4

ENGINE AIR STARTING SYSTEMS

A. GENERAL

4A1. Description. Modern submarine

diesel engines are started by admitting

compressed air into the engine

cylinders at a pressure capable of

turning over the engine. This process is

continued until the pistons have built

up sufficient compression heat to cause

combustion. The pressure used in air

starting systems is approximately from

250 to 500 psi.

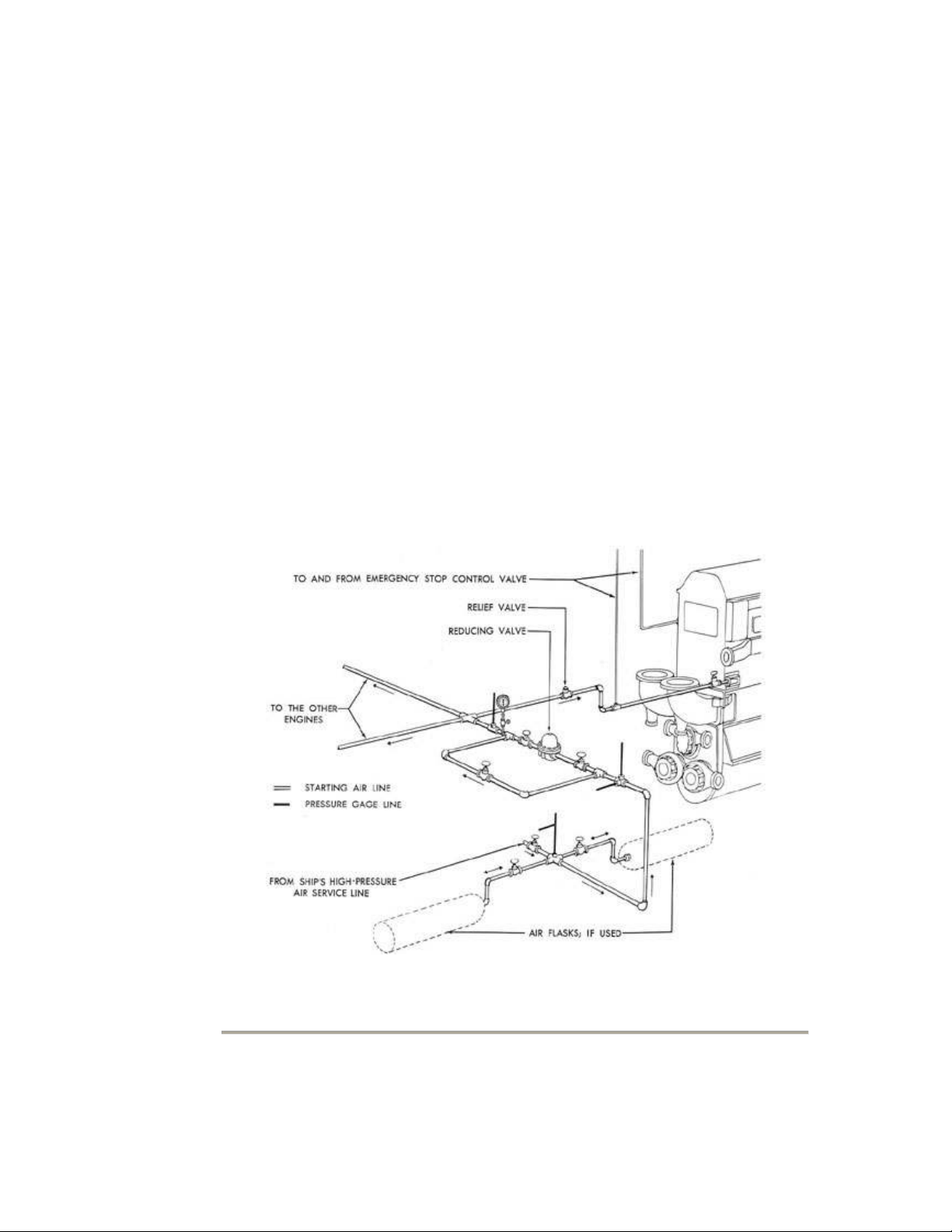

4A2. Source of starting air. Starting

air comes directly from the ship's high-

p

ressure air service line in which

p

ressures up to 3,000 psi are normally

maintained, or from starting air flasks

which are included in some systems for

the purpose of storing starting air. In

either

instance, the air on the way to the engine,

must pass through a pressure reducing

valve which reduces the higher pressure

to the operating pressure required to start

a particular engine. A relief valve is

installed in the line between the reducing

valve and the engine. This relief valve is

normally set to open at 25 to 50 pounds

in excess of the air starting pressure.

Thus, if the air pressure leaving the

reducing valve is too high, the relief

valve will protect the engine by releasing

air in excess of the value for which it is

set and permit only air at approximately

the proper pressure to reach the engine

cylinders.

Figure 4-1. Typical starting air piping system.

81

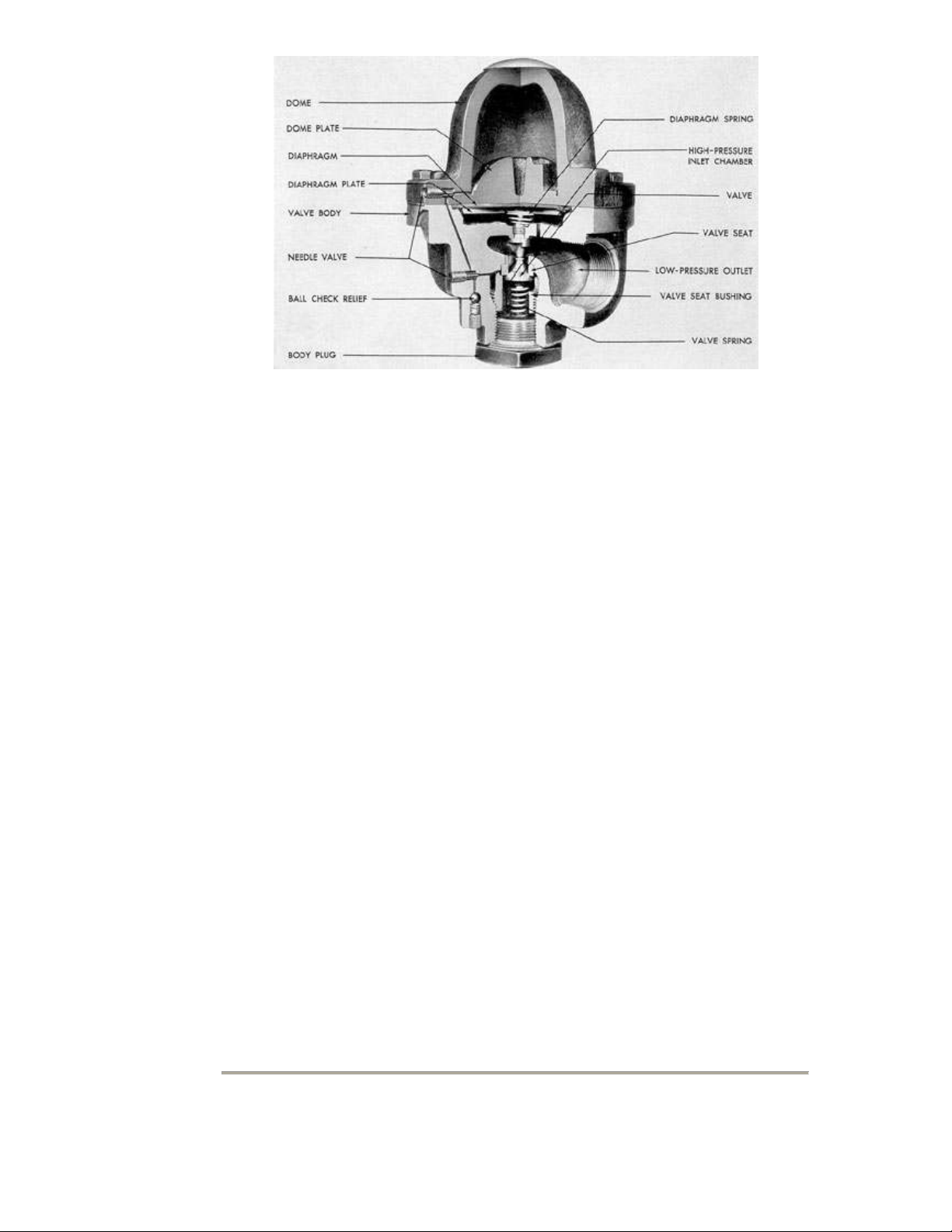

Figure 4-2. Grove regulator valve.

4A3. Pressure regulating valve. The

p

ressure reducing valve is a Grove

regulator (Figure 4-2) in which

compressed air, sealed in a dome,

furnishes the regulating pressure that

actuates the valve. Thus the

compressed air in the dome performs

the same function as a spring used in a

conventional type of valve.

The dome is tightly secured to the valve

body which is separated into an upper

(low pressure outlet) and a lower (high-

p

ressure inlet ) chamber by the main

valve. At the top of the valve stem is

another chamber which contains a

rubber diaphragm and a metal

diaphragm plate. This chamber has an

opening leading to the low-pressure

outlet chamber. When the outlet

p

ressure drops below the pressure in

the dome, air in the dome forces the

diaphragm and the diaphragm plate

down on the valve stein. This opens the

valve and permits high-pressure air to

p

ass the valve seat into the low-

p

ressure outlet and into the space under

the diaphragm. As soon as the pressure

under the diaphragm is equal to that in

the dome, the diaphragm returns to its

normal

p

osition and the valve is forced shut by

the high-pressure air acting on the valve

head. When air is being used from the

low-pressure side of the regulator, this

action is continuous and very rapid in

order to maintain the correct pressure on

the discharge side.

High-pressure air entering the valve body

is filtered through a screen to prevent the

entrance of any particles of dirt which

would prevent the valve from seating

p

roperly. The screen is held in position

around the space under the valve head

b

y

the threaded valve seat bushing. The

screen should be removed and cleaned

p

eriodically to insure an unrestricted

flow of air, If particles of dirt are

p

ermitted to remain and accumulate in

the screen, the high air pressure may tear

the screen from its position and force it

into the working parts, causing damage

to the valve seat.

Air for the original charging of the dome

is obtained from the high-pressure

chamber of the valve body by opening

two needle valves, As soon as the desired

p

ressure, as indicated by the gage on the

discharge side of the regulator,

82

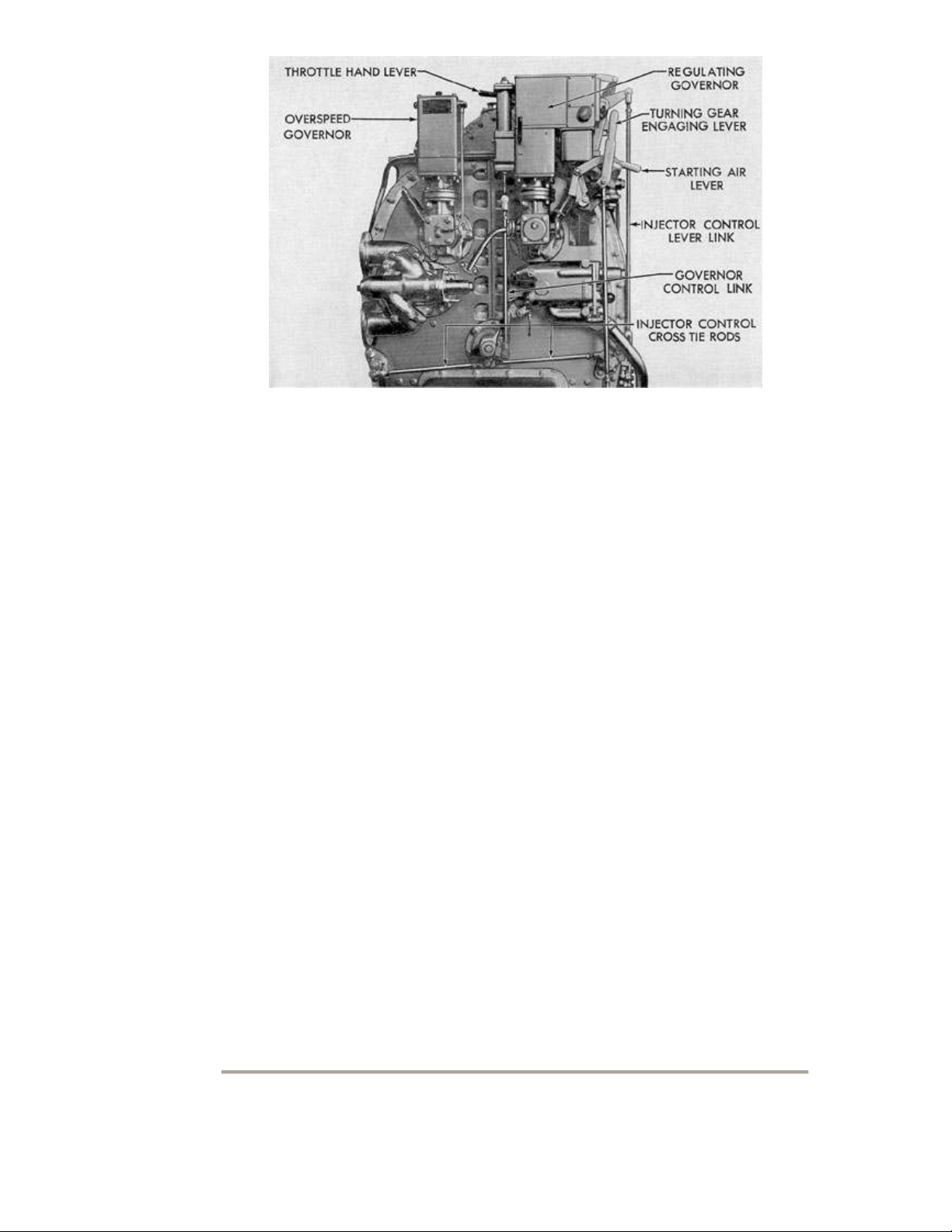

Fi

g

ure 4-3. En

g

ine startin

g

control levers, GM.

is reached, the needle valves must be

closed. The dome will then regulate and

maintain the discharge of air at that

p

ressure.

4A4. Starting the GM engine. The

GM engine is started by means of two

control levers, the throttle hand lever

and the air starter hand valve lever. The

throttle hand lever has three positions,

STOP, START, and RUN. In the

STOP, or central, position, the fuel

supply to the cylinders is cut off.

Moving the lever toward the START

p

osition rotates the fuel pump plunger

toward the full pump position. The

RUN position gives the Woodward

regulating governor unrestricted control

of the engine. The air starter hand valve

lever has only two positions, OPEN and

CLOSED.

Prior to starting the engine, and with

the throttle hand lever on the STOP

p

osition, the engine is turned over

several times by opening the air starter

hand valve with the cylinder test valves

open. This insures that there are no

obstructions to prevent the starting of

the engine.

The cylinder test valves are then closed.

The engine is started by holding the

throttle hand lever in the START position

and opening the air starter hand valve.

The engine should start after a few

revolutions if the fuel supply has been

p

rimed and is not airbound. As soon as

the engine is firing, the air starter hand

valve is closed and the speed of the

engine adjusted by means of the throttle

hand lever. As soon as the governor oil

p

ump has built up a working pressure,

the throttle lever is shifted to the RUN

p

osition. This shifts the engine to

governor control.

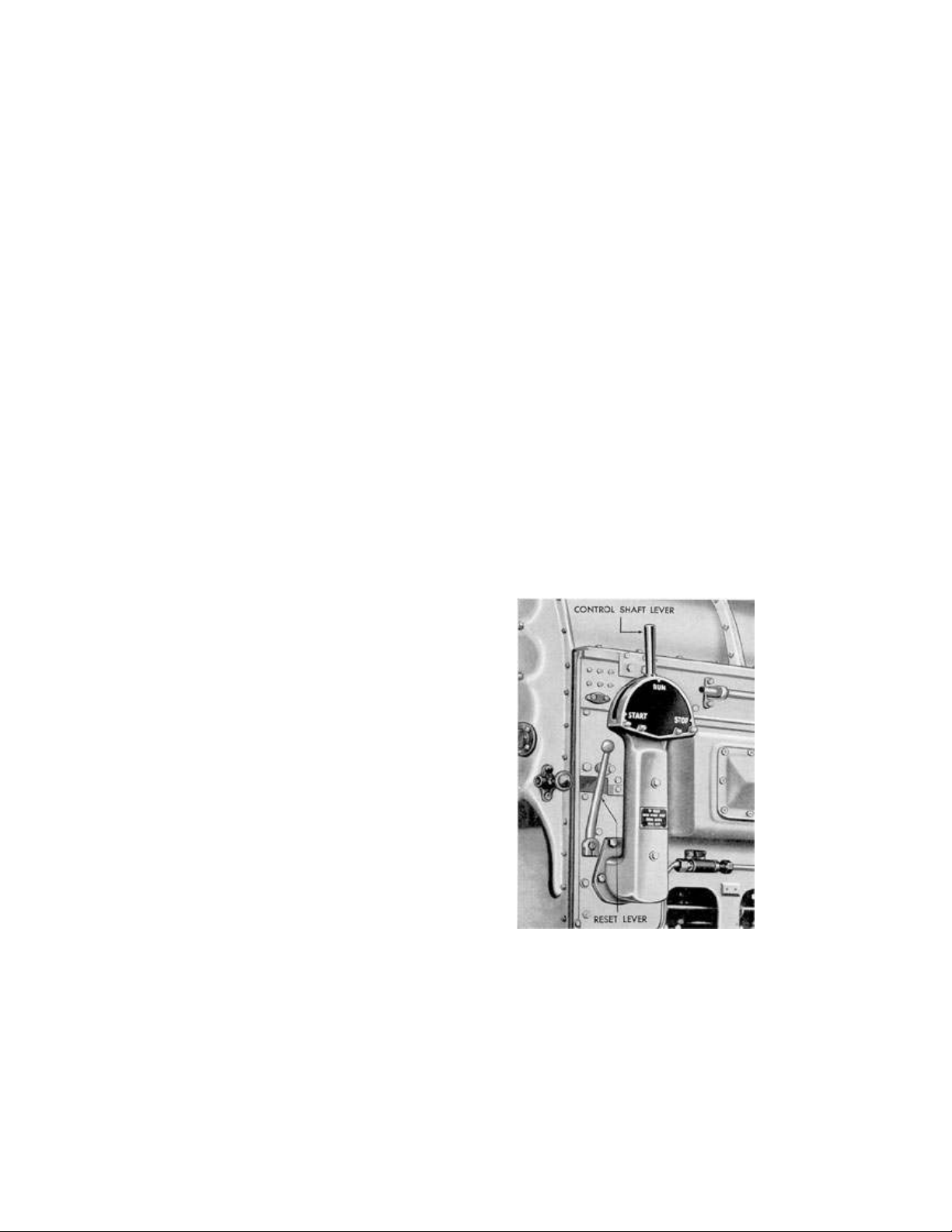

4A5. Starting the F-M engine. The F-M

engine is started by means of a control

shaft lever. This lever has three positions,

START, STOP, and RUN. In the STOP

p

osition, the fuel cutout cam on the

control shaft moves the fuel injection

p

ump control rod to the no fuel position.

When the lever is in the START position,

the air start control valve is opened,

allowing air starting of the engine. In the

RUN position, the engine is under full

governor control.

83

To start the engine, the governor is set

at idling speed and the control shaft

lever moved from the STOP position to

the RUN position and then toward the

START position. When the lever

lever reaches the START position, air

starting air begins to enter the cylinders.

As soon as the engine is firing, the

control shaft lever should be shifted to

RUN. This allows full governor control

p

asses the RUN position, the fuel

injection pump control rod is unlocked.

When the

and closes the air start control valve.

B. GENERAL MOTORS ENGINE AIR STARTING SYSTEM

4B1. Description. The engine air

starting system used on GM engines is

known as the separate distributor type,

the starting air distributor valve being a

separate unit for each cylinder. Each

distributor valve is individually

operated by its cam on the camshaft.

Eight of the 16 cylinders, six in one

bank and two in the other, are air

started, but all of the cylinder heads in

b

oth banks are equipped with air starter

check valves so as to maintain full

interchangeability. On the cylinders

that are not air started, the air inlet

opening is sealed with a removable

p

lug.

4B2. Operation. Air is supplied to the

air starting hand control valve from the

air supply line. The air starting control

valve is opened by a hand lever,

thereby admitting air to the starting air

manifold. The starting air manifold is a

steel pipe extending the full length of

the engine and is located on the top

deck of the engine below the exhaust

manifold. It is connected by air lines to

each of the starting air distributor

valves. The distributor valves are

opened in engine cylinder firing order

by their cams on the camshafts,

admitting air into the lines that connect

each distributor valve to its air starting

check valve. As the distributor valve

admits air into the line leading to the air

starting check valve, the pressure opens

the check valve, thereby admitting air

into the combustion chamber;

The air pressure moves the pistons and

turns the crankshaft until there is

sufficient compression for combustion.

Combustion pressure and exhaust gases

are kept from backing into the air

starting system by the check valves. As

soon as the engine is firing, the hand

lever is released, and spring pressure

closes the air starting control valve.

This shuts off the supply of starting air

bracket bolted to the camshaft drive

cover near the hand control lever. It is a

p

oppet type valve, opened manually by a

lever and closed by a spring. A plug in

the valve body holds the spring against

the valve head. The valve stem guide is a

bronze bushing pressed into the body. A

spring and head placed over the valve

stem, where it projects from the body,

return the hand lever to the valve's closed

p

osition. The hand lever and the

operating lever stop are keyed to a shaft

in the bracket.

A safety device prevents opening of the

air starting control valve while the engine

j

acking gear is engaged.

4B4. Air starting distributor valve.

Each

F

igure 4-4. Control shaft lever, F-M.

to the engine.

4B3. Air starting hand control valve.

The air starting hand control valve is

mounted on a

84

Figure 4-5. GM engine air starting system.

85

cylinder having air starting is equipped

with an air starting distributor valve.

The air starting distributor valves, or

timing valves as they are sometimes

called, are of the poppet type with

forged steel bodies that bolt to the

camshaft intermediate covers. The

valve is held closed by spring pressure

bearing against the top of the valve and

is guided in the hollow end of a cam

follower which rides on the camshaft

in the cylinder head. The valve body fits

into a recess in the cylinder head and is

held in place by a cap nut that screws

into the cylinder head and ears on the top

of the valve body. The valve body

contains the valve seat and serves as a

valve stem guide. Air is prevented from

leaking to the outside of the valve body

by a synthetic rubber seal ring located

above the inlet port. The valve face

makes direct contact with the valve seat

in the valve body. The valve is held

![Bài tập môn Cơ sở thiết kế máy [năm] [mới nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20251008/ltgaming1192005@gmail.com/135x160/26601759980842.jpg)

![Tài liệu huấn luyện An toàn lao động ngành Hàn điện, Hàn hơi [chuẩn nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20250925/kimphuong1001/135x160/93631758785751.jpg)