An experimental study of oil recovery from sewage sludge

by low-temperature pyrolysis in a fluidised-bed

q

Lilly Shen, Dong-Ke Zhang*

School of Chemical Engineering, Curtin University of Technology, GPO Box U1987, Perth, WA 6845, Australia

Accepted 9 September 2002; available online 22 October 2002

Abstract

Pyrolysis of activated sewage sludge was investigated under inert conditions in a fluidised-bed to study the effects of temperature and gas

residence time on the product distribution and composition with an aim to maximise the oil yield. The temperature was varied from 300 to

600 8C and the gas residence time from 1.5 to 3.5 s. Three groups of products were produced, namely, a non-condensable gas (NCG) phase, a

solid phase (char) and a liquid phase (oil). A maximum of 30% oil yield (wt% daf of sludge fed) was achieved at a pyrolysis temperature of

525 8C and a gas residence time of 1.5 s. Higher temperatures and longer gas residence times favoured the formation of NCG, suggesting that

secondary cracking reactions had occurred. The oil obtained was analysed using GC–MS and H NMR to determine the oil’s composition and

structure, a unit structure of the oil was proposed which consisted of aromatic rings connected by hydrocarbons with –OH functional groups

attached.

q2002 Elsevier Science Ltd. All rights reserved.

Keywords: Fluidised-bed reactor; Sewage sludge devolatilisation; Oil structure

1. Introduction

Sewage sludge like most organic wastes is abundant in

volatile matter and thus there exists an opportunity to

convert this stored energy into a usable energy source such

as for heating or perhaps as a liquid fuel substitute and the

production of speciality chemicals [1]. Presently, most of

the sewage sludge waste is disposed off in landfills, ocean or

via incineration [2,3]. The disposal of dewatered sewage

sludge in sanitary landfills is not very satisfactory because

of the inherent chemical energy lost and associated health

problems [4]. Ocean dumping disturbs, at least locally, the

ecology of the biosphere and should be avoided [5].

Incineration provides a large volume reduction of sewage

sludge and results in improved thermal efficiency. However,

the scrubbing costs of the product gases for air pollution

control are usually very high [3].

In the past decade, pyrolysis of sewage sludge in an

oxygen-free atmosphere at relatively low-temperatures (ca.

500 8C) has generated significant interest [6]. Particular

interest is shown in this process as a high recovery of liquid

oil is achieved, lower emissions of NO

x

and SO

x

also lower

operating costs when compared to incineration [7]. Tests

have shown that the oil obtained from sewage sludge

pyrolysis can be used directly in diesel fuelled engines and

is comparable to low-grade petroleum distillates from

commercial refineries [8].

Many researchers have investigated the effects of

operating parameters such as temperature and residence

time on product distribution [9,10]. However, many have

focused on fixed beds [11] and rotary reactors [9]. Very few

have performed low-temperature pyrolysis of sewage

sludge in fluidised-bed reactors [12]. In the few studies

that have used fluidised-bed reactors, the oil was lumped

together without further classification of their composition

or structure [13,14]. In this study a fluidised-bed reactor was

used to determine the oil recovery and product distribution

of sewage sludge under moderate temperatures (300–

600 8C) and varying gas residence time (1.5 –3.5 s). A

GC–MS was used to investigate the molecular distribution

and structure of the oil and H NMR analysis was used to

detect the type of functional groups in the oil and verify the

GC–MS results. H NMR analysis has been previously used

to determine tar composition from coal pyrolysis and has

shown to be useful in identifying the type of H-bonds in coal

derived oils [15].

0016-2361/03/$ - see front matter q2002 Elsevier Science Ltd. All rights reserved.

PII: S 0 0 1 6 - 2 3 6 1 ( 0 2 ) 0 0 2 9 4 - 6

Fuel 82 (2003) 465–472

www.fuelfirst.com

q

Published first on the web via Fuelfirst.com_http://www.fuelfirst.com

*Corresponding author. Tel.: þ61-8-9266-7581; fax: þ61-8-9266-3554.

E-mail address: dkzhang@che.curtin.edu.au (D.K. Zhang).

2. Experimental

2.1. Sample preparation

An activated sewage sludge from Western Australia was

used for this study to observe the effects of pyrolysis

temperature and gas residence time on product distribution

and their structures. Table 1 shows the analyses of the sewage

sludge sample. The dewatered sludge was crushed and sieved

to a particle size of 212– 355 mm and dried at 1058C for 24 h.

The dry sample was then kept in an airtight container to

prevent re-absorption of moisture before experimentation.

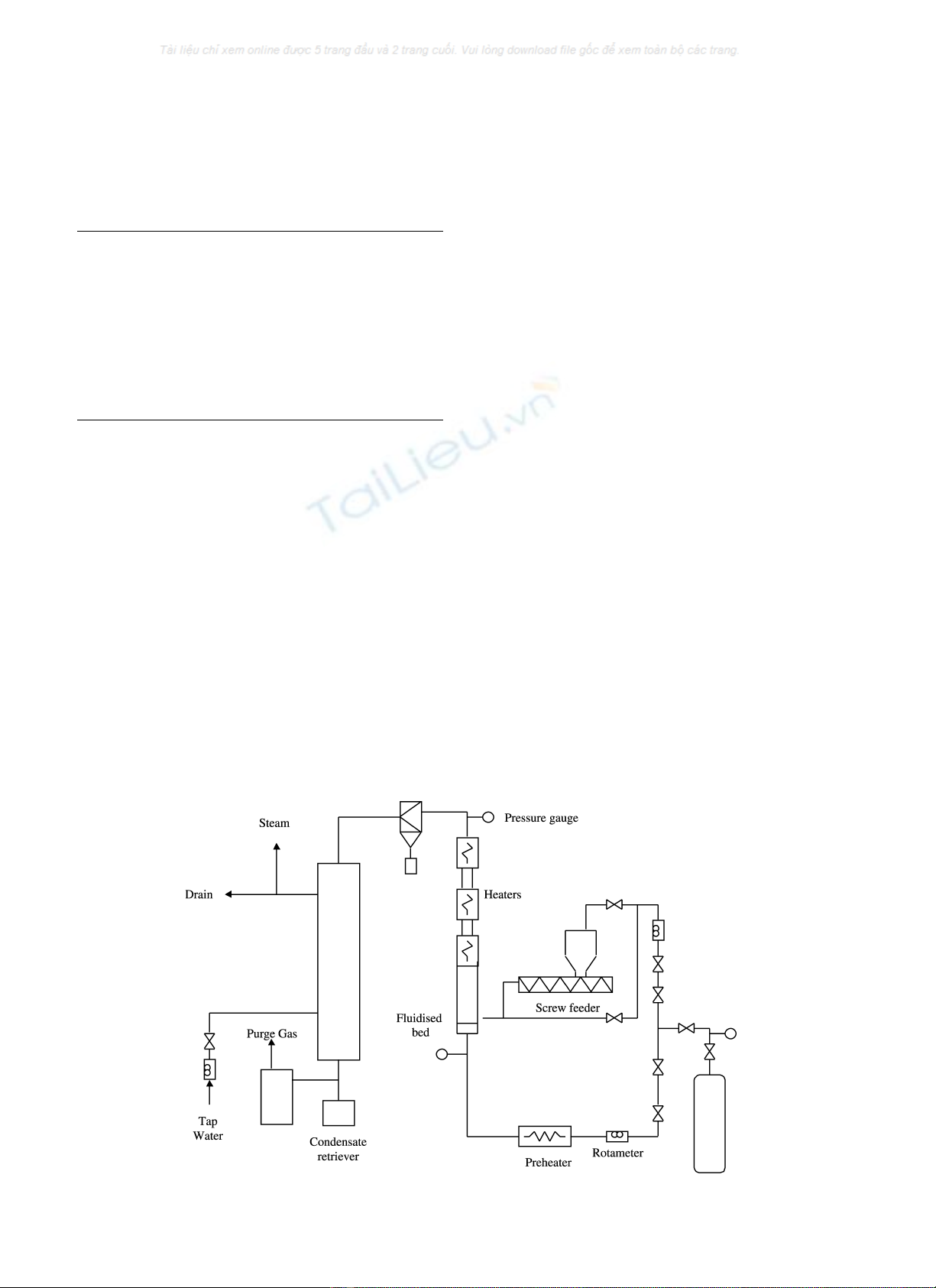

2.2. Experimental apparatus

Fig. 1 shows the schematic of the apparatus in which

pyrolysis of the sewage sludge is continuously performed in

a fluidised bed with an internal diameter of 50 mm. The

sludge is fed from the sludge hopper by a screw feeder,

40 cm above the distribution plate where nitrogen is used as

the fluidising gas. Nitrogen is also fed through the hopper

and the nozzle of the screw feeder to assist the flow of the

solid. The product gas leaves from the top of the reactor and

through a cyclone the solid residual (char) is separated and

collected in a char container situated below the cyclone. The

product gas is then condensed in a shell-and-tube stainless

steel condenser to ambient temperature using tap water as

the cooling medium. The condensed oil product is collected

in a container below the condenser and the non-condensable

gases (NCG) are sampled through a gas trap.

PLC controllers using a visual basic interface through a

PC, controls the process. The computer stores all the data

from sensors, such as, thermocouples and pressure trans-

mitters. The heating is provided by electric means as the

usage of NCG to provide the process heat is not feasible on

this scale, however, is an alternative for larger scale plants.

A pre-heater providing 230 W is used to heat the fluidising

gas to a pre-set temperature between 300 and 600 8C. The

pre-heater is supplied by a 15 A-power source with ceramic

beads packed into the heater for better heat transfer. Three

other heaters, each providing 120 W with 10 A are used in

the reactor to compensate the heat loss through the reactor

wall.

2.3. Experimental procedure

During an experimental run, the sludge hopper was filled

with sewage sludge and the fluidised bed was loaded with

quartz sand in the size fraction of 400– 555 mm (Umf:

Table 1

Proximate and ultimate analyses of the activated Western Australian

sewage sludge

Proximate analysis (wt%)

Moisture (as fed) 3

Ash (as fed) 22.6

Volatile matter (daf) 61.3

Fixed carbon (daf) 16.1

Ultimate analysis (wt% daf)

C 41.8

H 5.4

N 4.3

S 1.14

O, Cl (by diff.) 47.36

Fig. 1. A schematic diagram of the fluidised-bed pyrolysis reactor apparatus.

L. Shen, D.-K. Zhang / Fuel 82 (2003) 465–472466

42 mm s

21

at 400 8C). Nitrogen, flowing at five times the

minimum fluidising velocity was turned on to purge

the apparatus from gaseous residues and oxygen. Mains

tap water was turned (at 10 l min

21

) on to provide the

cooling medium for the condenser. The operating par-

ameters, such as temperature (300 –600 8C), feed rate of

sludge (3.3–4 g min

21

) and fluidising velocity were set by

the operator using the PC and the signals were then sent to

the controllers. After the system reached steady state the

screw conveyor (runs by a variable speed motor rotating at

50–120 rpm) is automatically switched on and the sludge is

uniformly fed to the reactor. The process was terminated by

stopping the feed and by controlled cooling of the apparatus.

Material balances were taken of sludge consumed and all

products collected. It was found that the material balances

are generally within 92 –95%.

Oil samples were retrieved from the apparatus with

acetone. The cyclone, condenser and other equipment where

oil may have deposited were washed with acetone as soon as

the experiment was finished to recover the maximum

amount of volatile released. The oil is analysed by a GC–

MS operating at 300 8C for 40 min so that sufficient

separation of the liquid could be achieved. The GC–MS

was able to determine the compounds and their molecular

structure in the oil ranging from C

4

–C

40

. The GC– MS has

an extensive library and the chromatograms of the

compounds in the oil were compared with the compounds

in the library. The library then generates all the information

available of the compounds, including their structures and

molecular weights. H NMR analysis was also performed on

the oil samples to determine the type of functional groups in

the oil. Gas samples were taken in 30 min intervals with

2–3 samples taken during a run from the gas-trap and

analysed using a GC. Gas yields were calculated from the

gas analysis and the total gas flow through the reactor at the

time of sampling. Averages of the samples were taken and

are reported in this paper. The operating conditions are also

summarised in Table 2.

3. Results and discussion

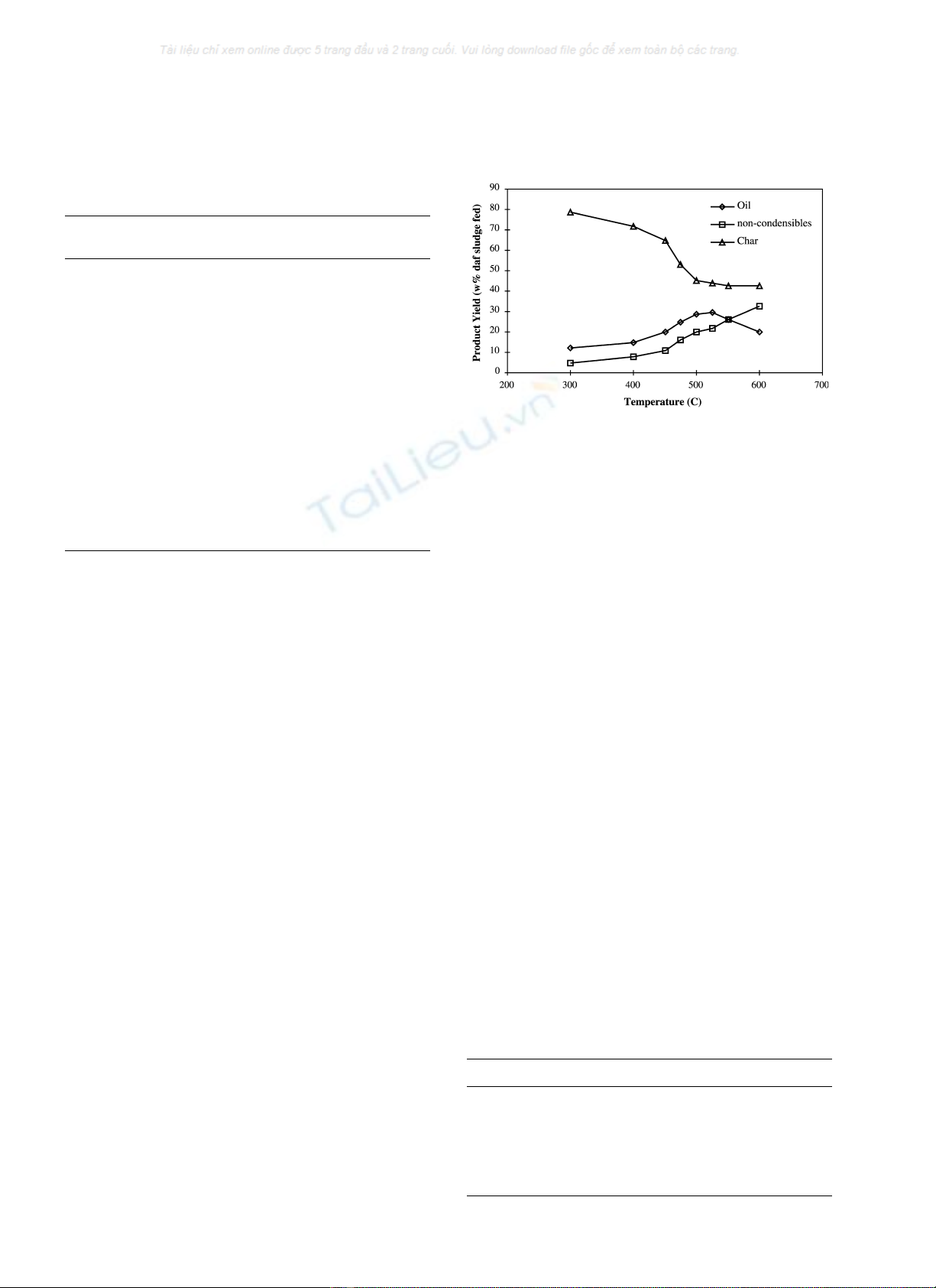

Fig. 2 shows the effect of pyrolysis temperature on oil,

char and NCG yields with a constant gas residence time of

1.5 s. The maximum oil yield obtained was 30% daf of the

feed at 525 8C. In order to understand this trend, organic

bonds that might have been broken at different temperatures

during the pyrolysis were obtained from the literature [16,

17] and summarised in Table 3. From Table 3 it can be seen

that at the temperature range of 500–575 8C carboxylic,

phenolic, ether oxygen and cellulosic bonds are broken [16,

17]. The temperature range, however, for maximum oil

yield is on the upper end of the temperature band for

decomposition of carboxylic and phenolic groups. Above

600 8C most of the carboxylic and phenolic bonds have been

broken and this is when the oil yield is observed to drop.

Suggesting that carboxylic and phenolic breakage from

Table 2

Summary of operating conditions for the experiments conducted

Test no. Pyrolysis temperature

(8C)

Test duration

(min)

Gas residence time

(s)

1 302 88 1.5

2 401 91 1.5

3 451 90 1.5

4 476 86 1.5

5 502 89 1.5

6 526 93 1.5

7 552 87 1.5

8 601 89 1.5

9 524 92 2.0

10 527 86 2.5

11 525 87 2.75

12 523 93 3.0

13 522 94 3.5

14 301 87 2.0

15 298 90 2.5

16 302 93 2.75

17 301 96 3.0

18 297 89 3.5

Fig. 2. Effect of bed temperature on product yields of oil, NCG and char for

sewage sludge expressed in percentage weight daf basis of sludge fed with a

constant gas residence time of 1.5 s.

Table 3

Temperature ranges for different groups of compounds to decompose

Groups of compounds decomposed Temperature range (8C)

Moisture [16] up to 150

Carboxylic [16] 150–600

Phenolic [16] 300–600

Ether oxygen [16] up to 600

Cellulosic [17] up to 650

Oxygen containing compounds [16] 150– 900

L. Shen, D.-K. Zhang / Fuel 82 (2003) 465–472 467

the feed generates the oil. Table 3 was obtained for brown

coal, however, this information is not yet available for

sludge. Thus this information can only be indicative of the

possible bonds that might also be present in the sludge [18,

19]. The char yield, on the other hand, decreased steadily

with increasing temperature, while the NCG yield increased

continuously.

The oil yields increase with increasing temperature

initially as sludge is subjected to more energy, stronger

bonds break and thus an increase in larger compounds are

observed. The decrease in oil yields above 525 8Cis

believed to be a result of secondary decomposition reactions

which break the oil into lighter, gaseous hydrocarbons. As a

consequence the NCG yields also increase. Char yields are

expected to decline as more volatiles are released. These

results are similar to the literature observations made in both

coal decomposition and wood decomposition [13,20– 22].

By convention used for coal oils [23], heavy oils are

defined as species with molecular weight greater than

150. In determining the quality of the oil produced, the

selectivity of the light oils is of great importance. In

most cases, light hydrocarbons are preferred as they can

be easily used as fuels. It was found that the species with

MW less than 150 in the oil consisted of compounds

with carbon numbers less than 9 and of aromatic nature.

Fig. 3 shows the selectivity of light oil to heavy oil for

different temperatures. The selectivity of light oils

increase significantly after 450 8C and stays relatively

constant before 450 8C. Therefore, it suggests that the

rate of secondary cracking reactions is only significant

after 450 8C at short residence times.

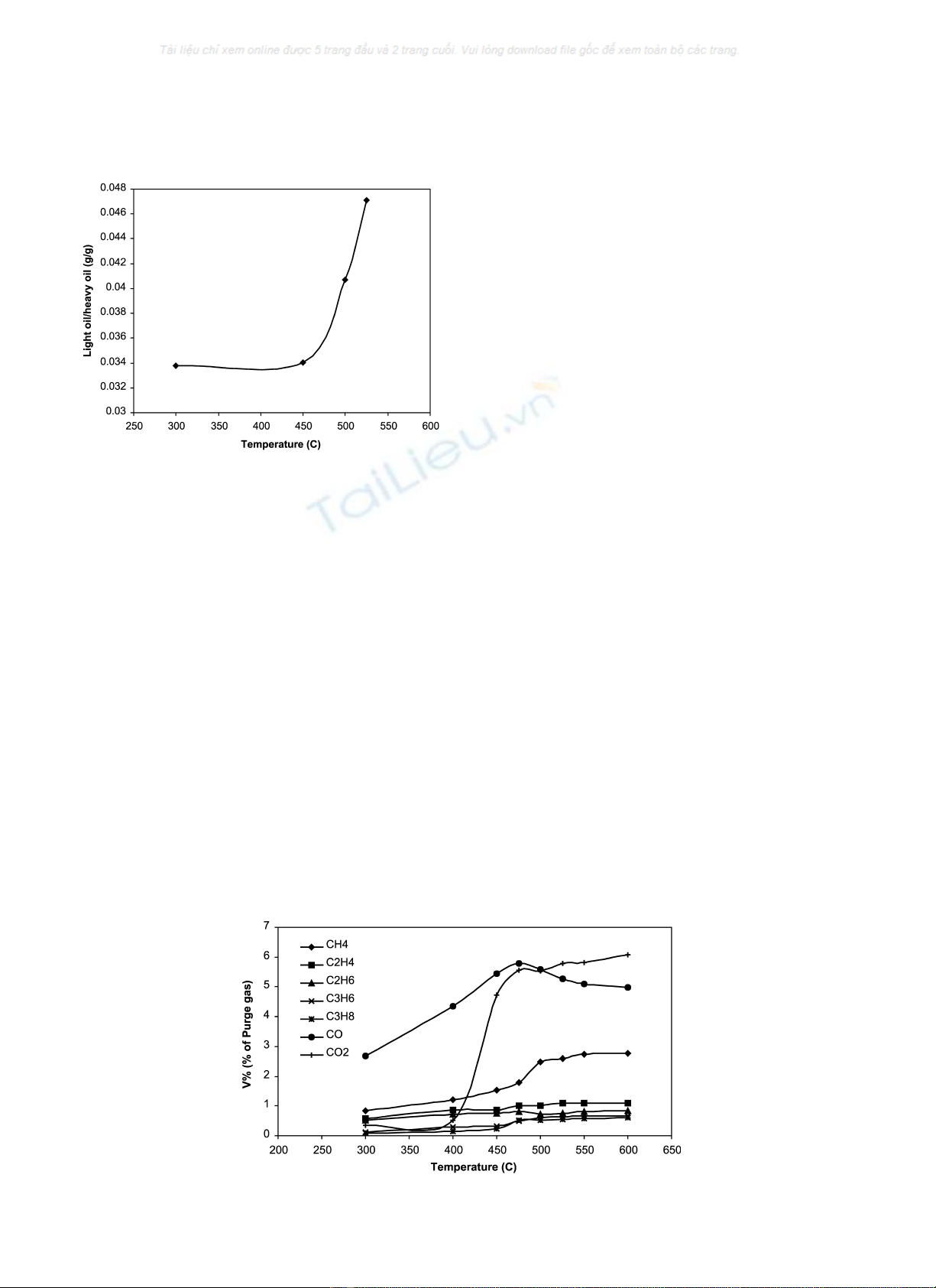

Fig. 4 shows the effect of pyrolysis temperature on

different NCG expressed as volume percent of purge gas,

gas detected after the condenser in Fig. 1. The gases

detected by the GC included CH

4

,C

2

H

4

,C

2

H

6

,C

3

H

6

,C

3

H

8

,

CO and CO

2

. Nitrous oxide (N

2

O) was also detected,

however, the maximum volume percent is 131 ppm at

600 8C and thus the trend cannot be represented clearly on

Fig. 4. The yields of all the gases increased steadily with

temperature with the exception of CO, a behaviour that is

typical of the pyrolysis of peat, lignite as well as cellulosic

biomass [23–26]. It can be observed that methane has the

highest yield, while propylene and propane the lowest

among all hydrocarbons. Carbon dioxide has the highest

yield of 6.3% of the non-hydrocarbon gases at a 600 8C.

Horne and William [24] has found similar concentrations of

CO and CO

2

under similar operating conditions, where CO

and CO

2

were found to be 6.8 and 6.7%, respectively, for a

biomass. Presently, there is no available data in the literature

for nitrous oxide yields for comparison. However, it has

been found that N

2

O is generally formed in reducing

atmospheres and low temperatures in fluidised bed reactors

[27]. This coincides with the operating conditions of this

study.

Fig. 3. The selectivity of light oils to heavy oils obtained from sewage

sludge pyrolysis at different temperatures with a gas residence time of 1.5 s.

Fig. 4. Effect of bed temperature on NCG yields for sewage sludge expressed in percentage volume of purge gas with a residence time of 1.5 s.

L. Shen, D.-K. Zhang / Fuel 82 (2003) 465–472468

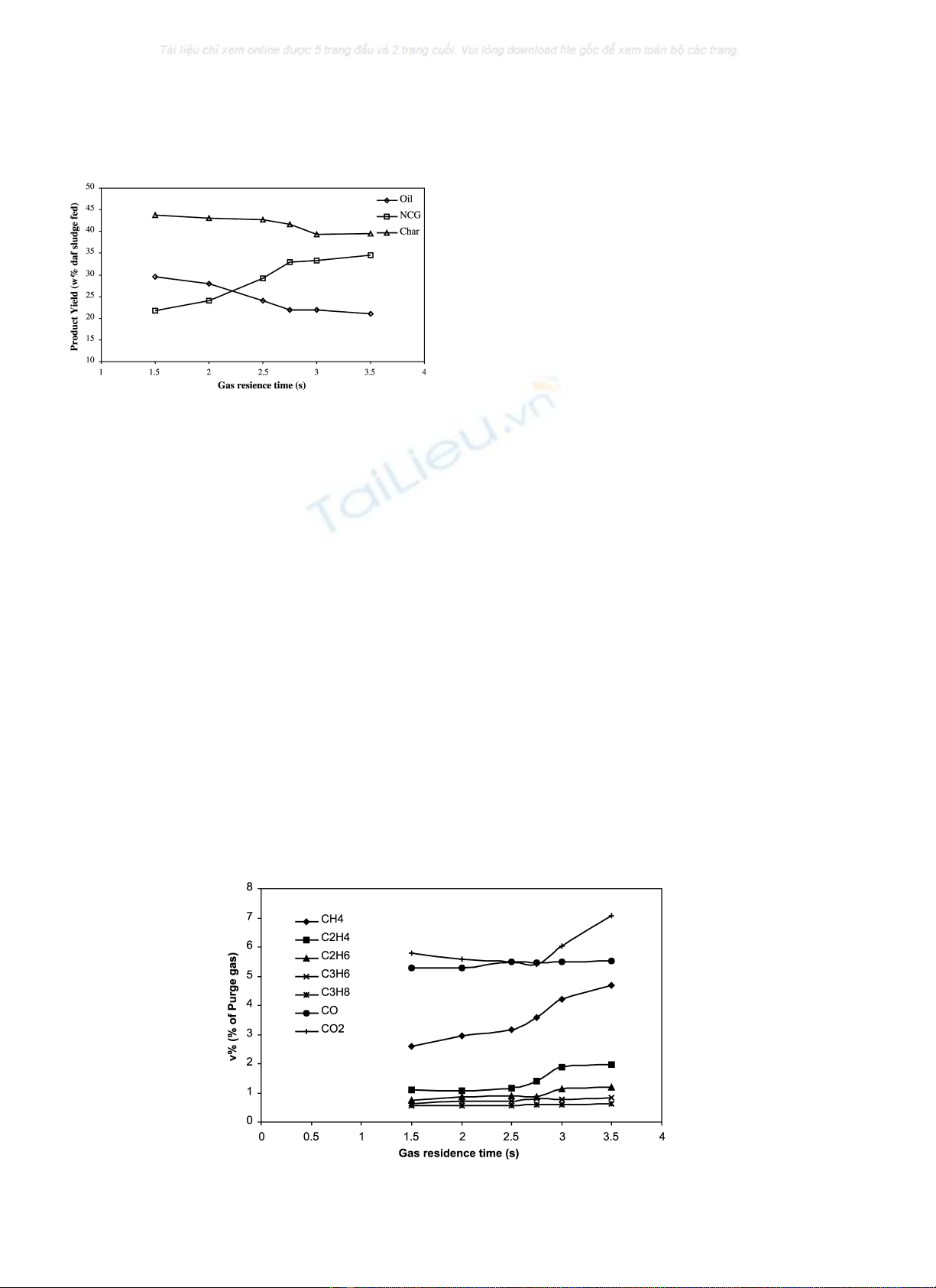

The effect of gas residence time was also studied and

the trends of product yields are shown in Fig. 5 for a

constant pyrolysis temperature of 525 8C. Oil and char

yields are both at maximum at the shortest residence

time of 1.5 s. This result is in agreement with other work

carried out with a variety of biomass and coal feeds [28,

29]. The decrease of char yield is accompanied by

evolution of more volatile matter from the sewage

sludge. Oil yields decrease from a maximum of 30 to

21% (daf of feed), which can be explained by

the occurrence of secondary cracking reactions, breaking

up larger species in the volatiles evolved. Henceforth the

yields of NCG increase.

The NCG represents all the gases identified in the gas

trap. The effect of gas residence time on C

1

–C

3

hydro-

carbons, CO and CO

2

are presented in Fig. 6. The maximum

yield of N

2

O is found to be 92 ppm at 3.5 s. This trend is not

presented in Fig. 6 as the values are too small in scale.

All the gas species increase with increasing gas residence

time and the rate of increase is similar for all gases. Methane

again has the highest conversion while propane has the

lowest out of the hydrocarbons and CO

2

again is the

dominant gas. CO

2

had a maximum yield of 7.2%. After

2.75 s the conversions of the hydrocarbons level off. This

may be associated with secondary decomposition in the

light hydrocarbons itself, where propane is broken down to

smaller species. This phenomenon has been observed in

previous studies where C

3

hydrocarbons start to decrease

with increasing pyrolysis temperature and residence time, as

seen in both coal [26] and biomass [21] pyrolysis.

When the yields of all the products are calculated, 92–

95% daf basis of the feed mass can be accounted for. The

discrepancy is a result of many factors and one of the major

reasons is that a portion of solid char is lost along with the

NCG due to the inability of the cyclone. Also at the

operating temperatures used in the experiment, light

hydrocarbons in the oil would be expected to evaporate as

soon as it was formed. When compared to previous studies

[24], the total products accounted for compared favourably.

The molecular distributions of the species in oil obtained

at varying temperature and gas residence time are shown in

Fig. 7. In this figure, peaks are seen at a molecular weight of

360. When the gas residence time increases, the curve shifts

towards the left, suggesting that smaller species are formed

when the time increases, apparently a result of secondary

reactions occurring.

Table 4 shows all the species that had been identified,

by the GC– MS, in the oil at 525 8C. Not all of the

compounds were identified in all of the experiments

conducted. For example, at 300 8C the heavier compounds

(MW .700) were not detected as shown in Fig. 7. These

identified compounds were made up of aromatic rings

linked by long straight hydrocarbon chains. Table 5 shows

Fig. 6. Effect of gas residence time on NCG yields for sewage sludge expressed in percentage volume of purge gas at a constant pyrolysis temperature of

525 8C.

Fig. 5. Effect of gas residence time on product yields of oil, NCG and char

for sewage sludge expressed in percentage weight daf basis of sludge fed at

a constant pyrolysis temperature of 525 8C.

L. Shen, D.-K. Zhang / Fuel 82 (2003) 465–472 469

![Bộ Thí Nghiệm Vi Điều Khiển: Nghiên Cứu và Ứng Dụng [A-Z]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20250429/kexauxi8/135x160/10301767836127.jpg)

![Nghiên Cứu TikTok: Tác Động và Hành Vi Giới Trẻ [Mới Nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20250429/kexauxi8/135x160/24371767836128.jpg)