Kinetic studies on endo-b-galactosidase by a novel colorimetric assay

and synthesis of

N

-acetyllactosamine-repeating oligosaccharide

b-glycosides using its transglycosylation activity

Takeomi Murata, Takeshi Hattori, Satoshi Amarume, Akiko Koichi and Taichi Usui

Department of Applied Biological Chemistry, Shizuoka University, Japan

Novel chromogenic substrates for endo-b-galactosidase

were designed on the basis of the structural features of

keratan sulfate. Galb1-4GlcNAcb1-3Galb1-4GlcNAcb-

pNP (2), which consists of two repeating units of N-acetyl-

lactosamine, was synthesized enzymatically by consecutive

additions of GlcNAc and Gal residues to p-nitrophenyl

b-N-acetyllactosaminide. In a similar manner, Glc-

NAcb1-3Galb1-4GlcNAcb-pNP (1), GlcNAcb1-3Galb1-

4Glcb-pNP (3), Galb1-4GlcNAcb1-3Galb1-4Glcb-pNP (4),

Galb1-3GlcNAcb1-3Galb1-4Glcb-pNP (5), and Galb1-

6GlcNAcb1-3Galb1-4Glcb-pNP (6) were synthesized as

analogues of 2. Endo-b-galactosidases released GlcNAcb-

pNP or Glcb-pNP in an endo-manner from each substrate.

A colorimetric assay for endo-b-galactosidase was devel-

oped using the synthetic substrates on the basis of the

determination of p-nitrophenol liberated from GlcNAcb-

pNP or Glcb-pNP formed by the enzyme through a coupled

reaction involving b-N-acetylhexosaminidase (b-NAHase)

or b-

D

-glucosidase. Kinetic analysis by this method showed

that the value of V

max

/K

m

of 2for Escherichia freundii endo-

b-galactosidase was 1.7-times higher than that for keratan

sulfate, indicating that 2is very suitable as a sensitive sub-

strate for analytical use in an endo-b-galactosidase assay.

Compound 1still acts as a fairly good substrate despite the

absence of a Gal group in the terminal position. In addition,

the hydrolytic action of the enzyme toward 2was shown to

be remarkably promoted compared to that of 4by the

presence of a 2-acetamide group adjacent to the p-nitro-

phenyl group. This was the same in the case of a comparison

of 1and 3. Furthermore, the enzyme also catalysed a

transglycosylation on 1and converted it into GlcNAc

b1-3Galb1-4GlcNAcb1-3Galb1-4GlcNAcb-pNP (9)and

GlcNAcb1-3Galb1-4GlcNAcb1-3Galb1-4GlcNAcb1-3Galb1-

4GlcNAcb-pNP (10) as the major products, which have

N-acetyllactosamine repeating units.

Keywords: endo-b-galactosidase; enzyme assay; kinetics;

poly (N-acetyllactosamine); transglycosylation.

Endo-b-galactosidases were discovered as keratan sulfate-

degrading enzymes, so-called keratanases, in culture filtrates

of Escherichia freundii (glycoside hydrolase family 16) [1],

Coccobacillus sp. [2], Pseudomonas sp. [3], Flavobacterium

keratolyticus (glycoside hydrolase family 16) [4,5], and

Bacteroides fragilis [6]. E. freundii keratanase was found to

have hydrolysing activity for a wide range of nonsulfated

oligosaccharides isolated from human milk and carbohy-

drate moieties of glycoproteins and glycolipids [7–10]. The

use of endo-b-galactosidase has been expanded to detection

of poly (N-acetyllactosamine) chains in a variety of complex

glycoconjugates in addition to keratan sulfate. Bacteroides

fragilis endo-b-galactosidase has properties similar to those

of E. freundii endo-b-galactosidase [11–13]. Therefore, the

endo-b-galactosidases from E. freundii and B. fragilis have

been widely used as tools for structural and functional

analyses of glycans involved in glycoconjugates.

An assay using keratan sulfate as a substrate has been

widely used for estimation of endo-b-galactosidase activity.

However, this method is not always reproducible because

of lack of uniformity of the polymer. Methods using

low molecular mass substrates have been preferred and

recommended for accurate determination of activities of

endoglycosidases such as a-amylase [14], lysozyme [15],

and endo-b-N-acetylglucosaminidase [16], because the

purity of the substrate and the reaction pattern can be

determined exactly. This led us to develop a substrate

suitable for use in the analysis of endo-b-galactosidase. A

series of chromogenic substances having a partially substi-

tuted unit of poly (N-acetyllactosamine) were designed as

substrate analogues for this enzyme because systematic

kinetic studies on the structural modification of substrates

would be helpful in revealing the requirements for binding

and catalytic specificity. In general, glycosidase can cause

transglycosylation as well as hydrolysis as a reverse

reaction [17–19]. Transglycosylation of endo-type glycosi-

dase is now used for the synthesis of N-acetyllactosamine-

repeating oligosaccharide.

Correspondence to T. Murata, Department of Applied Biological

Chemistry, Shizuoka University, 836 Ohya, Shizuoka, 422-8529,

Japan. Fax and Tel.: +81 54 238 4872,

E-mail: actmura@agr.shizuoka.ac.jp

Abbreviations:pNP, p-nitrophenyl; b-NAHase, b-N-acetylhexos-

aminidase; b4GalT, b-1,4-galactosyltransferase; b3GnT, b-1,3-N-

acetylglucosaminyltransferase; HPAEC-PAD, high-performance

anion exchange chromatography-pulsed amperometric detection.

Enzymes: endo-b-galactosidase (EC 3.2.1.103); b-

D

-galactosidase

(EC 3.2.1.23); b-1,4-galactosyltransferase (EC 2.4.1.22); b-1,3-N-

acetylglucosaminyltransferase (EC 2.4.1.149); b-D-glucosidase

(EC 3.2.1.21); b-N-acetylhexosaminidase (EC 3.2.1.52).

(Received 20 December 2002, revised 11 July 2003,

accepted 17 July 2003)

Eur. J. Biochem. 270, 3709–3719 (2003) FEBS 2003 doi:10.1046/j.1432-1033.2003.03757.x

In this paper, we describe the enzymatic synthesis of a

novel substrate 2and its analogues for use a colorimetric

assay of endo-b-galactosidase activity and the usefulness of

the resulting chromogenic substrates for kinetic studies on

the enzyme. In the latter part of this paper, synthesis of

N-acetyllactosamine-repeating oligosaccharide b-glycoside

utilizing endo-b-galactosidase-mediated transglycosylation

is described.

Materials and methods

Materials

Endo-b-galactosidases from E. freundii and B. fragilis were

from Seikagaku Corporation (Tokyo, Japan) and Wako

Pure Chemical Industries, Ltd. (Osaka, Japan), respectively.

b-

D

-Galactosidase from Bacillus circulans ATCC31382 [20]

was a kind gift from Meiji Milk Products Co. Ltd. (Tokyo,

Japan). b-

D

-Glucosidase from almonds was from Sigma

Chemicals. b-N-acetylhexosaminidase (b-NAHase) from

Amycolatopsis orientalis IFO 12806T was purified by 80%

saturated ammonium sulfate precipitation followed by

GlcNAc-cellulofine affinity chromatography. Bovine milk

b-1,4-galactosyltransferase (b4GalT) was from Calbiochem

(CA, USA). Crude b-1,3-N-acetylglucosaminyltransferase

(b3GnT) from bovine serum was prepared as follows.

Bovine serum was brought to 80% saturation with solid

ammonium sulfate and left standing overnight at 4 C. The

precipitate was collected by centrifugation at 5000 gfor

30 min, dissolved in 50 m

M

Tris/HCl buffer (pH 8.0), and

dialysed against distilled water overnight at 4 C. The

enzyme solution was lyophilized and then used for synthesis

of oligosaccharides without further purification. The crude

enzyme preparation catalysed the transfer of a GlcNAc

residue from UDP-GlcNAc to the OH-3¢positions of

Galb1-4Glc, Galb1-4GlcNAc, Galb1-4Glcb-pNP and

Galb1-4GlcNAcb-pNP. The specific activity for Galb1-

4GlcNAcb-pNP as an acceptor substrate was 69 lUÆmg

)1

.

Galb1-4GlcNAc, GlcNAcb1-3Galb1-4GlcNAc, Galb1-

4Glcb-pNP, Galb1-4GlcNAcb-pNP, and GlcNAcb1-

6Galb1-4Glcb-pNP were synthesized by our previously

described methods [21–24]. UDP-GlcNAc and UDP-Gal

were kind gifts from Yamasa Corporation (Choshi,

Japan). All other chemicals were obtained from commercial

sources.

Enzyme assay

b-

D

-Galactosidase, b-

D

-glucosidase and b-NAHase activit-

ies were assayed as follows. A mixture containing 2 m

M

substrate solution (Galb-pNP, Glcb-pNP, and GlcNAcb-

pNP) in 0.4 mL 50 m

M

sodium phosphate buffer pH 6.0

and an appropriate amount of enzyme in a total volume of

0.1 mL was incubated for 10 min at 40 C. One hundred

microlitres of the reaction mixture were then added to

0.1 mL 1.0

M

Na

2

CO

3

on a microplate at 2-min intervals

during to stop the reaction, and the amount of liberated

p-nitrophenol was determined by measuring absorbance at

405 nm using a microplate reader (Biolumin 960, Amer-

sham Pharmacia). One unit of enzyme was defined as the

amount releasing 1 lmol p-nitrophenolÆmin

)1

.Theb3GnT

assay was carried out as follows. Galb1-4GlcNAcb-pNP

(5 mg) and UDP-GlcNAc (3.6 mg) were dissolved in

0.5mL50m

M

Tris/HCl buffer pH 8.0 containing 1.6 mg

MnCl

2

and 0.5 mg ATP, followed by addition of an

appropriate amount of b3GnT preparation. The reaction

mixture was incubated at 37 C for 96 h. Fifty microlitres of

the reaction mixture was taken out at 24-h intervals during

the reaction and boiled for 5 min. Resulting GlcNAcb1-

3Galb1-4GlcNAcb-pNP was measured by HPLC as des-

cribed in the Analytical methods.

Analytical methods

HPLC was carried out using a Mightysil RP18ODS column

(4.6 ·150 mm, Kanto Chemical Co. Ltd, Tokyo, Japan) in

a Hitachi 6000-series liquid chromatograph with an L-4000

ultraviolet detector (absorbance at 300 nm). Elution of the

column was performed with H

2

O/CH

3

OH (95 : 5, v/v). The

flow rate was 1.0 mLÆmin

)1

at 40 C. HPAEC-PAD

analysis was conducted on a DX-300 Bio-LC system

equipped with a pulsed amperometric detector (Dionex,

Sunnyvale, USA). Oligosaccharides were analysed by a

CarboPac P-1 column (Dionex, 4 ·250 mm) at a flow rate

of 1 mLÆmin

)1

at room temperature. The elution was

effected with 100 m

M

NaOH for 40 min. For NMR

analysis, an appropriate oligosaccharide sample was dis-

solved in 200 lLofD

2

O and filtrated with a Millipore filter

(0.22 lm) and then put into a sample tube (i.d. 3 mm).

1

H- and

13

C-NMR spectra were recorded on a JEOL

JNM-LA 500 spectrometer at 25 C. Chemical shifts are

expressed in drelative to sodium 3-(trimethylsilyl) propio-

nate as an external standard. ESI-MS analysis was carried

out in the positive-ion mode on a JEOL MS-700 (JEOL

Ltd, Akishima, Japan) using 2,5-dihydroxy benzoic acid as

the matrix. Determination of the amount of protein was

carried out using a Bio-Rad protein assay kit. Determin-

ation of total carbohydrate was carried out as follows. One

hundred microliters of sample was put into a test tube

(1 ·10 cm), and 100 lL of 5% (w/v) phenol and 0.5 mL

concentrated sulfuric acid were immediately added. The

sample mixture was vortexed and then kept for 20 min at

room temperature, and absorbance was read at 490 nm.

Preparation of GlcNAcb1-3Galb1-4GlcNAcb-

p

NP (1)

and GlcNAcb1-3Galb1-4GlcNAcb-

p

NP (3)

Galb1-4GlcNAcb-pNP (504 mg, 1 mmol) and UDP-Glc-

NAc (651 mg, 1 mmol) were dissolved in 25 mL 50 m

M

Tris/HCl buffer pH 8.0 containing 99 mg MnCl

2

, followed

by addition of 850 mU of crude b3GnT preparation

from bovine serum. The mixture was incubated for 172 h

at 37 C, and the reaction was terminated by boiling for

5 min. The precipitate was removed by centrifugation

(8 000 g, 20 min), and the supernatant was loaded onto a

Toyopearl HW-40S column (5 ·100 cm) equilibrated with

25% methanol at a flow rate of 2 mLÆmin

)1

.Afterthe

chromatography, the eluate was monitored by measuring

the absorbance at 300 nm (p-nitrophenyl group) and at

490 nm (phenol-sulfuric acid method) by a spectrometer.

Both chromatograms showed two peaks (F-1, tubes 24–33;

F-2, tubes 49–60). F-1 was combined, concentrated, and

lyophilized to produce 1(24.1 mg) in a 3.4% total

yield based on the acceptor added. F-2 was recovered as

3710 T. Murata et al. (Eur. J. Biochem. 270)FEBS 2003

Galb1-4GlcNAcb-pNP (0.35 g). In the same way, com-

pound 3was prepared from Galb1-4Glcb-pNP (0.5 g) and

UDP-GlcNAc (450 mg) by use of bovine serum b3GnT in

a 4% total yield based on the acceptor added.

1

Hand

13

C-NMR data of 1and 3were almost identical to data

reported previously [24].

Preparation of GlcNAcb1-3Galb1-4GlcNAcb-

p

NP (2)

and GlcNAcb1-3Galb1-4GlcNAcb-

p

NP (4)

Compound 1(24.1 mg, 34.1 lmol) and UDP-Gal (42.6 mg,

68.2 lmol) were dissolved in 3.4 mL 100 m

M

sodium

cacodylate buffer (pH 6.8) containing 67.3 mg MnCl

2

followed by addition of 0.2 U b4GalT from bovine milk.

The mixture was incubated for 6 h at 37 C and separated

by a Toyopearl HW-40S column (2.5 ·80 cm) as described

above. Compound 2was obtained in an 82% total yield

(24.3 mg) based on the acceptor added. In the same

way, compound 4was obtained in a 71% total yield

(13.2 mg) based on the acceptor from 3and UDP-Gal.

1

Hand

13

C-NMR data of 2and 4are summarized in

Table 1.

Preparation of GlcNAcb1-3Galb1-4GlcNAcb-

p

NP (5) and

its positional isomer GlcNAcb1-3Galb1-4GlcNAcb-

p

NP (6)

Compound 3(85 mg, 128 lmol) and o-nitrophenyl b-

D

-

galactopyranoside (Galb-oNP, 238 mg, 790 lmol) were

dissolved in 5.8 mL 40 m

M

sodium acetate buffer pH 5.5

followed by addition of 98 mU of b-

D

-galactosidase from

Bacillus circulans ATCC31382. The mixture was incubated

for 10 h at 50 C and was loaded onto an ODS DM1020T

column (5 ·100 cm) equilibrated with 5% methanol at

a flow rate of 5 mLÆmin

)1

in order to remove the

o-nitrophenol liberated during the reaction. The fractions

showing absorbance at 300 nm were concentrated and

loaded onto a Toyopearl HW-40S column as above. The

chromatogram showed two peaks (F-1, 1340–1520 mL;

F-2, 1640–1880 mL). F-2 contained 3(43 mg) used as the

acceptor substrate. F-1 was further separated by a Shodex

Asahipak NH2P-50 column (21.5 ·300 mm) equilibrated

with 80% acetonitrile at a flow rate of 5 mLÆmin

)1

at 40 C.

Eluate was monitored on-line by measuring the absorbance

at 300 nm. The chromatogram showed two peaks (F-1a,

327–390 mL; F-1b, 396–450 mL). These peaks were

Table 1.

1

H- and

13

C-chemical shifts of transfer products in D

2

O solution. J

1,2

, coupling constants are given in Hz.

Compounds

Chemical Shifts (d)

C-1 C-2 C-3 C-4 C-5 C-6 NHCOCOCH

3

o-ph m-ph p-ph C-O H-1 J

1,2

CH

3

2pNP 119.3 128.9 145.5 164.4

GlcNAc 101.3 57.6 74.8 80.9 77.9 62.6 177.7 24.8 5.35 8.5 2.02

Gal 105.7 72.7 84.9 71.1 77.7 63.81 4.51 8.3

GlcNAc 105.63 58.0 75.0 80.8 77.3 62.5 177.7 24.9 4.72 8.3 2.05

Gal 105.58 73.7 75.3 71.3 78.1 63.77 4.49 8.2

4pNP 119.3 128.9 145.5 164.5

Glc 102.0 75.2 77.9 80.7 76.9 62.7 5.31 7.7

Gal 105.8 72.8 84.9 71.2 77.7 63.7 4.486 7.7

GlcNAc 105.7 58.0 77.9 81.0 77.4 62.6 177.7 25.0 4.72 8.2 2.05

Gal 105.6 73.8 76.9 71.4 78.2 63.8 4.490 7.7

5pNP 119.2 128.9 145.4 164.4

Glc 102.0 75.2 77.9 80.6 76.8 62.6 5.30 8.0

Gal 105.4 72.8 84.79 71.1 77.7 63.77 4.47 7.9

GlcNAc 105.7 57.5 84.83 71.2 78.0 63.3 177.8 25.0 4.73 8.5 2.02

Gal 106.3 73.5 75.3 71.3 78.1 63.82 4.44 7.7

6pNP 119.3 128.9 145.4 164.4

Glc 102.0 75.2 77.9 80.6 76.8 62.6 5.30 8.0

Gal 105.74 72.8 84.8 71.1 77.7 63.78 4.47 7.7

GlcNAc 105.71 58.94 76.3 72.3 77.4 71.3 177.8 25.0 4.69 8.6 2.02

Gal 106.36 73.5 75.5 71.4 78.0 63.81 4.44 8.0

7pNP 118.2 127.3 143.3 164.0

Gal 101.8 72.1 83.4 68.6 77.1 61.7 5.20 6.5

GlcNAc 103.8 57.9 75.4 70.6 78.5 62.6 171.8 24.7 4.78 8.1 2.06

8pNP 118.2 127.5 143.2 164.2

Gal 102.3 72.2 75.1 70.4 78.4 70.1 5.22 7.6

GlcNAc 103.2 57.1 74.5 71.5 78.7 62.8 170.7 24.8 4.55 8.4 1.78

9pNP 119.3 128.9 145.5 164.5

GlcNAc 101.3 57.6 74.8 81.0 78.0 62.7 177.7 24.9 5.34 8.3 2.01

Gal 105.8 72.8 84.9 71.2 77.7 63.8 4.49 8.0

GlcNAc 105.67 58.0 75.0 80.9 77.4 62.6 177.7 25.0 4.70 8.2 2.03

Gal 105.58 72.8 84.8 71.2 77.7 63.8 4.46 8.0

GlcNAc 105.71 58.5 76.4 72.5 78.5 63.3 177.8 25.0 4.67 8.6 2.03

FEBS 2003 Kinetic studies on endo-b-galactosidase (Eur. J. Biochem. 270) 3711

combined, concentrated, and lyophilized to produce 5

(5.5 mg) and 6(7.2 mg) in 5.2 and 6.8% yields based on the

acceptor added, respectively.

1

H- and

13

C-NMR data of 5

and 6are summarized in Table 1.

Preparation of GlcNAcb1-3Galb1-4GlcNAcb-

p

NP (7)

and GlcNAcb1-3Galb1-4GlcNAcb-

p

NP (8)

Galb-pNP (390 mg, 1.29 mmol) and N, N¢-diacetylchito-

biose (GlcANc

2

, 531 mg, 1.25 mmol) were dissolved in

7.5mL20m

M

sodium acetate buffer pH 5.0 followed by

addition of 8.7 U of A. orientalis b-N-acetylhexosamini-

dase. The mixture was incubated for 100 h at 40 C, and the

reaction was terminated by boiling for 5 min. The precipi-

tate was removed by centrifugation (8 000 g, 15 min), and

the supernatant was loaded onto a Toyopearl HW-40S

column (5 ·100 cm) as above. Eluate was monitored by

measuring the absorbance at 300 nm (p-nitrophenyl group)

and at 490 nm (phenol-sulfuric acid method). The chroma-

togram showed four peaks (F-1, 135–150 mL; F-2, 190–

225 mL; F-3, 275–295 mL; F-4, 420–470 mL). F-2 and F-3

were combined, concentrated, and lyophilized to produce 8

(33.8 mg) and 7(8.6 mg), respectively, in a 6.5% total yield

based on the donor added.

1

H- and

13

C-NMR data of these

disaccharides are summarized in Table 1.

Hydrolytic actions of endo-b-galactosidase

on

p

-nitrophenyl b-glycosides

The hydrolytic actions of endo-b-galactosidase on p-nitro-

phenyl oligosaccharide b-glycosides and a reducing oligo-

saccharide listed in Table 2 were investigated by incubating

a mixture (50 lL) containing 1 m

M

of substrates in 50 m

M

sodium acetate buffer pH 5.8 with 1 mU of the enzymes at

37 C for 20 min. The enzyme hydrolysates were analysed

by HPLC or HPAEC-PAD as described in the Analytical

method section. The reaction was linear from 5 to 15 min.

Therateofattackon2was arbitrarily set at 100.

Colorimetric assay of endo-b-galactosidase activity

A mixture containing 0.5 m

M

of each p-nitrophenyl oligo-

saccharide b-glycoside and 50 mU of b-

D

-glucosidase or

25 mU of b-N-acetyllactosaminide in 500 mL 50 m

M

sodium acetate buffer pH 5.8 and an appropriate amount

of the enzyme was incubated at 37 C. Samples (each

50 lL) were taken at intervals (0, 5, 10, 15 and 20 min)

during the incubation and inactivated by adding 50 lL

1.0

M

Na

2

CO

3

. The amount of liberated p-nitrophenol was

determined by measuring absorbance at 405 nm using a

microplate reader. One unit of the enzyme was defined as

the amount hydrolysing 1 lmol of 2per min. The initial

rates of the enzymatic reaction were evaluated from kinetic

curves of product accumulation as described above. The

parameters of Michaelis–Menten-type kinetics were evalu-

ated by 1/v–1/[S] plots and the least-squares method. The

substrate concentration ranges used for compounds 1, 2, 3,

4 and 5 were 0.05–0.4, 0.02–0.75, 0.1–0.8, 0.25–2.0 and 0.25–

1.5 m

M

, respectively.

Assay of endo-b-galactosidase activity by HPLC

The standard assay was carried out as follows. A reaction

mixture (500 lL) containing an appropriate substrate and

endo-b-galactosidase in 10 m

M

sodium acetate buffer

(pH 5.8) was incubated at 37 C, and samples (each

50 lL) were taken at 3-min intervals during incubation.

After inactivation of each sample by adding 150 mL of 1

M

acetic acid, the amount of liberated GlcNAcb-pNP was

determined by HPLC as described in Analytical methods.

Transglycosylation reaction of endo-b-galactosidase

from

E. freundii

Compound 1(16 mg, 23 lmol) was dissolved in 1.9 mL

20 m

M

sodium acetate buffer pH 5.8 followed by addition

of 2.3 mU endo-b-galactosidase from E. freundii.The

mixture was incubated for 30 days at 37 C and was loaded

onto a Sep-pak accel QMA column (2 ·4 cm) equilibrated

with H

2

O at a flow rate of 1 mLÆmin

)1

. Eluate was collected

in 2-mL fractions and monitored by measuring the absorb-

ance at 300 nm using a spectrometer. The fractions showing

absorbance at 300 nm were combined, concentrated and

loaded onto a Shodex Asahipak GS-220FP column

(7.6 ·250 mm) equilibrated with H

2

O at a flow rate of

0.6 mLÆmin

)1

at 40 C. Eluate was monitored on-line by

measuring the absorbance at 300 nm. The chromatogram

showed four peaks (Fig. 1A). Peak B, which was presumed

to be a transglycosylation product, was concentrated and

lyophilized to produce 9(0.8 mg) in 3.3% yield based on the

substrate added.

1

H- and

13

C-NMR data of 9are summar-

ized in Table 1.

Results

Preparation of colorimetric substances

A series of chromogenic substances were designed as

substrates of endo-b-galactosidase based on the structural

features of keratan sulfate, which is an alternating polymer

of N-acetyllactosamine units jointed to each other by a

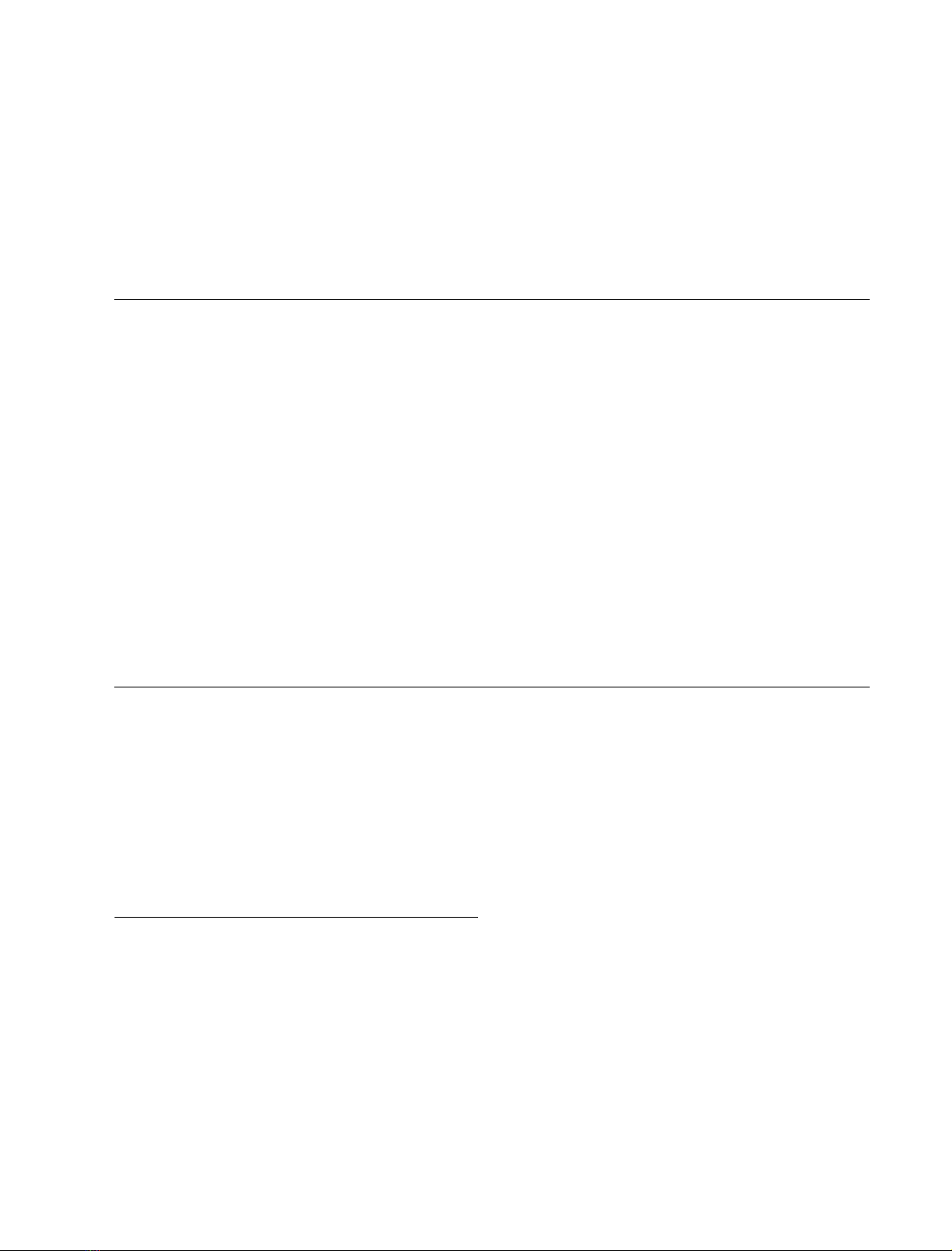

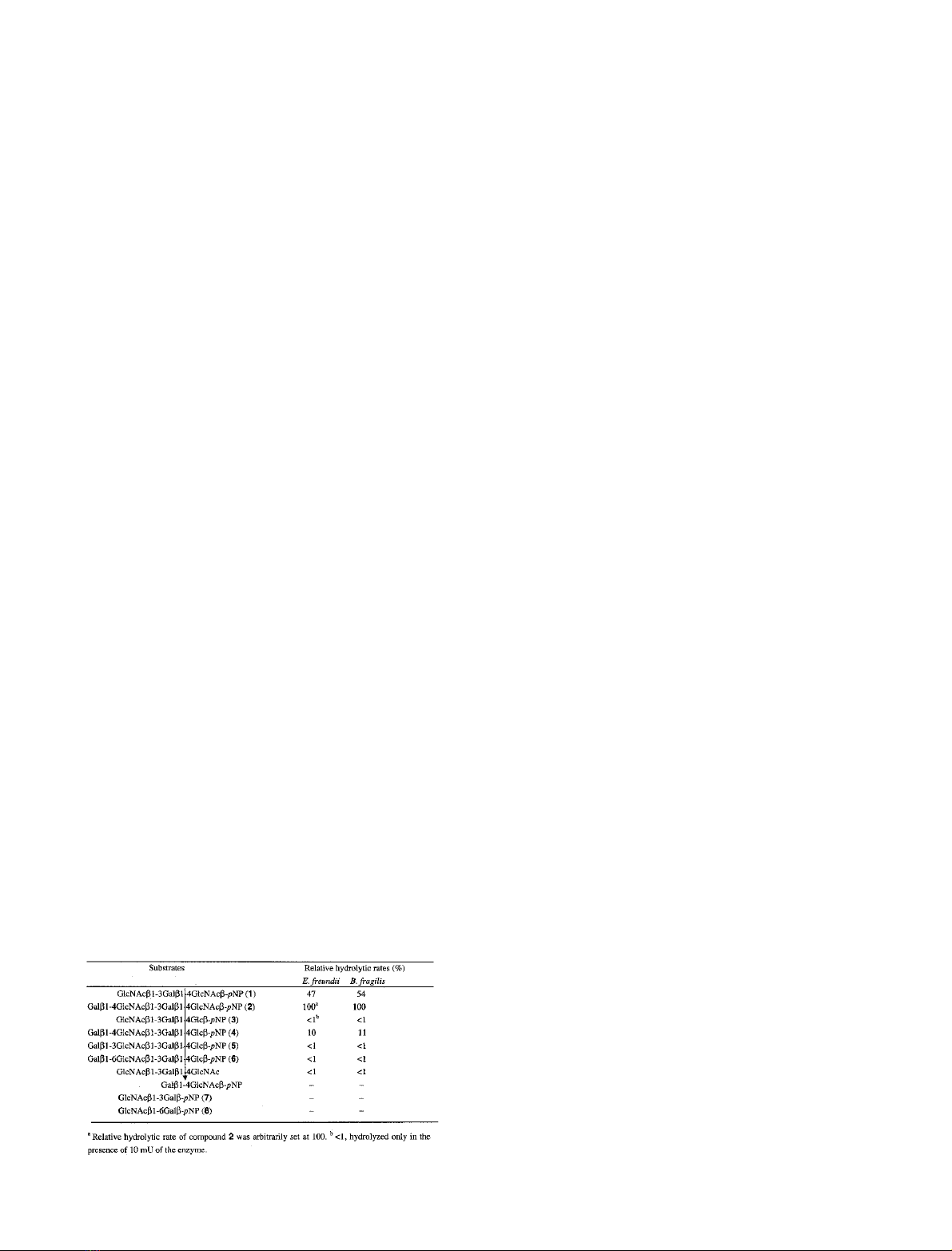

Table 2. Relative hydrolytic rates of endo-b-galactosidases on p-nitro-

phenyl oligosaccharide b-glycosides. The hydrolytic actions of endo-

b-galactosidase on different substrates were investigated as described in

Materials and methods. The vertical arrow indicates the point of

cleavage. One mM of each substrate was used for the determination of

relative hydrolytic rates. –, not hydrolyzed even in the presence of 10

mU of the enzyme.

3712 T. Murata et al. (Eur. J. Biochem. 270)FEBS 2003

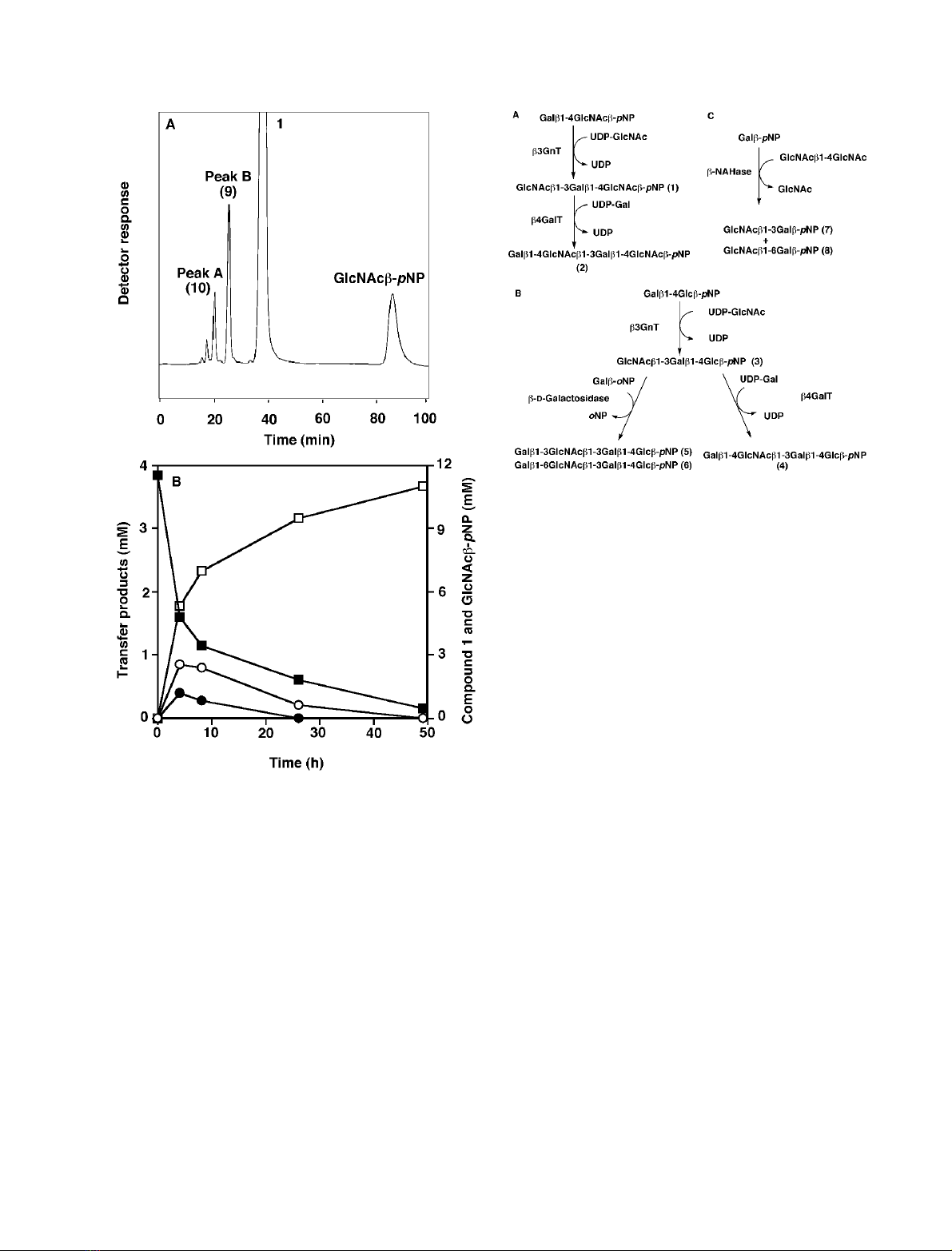

b-(1-3) linkage. Tetrasaccharide 2containing two N-acetyll-

actosamine repeats and its analogues were synthesized by

the alternative addition of b-(1-3) linked GlcNAc and b-(1-

4) linked Gal to Galb1-4GlcNAcb-pNP and Galb1-4Glcb-

pNP, respectively, using two kinds of glycosyltransferases.

Thus, compounds 1and 3were first prepared by the

regioselective transfer of GlcNAc residue from UDP-

GlcNAc to Galb1-4GlcNAcb-pNP and Galb1-4Glcb-pNP

by b3GnT from bovine serum. They were further converted

into 2and 4utilizing b4GalT from bovine milk (Fig. 2A,B).

The enzyme efficiently catalysed the transfer of a Gal moiety

to the OH-4¢position of the acceptors in high yields (82 and

71%) depending on the acceptor. The positional isomers 5

and 6were prepared simultaneously by Gal transfer from

Galb-oNP to the OH-3¢and OH-6¢positions of 3using

B. circulans b-

D

-galactosidase-mediated transglycosylation

(Fig. 2B). The resulting products were obtained in a molar

ratioof1:1.3andina12%overallyieldbasedonthe

acceptor added. Compound 7and its isomer 8were

prepared from Galb-pNP using b-NAHase-mediated trans-

glycosylation (Fig. 2C).

Hydrolytic actions of endo-b-galactosidases

The hydrolytic actions of endo-b-galactosidases on synthetic

chromogenic substances (each 1 m

M

) were investigated by

using enzyme preparations from E. freundii and B. fragilis.

Each enzyme splits compounds 1–6 into the corresponding

reducing oligosaccharides and chromogenic substances,

GlcNAcb-pNP/Glcb-pNP. For example, compound 2was

completely hydrolysed in an endo-manner into Galb1-

4GlcNAcb1-3Galband GlcNAcb-pNP. The relative hydro-

lytic rates of 1and 4compared with that of 2(set at 100)

were 47 and 10, i.e. 2- and 10-fold differences, respectively.

The hydrolytic activities toward 3,5and 6were not detected

under the experimental conditions as described in the

Materials and methods. Furthermore, the hydrolytic rate of

reducing trisaccharide GlcNAcb1-3Galb1-4GlcNAc was

compared with that of its glycoside 1in order to examine

how the p-nitrophenyl group participates in the hydrolytic

action. There was little progression of hydrolysis of the

reducing trisaccharide under the experimental conditions,

Fig. 1. HPLC analysis of the reaction mixture obtained by endo-b-

galactosidase-mediated transglycosylation and time courses of the pro-

duction of transglycosylation products 9 and 10 from 1 and degradation

of 1. (A) HPLC analysis was performed as described in Materials and

methods. (B) A reaction mixture (50 lL) containing 11.5 m

M

com-

pound 1, 0.1% BSA and 1.5 mU E. freundii endo-b-galactosidase in

20 m

M

sodium acetate buffer, pH 5.8, was incubated at 37 C. The

amount of each product formed from the initial substrate was deter-

mined by HPLC. s, Peak B (compound 9); d, peak A (compound 10);

h, GlcNAcb-pNP; j, compound 1.

Fig. 2. Summary of enzymatic synthesis of p-nitrophenyl oligosaccha-

ride b-glycosides used in this work. (A) Consecutive additions of Glc-

NAc and Gal to Galb1-4GlcNAcb-pNP by b3GnT and b4GalT. (B)

Consecutive additions of GlcNAc and Gal to Galb1-4Glcb-pNP by

b3GnT and b-

D

-galactosidase or b4GalT. (C) N-acetylglucosaminy-

lation of Galb-pNP by b-N-acetylhexosaminidase-mediated transgly-

cosylation.

FEBS 2003 Kinetic studies on endo-b-galactosidase (Eur. J. Biochem. 270) 3713