13

REDUCTION GEARS

A. REDUCTION GEAR UNITS

13A1. Function and type. The main

diesel engines are directly connected to

the main generators which furnish

p

ower to the main motors or battery

through the control cubicle. Two types

of main drive installations are now in

use in modern fleet type submarines.

The older type which is at present used

in about 95 percent of our submarines

consists of four main motors arranged

in pairs to drive each of the propeller

shafts through a reduction gear. This

type of installation uses a single control

cubicle. The latest type of main drive

installation consists of a split control

cubicle and two large, slow-speed,

double-armature motors which are

directly connected to the propeller

shaft. Each section of the split control

cubicle is designed primarily to control

p

ropulsion on its particular side. It is

p

ossible, however, to tie the two sides

of the split cubicle together and

therefore use port engines on the

starboard screw and vice versa.

This description of reduction gears is

limited to the older type installation.

Each reduction gear reduces the high

main motor speed of approximately

1300 rpm to the propeller shaft speed o

f

280 rpm. The ratio of reduction is

determined by the maximum efficiency

obtainable from the propellers without

loss of power at varying motor and

p

ropeller speeds.

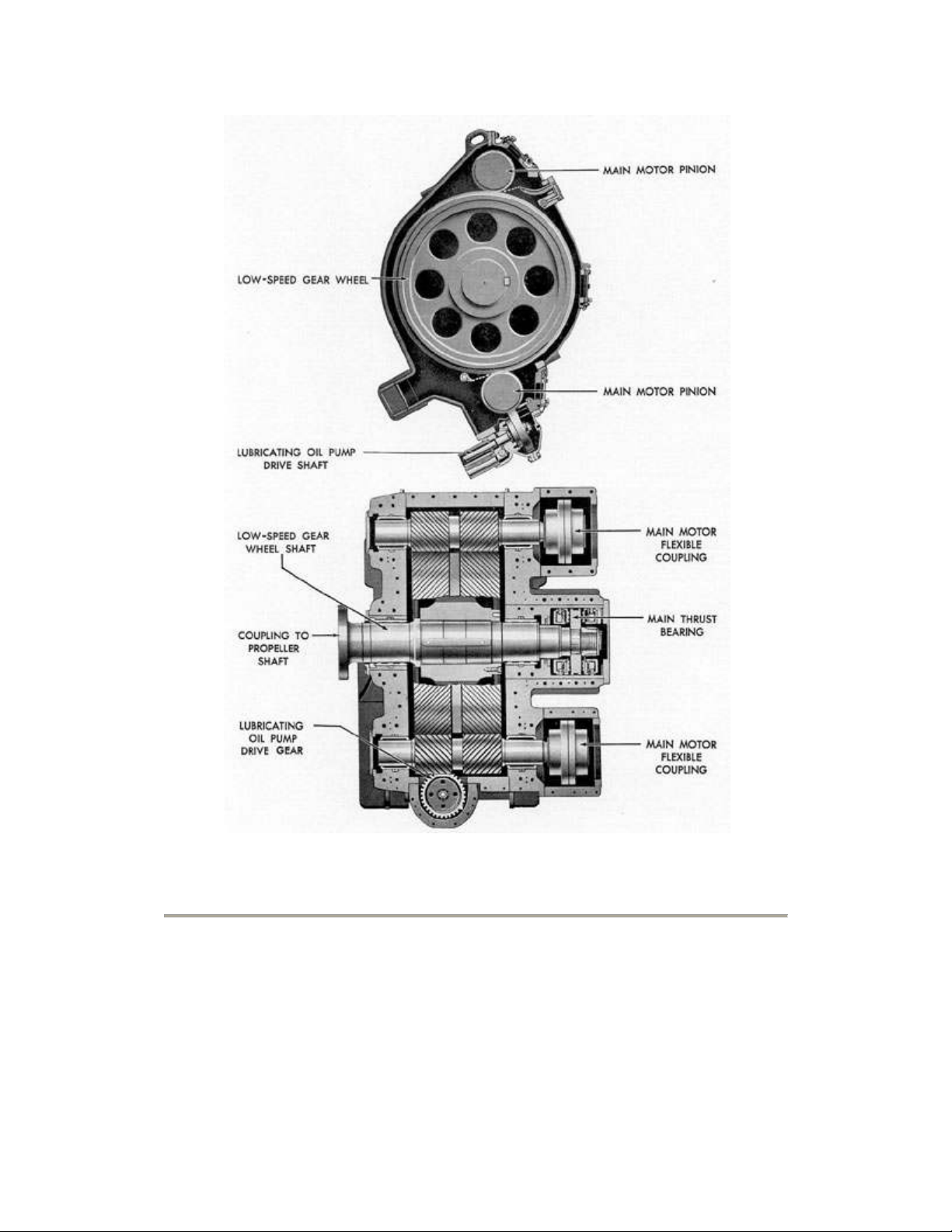

The gears are single reduction, double

helical type, a right- and left-hand helix

being used to balance the fore and aft

components of the tooth pressure.

The reduction gear assembly consists

essentially of two main motor pinions

forged and cut integral with the pinion

shafts, one main gear or bull gear which

is connected to the propeller shaft, and a

lubricating oil pump gear which is geared

to the inner pinion shaft. The forward

ends of the pinion shafts are connected to

their respective motors through flexible

couplings. Each pinion shaft is supported

by a cylindrical type bearing at each end.

The main gear is pressed and keyed to

the gear shaft. The aft end of the shaft is

coupled to the propeller shaft. On the

forward end of the main gear shaft is

mounted the collar of the main thrust

bearing which absorbs the propeller

thrust. The gear and shaft are carried on

two sleeve bearings.

The sleeve bearings consist of steel shells

lined with babbitt. The bearing shells are

split

These helical gears produce a smoother

action and avoid the tooth check of spur

gears.

13A2. Description and operation.

With the exception of minor differences

in design, gear units produced by

various manufacturers and installed on

fleet type submarines today are similar.

Specifications to which they are built

will be found in the manufacturer's

instruction book pertaining to the unit

in question. The two units used on each

ship are alike except that one is for port

p

ropulsion and the other for starboard

p

ropulsion. Facing aft, the port shaft

rotates clockwise, and the starboard

shaft rotates counterclockwise.

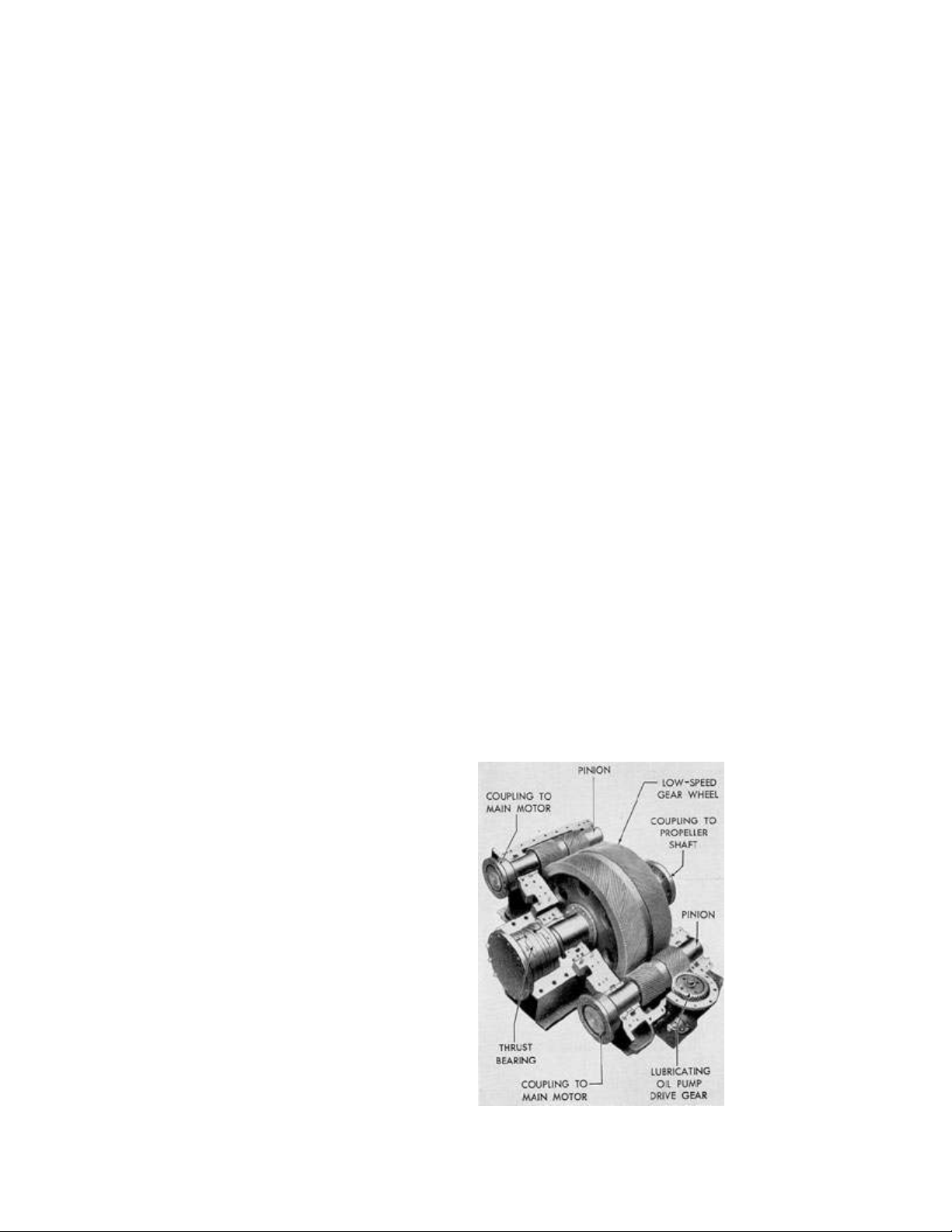

F

igure 13-1. Reduction gear, top case

removed.

261

Figure 13-2. Sectional views of reduction gear.

262

and the two halves of each shell are

held in alignment by dowels set in the

lower half. Dowels in the bearing caps

p

revent the shells from rotating. The

lubrication of the bearings is explained

in Section 13A4f.

13A3. Flexible couplings between

pinion and motor shafts. The

An accurate record of all repairs,

adjustments, readings, and casualties

should be kept in the machinery history.

b. Unusual sounds. A properly operating

reduction gear has a certain definite

sound which the trained operator can

easily recognize. The cause of any

unusual noises should be investigated,

couplings between the two main motor

armature shafts and the pinion shafts of

the reduction gear are of the enclosed

flexible type. Each coupling consists

essentially of two hubs with external

spur gears, and two sleeves with

internal spur gears. The hubs are

p

ressed on and keyed to their respective

shafts. The floating sleeves fit around

the hubs so that the spur gear teeth are

p

ermanently meshed. The floating

sleeves are bolted together.

This type of coupling provides

longitudinal flexibility between the

driving and driven shafts and thereby

p

ermits the pinion to trail the main

gear. Movement of the main gear is in

turn limited by the clearance in the

thrust bearing. The coupling permits a

small amount of misalignment of the

hubs to occur without causing

operational difficulties. However, it is

not advisable to operate continuously

with the hubs out of alignment because

the coupling is not intended to function

as a universal joint. Continuous

operation with the hubs out of

alignment will result in excessive

friction and gear teeth wear, and

eventually will cause a breakdown.

The couplings are lubricated by a

continuous stream of oil supplied by

the main motor and reduction gear

lubricating oil pump. Oil enters through

a nozzle and after passing between the

gear teeth is discharged through holes

in the sleeve.

13A4. Maintenance. a. Machinery

history. It is of great importance that

the machinery history contain a

complete record of the installation from

the time of commissioning. Complete

installation data as furnished by the

and the gears should be operated with

caution until the source is located and

remedied.

c. Tooth contact. It is essential, for prope

r

operation of the gears, that the total tooth

p

ressure be uniformly distributed over

the total area of the tooth faces. This is

accomplished by accurate alignment, and

adherence to the designed clearance

limits. Alignment should be checked at

the time the gear is installed, during each

major overhaul, and after any casualty

severe enough to threaten the alignment.

Operating gears with faulty alignment are

detrimental to the life and performance o

f

the teeth. Continued quiet operation and

good tooth contact are the best

indications of proper tooth alignment.

d. Backlash. Backlash is measured by

locking the main gear in its forward

p

osition and then moving each pinion

j

ust far enough forward and aft to make

firm contact each way. The total

lengthwise movement measured when

doing this is the axial backlash. The

backlash will increase with wear, and it

can increase considerably without

causing trouble. The actual longitudinal

movement, as measured at the time the

unit was built at the factory, should be

found stamped on all pinion shafts except

spares, and should be recorded in the

machinery history. This measurement is

the minimum allowable backlash.

e. Flexible couplings. The coupling

backlash should be checked at regular

intervals to see that it has not increased

excessively. A dial indicator is used to

measure the total backlash without

dismantling the coupling. The one shaft

is held stationary, and the dial indicator is

mounted on the opposite or moving shaft

with the indicator needle on some Dart o

f

contractor should be entered in the

machinery index by prospective

engineer officers at the contractor's

yard. This should include the original

bearing crown thickness or bridge gage

readings, bearing clearances, thrust

settings and clearances, and tooth

clearances (backlash and root) of the

gear wheel and pinion teeth. It is

essential that these data be on hand

when the alignment is subsequently

checked.

the coupling housing. By twisting the

movable shaft back and forth without

allowing the stationary shaft to move, the

total backlash will be indicated on the

dial indicator.

263

The backlash when found should be

checked with the recorded initial

backlash. If subsequent wear has

increased the backlash to twice the

original amount, replacement of the

coupling should be considered.

Since the condition of the bearing

surfaces depends upon the axial

alignment of the shafts, regular

inspection should include a check to

see that proper alignment is maintained.

To check the alignment, the flexible

coupling must first be dismantled. To

accomplish this, the manufacturer's

instruction book should be consulted.

f. Bearings. All of the bearing caps may

be removed for bearing inspection or

replacement without disturbing the gear

case. The pinions are light enough so

that no trouble should be experienced

when rolling out the lower halves of the

p

inion bearings once the shaft has been

raised.

When assembling, all bearing shells

should be replaced in their original

p

ositions. Old cement should be

cleaned off the mating surfaces of the

bearing caps, end caps, and case, and a

g. Bearing wear. The amount of wear of

reduction gear bearings must not be

allowed to become sufficiently great to

cause incorrect gear tooth contact. The

designed clearances, load diagrams, and

methods of measuring bearing wear are

given in the manufacturer's instruction

book pertaining to the unit in question.

13A5. Special precautions. a. In case of

churning or emulsification of the oil in

the gear case, the gear must be slowed or

stopped until the defect is remedied.

b. If for any reason, the supply of

lubricating oil to the gears fails, the gears

should be immediately stopped until the

cause can be located and remedied.

c. When bearings are known to have been

overheated, gears should not be operated,

except in cases of extreme emergency,

until bearings have been examined and

the defects remedied.

d. If excessive flaking of metal from gear

teeth occurs, the gears should not be

adjusted, except in case of emergency,

until the cause has been determined. Care

should be taken, however, to prevent the

entry of the metal flakes into the general

![Giáo trình Công nghệ sửa chữa và bảo dưỡng ô tô - Trường Đại học Công nghiệp Việt - Hung [Mới nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20251201/gmducdat11a4@gmail.com/135x160/65741764643914.jpg)