See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/260868676

Optimal design of high damping force engine mount featuring MR valve

structure with both annular and radial flow paths

ArticleinSmart Materials and Structures · October 2013

DOI: 10.1088/0964-1726/22/11/115024

CITATIONS

54

READS

751

4 authors, including:

Hung quoc Nguyen

Vietnamese-German University

182 PUBLICATIONS3,325 CITATIONS

SEE PROFILE

S. B. Choi

SUNY Korea

867 PUBLICATIONS16,918 CITATIONS

SEE PROFILE

Yuan-Shin Lee

North Carolina State University

219 PUBLICATIONS6,601 CITATIONS

SEE PROFILE

All content following this page was uploaded by Hung quoc Nguyen on 16 July 2014.

The user has requested enhancement of the downloaded file.

This content has been downloaded from IOPscience. Please scroll down to see the full text.

Download details:

IP Address: 165.246.74.129

This content was downloaded on 31/12/2013 at 09:07

Please note that terms and conditions apply.

Optimal design of high damping force engine mount featuring MR valve structure with both

annular and radial flow paths

View the table of contents for this issue, or go to the journal homepage for more

2013 Smart Mater. Struct. 22 115024

(http://iopscience.iop.org/0964-1726/22/11/115024)

Home Search Collections Journals About Contact us My IOPscience

IOP PUBLISHING SMART MATERIALS AND STRUCTURES

Smart Mater. Struct. 22 (2013) 115024 (10pp) doi:10.1088/0964-1726/22/11/115024

Optimal design of high damping force

engine mount featuring MR valve

structure with both annular and radial

flow paths

Q H Nguyen1, S B Choi2,4, Y S Lee3and M S Han3

1Department of Mechanical Engineering, Ho Chi Minh University of Industry, Ho Chi Minh City,

Vietnam

2Smart Structures and Systems Laboratory, Department of Mechanical Engineering, Inha University,

Incheon 402-751, Korea

3Faculty of Mechanical and Automotive Engineering, Keimyung University, Daegu 704-751, Korea

E-mail: seungbok@inha.ac.kr

Received 19 June 2013, in final form 10 September 2013

Published 17 October 2013

Online at stacks.iop.org/SMS/22/115024

Abstract

This paper focuses on the optimal design of a compact and high damping force engine mount

featuring magnetorheological fluid (MRF). In the mount, a MR valve structure with both

annular and radial flows is employed to generate a high damping force. First, the configuration

and working principle of the proposed MR mount is introduced. The MRF flows in the mount

are then analyzed and the governing equations of the MR mount are derived based on the

Bingham plastic behavior of the MRF. An optimal design of the MR mount is then performed

to find the optimal structure of the MR valve to generate a maximum damping force with

certain design constraints. In addition, the gap size of MRF ducts is empirically chosen

considering the ‘lockup’ problem of the mount at high frequency. Performance of the

optimized MR mount is then evaluated based on finite element analysis and discussions on

performance results of the optimized MR mount are given. The effectiveness of the proposed

MR engine mount is demonstrated via computer simulation by presenting damping force and

power consumption.

(Some figures may appear in colour only in the online journal)

1. Introduction

It is well known that engine mounts are extremely important

vehicle parts that stabilize and align a vehicle engine inside

the engine compartment. The engine mounts are also used to

suppress vibration from the vehicle engine being transferred

to the vehicle chassis to improve ride comfort performance

of the vehicle. Many types of engine mounts have been

developed and reported in the literature, and some of them

are now commercialized. Essentially, based on the amount

of external power required, engine mounts are classified

4www.ssslab.com.

into three types: the passive, the active and the semi-active.

The rubber mount is one of the most commonly used

passive mounts and has been widely used since the 1930s

because of its compactness, cost-effectiveness and its quality

of being maintenance-free. The rubber mount, a typical

passive engine mount which has low damping, shows efficient

vibration isolation performance in high frequency excitation.

But it cannot have a favorable performance at the resonant

frequency range—low frequency [1]. In order to compensate

for these limitations, various types of hydraulic mounts have

been developed and commercialized for several applications

including vehicles [2–8]. Briefly, the hydraulic mount is a type

10964-1726/13/115024+10$33.00 c

2013 IOP Publishing Ltd Printed in the UK & the USA

Smart Mater. Struct. 22 (2013) 115024 Q H Nguyen et al

of elastomeric mount with fluid traveling through the inertia

track between two compliant rubber chambers. The inertia

track imparts a frequency-dependent stiffness and damping

behavior to a hydraulic mount. At low frequencies, the mass

of fluid in the inertia track offers little resistance to motion

of the stiffer rubber element, and the mount stiffness is

primarily defined by the shear stiffness of the rubber. At a

characteristic frequency, the fluid in the inertia track moves

in resonance with the rubber element and the mount displays

a minimum in dynamic stiffness, known as the low-stiffness

notch. The phase angle, which is a measure of the phase

difference between the input and transmitted vibration, and

therefore also a measure of the damping behavior, reaches a

maximum near the notch frequency as well. This combination

of low dynamic stiffness and high damping is ideal for

damping in large motions. Above the notch frequency, the

fluid motion in the inertia track first opposes the rubber motion

and then becomes essentially static, causing an increase

and then a stabilization of the stiffness at a higher value

determined primarily by the bulge stiffness of the rubber [9].

For best noise/vibration isolation at high frequencies and low

amplitudes a softer mount is preferred. Therefore, hydraulic

mounts with an amplitude-sensitive decoupler are employed.

Although incorporating a decoupler, the hydraulic mounts still

have high dynamic stiffness at high frequency which results

in worse vibration isolation efficiency in the high frequency

domain. In addition, the notch frequency and stiffness of a

passive mount are fixed by its design and cannot respond to

changing conditions.

In order to improve the performance of passive engine

mounts, the active mount has been introduced and commer-

cialized. There have been different types of active mounts

reported in the literature such as the electromagnetic mount

developed by Muller et al [10], the hydraulic/pneumatic

mount proposed by Hodgson [11] and the active en-

gine mount featuring a piezoelectric actuator [12,13].

Generally, with an additional active force introduced as a

part of the active mount, the mount system can be controlled

using different algorithms to make it more responsive to

sophisticated sources of disturbance. Although the active

system can provide high control performance in a wide

frequency range, it is not widely utilized due to its

complex structure, large power requirement, and high cost

of manufacture and operation. A semi-active configuration

addresses these limitations by effectively integrating a tuning

control scheme with tunable passive devices. For this, the

active force generators in the active mount system are replaced

by modulated variable compartments such as variable-rate

valve and variable stiffness material. These semi-active

systems benefit from the advantages of active systems

combined with the reliability of the passive systems. If the

control system fails, the semi-active isolator can still work

in the passive mode. In addition, the power consumption

of these systems is very low, while they can change their

characteristics to make different levels of resisting forces

according to a low power-commanding signal. With these

strong points, the semi-active vibration control systems have

received much attention for automotive application. Recently,

there have been several research works on semi-active mounts

using MRF [9,14–16].

It is well known that MRF is a type of smart

fluid in a carrier fluid, usually a type of oil. When

subjected to a magnetic field, the fluid rapidly and

greatly increases its apparent viscosity, to the point

of becoming a viscoplastic solid. With these advanced

characteristics, many MRF based devices and systems

have been developed and successfully applied in the

industrial field such as MR valves, MR shock absorbers

and dampers, engine mounts and clutch/brake systems.

Generally, MRF based devices can be operated under three

different fluid working modes: shear [17,18], flow [19,20],

and squeeze [21,22]. A combination of these modes to

produce more advanced MRF based devices have been studied

in several research works [23]. Most of MR mounts operate

based on flow working mode of MRF [14,15]. However,

a combination of flow mode and squeeze mode has been

used in some research works to improve the vibration control

range of MR mount [16]. Although there have been many

research works on MR mount employing flow mode, only the

annular MRF flow is employed in these research works, so

the damping force generated by the MR mounts are not very

high. In addition, the optimal design of MR valve structure of

the mounts was not considered in these works. Consequently,

the main contribution of this research work is to propose a

new configuration of MR mounts employing both annular

and radial flows of MRF to generate a high damping force.

In order to achieve this research goal, optimal design is

performed considering the high damping force as well as the

compactness and the dynamic range of the MR mount. The

effectiveness of the proposed optimal design is demonstrated

via computer simulation and the results are discussed.

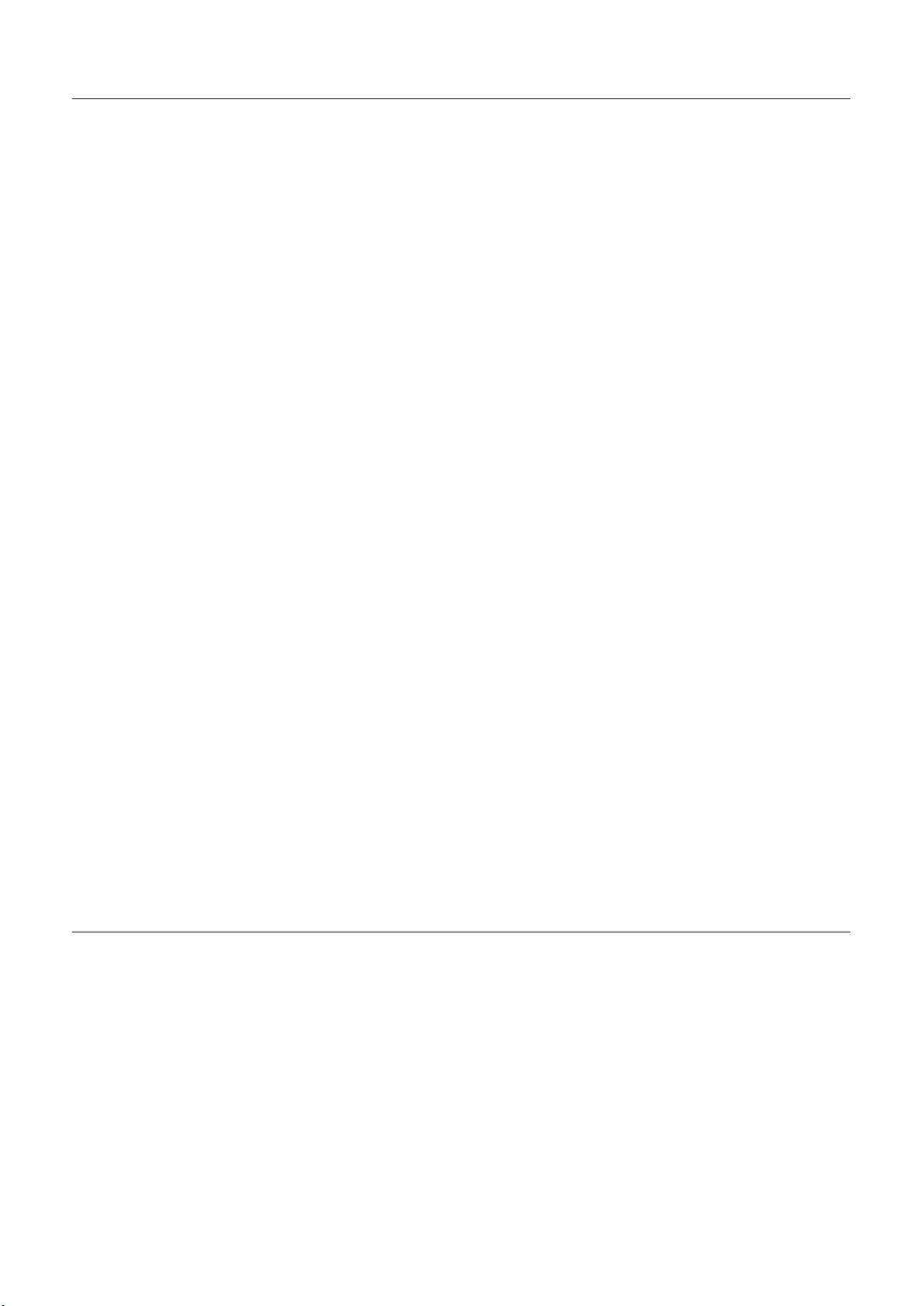

2. The high damping MR mount

In this section, configuration of the proposed MR mount is

introduced. In addition, damping force and off-state force of

the mount is derived based on the Bingham plastic behavior

of the MRF. Figure 1shows the configuration of the proposed

MR mount in this study. As shown in the figure, a MR valve

structure with both annular and radial flows is employed to

create a high damping force. The MR valve structure separates

the mount into two parts: the upper and the lower part. The

upper part consists of a rubber element, an upper base which

is fastened to the valve body to support the rubber element

and the top plate with a bolt in order to fasten the mount to

the engine. The hollow structure of the rubber element forms

the upper chamber of MRF above the valve structure. The

lower part consists of the mount body, the supporter on which

the core of the MR valve structure is placed and the rubber

diaphragm. The rubber diaphragm is placed right below the

valve structure to form the lower chamber. The MR valve

structure essentially consists of the valve body, the separating

ring, the upper and lower plates, the middle core and the

pins. The upper plate, the lower plate and the middle core are

all fixed together by the fastening bolt. The pins are placed

between the plates and the middle core to form radial flow

2

Smart Mater. Struct. 22 (2013) 115024 Q H Nguyen et al

Figure 1. Configuration of the proposed MR mount.

(a) 2D-configuration and (b) 3D CAD model.

paths of the valve. A nonmagnetic ring is placed between the

middle core and the MR valve body functioning as a magnetic

separator to prevent magnetic flux going from the middle core

to the valve body and also to force the MRF flows from

the upper chamber to the lower chamber through the radial

paths. When a high damping force is required, a current is

applied to the coil of the valve and a magnetic circuit going

across the MRF paths is generated. The generated magnetic

circuit causes an increase of yield stress and viscosity of the

MRF in both the annular and radial paths. By controlling the

applied current, the induced damping force of the mount can

be controlled.

The difference between the pressure in the upper chamber

(P1)and the pressure in the lower chamber (P2) can be

calculated by

P1−P2=1PI+1Pη+1PMR (1)

where 1PIis the pressure drop due to inertia of the MRF flow,

1PI=IeqQi, here Ieq is the equivalent inertance and Qiis

the average flow rate of the MRF flow in the mount. 1Pηis

the pressure drop of the MRF flow due to MRF viscosity and

1PMR is the pressure drop due to yield stress of MRF. By

assuming Bingham plastic behavior of MRF, 1Pηand 1PMR

can be approximately calculated by [24]

1Pη=12ηLp

πt3

gaRd

+η

πt3

gr

lnRo

Ri

+ηLc

π(Ri−Rb)3(Ri+Rb)Qi

=RηQi(2)

1Py=2Ca

Lp

tga

τya +Cr

Ro−Ri

tgr

τyr.(3)

In the above, ηis the post-yield viscosity of MRF, τya and τyr

are yield stress of MRF in the annular and the radial flow paths

respectively, Roand Riare respectively the outer and inner

radius of the valve core, Rbis the radius of the fastening bolt,

Lpand Lcare respectively the thickness of the core plates and

the middle core, tga and tgr are respectively the gap size of the

annular and the radial MR flow paths, Rdis the MR annular

duct radius Rd=Ro+tga/2,Rηis the viscous resistance of

the MRF flow, and Caand Crare coefficients which depend

on flow velocity profile and often has a value range from 2.0

to 3.0.

The pressure in the lower chamber can be estimated by

˙

P2=Qi

C2

or P2=Vi

C2

,(4)

where C2is the compliance of the lower chamber, and Viis

the volume of MRF from the upper to the lower chamber.

The MRF flow rate Qiis related to the pressure in the upper

chamber P1and the displacement of the top plate zby the

following equation of volume conservation:

˙

P1C1=Aef˙z−Qi,(5)

where Aef is the effective area of the upper chamber, and

C1is the compliance of the upper chamber. It is noted that

the rubber element of the mount is very stiff and hence the

upper chamber compliance C1is very small. In this study, by

neglecting the upper chamber compliance, the MRF flow rate

can be approximately determined by

Qi=Aef˙zor Vi=Aefz.(6)

From the above, the pressure in the upper chamber can be

calculated by

P1=Ieq

Aef

¨z+RηAef˙z+2Ca

Lp

tga

τya +Cr

Ro−Ri

tgr

τyr

×sgn(˙z)+Aefz

C2

.(7)

Now, the damping force of the MR mount can be determined

by

Fmr =P1Aeq =Ieq

Aeq

Aef

¨z+RηAefAeq˙z+Fy+AefAeqz

C2

,(8)

3

![Bài giảng Kỹ thuật điện - điện tử ô tô [chuẩn nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2026/20260121/hoatrami2026/135x160/37681769069450.jpg)

![Câu hỏi ôn tập Truyền động điện [mới nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20250613/laphong0906/135x160/88301768293691.jpg)

![Giáo trình Kết cấu Động cơ đốt trong – Đoàn Duy Đồng (chủ biên) [Phần B]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20251120/oursky02/135x160/71451768238417.jpg)