direct use of oils is

their high viscosity, which interferes with fuel injection

and atomization, which contribute to incomplete

combustion, nozzle coking, engine deposits, lubricating

oil dilution and ring sticking [1-2]. Several researchers

have investigated experimentally the performance and

emissions characteristics of either the vegetable oils or

biodiesels when fuelling diesel engines [3-6]. However,

the use of these biofuels in diesel engines will depend

on their individual physicochemical properties. Most of

the researchers just blend the produced biodiesels with

diesel. Studies on the use of ethanol in the blends are

very limited and not yet fully understood. Fuel

properties are the main factors for performance and

emission control. The present study examines the blend

of conventional diesel fuel, palm oil biodiesel and

ethanol in a standard, fully instrumented, four strokes,

direct injection diesel engine. In this way, a clearer

picture is produced showing the relative performance

and emissions characteristics of the blends.

2.0 METHODOLOGY

A Kipor KM 170F diesel engine was

used in this

study. Specifications of the engine are presented in Table

1. The following test fuels were used in this study:

a) 100% diesel fuel (baseline).

b) 85% diesel fuel,10% palm oil biodiesel and

5% ethanol.

c) 80% diesel fuel, 10% palm oil biodiesel and

10% ethanol.

d) 70% diesel fuel, 25% palm oil biodiesel and

5% ethanol.

Table 1 Engine specifications.

Specifications

Kipor KM 170F

Type of engine

1 cylinder, 4 strokes, DI

Bore x stroke

70 mm x 55 mm

Displacement

0.211 L

Rated power

2.5 kW

Compression ratio

20

Fuel tank capacity

2.5 L

Engine testing on the above fuels was performed at

load ranging from 0 bar to 20 bars, at full throttle using

standard method SAE J1349 and emissions

characteristics were determined using SAE J1312

standard. The sequence of fuels used was completely

randomized. Standard performance and exhaust

emission data were recorded and each test run replicated

thrice. The engine was run at the specific speeds and

loads for a minimum of 6 min and data were recorded

during the last 2 min of operation. The response

variables included power, brake specific fuel

consumption (BSFC), and HC emission. These data

were recorded at 5 s intervals for 2 min and averaged

over that period. After completion of one set of

experiments with four fuels the whole set was

replicated. Statistical analyses for the response of the

engine with different fuel blends were performed to

determine the trends of the response variables. The

response variables considered were engine power

output, BSFC and HC emission. The optimization was

based on maximizing power output and minimizing

BSFC and engine emissions. Response surfaces for

power, BSFC and response curves for HC emission

characteristics tests were plotted.

3.0 RESULTS AND DISCUSSION

3.1 Engine performance

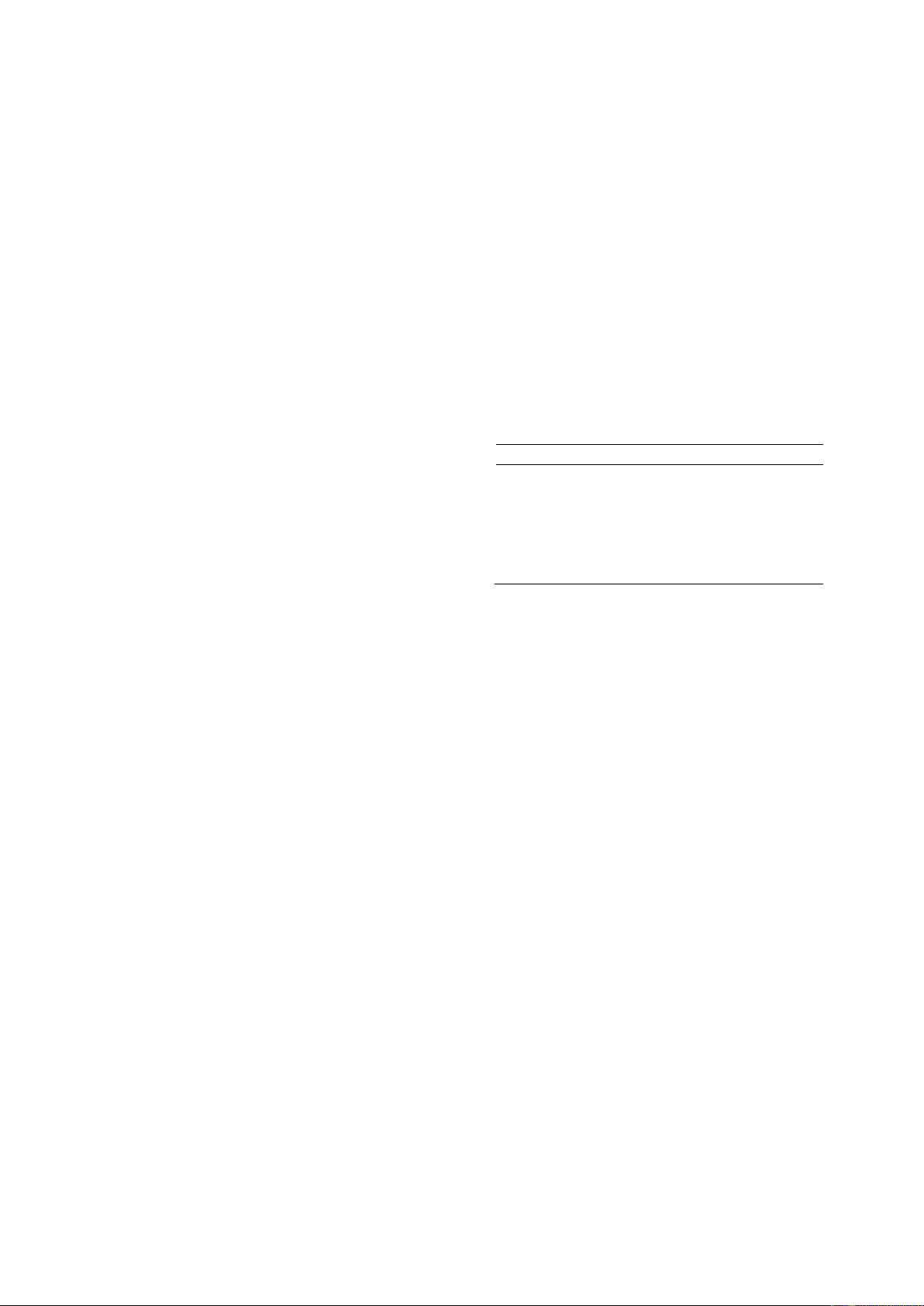

Figure 1 shows the statistical analyses performed

to find the effects of fuel blends on power output. The

figure showed that there is a significant linear and

quadratic effect of ethanol on power output, whereas the

biodiesel had a very small effect on the power output.

No interaction between ethanol and biodiesel was

observed. The regression model for the power output

Ali and Seathuraman, 2018

269

was:

P = 2.55 – 0.001E – 6.988 x 10-19B – 0.001E2

Where P = power (kW), E = ethanol (%) and B =

biodiesel (%). The engine power output at each load

was compared for each fuel blend. A drop in power

output was observed when the biodiesel:ethanol blend

was increased. The reduction in power output up to

7.4% with an increase in biodiesel:ethanol was expected

as this blend had less energy content than diesel fuel.

The contour plot with the darkest region would be the

optimized region. Since the aim is higher power so the

darker region must be observed, and the darkest region

would be the optimized region while the lightest region

is out of the optimization region.

The BSFC for all fuel blends are shown in Figure 2.

Statistical analyses showed that there was no interaction

between biodiesel and ethanol. The regression model for

BSFC was:

BSFC = 0.1128 + 0.00981E + 0.00036B – 4.6 x 10-5E2

Where BSFC = brake specific fuel consumption (kg/

kW-h); E = ethanol (%) and B = biodiesel (%).

Figure 1 Surface and contour plot of power against

ethanol and biodiesel.

Figure 2 Surface and contour plot of BSFC against

ethanol and biodiesel.

When the fuel consumption of the engine was

considered on the basis of energy supplied per kWh, this

showed that there was a drop of energy available for

each increament in biodiesel:ethanol blend per kWh and

thus a drop of power for the respective blend was

justified. The BSFC at any load was minimum with

diesel fuel and it increased linearly with an increase in

the biodiesel:ethanol content in the blend.

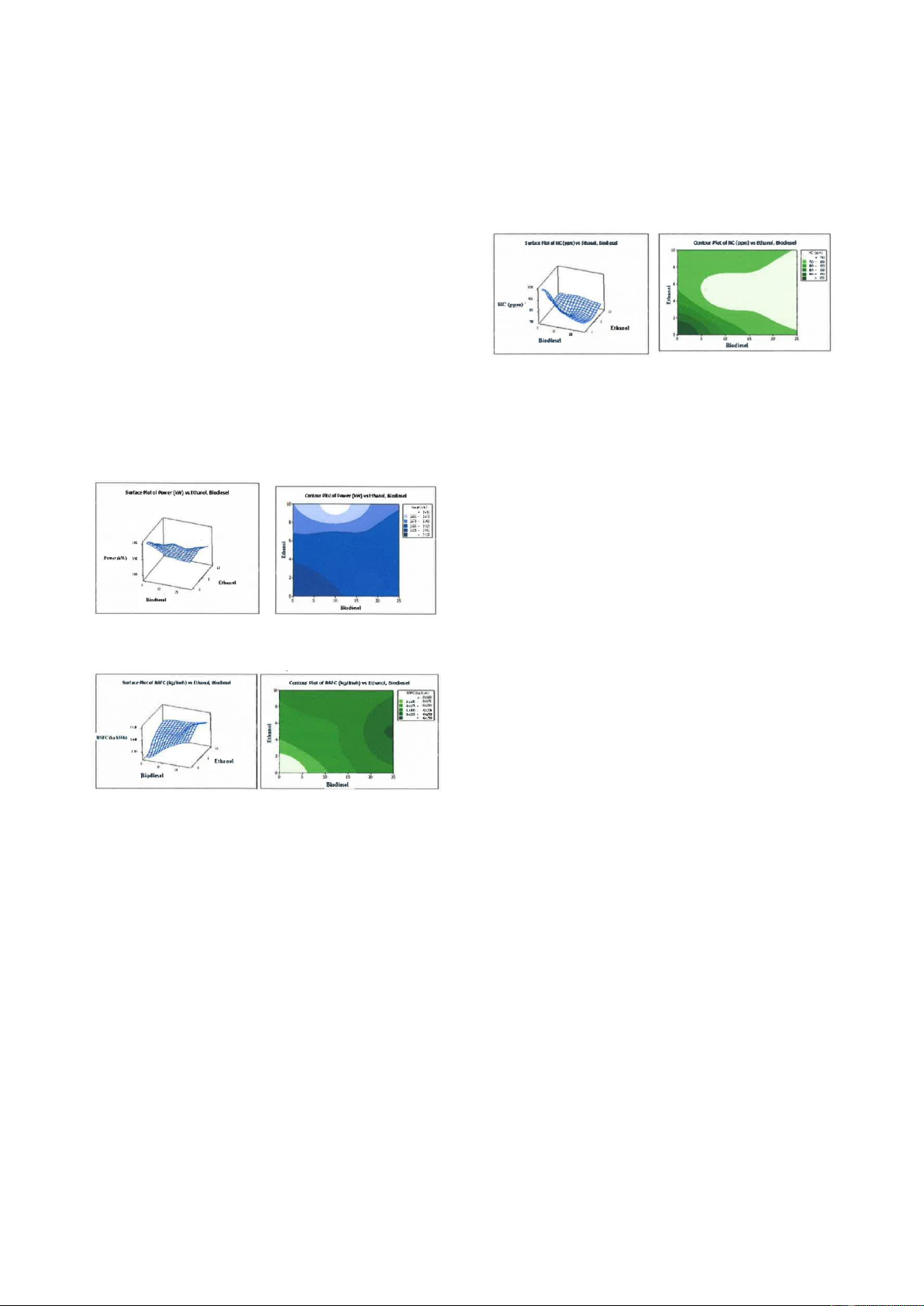

3.2 Emission analysis

Variations of HC emissions with different fuel

blends are shown in Figure 3. Regression analyses

performed for the effect of fuel blends on HC emissions

showed a significant quadratic effect. The regression

model for variation in HC emissions with fuel blends

was:

HC = 987 – 87.9E – 0.26667B + 6.76667E2

Where HC = HC emissions (ppm), E = ethanol (%) and

B = biodiesel (%). The purpose for surface plot is to

obtain lower HC level than diesel fuel. Since, the

intention is to lower HC, so the lighter region must be

observed, and the lightest region would be the

optimized region while darkest region is out of the

optimization region. A significant reduction in HC

emissions was observed when diesel was blended with

biodiesel and ethanol in the ratio of 70:25:5 percent,

respectively.

Figure 3 Surface and contour plot of HC emission

against ethanol and biodiesel.

4.0 CONCLUSION

Engine performance with a diesel:biodiesel:ethanol

fuel blend was not affected to a great extent from that of

diesel fueled engine performance. There was a 7.4%

power reduction, brake specific fuel consumption was

increased by 10.9% for 70:25:5 diesel:biodiesel:ethanol

blend and a significant reduction in HC emissions. The

optimized blend were observed with the 85:10:5, die-

sel:biodiesel:ethanol blend.

ACKNOWLEDGEMENT

The authors wish to acknowledge the financial

support of Universiti Teknikal Malaysia Melaka (grant

number: PJP/2013/FKM(2A)/S01141).

REFERENCES

[1] May, C. Y., Liang, Y. C., Foon, C. S., Ngan, M. A.,

Hook, C. C., & Basiron, Y. (2005). Key fuel

properties of palm oil alkyl esters. Fuel, 84(12-13),

1717-1720.

[2] Ozsezen, A. N., Canakci, M., Turkcan, A., &

Sayin, C. (2009). Performance and combustion

characteristics of a DI diesel engine fueled with

waste palm oil and canola oil methyl

esters. Fuel, 88(4), 629-636.

[3] Dhingra, S., Bhushan, G., & Dubey, K. K. (2013).

Performance and emission parameters optimization

of mahua (Madhuca indica) based biodiesel in

direct injection diesel engine using response

surface methodology. Journal of Renewable and

Sustainable Energy, 5(6), 1-14.

[4] Giakoumis, E. G. (2013). A statistical investigation

of biodiesel physical and chemical properties, and

their correlation with the degree of

unsaturation. Renewable Energy, 50, 858-878.

[5] Montgomery, D. T., & Reitz, R. D.

(2000). Optimization of heavy-duty diesel engine

operating parameters using a response surface

method. SAE Technical Paper, 1-15.

[6] Can, Ö. (2014). Combustion characteristics,

performance and exhaust emissions of a diesel

engine fueled with a waste cooking oil biodiesel

mixture. Energy Conversion and Management, 87,

676-686.

![Bài giảng Kỹ thuật điện - điện tử ô tô [chuẩn nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2026/20260121/hoatrami2026/135x160/37681769069450.jpg)

![Câu hỏi ôn tập Truyền động điện [mới nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20250613/laphong0906/135x160/88301768293691.jpg)

![Giáo trình Kết cấu Động cơ đốt trong – Đoàn Duy Đồng (chủ biên) [Phần B]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20251120/oursky02/135x160/71451768238417.jpg)