Tập 18 Số 4-2024, Tạp chí Khoa học Tây Nguyên

10

UTILIZATION OF SOYBEAN RESIDUE BY PRODUCT FOR BIOPRODUCTION OF

1-HYDROXYPHENAZINE - A POTENTIAL FUNGICIDAL COMPOUND

Nguyen Van Bon1

Received Date: 05/8/2024; Revised Date: 14/8/2024; Accepted for Publication: 15/8/2024

ABSTRACT

1-Hydroxyphenazine (HP) is a heterocyclic nitrogenous compound which reported various potential

bioactivities. The current work aimed to utilize soybean residue by-product (SRBP) as a C/N source

for the biosynthesis of HP via fermentation and investigated its potent inhibition against some plant

pathogen fungi. The novel medium for effective HP production by P. aeruginosa TUN03 was investigated

comprising 1.75% C/N source (SRBP/Tryptic Soy Broth (TSB) ratio of 8/2), 0.05% FeSO4, and 0.05%

K2HPO4 to obtain a high yield of HP at 19.23 μg/mL in a small flask. HP was pathogen using a 14

L-bioreactor and achieved higher productivity (32.01 μg/mL) in a shorter fermentation time (10 h)

compared to its fermenting at a small scale in flask. In anti-fungal tests, this compound showed potential

inhibition against Fusarium oxysporum F10 with a high inhibitory value of 65% and moderate effect

against Gongronella butleri F07 (35%) and Fusarium incarnatum F13 (30%). HP was further evaluated

for its effect against spore germination of F. oxysporum F10 and showed high inhibition value of 75%.

The result of this work suggested that SRBP is a suitable C/N source for the production of HP with

potential use a fungicidal agent.

Keywords: soybean residue by- product, 1-Hydroxyphenazine, bioreactor, anti-fungal activity.

1. INTRODUCTION

Phenazine - a nitrogenous and heterocyclic

compound has the formula of (C6H4)2N2. More

than 100 phenazine compounds have been found

in nature and their chemical structures are formed

from the basic chemical structure of phenazine

(Cimmino A. et al., 2012). Almost all the

natural phenazine derivatives are biosynthesized

via microbial fermentation, and more than 50

phenazines were reported being produced by

Pseudomonas species (Liu H. et al., 2007), of

which Pseudomonas aeruginosa is a major

phenazines-producing bacterial strain, as such

this bacterium has been extensively used in the

biosynthesis of phenazines.

In various earlier reports, commercial media

were used as a C/N source for P. aeruginosa

fermentation to produce phenazines, and the culture

processes were mainly performed on a minor scale

of flasks (Nguyen T.H. et al., 2022a). Concerning

eco-friendly and cost-effective production, we

established the fermentation process using some

organic by-products, such as squid pens (Nguyen

T.H. et al., 2022a), cassava residue (Phan T.Q. et

al., 2024), and groundnut cake (Nguyen V.B. et al.,

2023). In this study, soybean residue by-product

(SRBP) was considered used for fermentation.

Soybean is a species of legume, which is

native to East Asia, widely grown for harvesting

its edible bean. Soybean has been widely used for

oil extraction, production of soymilk, and other

products (Riaz M.N. et al., 2023). soybean residue

by-product (SRBP) is the main by-product from

oil extraction and soymilk manufacturing with a

reported highest residue yield of nearly 90% (Sun

Y. et al., 2021). This residue was found rich in

protein (16.1-33.4%), fat (8-22.3%), carbohydrates

(under 53.6%), and total minerals (0.2-5.3%) in

a survey by Shuhong Li et al 2013. Thus, SWRP

has been utilized for many purposes. In this work,

SWRP was used as a C/N source for fermentation

to produce 1-hydroxyphenazine (HP) – a phenazine

compound with potential fungicidal effects.

To date, phenazines have been reported for their

potential fungicidal effects against pathogenic

fungi in human (Zahraa J.J. et al., 2017; Sudhakar

T. et al., 2017), and toxigenic fungi in food (Zahraa

J.J. et al., 2017; Mohamed N.F.H. et al., 2020;

Hina S. et al., 2021). Notably, phenazines showed

inhibition against various plant pathogenic fungi,

including Botrytis cinerea, Alternaria alternate,

Fusarium graminearum, Fusarium oxysporum,

Magnaporthe grisea, Rhizoctonia solani,

Sitophilus oryzae, Macrophomina phaseolina,

Colletotrichum capsici, Colletotrichum

gloeosporioides, Comastoma falcatum,

Phaeosphaerella theae based on our recent survey

(Nguyen T.H. et al., 2022b). Recently, HP was

found as a potential fungicide against Fusarium

oxysporum with the anti-mycelial growth and anti-

1Institute of Biotechnology and Environment, Tay Nguyen University;

Corresponding author: Nguyen Van Bon; Tel: 0842458283; Email: nvbon@ttn.edu.vn.

Tập 18 Số 4-2024, Tạp chí Khoa học Tây Nguyên

11

spore germination activity of 68.7% and 98.4%,

respectively (Phan T.Q. et al., 2024). In this study,

we evaluated the potential fungicidal effects of HP

against some plant pathogenic fungi collected in

the Central Highland of Vietnam.

Fermentation in

Small Scale

Soybean residue

by-product Scale-up Production of HP

in a 14 L- Bioreactor

Extraction &

Isolation of PG

Testing

fungicidal

Effect of HP

Scheme 1. The steps and contents for performing experiments in this work

2. MATERIALS AND METHODOLOGY

2.1. Study contents

- Establishment of the fermentation process for

the production of 1-hydroxyphenazine.

- Purification of 1-hydroxyphenazine from the

culture medium.

- Assessment of the potential fungicidal activity

of 1-hydroxyphenazine.

The contents and experimental stepts of this

study were illustrated in Scheme 1.

2.2. Materials

P. aeruginosa TNU03 was isolated from

the soil of Dak Lak province of Vietnam in the

previous work (Nguyen T.H. et al., 2022c).

Silicagel (Geduran® Si 60, size: 0.040-0.063 mm)

was purchased from Merck Sigma Chemical

Co. (St. Louis City, MO, USA). Some plant

pathogenic fungi were obtained from our earlier

report (Nguyen D.N. et al., 2021).

2.3. Methodology

2.3.1. The effect of SRBP/TSB ratio and their con-

centration added in medium on HP yield

- The fermentation process: SRBP was

combined with TSB at several ratios (SRBP/TSB,

w/w) of 5/5, 6/4, 7/3, 8/2, 9/1, and 10/10 then

used as C/N sources for cultivation. 30 mL culture

medium in a 100 mL-flask containing 1% C/N

source, 0.05% K2HPO4, and 0.05% FeSO4, initial

pH 7 was fermented by P. aeruginosa TUN03 at

30°C with a shaking speed of 150 rpm for 3 days

(this fermentation process is denoted by *). The

supernatant was harvested by centrifugation at

10,000× g for 15 min and used to determine the

target compound (HP) concentration.

- Various concentrations of C/N source (SRBP/

TSB at the ratio of 8/2), including 0.5, 0.75, 1.0,

1.25, 1.5, 1.75, and 2.0% were prepared in a liquid

medium containing 0.05% K2HPO4 and 0.05%

FeSO4 with initial pH 7, then were fermented using

the above protocol (*) to investigate the suitable

C/N concentration.

- Scale-up production of HP in a bioreactor

system: bacterial strain TNU03 was pre-cultivated

in culture broth TSB in some 500 mL flasks at the

temperature of 30 °C for 1.5 days, then a total of

400 mL of fermented medium (bacterial inoculum)

was added to the reactor containing 4.6 L of the

newly investigated culture medium containing

1.5% C/N source (SRBP/TSB at the ratio of 8/2),

0.05% K2HPO4 and 0.05% FeSO4, initial pH 7.0

The fermentation was performed at 30°C, 250

rpm, and dissolved oxygen of 1.2 vvm for 12 h,

and the HP produced by TNU03 was determined

every 2 h.

2.3.2. The purification and evaluation of fungicid-

al activity of HP

HP was isolated from the culture broth in a

bioreactor according to the protocol previously

presented in our report (Nguyen T.H. et al., 2022c).

Its GCMS and HPLC profiles were conducted

following the method reported by Nguyen V.B. et

al. (2023).

The fungicidal activity was tested via mycelial

growth inhibition and fungal spore germination

inhibition, which were presented in detail in our

previous work (Nguyen T.H. et al., 2024).

2.3.3. Statistical Analysis

The experimental data were obtained and

analyzed via the simple variance (ANOVA)

Tập 18 Số 4-2024, Tạp chí Khoa học Tây Nguyên

12

then Duncan′s multiple range tests (when the

experiment contains ≥ 6 items that need to be

compared) and Fisher’s LSD tests (when the

experiment contains ≤ 5 items that need to be

compared) at p = 0.01 were evaluated. Statistical

Analysis Software (SAS-9.4) purchased from

SAS Institute Taiwan Ltd (Taipei, Taiwan) was

used for statistical analysis.

3. RESULT AND DISCUSSION

3.1. Establishment of the fermentation process

for the production of HP.

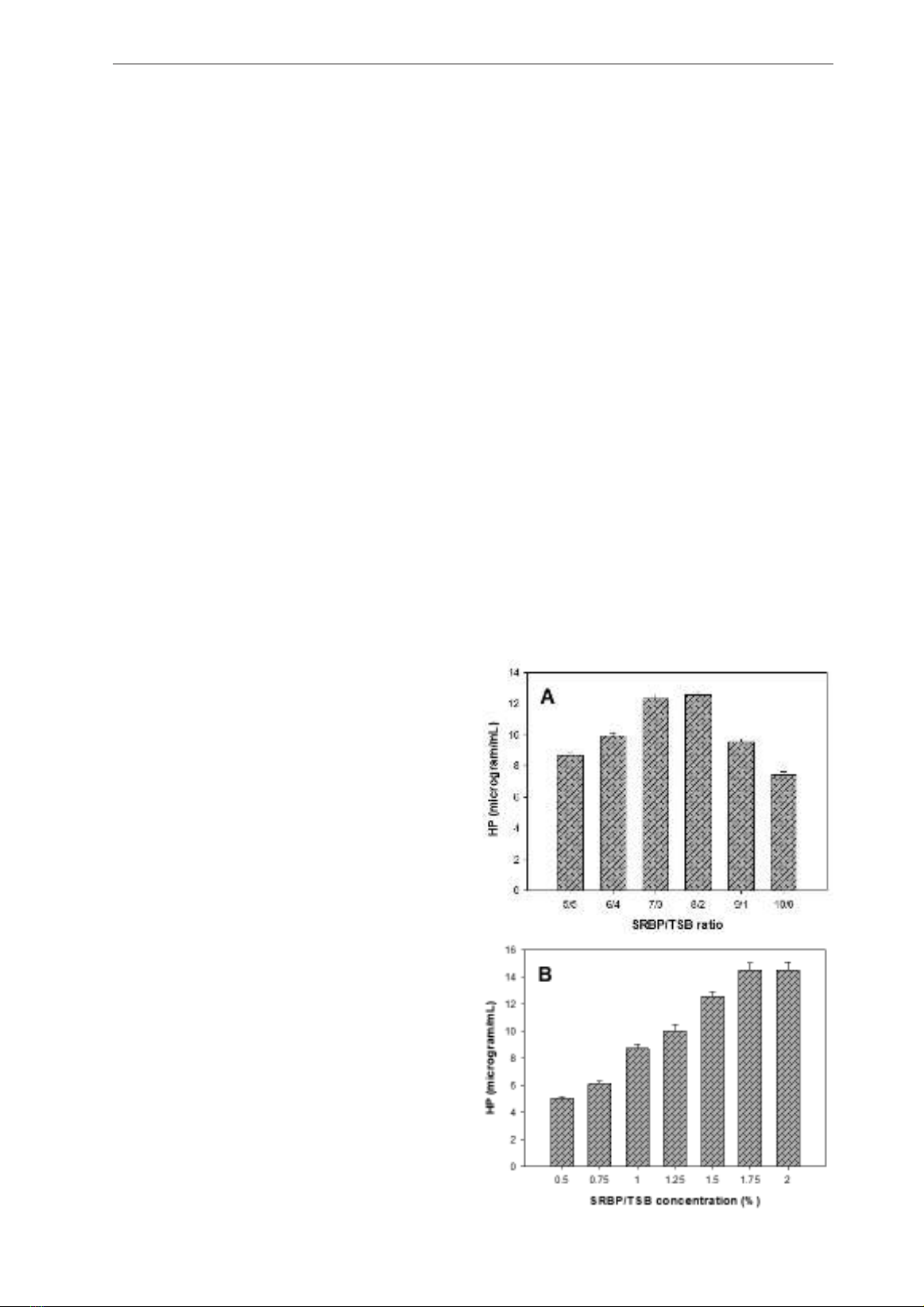

The effect of SRBP/TSB ratio and their

concentration added in medium on HP yield:

TSB was used as free protein for adding into

the culture medium. SRBP was combined with

this free protein at several ratios and used as a C/N

source for fermentation. As shown in Figure 1A,

the SRBP/TSB ratios of 7/3 and 8/2 gave the high

content of HP (12.3-12.5 μg/mL) in the fermented

medium. For cost-effectiveness, the ratio of 8/2

was chosen for further investigation to determine

the most suitable C/N source concentration.

The C/N source (SRBP/TSB at the ratio of 8/2)

was added into the cultured media with various

concentrations of 0.5, 0.75, 1.0, 1.25, 1.5, 1.75, and

2.0% then used for fermentation by P. aeruginosa

TUN03. As presented in the Figure 1B, the C/N

source at the concentration of 1.75-2% gave the

high yield of HP (14.50-14.52 μg/mL) in the

fermented media, and 1.75% C/N was chosen as

the suitable and cost-effective for fermentation to

produce HP.

Phenazine compounds were reported to

numerous bioactivities and as such received

much attention for their production. In many

previous reports, commercial media like King’s

B, King’s A, tryptone, peptone, and nutrient broth

for fermentation and phenazines were produced

at the content of 5.2-33.0 μg/mL (Elbargisy

R.M. 2021; Devnath P. et al., 2021; Ozdal M. et

al., 2019; Barakat K.M. et al., 2015; Ozdal M.

2019). For the lower cost of bioproduction of

phenazines, several low-cost organic materials

such as corn, cottonseed, sweet potato, soya

bean, groundnut, peat moss, and taro leaves

were investigated for phenazines producing by

fermentation, however, these compounds were

synthesized at low productivity under 4 µg/mL

mL (DeBritto S. 2020; El-Fouly M.Z. et al.,

2015).

Phenazines were also produced by using

some organic wastes, such as tea wastewater,

waste cheese whey, waste frying oil, olives

waste, maize wastewater, sugar beet molasses,

craft beer waste, peapods, and the phenazines

yield were obtained in the rang of 1.3-58 μg/

mL. Of these, craft beer waste was found as the

most potential C/N source for fermentation, and

phenazines were produced at a high of 21-58 μg/

mL according to a recent survey by Nguyen et al.

(2023). In this study, soybean residue by-product

(SRBP) combined with a minor amount of TSB

was first reported as being used as a potential

C/N source for fermentation to produce HP with

a high yield of 14.52 μg/mL.

Scaling up of 1-hydroxyphenazine production

using a 14 L-bioreactor system

In microbial fermentation technology,

bioreactor systems are considered valuable

quipment to effectively bio-produce secondary

metabolites with a high-level yield and reduce

the fermentation time (Nguyen, T.H. et al.

2021). In this work, HP was produced in mass

using a 14 L-bioreactor system. As illustrated in

Figure 1C, HP was synthesized by P. aeruginosa

TUN03 with a significant amount from 6 h

of cultivation. The HP yield was significant

enhanced till 10 h (reached the yield of 32.01

μg/mL), and no further HP was produced from

10-12 h of fermentation.

Tập 18 Số 4-2024, Tạp chí Khoa học Tây Nguyên

13

Figure 1. Production of 1-Hydroxyphenazine

(HP) via fermentation.

Note: The effect of SRBP/TSB ratio (A) and

their concentration added in medium (B) on HP

yield. Scaling up of HP production using a 14

L-bioreactor system).

Recently, HP was produced in bioreactor

systems using peanut oil processing by-product

(Nguyen V.B. et al., 2023) and cassava starch

processing by-product (Phan T.Q. et al., 2024)

resulting in harvesting high productivity of 35.1

and 36.5 µg/mL, respectively.

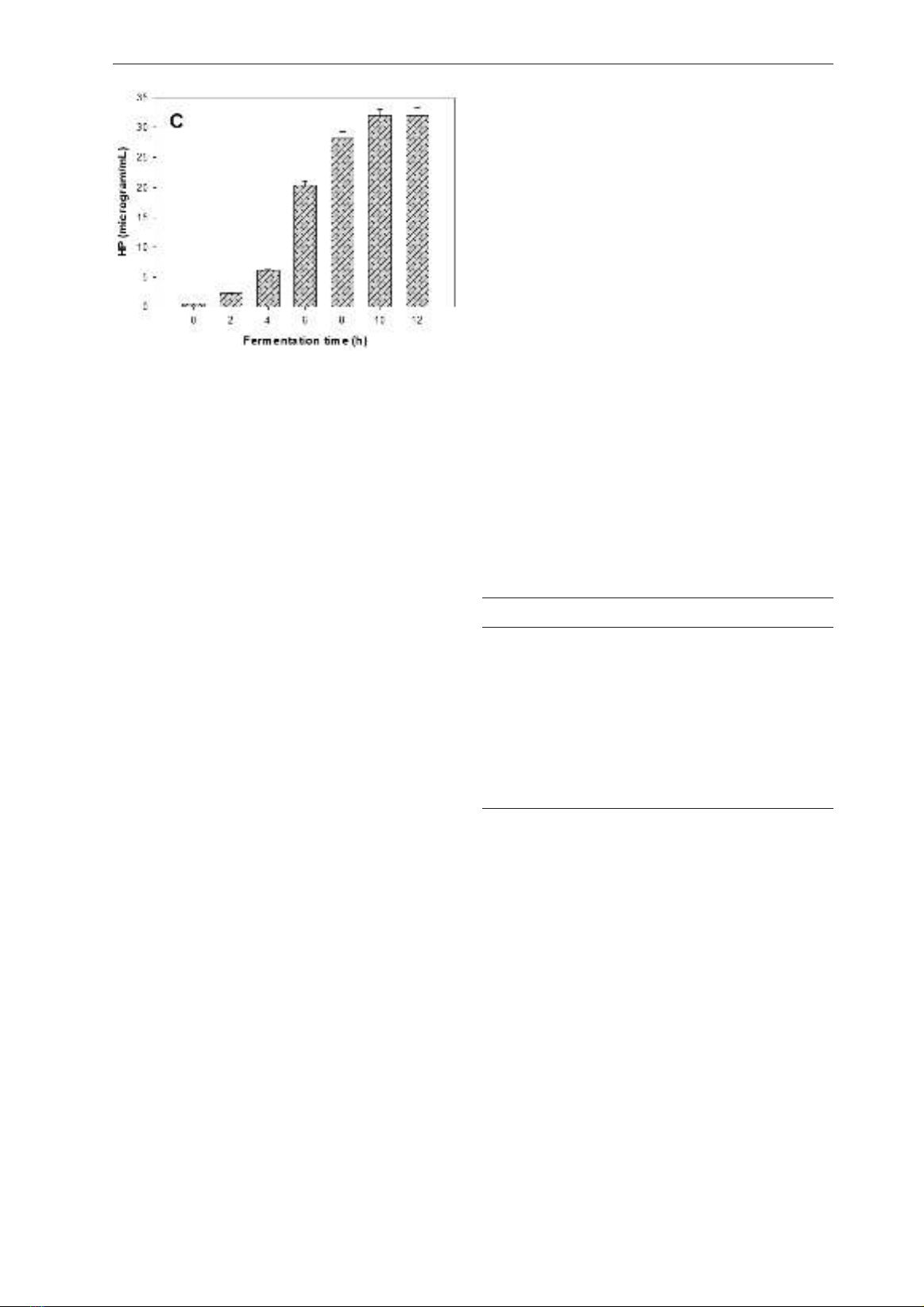

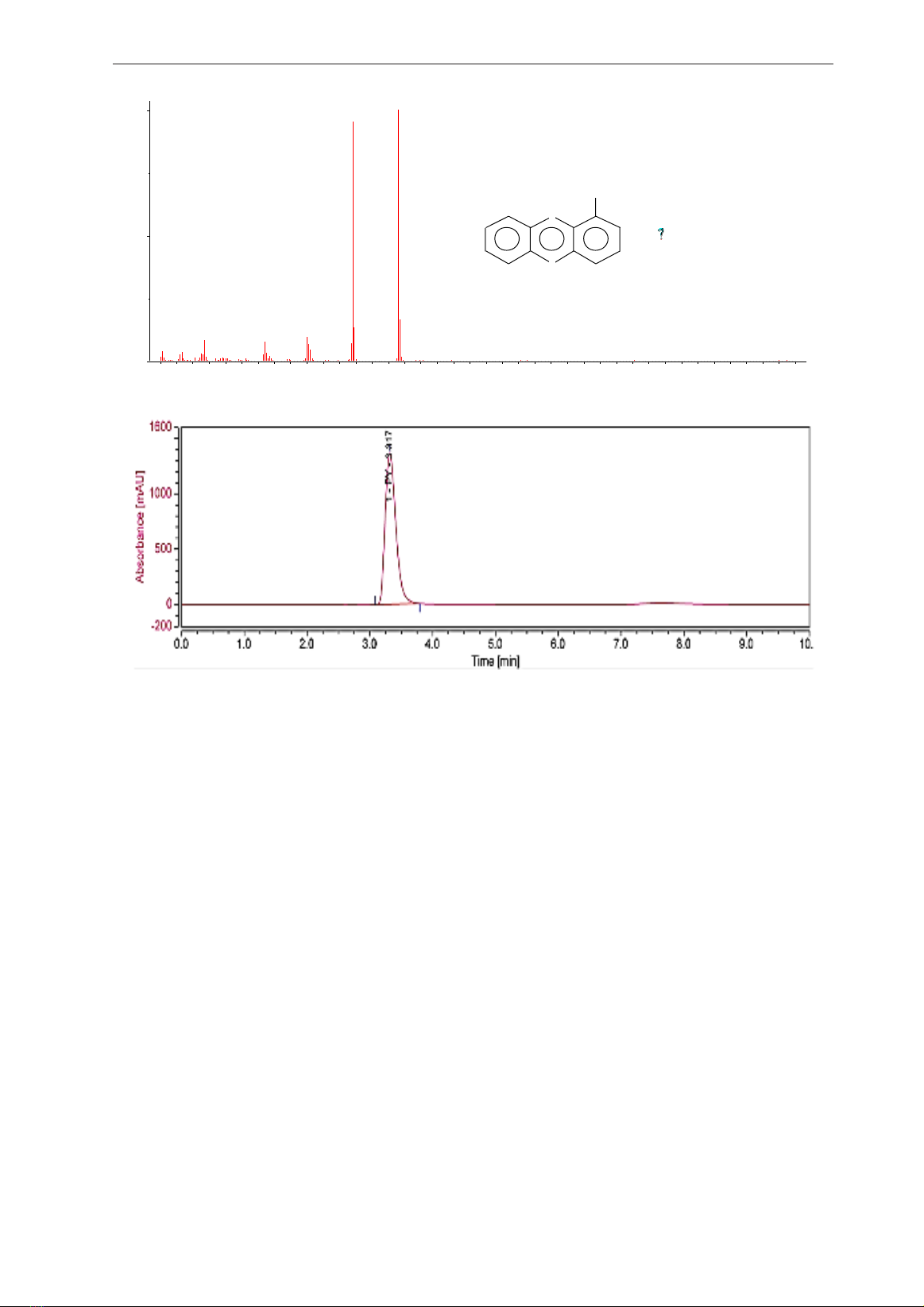

3.2. The purification and evaluation of fungicidal

activity of HP.

The phenazine compound was isolated and

purified from the cultured broth in a bioreactor

system using the method presented in our

earlier report (Nguyen T.H. et al., 2022c). The

purified yellow compound was confirmed as

1-Hydroxyphenazine using GCMS analysis

(Figure 2). Based on the HPLC profile of HP

produced in this work, it was found to have a

high purity (Figure 3) as such it could be used for

further study in bioactivity tests.

To confirm the purified compound – HP

produced in this study is an active fungicidal

compound, various plant pathogenic fungal

strains obtained from the previous work (Nguyen

D.N. et al., 2021) were used for testing the

fungicidal effect of HP. As shown in Table 1, HP

shows inhibition against some fungal strains,

including Fusarium solani F02, Fusarium

solani F03, Fusarium solani F04, Gongronella

butleri F07, Fusarium oxysporum F10, and

Fusarium incarnatum F13 with the inhibition

values in the range of 7-65%. Of those, HP had a

weakly inhibition against Fusarium solani F02,

Fusarium solani F03, Fusarium solani F04 with

an inhibition of 7-16%, moderately effect against

Gongronella butleri F07 (35%) and Fusarium

incarnatum F13 (30%). This compound showed

the most effect against Fusarium oxysporum F10

with a high inhibitory value of 65%. The result of

this work suggested HP may be a high potential

candidate for management of Gongronella butleri

F07, Fusarium oxysporum F10 and Fusarium

incarnatum F13.

The fungal spores were reported to play an

important role in the pathogenesis of pathogenic

fungal strains, in addition, this is also recognized

as the most sensitive stage to inhibition, as

such, assessing the inhibitory effect of both

mycelial growth and spore germination is an

effective strategy for the phytopathogenic

fungi management (Phan T.Q. et al., 2024). To

futher characterize HP as a potential fungicide

against Fusarium oxysporum F10, the fungal

spore germination inhibition of HP was also

tested. The result showed that HP demontated

better inhibitory effect for spore germination

(75%) than inhibition against mycelial growth

(65%).

Table 1. Inhibitory effects of HP on some

pathogenic fungal strains

Fungal strains Anti-fungi (%)

Fusarium solani F02 7

Fusarium solani F03 16

Fusarium solani F04 11

Gongronella butleri F07 35

Fusarium oxysporum F10 65

Fusarium incarnatum F13 30

4. CONCLUSIONS

This study achieved finding a novel culture

medium comprising 1.75% C/N source (SRBP/

TSB ratio of 8/2), 0.05% FeSO4, and 0.05%

K2HPO4. HP was then scale-up produced using a

14-L bioreactor system resulting in a high HP yield

of 32.01 μg/mL. The purified HP demonstrated

potential inhibition against Fusarium oxysporum

F10 (65%) and a moderate effect against

Gongronella butleri F07 (35%) and Fusarium

incarnatum F13 (30%). In addition, HP also

demontated high effect against F. oxysporum F10

spore germination of (75%).

Tập 18 Số 4-2024, Tạp chí Khoa học Tây Nguyên

14

(Text File) PYO01_120729234758#1070 RT: 13.47 AV: 1

50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200 210 220 230 240 250 260 270 280 290 300 310 320 330 340 350 360 370 380 390 400 410 420 430 440

0

50

100

51 63

77

88 102

114

128

140

153

168

196

207 229 271 341 430

ine

N

N

OH

Figure 2. The GCMS profile of 1-hydroxyphenazine

Figure 3. The HPLC profile of 1-hydroxyphenazine purified in this work.

![Bài giảng Chế biến khoáng sản vô cơ [Mới nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20251025/thanhvan173002/135x160/21521761538638.jpg)

![Bài giảng Giản đồ pha: Chương 2 - Nguyễn Văn Hòa [FULL]](https://cdn.tailieu.vn/images/document/thumbnail/2018/20180409/tieu_vu10/135x160/531523282915.jpg)