Full Terms & Conditions of access and use can be found at

http://www.tandfonline.com/action/journalInformation?journalCode=tprs20

Download by: [University of Saskatchewan Library] Date: 01 March 2016, At: 13:08

International Journal of Production Research

ISSN: 0020-7543 (Print) 1366-588X (Online) Journal homepage: http://www.tandfonline.com/loi/tprs20

An extended scheduling model for producing

corrugated boxes

Ahmet Bolat

To cite this article: Ahmet Bolat (2000) An extended scheduling model for producing

corrugated boxes, International Journal of Production Research, 38:7, 1579-1599, DOI:

10.1080/002075400188735

To link to this article: http://dx.doi.org/10.1080/002075400188735

Published online: 14 Nov 2010.

Submit your article to this journal

Article views: 37

View related articles

Citing articles: 3 View citing articles

INT

.J.PROD

.RES

., 2000, VOL.38, NO

.7, 1579±1599

An extended scheduling model for producing corrugated boxes

AHMET BOLAT{

Today, custom and shipping regulations recognize the importance of lightweight

and high performance corrugated boxes, and encourage wider usage of them.

Usually, the boxes are produced by glueing layers of paper from roll stocks

and cutting carton boards in certain sizes in the corrugater machine, drying

them in the bu er area, and converting the ¯ at boards into boxes in the convert-

ing machines. Similar to previous work, this study also deals with the cutting

stock, bu er utilization and machine loading problems. Additionally, it includes

set-ups in the converting machines and operating characteristics of roller con-

veyors in the bu er area. A binary linear program is proposed to maximize the

total length of converted paper boards in one shift and to minimize the percentage

trim loss. An optimal decomposition algorithm is developed to employ Successive

Linear Programming Relaxations until the upper bound on the throughput is

reached. An experimental study, with the real data obtained from a local com-

pany, indicates that implementable optimal solutions can be e ciently achieved.

Furthermore, an approach is proposed for conducting the trade-o studies

between the total throughput and the total trim loss.

1. Introduction

Today, most products shipped by air, rail, motor transport and other modes of

transport are carried in corrugated boxes. Usually, shipping regulations recognize

the importance of box compression strength and encourage wider use of lightweight,

high-performance corrugated boxes. The drying time of the glued layers in corru-

gated carton boards directly a ects the performance measures of the boxes. For

example, boxes made from boards immediately o the corrugater machine have

top-to-bottom compression values lower than those made from fully dried boards.

However, a variety of storage and operating conditions, and time limits may exist in

the factories, restricting the drying time of boards. Thus, a production planning

model is needed to meet industries’ expectations that producing boxes be economical

yet accommodate shipping standards.

While the corrugated boxes can be produced by various methods, the following is

the most common in the industry. The process of producing a corrugated box starts

with the corrugater machine. One or two layers of corrugated paper are sandwiched

between two or three layers of ¯ at paper from roll stocks and they are all glued

together to form the basic carton board. The cartons are then dried by heating and

are cut into the required dimensions in a continuous manner. Initially, the paper roll

is selected from among the ones available in di erent thicknesses and widths, and the

products and their combination are determined so that they can be produced from

this roll e ciently. Once the paper roll and the mix of products are selected, the

International Journal of Production Research ISSN 0020±7543 print/ISSN 1366±588X online #2000 Taylor & Francis Ltd

http://www.tandf.co.uk/journals/tf/00207543.html

Revision received September 1999.

{Mechanical Engineering Department, King Saud University, PO Box 800, Riyadh 11421,

Saudi Arabia. e-mail: abolat@ksu.edu.sa

Downloaded by [University of Saskatchewan Library] at 13:08 01 March 2016

cutting locations of the knives are adjusted according to the sizes (cutting pattern) of

the products.

Cut boards are stacked at the end of the corrugater by manual or automatic

stackers. The stacks are transferred to the bu er (storage) area by roller conveyors.

(Depending on its thickness, the stack heights are determined so that they can be

moved safely.) The storage area consists of 19 roller conveyers, each 21.6 m long and

0.64 m wide. The hot corrugated and glued boards must wait in storage for a certain

period of time so that the required strength of the boxes can be achieved.

After the curing in storage, the pile of boards is moved to the converting

machines by the controller truck. There are two die cutting machines and two

case makers used in converting operations. According to its speci® cations, each

board will be processed by one of the two groups of converting machines. At the

end of the converting machines, the shaped and printed boards are strapped in

bundles and sent to the ® nal product inventory. (The interested reader is referred

to Savsar and Cogun 1994 for full explanations of the technical terms, and for

diagrams relating to the layout and the process ¯ ow in the box factory.)

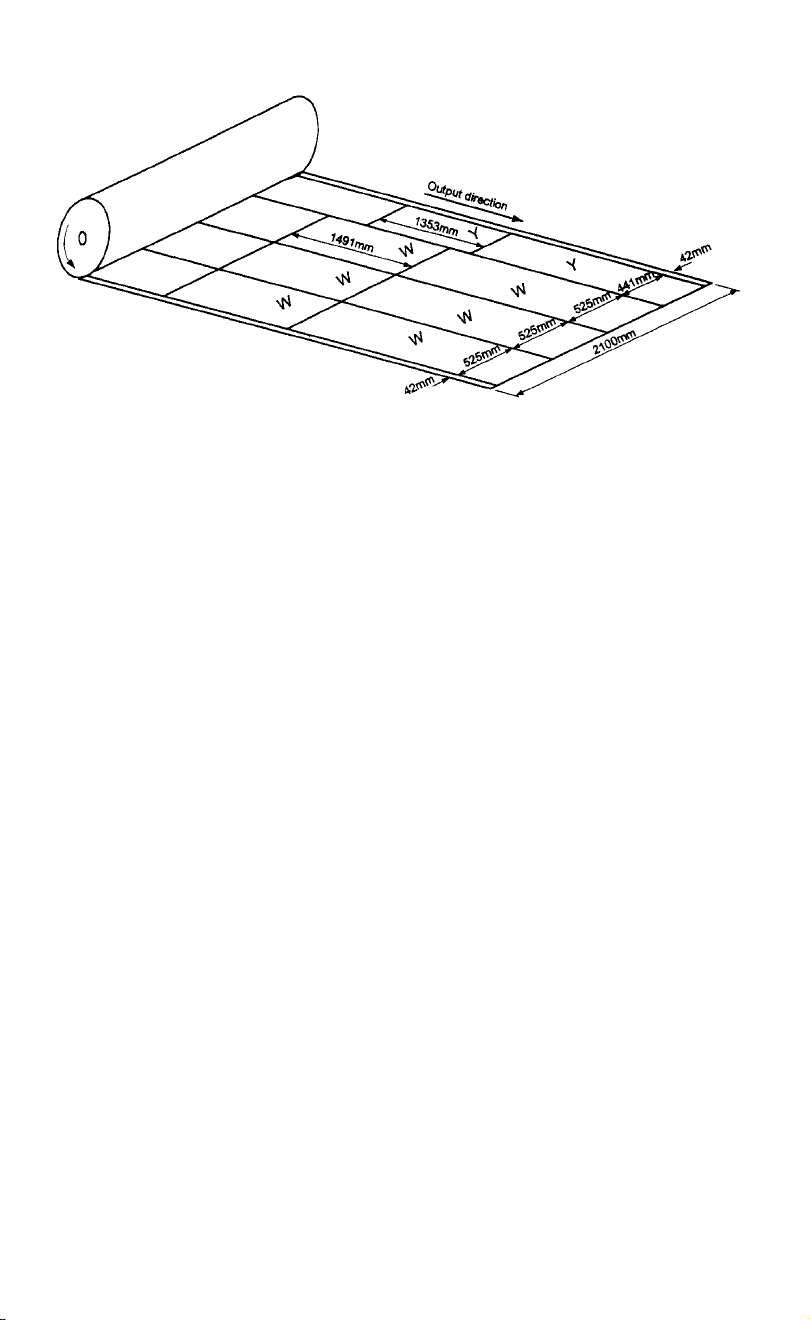

Usually, a number of di erent products requiring the same thickness of board

can be mixed and cut from the same paper roll. For example, consider a paper roll

with width 2100 mm, and product Wwith width 525 mm and product Ywith width

441 mm. If three cuts from Wand one cut from Yare made from the whole roll

continuously, then there will be 42 mm loss at each side of the roll.

The corrugater machine uses two types of blades: slitters for separating boards

from the roll in the input (moving) direction of the paper and cutters for separating

them in the perpendicular direction of the input paper. Usually, the length of a

carton board is more than 1 m and the ratio of its length to its width is around 2

to 1. Thus, cutting the widths of boards by slitters and the lengths by cutters gives

more ¯ exibility for mixing two or more products in various combinations so that the

trim loss at each side of the whole roll is minimized. For the above example, ® ve

slitters will be used. The ® rst one will be positioned in such a way that it will trim

42 mm from the left (or right) side of the roll. The following three slitters will be

positioned by leaving exactly 525 mm distance between two adjacent slitters. Finally,

the ® fth slitter positioned exactly 441 mm after the fourth one will cut the width of

product Ywhile separating 42 mm trim waste from the right (or left) side of the roll

(® gure 1). In fact, the slitters cut the whole paper roll with 2100 mm width into

three rolls each with 525 mm width and one roll with 441 mm width in the output

direction.

How to choose the paper roll among the several rolls with di erent widths, and

to select the mix of products with di erent widths and position slitters (cutting

pattern) with the minimum total trim loss from both sides is the ® rst issue to be

considered in the process. This is very similar to the well-known one-dimensional

cutting stock problem. (After considering the length of the whole paper roll, one can

see that the waste occurring at the beginning and end of the roll, from the cuttersÐ

which de® ne the lengths of the carton boardsÐ is negligible. In order to clarify this

point, a numerical example will be given from the case study in section 5.)

The cutting stock problem has been studied for more than three decades. After

the initial work by Gilmore and Gomory (1961, 1963) linear programming models

have been applied with appropriate assumptions. (See Reinders 1993 and Schultz

1995 for recent applications.) When the production levels are restricted to be integer

values, other optimization techniques and heuristic procedures are utilized. For

1580 A. Bolat

Downloaded by [University of Saskatchewan Library] at 13:08 01 March 2016

example, one-dimensional cutting stock procedures include Chen et al. (1996) and

Vance (1998), whereas multi-dimensional ones include Ghandforoush and Daniels

(1992), Morabito et al. (1992) , and Riehme et al. (1996). Finally, it should be men-

tioned that the cutting patterns in this work are not limited to having, at most, two

product types, as in the early works, such as Gilmore and Gomory (1965).

The second issue is the limitations on the storage area, which is composed of

several identical and individually operated roller conveyors. Coming out from the

corrugater machine, carton boards for the same product are piled together in stacks

and stored on the conveyors on the basis of `® rst available ® rst ® lled’. After the

curing period in the storage area, the boards are transferred to the converting

machines. The storage area also serves as a bu er zone to smooth out the variations

in the production rates of the corrugater and converting machines. Usually, the rate

of the corrugater machine is higher; within a 4±6 hour period it produces enough

load for four converting machines to operate for 10±12 hours continuously. Most of

the previous works on storage have proposed models and procedures to determine

the size of bu er while studying its e ects on the overall performance of the produc-

tion system (see Suri and Diehl 1986, Martin 1990, Commault and Dallery 1990,

Mahadevan and Narendran 1993, and Bolat 1996). On the other hand, production

models should also consider the e cient usage of existing bu er capacities.

The third issue is the loading (utilization) of the converting machines, which are

used to cut dies or make cases. The dried boards are routed stack by stack to one of

the two groups of machines for converting into boxes. The machines may vary in

production rate, but all require a set-up (1.5±2 h) whenever a new product is intro-

duced. Thus, a schedule that minimizes the trim loss by combining several products

with smaller quantities will require several set-ups, resulting in low capacity utiliza-

tion on the converting machines. The existing works on machine utilization are

mainly concerned with balancing the load among the machines (Raman et al.

1989, Zhou and Egbelu 1989, and Gaudiosa and Legato 1990). The problem of

how to utilize the converting machines e ciently (the number of set-ups during a

shift) is an important aspect of the larger production scheduling problem, which also

includes the utilization of the limited storage capacity in the drying area and the total

trim loss resulting from cutting the paper rolls in the corrugater machine.

1581Extended scheduling model for producing corrugated boxes

Figure 1. Trim losses for a speci® c cutting pattern.

Downloaded by [University of Saskatchewan Library] at 13:08 01 March 2016

There are few works that adopt the total planning concept considering the areas

mentioned above. In a collaboration with a copper component manufacturer,

Hendry et al. (1996) have combined scheduling and cutting stock problems for

melting scrap metal and casting it as logs, and then for cutting logs into billets. A

two-stage solution procedure is proposed to minimize costs whilst meeting the

demand for billets at the bottleneck. Tachibana (1997) has dealt with the cutting

stock problem for the manufacturing process of the paper industry. The goals are

decreasing the paper loss, levelling of the weight of paper lots and decreasing the

number of lots. Savsar and Cogun (1994) have demonstrated that corrugated box

production plans must also consider the bottleneck bu er area between corrugater

and converting machines. They have formulated a linear programming model to

minimize trim loss, while considering the capacity limits of converting machines

and storage area. The model by Savsar and Cogun (1994), MSC, is applied in a

box factory located in Riyadh.

Although the MSC model is the ® rst to combine several aspects of corrugated

box production and has introduced a lot of new ideas, it has some shortcomings. The

purpose of this work is to remove some of its simplifying assumptions, and develop a

procedure to produce more implementable solutions e ciently. The rest of the paper

is organized as follows. In sections 2 and 3 we demonstrate the weaknesses of the

previous model and propose an alternative one. Following this is the solution

approaches to the new model. In section 5, we present experimental results.

Finally, section 6 contains concluding remarks.

2. Critique of the previous model

The objective of the previous model MSC is to minimize the total amount of trim

loss in one shift. An optimum solution may require the combination of several

cutting patterns, resulting in the production of several products with di erent

widths. Obviously, introducing a new product will require a set-up and will decrease

the operating time of converting machine. However, the constraints related to the

converting machine capacities in MSC assume that there will be only one type of

product to be produced at each machine group (one set-up) during one shift.

Furthermore, a trade-o study may be required between the total trim loss and

the number of set-ups in one shift.

Secondly, the MSC assumes that the bu er is one big area rather than being

made up of several conveyors and the storage area can be utilized continuously in

both directions. This means that, for example, three piles of paper each of 0.42 m

width can be stored side by side on two neighbouring conveyors each of 0.64 m

width. In reality, because of its dimensions, there is only one way to lay a carton

board on the conveyor, and that is lengthwise, i.e. its longer sides will be parallel to

the moving direction of the conveyor. Furthermore, the conveyors are loaded one by

one on the basis of `® rst available’ and unloaded to feed the related converting

machine group on the basis of `longest waited’ . Finally, the converting machines

are jointly operated, i.e. all converting machines in one group process the same

product until all the papers of this product are depleted on the conveyors.

The following example, taken from Savsar and Cogun (1994), clearly illustrates

both points. For the next 12 h production period, ® ve products V,W,X,Yand Zare

considered with di erent demands to be cut from ® ve paper rolls with di erent

widths. The total number of allowed cutting patterns is 73. The data for the products

and the results of the proposed solution are given in table 1. There are two AP-type

1582 A. Bolat

Downloaded by [University of Saskatchewan Library] at 13:08 01 March 2016

![Bài giảng Vẽ kỹ thuật cơ khí: Chương 2 - Trường ĐH SPKT (ĐH Đà Nẵng) [Mới nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2026/20260303/zinedinezidane06/135x160/64351772685568.jpg)