Oxidation of phenols by laccase and laccase-mediator systems

Solubility and steric issues

Francesca d’Acunzo, Carlo Galli and Bernardo Masci

Dipartimento di Chimica and Centro CNR Meccanismi di Reazione, Universita

`La Sapienza, 00185 Roma, Italy

To investigate how solubility and steric issues affect the

laccase-catalysed oxidation of phenols, a series of oligomeric

polyphenol compounds, having increasing size and

decreasing solubility in water, was incubated with laccase.

The extent of substrate conversion, and the nature of the

products formed in buffered aqueous solutions, were com-

pared to those obtained in the presence of an organic

cosolvent, and also in the presence of two mediating species,

i.e. N-hydroxyphthalimide (HPI) and 2,2,6,6-tetramethyl-

piperidin-1-yloxy (TEMPO). This approach showed not

only an obvious role of solubility, but also a significant role

of the dimension of the substrate upon the enzymatic reac-

tivity. In fact, reactivity decreases as substrate size increases

even when solubility is enhanced by a cosolvent. This effect

may be ascribed to limited accessibility of encumbered sub-

strates to the enzyme active site, and can be compensated

through the use of the appropriate mediator. While TEMPO

was highly efficient at enhancing the reactivity of large, less

soluble substrates, HPI proved less effective. In addition,

whereas the laccase/HPI system afforded the same products

as laccase alone, the use of TEMPO provided a different

product with high specificity. These results offer the first

evidence of the role of oxidation shuttlesthat the media-

tors of laccase may have, but also suggest two promising

routes towards an environmentally friendly process for

kraft pulp bleaching: (a) the identification of mediators

which, once oxidized by laccase, are able to target strategic

functional groups present in lignin, and (b) the introduction

of those strategic functional groups in an appropriate

pretreatment.

Keywords: laccase; phenols; lignin degradation; HPI;

TEMPO.

Lignin is a three-dimensional, insoluble aromatic polymer

that constitutes 15–33% of biomass. Its structure encom-

passes a number of different types of links between its

constituents, namely ether and C-C diaryl linkages [1].

White-rot fungi achieve the oxidative depolymerization of

lignin by secreting several enzymes, such as lignin peroxidase

[2], manganese peroxidase [3], and laccase (EC 1.10.3.2) [4].

In contrast with lignin peroxidase and manganese peroxi-

dase, laccase can only oxidize the phenolic constituents of

lignin, due to its lower oxidation potential. On the other

hand, it is more readily available and easier to manipulate

than the other two enzymes, and its substrate specificity is

low, as long as a good match of oxidation potentials is

provided [5–8]. In addition, the use of appropriate low

molecular-mass compounds (viz., mediators), in combina-

tion with laccase, makes this enzyme competent for the

oxidation of non-naturalnonphenolic substrates [9–12]. In

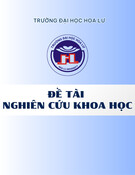

fact, the oxidized mediator (Fig. 1) can rely on an oxidation

mechanism that is not available to the enzyme [13].

Laccase can therefore be turned into a much more

versatile enzyme, and this opens up various possible

applications, as in the textile dye bleaching [14], or for

environmentally respectful kraft pulp delignification [10,15],

or also in selective organic transformations [16–19]. The

study presented here is part of our efforts to elucidate the

mechanisms of action of the laccase/mediator systems [20] in

the oxidation of lignin model compounds, as well as non-

lignin-related structures (Fig. 1).

A conceivable role of the mediator could be that of a sort

of electron shuttlebetween the enzyme and the substrate

[21]. Once the mediator is oxidized by the enzyme, it diffuses

away from the enzymatic pocket and in turn oxidizes

substrates that, due to their size, could not directly enter the

enzymatic pocket. Within this framework, we wished to

investigate the influence of substrate size and solubility on

the effectiveness of laccase oxidation, and also the effect of

mediators endowed with possibly different mechanisms of

action. To this aim, we needed to start from a simple

phenolic structure, which laccase could recognize as a

naturalsubstrate, and modify it into bigger and more

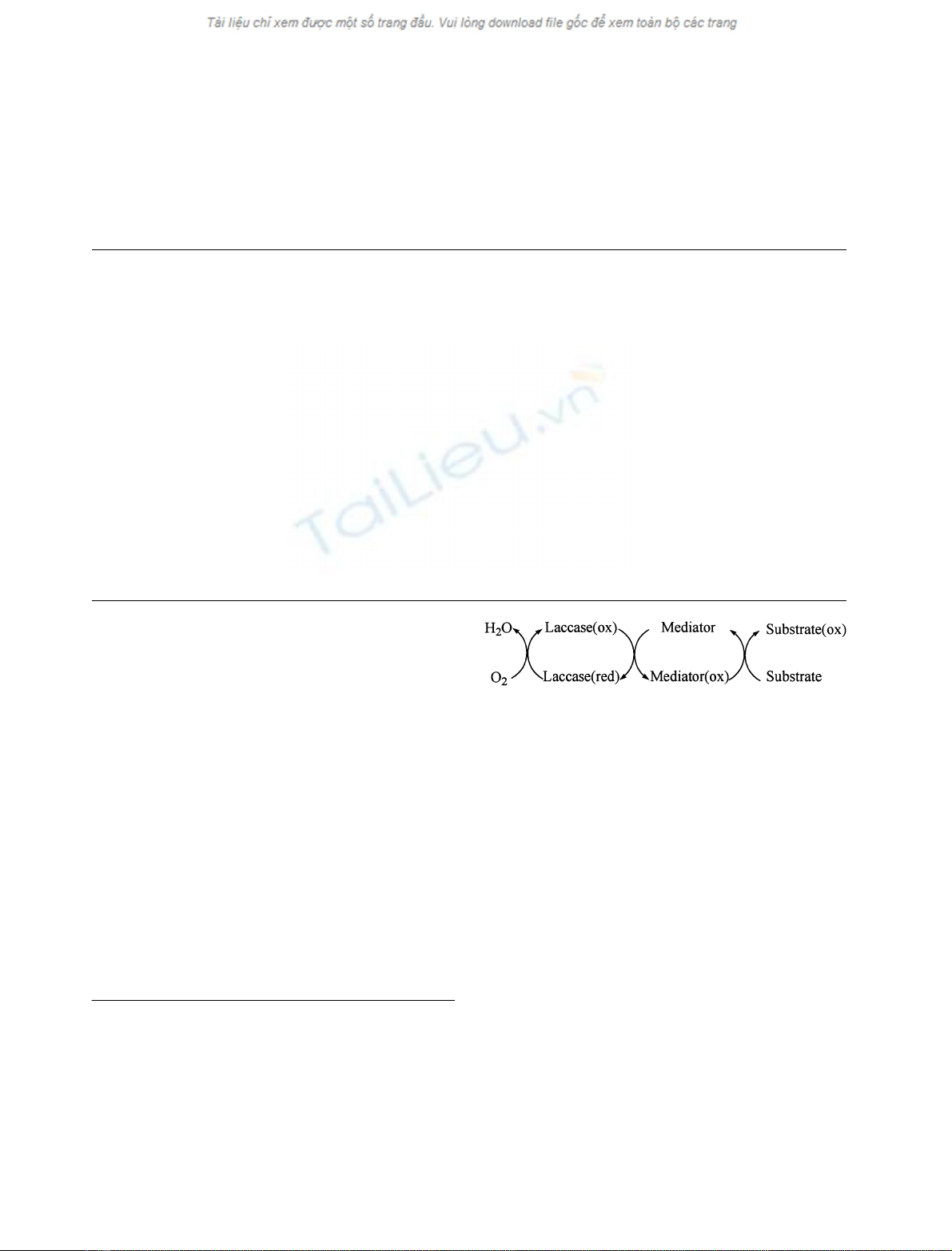

insoluble derivatives. The oligomeric series shown in Fig. 2

served our purposes for the following reasons: (a) each

repeat unit is a phenol, and therefore subject to oxidation

by laccase, at least in terms of redox potential; (b) the

number of repeat units in each oligomer, and therefore its

size, is exactly determined, because directed synthesis and

Fig. 1. Catalytic cycle of a laccase-mediator oxidation system.

Correspondence to C. Galli, Dipartimento di Chimica and Centro

CNR Meccanismi di Reazione, Universita

`La Sapienza,

00185 Roma, Italy. Fax: + 39 06 490421,

E-mail: carlo.galli@uniroma1.it

Abbreviations:HPI,N-hydroxyphthalimide; TEMPO, 2,2,6,6-

tetramethylpiperidin-1-yloxy; ABTS, 2,2¢-azinobis-(3-ethylbenzothi-

azoline-6-sulfonate).

(Received 18 June 2002, revised 9 September 2002,

accepted 12 September 2002)

Eur. J. Biochem. 269, 5330–5335 (2002) FEBS 2002 doi:10.1046/j.1432-1033.2002.03256.x

suitable purification allowed pure monodisperse oligomers

to be available; (c) solubility in water decreases as size

increases; and (d) o-o-p-substitution should inhibit C-C

diaryl bond formation, a well-known reaction pathway of

phenoxy radicals [1,12].

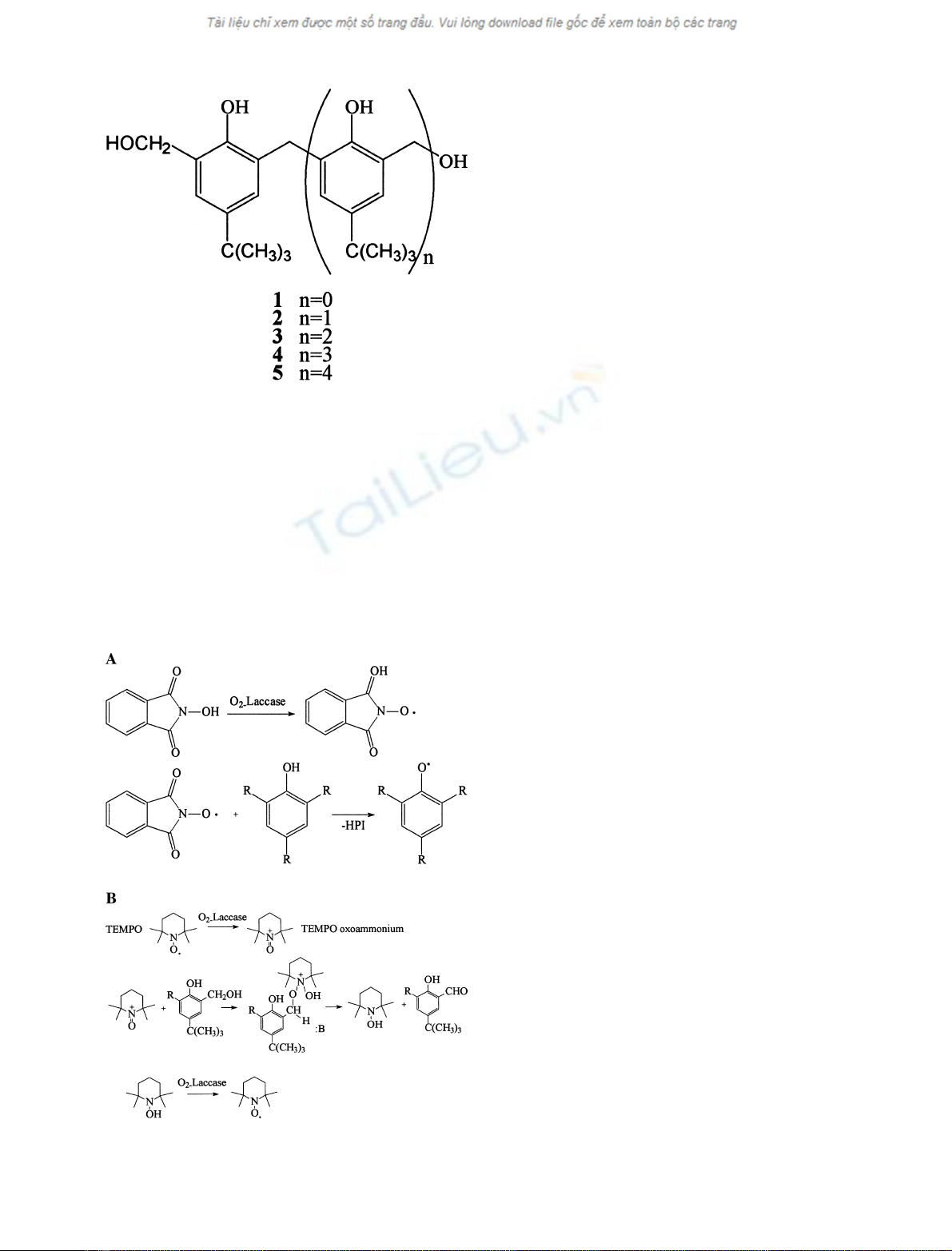

We chose N-hydroxyphtalimide (HPI) and 2,2,6,6-

tetramethylpiperidin-1-yloxy free radical (TEMPO) as

mediators, since they greatly differ both in their mechan-

ism of action and in their specificity. In fact, HPI is

representative of a mediator that, after having been oxidized

by laccase, should only induce the generation of phenoxy

radical(s) from the substrate (Fig. 3A) [18,20,22–24]. This

radical role of the oxidized HPI would be comparable to the

naturaloxidation role of the enzyme, with the only

difference of presenting fewer stringent steric and solubility

requirements. The phenoxy radical of the product, in turn,

should evolve towards end-products with little or no further

intervention from HPI.

On the other hand, TEMPO is representative of a

mediator that, by selectively interacting with specific func-

tional groups [25] (i.e. alcohols) (Fig. 3B), not only acts as a

shuttle for the oxidizing power of laccase towards insoluble

or bulky substrates, but also induces the formation of

different products than the physiologicalones. This aspect

may prove useful for synthetic purposes, as well as in lignin

degradation. The mechanism reported in Fig. 3B matches

the well-established one reported for the oxidation of

alcohols by catalytic amounts of TEMPO with stoichio-

metric co-oxidants [25–27]. In all these cases the oxoam-

monium form of TEMPO is involved. In our particular

case, laccase would be the catalytic oxidant of TEMPO [17].

Following a nucleophilic attack of the lone-pair of the

alcohol onto the TEMPO-oxoammonium ion, the interme-

diate adduct is deprotonated at the a-C-H benzylic bond by

the base-form of the buffer B [17,25–27].

In order to decouple the effect of increasing substrate-size

and decreasing solubility, the oxidations were carried out in

1 : 1 aqueous buffer/dioxane, and the results compared with

those obtained in 100% aqueous buffer.

MATERIALS AND METHODS

Laccase

Laccase from Poliporus pinsitus was kindly donated by

Novo Nordisk Biotech and purified by ion-exchange

chromatography on Q-Sepharose by elution with phosphate

buffer [5,20], and an activity of 10 000 UÆmL

)1

determined

spectrophotometrically by the standard reaction with ABTS

[28]. Laccase having an absorption ratio A

280

/A

610

of 20–30

was considered sufficiently pure [5].

Materials

HPI and TEMPO were used as received from Aldrich. The

solvents were from Aldrich, Merck or Carlo Erba.

Synthesis of substrates

Compounds 2–4 were prepared according to a literature

procedure [29]. The latter procedure was also extended to

the stepwise synthesis of compound 5, the pentaphenol

condensation product obtained from compound 3and

4-tert-butylphenol being bis-hydroxymethylated. The purity

of these compounds (> 96%) was checked by

1

HNMR

and HPLC.

Spectrophotometric determination of laccase activity

The activity of laccase was determined by following the rate

of oxidation of 2,2¢-azinobis-(3-ethylbenzothiazoline-6-

sulfonate) (ABTS) to ABTS radical cation (ABTS

•+

), by

plotting the absorbance at 414 nm against time [28].

The extinction coefficient of ABTS

•+

at 414 nm is

3.15 ·10

)4

M

)1

Æcm

)1

. ABTS (Aldrich) was recrystallized

Fig. 3. Mechanisms of the O

2

-laccase-HPI (A) and O

2-

laccase-

TEMPO (B) oxidation of substrates 1–5 (Fig. 2).

Fig. 2. Oligomeric compounds 1–5.

FEBS 2002 Oxidation of phenols (Eur. J. Biochem. 269) 5331

from ethanol prior to use. A stock solution was prepared by

dissolving 3 mg of ABTS in 10 mL 0.1

M

citrate buffer at

pH 5.0; 200 lL of the stock solution were added to 3 mL

citrate buffer in a quartz cuvette (10 mm pathlength); 1 lL

of laccase solution, approximately 10–20 UÆmL

)1

,was

then added, and the initial rate of ABTS

•+

formation

was determined. The 10–20 UÆmL

)1

laccase activity was

achieved by diluting the purified laccase solution in citrate

buffer.

Evaluation of substrates solubility

The solubility of substrates 2,3,5was evaluated by UV-Vis

spectrometry. A Hewlett Packard 8453 diode-array single

beam spectrophotometer was used. A 2.0-m

M

stock solution

of each substrate was prepared in dioxane; aliquots (5.0 lL)

of the stock solution were added to 2.5 mL of 1 : 1 (v/v) 0.1

M

citrate buffer pH 5.0/dioxane mixed solvent in a 10-mm

quartz cuvette. Spectra were recorded in the 220–320 nm

range, and the absorbance at 280 nm was plotted against

concentration.

Oxidations catalysed by laccase and laccase/mediator

systems

In a typical experiment, 60 lmol of substrates 1–5were

weighedina2-mLscrew-capvialequippedwithastirring

bar. In the experiments with mediators, 20 lmol HPI or

TEMPO were also added. In the experiments with aqueous

solvent only, 0.3 mL of 0.1

M

citrate buffer, pH 5.0, were

added at this point, followed by 9–10 U of purified laccase.

In the experiments with the mixed solvent, 0.15 mL of

dioxane were added first, followed by an equal amount of

citrate buffer and 9–10 U laccase. The reaction mixture was

allowed to react at room temperature for 24 h. The vials

were left uncapped and vigorous stirring was maintained in

order to ensure oxygen saturation.

HPLC determination of substrate conversion

Substrate consumption after a 24-h reaction time was

determined using a Hewlett-Packard 1050 HPLC system

(pump, detector, and solvent delivery system) equipped with

a Supelcosil LC-18-DB 25 cm ·4.6 mm column and a HP

3395B integrator. The analyses were carried out with

gradients of water/methanol/isopropanol mixtures, contain-

ing 0.03% trifluoroacetic acid, at 0.5–1 mLÆmin

)1

flow rate.

Quantitation of unreacted substrate was achieved by using

2-bromonaphtalene (Aldrich) as the internal standard. The

standard was added to the reaction crude, which was then

diluted in the mobile phase and filtered through 0.2 lm

Teflon syringe filters (Superchrom Varisep) prior to

analysis.

Product analysis: liquid mass spectrometry (LC-MS)

The analysis was carried out using a triple quadrupole

Perkin Elmer Sciex API 365 spectrometer with a turbo–ion

spray interface. Samples were diluted in HPLC-grade

methanol and filtered through 0.2 lm Teflon syringe filters

prior to injecting. The samples were directly injected into the

ion spray chamber without chromatographic separation.

Product analysis:

1

H-NMR

Samples were dissolved in dimethylsulfoxide-d

6

(Merck)

and spectra were acquired using a Varian 300 MHz

spectrometer with a Mercury console.

RESULTS AND DISCUSSION

Solubility of substrates

This was assessed by a UV-Vis spectrophotometric experi-

ment, aimed at verifying that the substrates were soluble in

the buffer/dioxane mixed solvent up to the concentration

used in the laccase-catalysed reaction. We checked that the

absorbance at 280 nm, corresponding to the maximum

absorbance of the substrates, increases linearly with sub-

strate concentration without scatter from precipitation.

Furthermore, we checked that the absorbance falls to zero

outside the peak, i.e. that no wavelength-independent

turbidity arises from precipitation. We thus verified that

solutions of substrates 2–5as concentrated as 85 l

M

can be

prepared. However, the solution containing substrate 5

became visibly turbid after 24 h. We therefore concluded

that the heaviest of our substrates can yield over-saturated

solutions in the buffer/dioxane mixed solvent, at the

concentrations used for the oxidation reaction.

Substrate consumption

Table 1 summarizes the results of our laccase oxidations of

substrates 1–5, and the effect of the cosolvent and of the

mediators on the amount of substrate metabolized by the

enzyme.

(a) Laccase and laccase/HPI. In general, the use of the

buffer/dioxane mixed solvent enhances substrate conversion

both with and without mediator. The monomeric substrate

Table 1. Percent of substrate metabolized by laccase or laccase/mediator systems with and without an organic cosolvent. Substrate recovery was

determined by HPLC.

No mediator HPI TEMPO

Substrate Buffer Buffer/dioxane Buffer Buffer/dioxane Buffer Buffer/dioxane

1100 100 – – – –

233 96 – 100 – 96

318 55 20 60 32 95

400 0 0 687

500 0 0 040

5332 F. d’Acunzo et al.(Eur. J. Biochem. 269)FEBS 2002