http://www.iaeme.com/IJMET/index.asp 994 editor@iaeme.com

International Journal of Mechanical Engineering and Technology (IJMET)

Volume 10, Issue 03, March 2019, pp. 994-1000. Article ID: IJMET_10_03_100

Available online at http://www.iaeme.com/ijmet/issues.asp?JType=IJMET&VType=10&IType=3

ISSN Print: 0976-6340 and ISSN Online: 0976-6359

© IAEME Publication Scopus Indexed

EFFECT OF HOT-SPOTTED CELL ON PV

MODULE PERFORMANCE

Najib Hamisu Umar*

Sharda University, Greater Noida (NCR, Delhi) - 201306, India

Birinchi Bora and Chandan Banerjee

National Institute of Solar Energy, Gurugram, India

*corresponding author

ABSTRACT

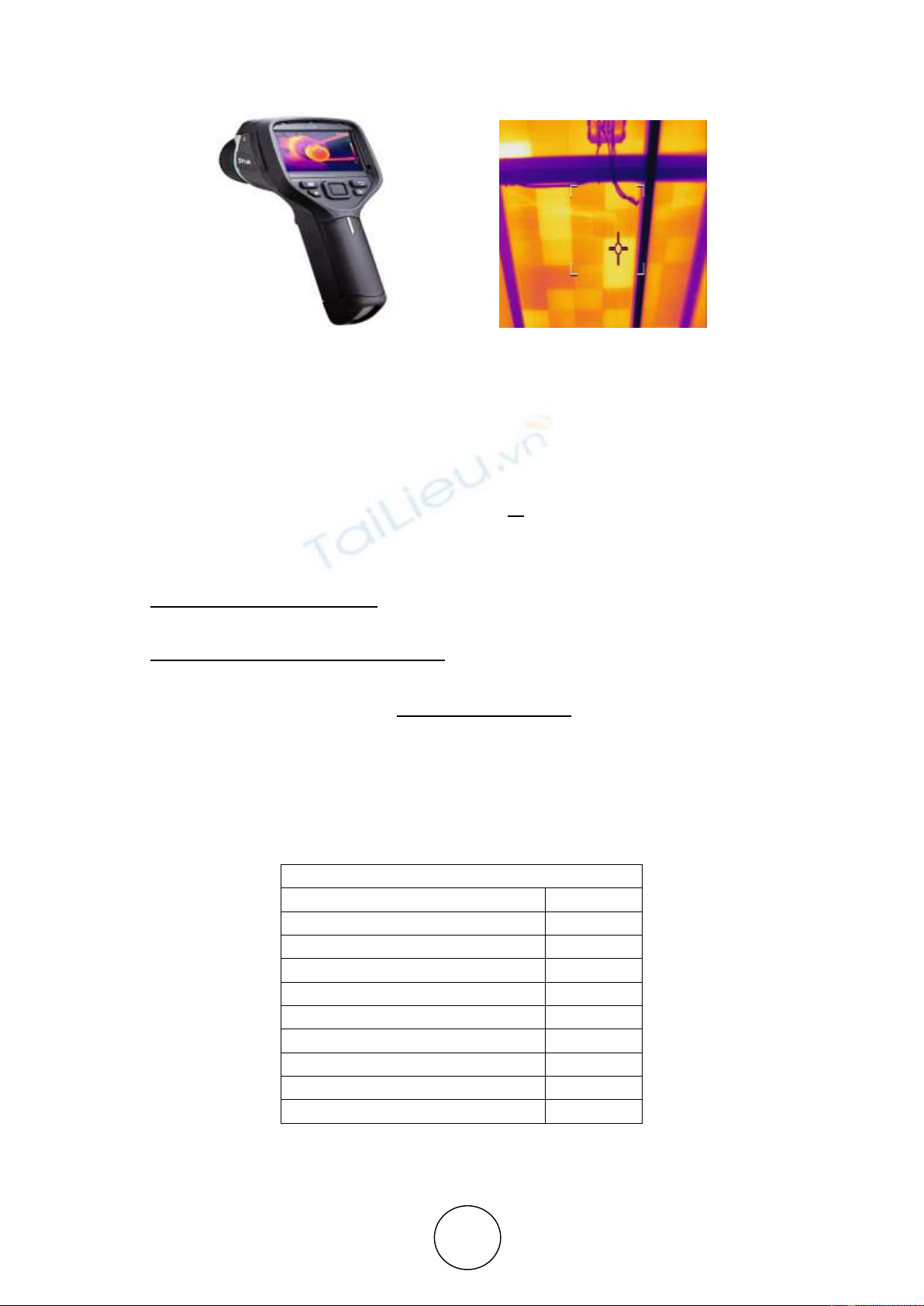

In this paper, the effects of the hot-spotted cell on PV module were evaluated. The

experimental observation was based on 100 kW PV array composed of 20 PV modules.

It was found that an increasing number of hot-spotted solar cells in a PV module would

likely increase its output power loss. It was also noticed that most of the PV modules

affected by hot-spotted PV string are relatively affected by high-temperature levels,

dust, and Partial shading due to trees or tall vegetation. Furthermore, the average

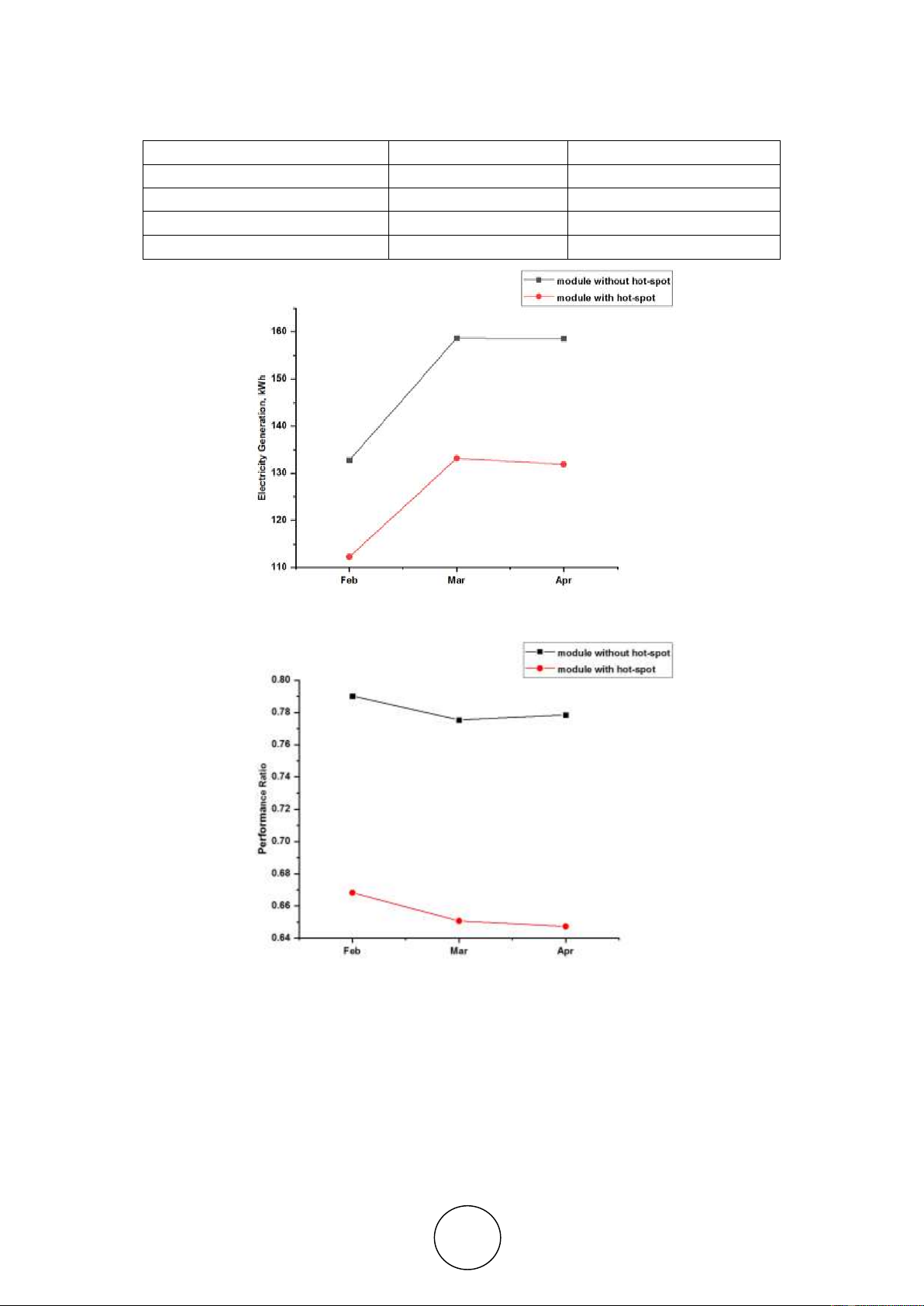

performance ratio (PR) and degradation rate (DR) of all examined PV modules were

analyzed. PR was observed to have a higher value of 0.78 in a non-hot-spotted PV array,

whereas low PR of 0.65 was observed in a hot-spotted PV array. High DR of 3.13/year

was observed in hot-spotted PV array; while low DR of 1.48/year was found in a module

with no hot-spot. It was evident that the mean PR is significantly reduced due to the

existence of hot-spots in the PV modules. DR was also increased due to hot-spot in the

PV array. Hence, it is important to select materials that have the highest thermal

stability to avoid mild hot spot situations that will lead to immediate damage of the

panel. Hot-spot study analysis will help increase PV lifetime power output by detecting

and preventing hot spotting before it permanently damages the PV panel.

Keyword: Photovoltaic system, Hot-spot, Performance ratio, Degradation rate,

Module defects, PV module

Cite this Article Najib Hamisu Umar, Birinchi Bora and Chandan Banerjee, Effect of

Hot-Spotted Cell on Pv Module Performance, International Journal of Mechanical

Engineering and Technology, 10(3), 2019, pp. 994-1000.

http://www.iaeme.com/IJMET/issues.asp?JType=IJMET&VType=10&IType=3

1. INTRODUCTION

In recent years, the deployment of photovoltaic (PV) system has increased significantly due to

its availability and cleanliness. Hence it is essential to conduct accurate studies on degradation