Journal of Water Resources & Environmental Engineering - No. 87 (12/2023)

16

A study of flow structure, drag force, and particle tracking

through many circular cylinders

Vu Huy Cong

1

Abstract: The variation of multiple circular c

ylinders' drag coefficient was investigated using numerical

methods. Moreover, the particle tracking simulation was also performed to show the flow structure and

how particles move inside the cylinder array. It was found that the density and location of cy

linders

have a significant influence on the fluid forces, flow structure, and particle movement inside them.

The

results showed that when the number of cylinders increases per unit area, the total drag coefficient

increases but the average drag coefficient

per cylinder decreases. A functional relationship between the

drag coefficient and the density of cylinders was determined. The distribution or position of the

cylinders has a considerable impact on particle distribution. The cylinders in the staggered ar

rangement

disperse the particles more in a fan-

shaped manner, spreading them out in the cylinder array. The results

will advance knowledge of the drag force and flow field, particularly in matter propagation or dispersion

through systems of objects.

Keywords: Drag fore coefficient, cylinder, particle tracking, flow structure.

1. Introduction

*

Flow around circular cylinders has attracted a

lot of attention in the past due to its importance

and practical application in engineering

systems. The cylinder-like structures can be

found alone or in groups in water or air

environments, such as in studies of submerged

vegetation, offshore and infrastructure works,

heat exchangers, and cooling systems.

Ghisalberti and Nepf (2004) simulated flow

around vegetation using cylinder structures.

They reported that the vortex behind the

cylinders controls the exchange of nutrients and

larvae. Bennett, et al. (2002) studied the stream

flow direction and flow structure surrounding

the emergent vegetation, simplified as a cylinder

model. (Tanino & Nepf, 2008) performed an

experiment to examine the drag force of

vegetation using an array of cylinders and found

1

Faculty of Water Resources Engineering, The University

of Danang- University of Science and Technology

Email: vhcong@dut.udn.vn

Received 17

th

Aug. 2023

Accepted 1

st

Sep. 2023

Available online 31

st

Dec. 2023

that as vegetation density increases, the average

drag coefficient of each cylinder decreases. The

cylinders' drag coefficient, which directly

influences the flow's characteristics, is a crucial

component. Nepf (1999) demonstrated

connections between cylinder drag coefficient,

turbulence intensity, and diffusion. Recently,

Yamasaki, et al. (2021) examined how the

hydrodynamic interaction between neighboring

patches of model vegetation (circular cylinder)

impacted deposition. Han et al. (2023)

researched on water flow resistance

characteristics in a vegetation environment,

which is primarily concentrated on the

calculation of the vegetation drag coefficient.

Previous studies indicated that the cylinders'

gap spacing and flow direction have a

significant impact on the drag coefficient.

Depending on how the cylinders are organized,

the drag on two could be either smaller or larger

than that of a single cylinder when they are

close. It is clear that as the number of cylinders

increases, the complexity of the flow around the

cylinders also increases. Although multiple

Journal of Water Resources & Environmental Engineering - No. 87 (12/2023)

17

cylinders are often observed in practice, the

complexity of flow structures and the drag

coefficient have prevented detailed research. It

is difficult to determine whether the drag

coefficient of a cylinder is increased or

decreased due to a large number of

characteristics, such as geometric parameters

related to cylinder position, which may result in

multiple interferences. Studies on the drag

coefficient of cylinder arrays are currently

scarce, and most of them are experiments (Zong

& Nepf 2011). Nowadays, numerical models are

commonly used to study the flow around one or

more cylinders. Numerical models are

especially beneficial for simulating different

scenarios and reducing experimental costs

dramatically. There are popular methods in

numerical modeling for cylinders, such as the

finite element method (FEM) (Kumar & Mittal,

2006), the finite volume method (FVM) (Jiang

& Cheng, 2021), the finite difference method

(FDM) (Parnaudeau, et al. 2008), or other

methods, such as the Lattice Boltzmann method

(Grucelski & Pozorski, 2013). This study

investigates the average drag coefficient of a

cylinder array with regard to cylinder density

using FVM. Additionally, the impact of the

cylinders' distribution type on particle

dispersion will be investigated.

2. Numerical methods

2.1. The particle tracking in CFD model

A computational fluid dynamic program

(CFD) with an FVM approach is used in this

study. The drag force and flow structures are

simulated in hydraulic mode. Furthermore, the

Discrete Phase Model is used to track the

motion of discrete particles. The equation is

provided below.

p

p

D

du

F u u

dt

(1)

The inertial force per unit mass (m s

-2

) is

shown on the left-hand side of Eq. (4), where

p

u

is the particle velocity vector. The drag term,

where F

D

is the inverse of relaxation time (s

-1

),

is found on the right-hand side of the equation.

The drag force follows Stokes’ drag law:

2

18

drag p p

D

p p c

F F u u u u

d C

(2)

where

, d

p

are the dynamic viscosity and the

particle diameter, respectively. The Stokes' drag

law Cunningham correction is denoted by the

factor C

c

. These forces' detailed descriptions are

available in document material.

In the simulation, the following assumptions

are made concerning particle motion analysis:

(1) Every particle is a sphere with the same

density

p

and identical diameter d

p

; (2)

The one-way coupling is taken into account,

and the return effects of particle-to-carrier flow

are neglected; (3) Interactions between particles

are neglected.

2.2. Fluid force

Drag coefficient (C

D

) is the dimensionless

variable associated with fluid force. It should be

noted that the pressure and skin friction

components, which are described in Eq. (3), are

added to obtain the drag force.

2 2

0 0

cos sin

D w

F R p d R d

(3)

where F

D

is the drag force acting on the

cylinder, R (=D/2) is the cylinder's radius,

w

is

the local wall shear stress, θ is the angular

displacement from the front stagnation point.

The drag force coefficient of single cylinder

can be determined from its original definition.

2 2

2 2

0 0

2 1 1

cos sin

2

D

Di p w

o o

F

C C d d

U D U

(4)

We define the total drag coefficient of

multiple cylinders, C

D_total

as follow:

_

1

n

D total Di

i

C C

(5)

The average drag coefficient C

D_av

is defines

as follows:

Journal of Water Resources & Environmental Engineering - No. 87 (12/2023)

18

1

_

n

Di

i

D av

C

C

n

(6)

where n is number of cylinders.

2.3. Numerical setup

2.3.1. Case of single cylinder and validation

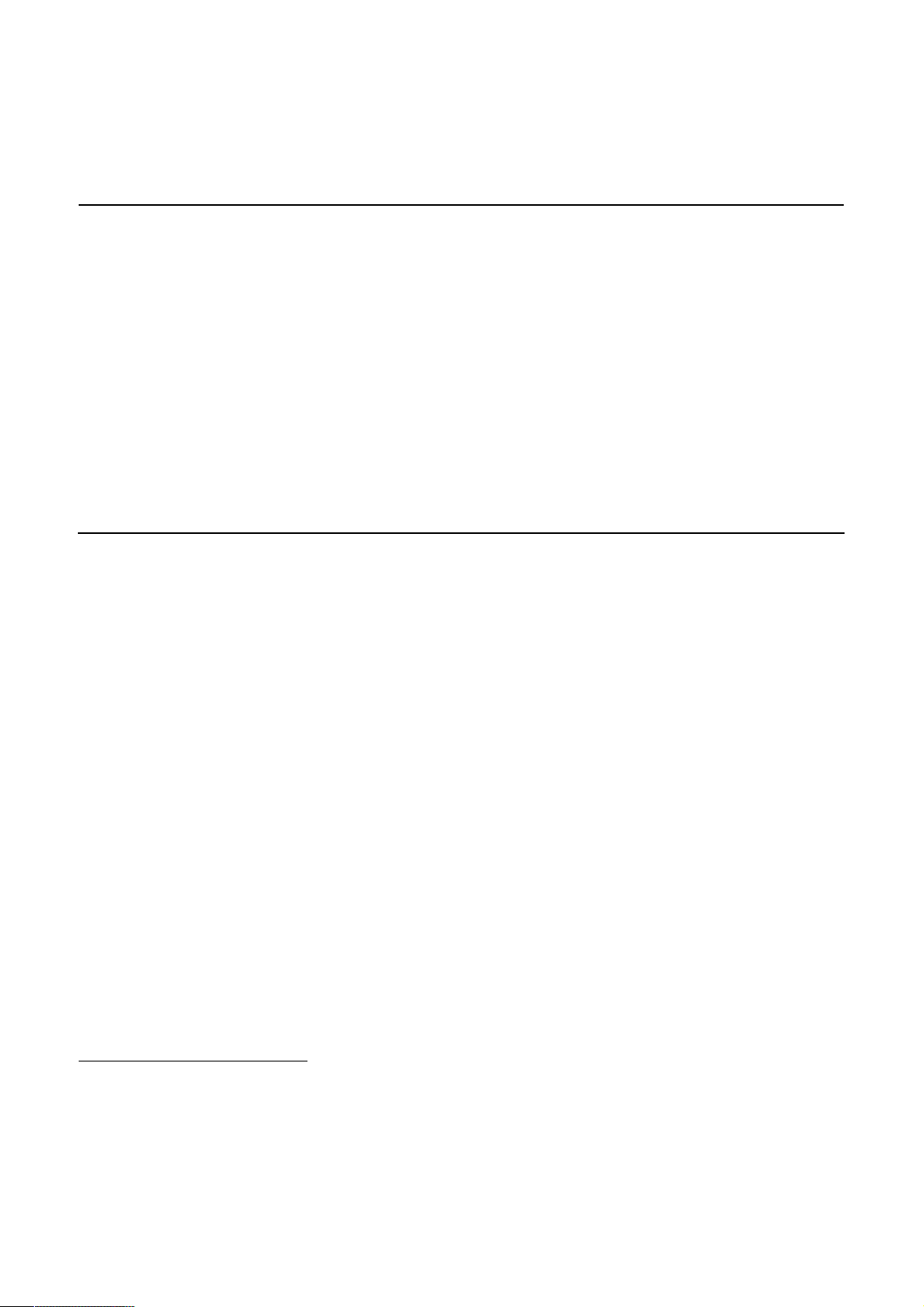

Figure 1. Computational domain and meshing

for the case of single cylinder

The case of a circular cylinder is simulated first

to test the model. Figure 1a shows schematic

diagrams of the computational domains for this

case. The computational domains were meshed

with triangle grid systems. Finer cells were used

near the cylinder surface, whereas coarser cells

were adopted near the wall boundary (Figure 1b).

Figure 1c shows details of the grid around the

cylinder. The test for the grid independence of the

flows around a single cylinder was performed

with three mesh resolutions. The numbers of grid

cells employed around the circumference of the

cylinder were 160, 240, and 320. The total grid

cells for the computational domain are 89090,

95636, and 104498, respectively. The Reynolds

number was set at 200 for this test.

The semi-implicit pressurelinked equations

(SIMPLE) approach is used to deal with the

pressure-velocity coupling in the numerical

setup. A second order upwind technique is used

to discretize the convective terms. A shear

Stress Transport (SST) k-omega model is used

to simulate the turbulent flow. This may be

attributed to the improvement of SST k-omega

compared with k-epsilon models in predicting

flow separation under adverse pressure

gradients (Vu, et al. 2015). Separation is an

important behavior of flow when it passes

through a circular cylinder.

For validation of the grid independence, the

drag coefficients of a single cylinder was

simulated for Re=200. Corresponding to the

number of grid cells around the cylinder of 160,

240, and 320, the coefficients C

D

obtained are

1.37, 1.33, and 1.307 respectively. The drag

coefficients found above show good agreement

with previous studies, for example, (Lam et al.

(2008) with C

D

=1.32; Ding, et al. (2007) with C

D

=

1.348±0.05; Meneghini, et al. (2001) with C

D

=1.3.

From the above results, it can be seen that all three

cases above have similar results for C

D

. The size

of such cells is to ensure that the properties of the

flow around the cylinder can be simulated. The

case of 240 grid cells around the cylinder is

selected to set up other simulations.

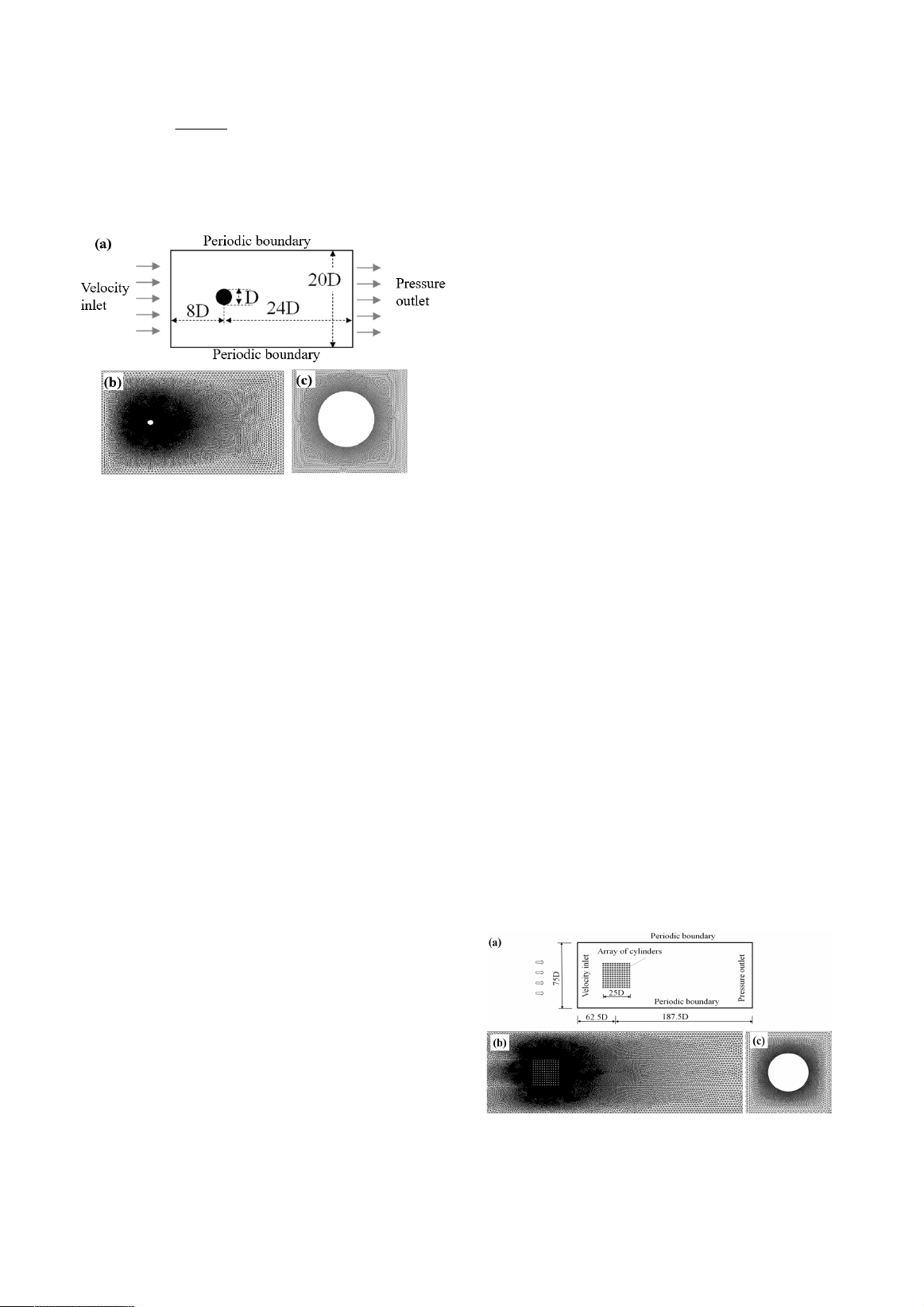

2.3.2. Case of multiple cylinders

The computational domain and boundary

conditions for an array of cylinders were the

same as those of a single cylinder case (Figure

2a). The size of the cylinder is also the same as

in the previous case. The array of cylinders is

located in the middle of the channel, with

dimensions of 25D×25D. The meshing method

is done in the same way as above. There are

approximately 1946760 grid cells in the domain

as a whole. A detail of the mesh along a

cylinder wall is shown in Figure 2c.

Figure 2. Computational domain meshing

for the case of multiple cylinders

Journal of Water Resources & Environmental Engineering - No. 87 (12/2023)

19

The simulated cylinders are located in a

square area 25D×25D (1m

2

). In order to

change the density of cylinders, the

number of cylinders per area varies from 4

to 144.

3. Results

3.1. Drag force

The drag force of cylinders is shown in Table

1. It was found that this drag force is strongly

governed by the number of cylinders. The total

drag coefficient (C

D_total

) increases as the

density increases.

Table 1. The drag force coefficient

Case Number of cylinders aD C

D_total

C

D_av

1 4 0.0064 3.5732 0.8933

2 9 0.0144 7.5519 0.8391

3 16 0.0256 11.5344 0.7209

4 25 0.04 16.385 0.6554

5 36 0.0576 21.15 0.5875

6 49 0.0784 27.6213 0.5637

7 64 0.1024 33.7984 0.5281

8 100 0.16 47.23 0.4723

9 144 0.2304 53.64 0.3725

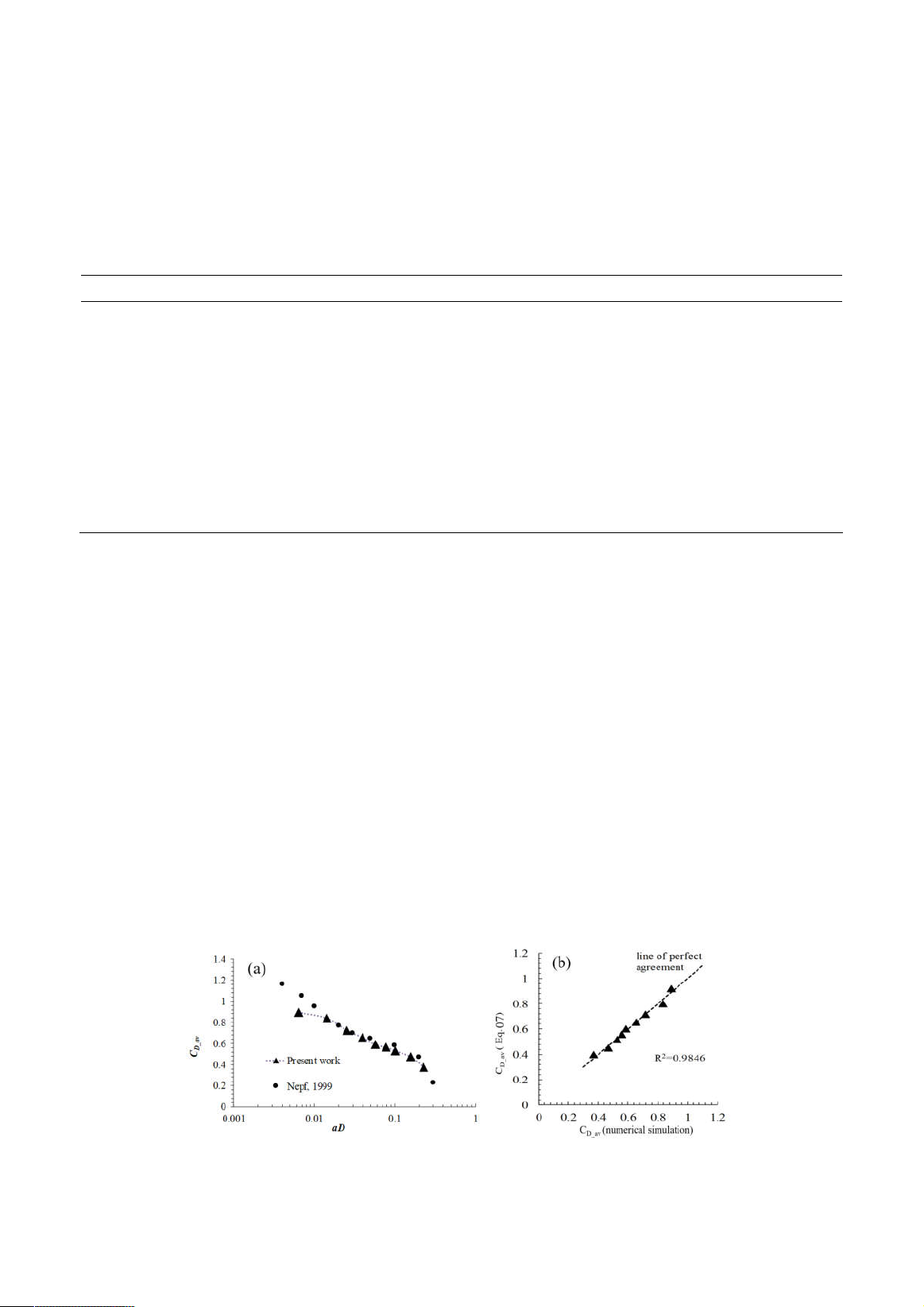

Figure 3a presents the results, C

D_av

, for an

array of multiple cylinders. In this case, the

density parameter is aD, which was proposed by

(Nepf, 1999), where a = nD, n is the number of

cylinders in the array. The Rennolds coefficient

in this simulation is 200, similar to the

experiment of (Nepf, 1999). The shapes of the

cylinders are also circular. It can be seen that

C

D_av

gradually decreases as the density of the

cylinder increases. This average drag coefficient

was found to be in good agreement with

previous experiment results (Nepf, 1999).

The functional relationship between C

D_av

and aD was proposed to determine C

D_av

:

C

D_av

= -0.145ln(aD) + 0.1872 (0.005 < aD < 0.2) (7)

This equation was found by fitting the data

shown in Figure 3b to predict the value of C

D_av

in

the studied density range. Prediction with Eq. (7)

gives a correlation coefficient of 0.985. It can be

seen that a very high degree of agreement was

found between C

D_av

obtained from Eq. (7) and the

numerical result. In other words, the average drag

coefficient can be easily evaluated with Eq. (07).

Figure 3. The average drag coefficient (a) compare to Nepf, 1999; (b) compare to Eq. (7)

Journal of Water Resources & Environmental Engineering - No. 87 (12/2023)

20

Increasing the density of the cylinders causes a

reduction in the average drag coefficient.

Returning to the study of cylinder interaction (Vu,

et al., 2015) will help us understand this

relationship. The author pointed out that the wake

of an upstream cylinder can suppress the drag

coefficient on the downstream cylinder. This

effect increases as the longitudinal spacing

between cylinders decreases, and it results from

two properties of the wake. First, the downstream

cylinder experiences a lower impact velocity due

to the velocity reduction in the vortex wake.

Second, the downstream cylinder is also located in

a low-pressure area caused by the upstream

cylinder. Both of these vortex wake characteristics

contribute to a decrease in the drag on the

downstream cylinders. Based on the observation

of two cylinders, it is expected that the average

drag coefficient for multiple cylinders will

decrease as the element spacing decreases or the

density of the cylinder array increases.

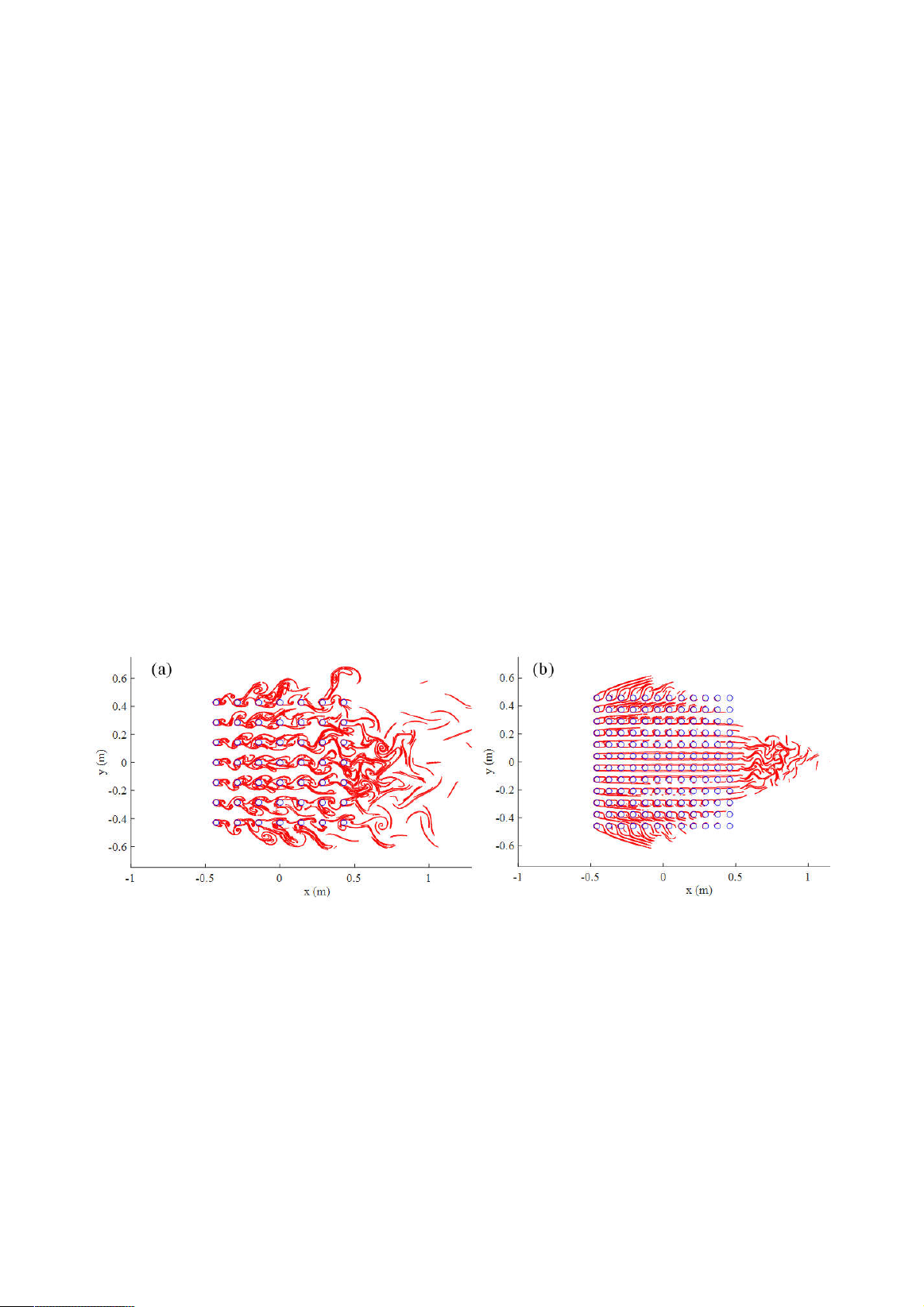

Lagrangian Coherent Structure (LCS) (Vũ,

2017) was employed as a technique to

investigate the flow structure around cylinders

in more detail. Figures 4 (a) and (b) present the

structure of vortex wake behind cylinders using

the LCS technique, with the number of

cylinders being 49 and 144, respectively. Each

vortex-shedding location, as well as the lines

connecting them, is depicted in detail. The gaps

between the cylinders in Figure 4(a) are

sufficiently wide for vortex shedding to take

place. In other words, because the downstream

cylinder is outside the upstream cylinders'

vortex wake, the drag coefficient is not

decreased as much. As the density rises,

however, as shown in Figure 4(b), the wake

from the upstream one entirely covers the

downstream one or reattaches to the

downstream one. Since the downstream ones are

now in lower velocity and pressure regions, the

drag coefficient is significantly reduced.

Figure 4. The effect of distance between cylinders on flow structure,

(a) 49 cylinders, (b) 144 cylinders

3.2. Flow structure

Figure 5 shows the variance in flow structure

with regard to the cylinder arrangement. The

placement of the cylinders in the array has a

significant impact on the flow characteristics.

The flow is mostly concentrated in the

horizontal gap between the cylinders

for uniform distribution. The velocity in this gap

is roughly twice as high as the velocity at the

upstream array. The velocity sharply drops

down directly behind the cylinders or at the

vertical gap. The flow is deflected away from

the array at its lateral borders, where vortexes

are created (see Figure 5c).

![Giáo trình Vật liệu cơ khí [mới nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20250909/oursky06/135x160/39741768921429.jpg)