Chapter 7

Dimerization, oligomerization and polymerization of

alkenes and alkynes

The annual production of various polymers can be measured only in

billion tons of which polyolefins alone figure around 100 million tons per

year. In addition to radical and ionic polymerization, a large part of this

huge amount is manufactured by coordination polymerization technology.

The most important Ziegler-Natta, chromium- and metallocene-based

catalysts, however, contain early transition metals which are too oxophilic to

be used in aqueous media. Nevertheless, with the late transition metals there

is some room for coordination polymerization in aqueous systems [1,2] and

the number of studies published on this topic is steadily growing.

7.1 Dimerization and polymerization of ethylene

Coordination polymerization of ethylene by late transition metals is a

rather slow process especially when the catalyst is dissolved in water. In a

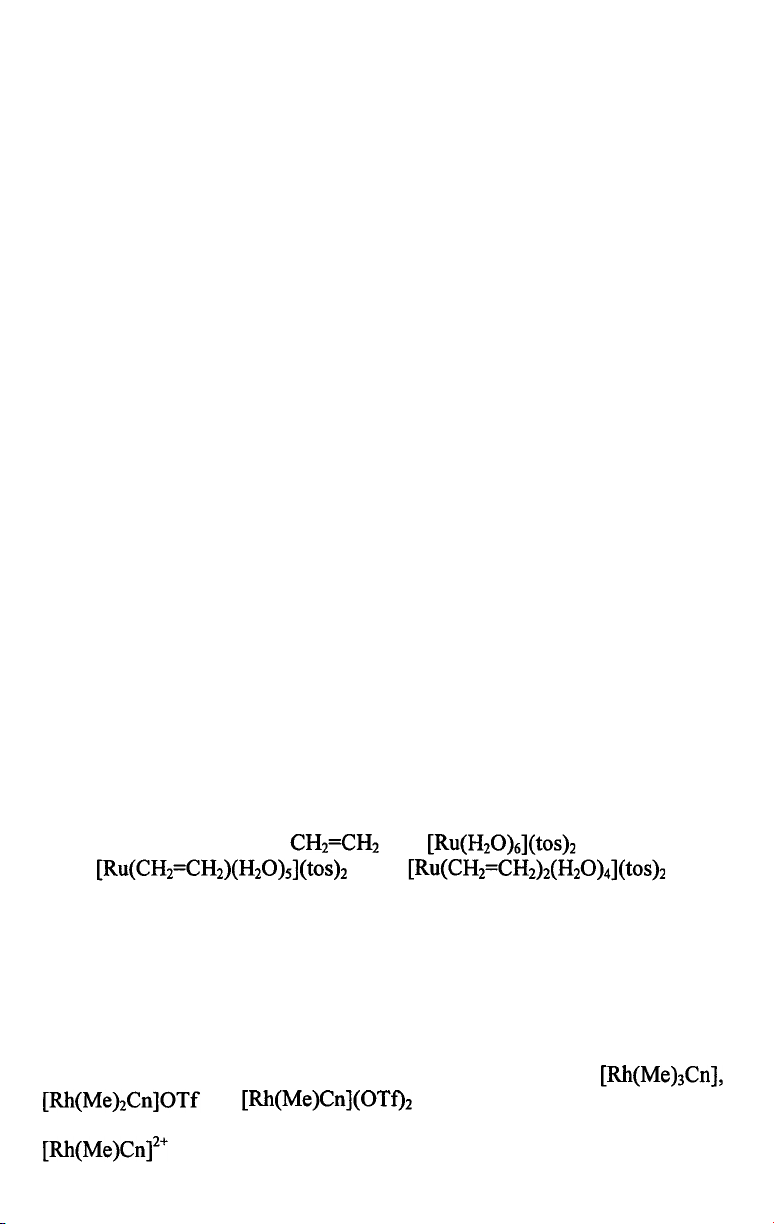

study of the interaction of and (tos = tosylate),

both and were

isolated by evaporation of the aqueous phase which had been previously

pressurized with 60 bar ethylene at room temperature for 6 and 18 hours,

respectively. Longer reaction times (72 h) led to the formation of butenes

with no further oligomerization. This aqueous catalytic dimerization was not

selective, the product mixture contained Z-2-butene, E-2-butene and 1-

butene in a 1/2.2/2.2 ratio [3].

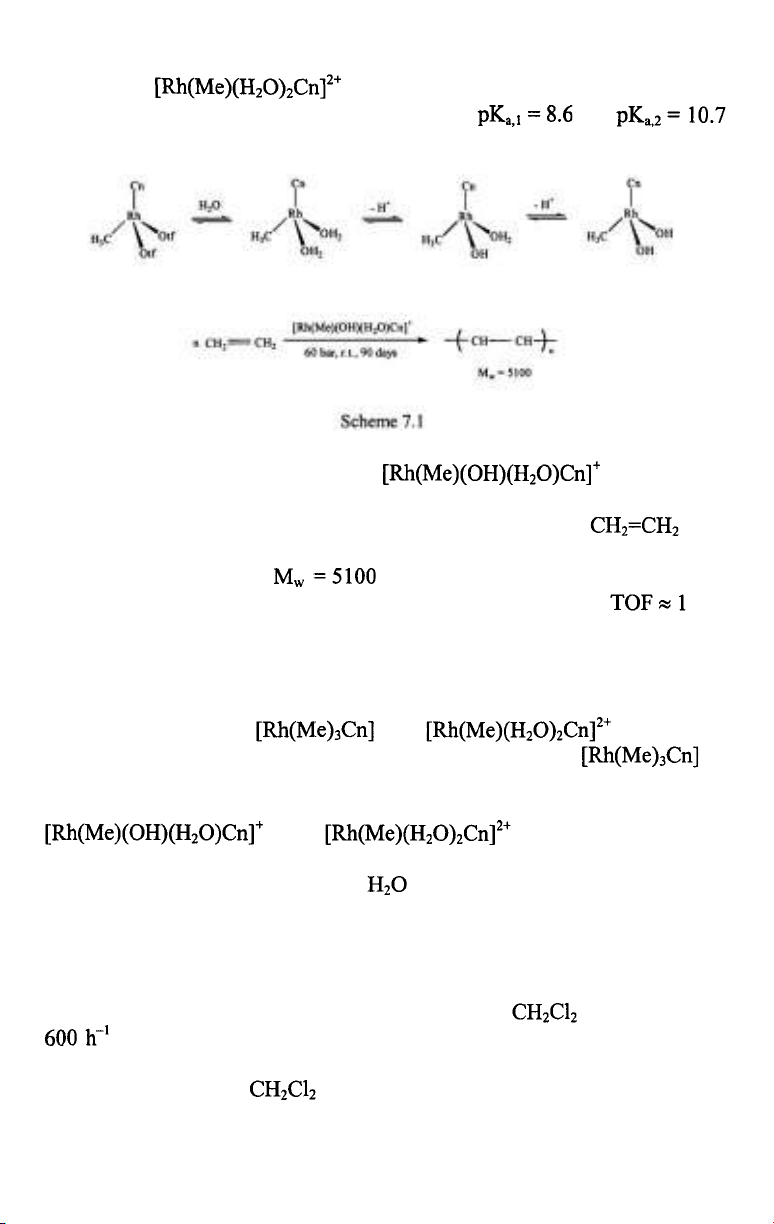

The facially coordinating l,4,7-trimethyl-l,4,7-triazacyclononane (Cn)

ligand forms stable methylrhodium(III) complexes, such as

and (OTf=trifluoromethanesulfonate)

and the latter two have rich aqueous chemistry. When dissolved in water,

readily coordinates two water molecules to form the

237

238

Chapter 7

octahedral in which the aqua ligands undergo

sequential deprotonation in basic solutions with and

(Scheme 7.1) [4].

At 24 °C and 15-60 bar ethylene, catalyzed the

slow polymerization of ethylene [4]. Propylene, methyl acrylate and methyl

methacrylate did not react. After 90 days under 60 bar (the

pressure was held constant throughout) the product was low molecular

weight polyethylene with and a polydispersity index of 1.6. This

is certainly not a practical catalyst for ethylene polymerization ( in a

day), nevertheless the formation and further reactions of the various

intermediates can be followed conveniently which may provide ideas for

further catalyst design. For example, during such investigations it was

established, that only the monohydroxo-monoaqua complex was a catalyst

for this reaction, both and were found

completely ineffective. The lack of catalytic activity of is

understandable since there is no free coordination site for ethylene. Such a

coordination site can be provided by water dissociation from

and and the rate of this

exchange is probably the lowest step of the overall reaction.The hydroxy

ligand facilitates the dissociation of

and this leads to a slow catalysis of

ethene polymerization.

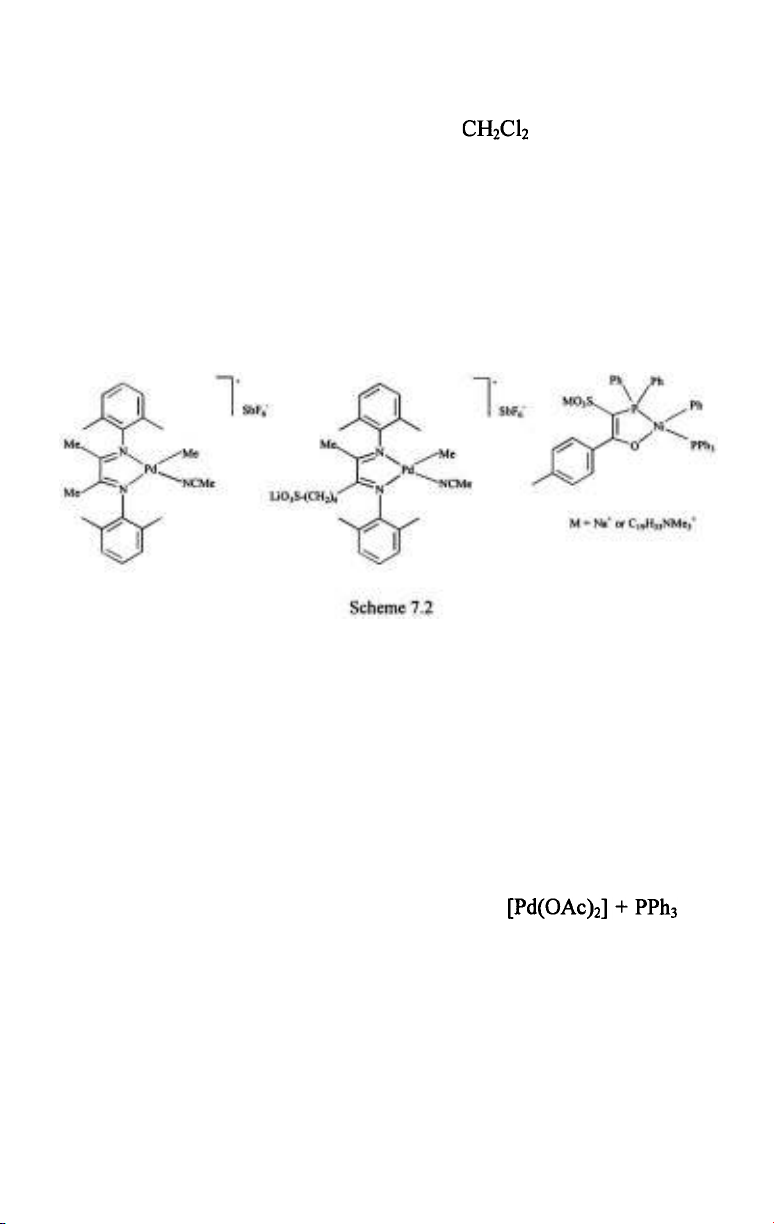

Cationic Pd- and neutral Ni-complexes of chelating N-N or P-O ligands

catalyze the polymerization of ethylene in aqueous media with reasonably

high acitivity (Scheme 7.2) [5,6,61,62]. In fact, the turnover frequencies are

close to those obtained with the same catalysts in (TOF-s 450 vs.

at room temperature). On the other hand, aqueous polymerizations

provided polymers with much higher molecular mass (e.g. 77700 compared

to 14500, obtained in ). The same kind of branching was found in

these polymers, nevertheless the higher molecular mass was manifested in

the physical apperance - the polymers obtained in the aqueous reactions

Dimerization, oligomerization and polymerization of alkenes and

alkynes

239

were rubbery solids while polymerizations in afforded viscous oils.

Very importantly, the active Pd- and Ni-catalysts are water-insoluble,

consequently these aqueous polymerizations were catalyzed by solid

particles of the catalysts suspended in the aqueous phase rather than by

homogeneously dissolved metal complexes. When a palladium catalyst was

made water-soluble by using a sulfoalkyl-modified diimine ligand no

activity whatsoever was observed. The catalytic activity was similarly lost

upon dissolution of the catalysts in the aqueous phase by co-solvents, such

as acetone.

7.2 Telomerization of dienes

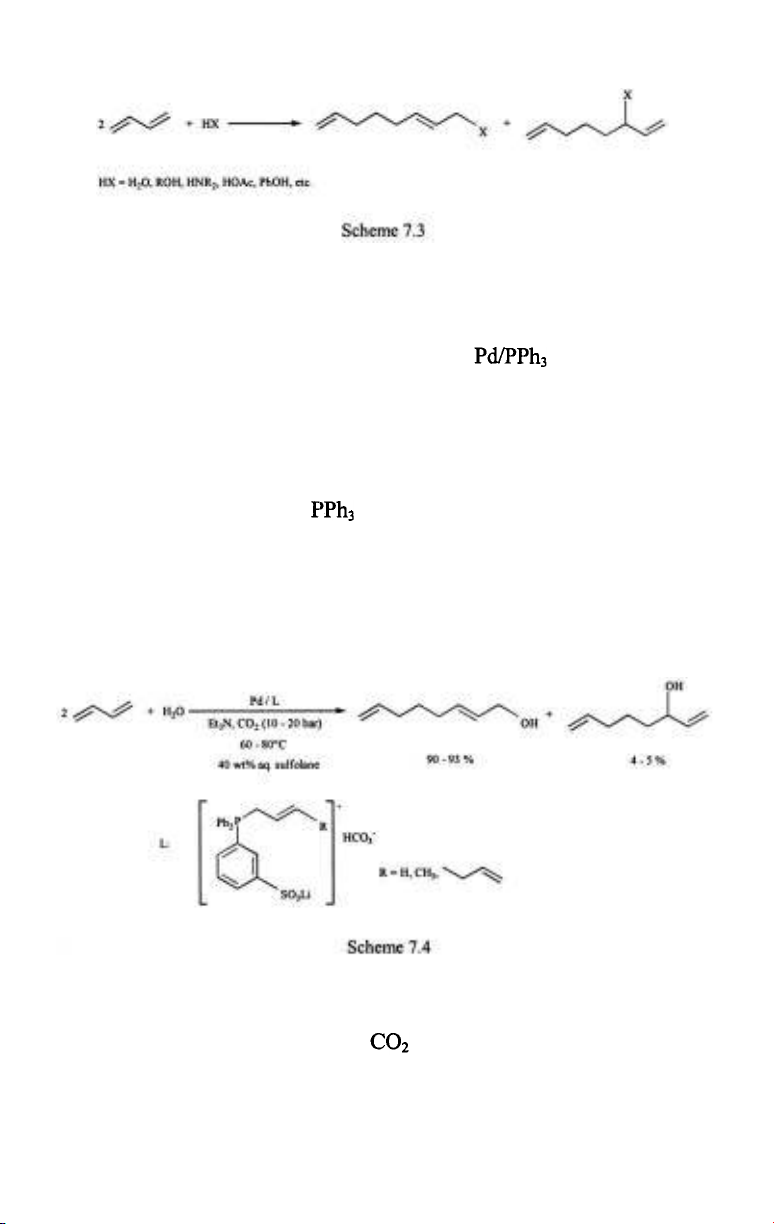

The linear telomerization reaction of dienes was one of the very first

processes catalyzed by water soluble phosphine complexes in aqueous

media [7,8]. The reaction itself is the dimerization of a diene coupled with a

simultaneous nucleophilic addition of HX (water, alcohols, amines,

carboxylic acids, active methylene compounds, etc.) (Scheme 7.3). It is

catalyzed by nickel- and palladium complexes of which palladium catalysts

are substantially more active. In organic solutions gives

the simplest catalyst combination and Ni/TPPTS and Pd/TPPTS were

suggested for running the telomerizations in aqueous/organic biphasic

systems [7]. An aqueous solvent would seem a straightforward choice for

telomerization of dienes with water (the so-called hydrodimerization). In

fact, the possibility of separation of the products and the catalyst without a

need for distillation is a more important reason in this case, too.

240

Chapter 7

The most important aqueous catalytic telomerization reaction is that of

butadiene with water affording octadienols. 2,7-Octadien-1-ol can be easily

hydrogenated to yield 1-octanol, which is used as a raw material for

obtaining phtalate plasticizers for PVC. With or with Pd/TPPTS

this reaction could not be developed into a commercial process due to the

rapid degradation of the catalyst. Such a degradation can be retarded with a

large excess of the respective triarylphosphine, unfortunately this leads to an

almost complete loss of catalytic activity [9]. This problem was solved by

researchers of Kuraray who introduced the phosphonium salt depicted on

Scheme 7.4 in place of [9-11]. The water-solubility of this

Pd/phosphonium salt catalyst allows to run the hydrodimerization of

butadiene in aqueous/organic two-phase systems. For industrial applications

an aqueous phase containing 40 wt% sulfolane was found the most

advantageous for good reaction rates, easy phase separation during workup

and excellent retainment of the Pd-catalyst.

In the industrial process [12] 1,3-butadiene and water are reacted at 60-

80 °C in an aqueous sulfolane solvent in the presence of triethylamine

hydrogencarbonate under 10-20 bar pressure. The reaction yields linear

telomers mainly, with a 90-93 % selectivity to 2,7-octadien-1-ol together

with 4-5 % l,7-octadien-3-ol. Most of the products are removed from the

reaction mixture by extraction with hexane, and the aqueous sulfolane phase

with the rest of the products, the catalyst and the ammonium bicarbonate is

Dimerization, oligomerization and polymerization of alkenes and

alkynes

241

recycled. The loss of the catalyst is in the range of a few ppm. Based on this

process, Kuraray operates a plant with a capacity of approximately 5000 t/y.

Interestingly, various phosphonium salts have been applied [13] as

constituents of palladium catalysts for hydrodimerization of butadiene and

isoprene about the same time when the results of Kuraray were disclosed.

These were obtained by quaternization of aminoalkylphosphines with

methyl iodide or HCl (

type compounds are known to yield

phosphonium salts with these reagents). Although the catalysts prepared in

situ from were reasonably active (TOF-s of ) the reactions

always yielded complex product mixtures with insufficient selectivity

towards the desired 1,7-octadienyl derivatives.

Aqueous/organic biphasic reaction systems with no co-solvents (such as

the sulfolane above) would be desirable for simplified technologies of diene

telomerization. It was found that with the use of amines which possess one

long alkyl chain, such as dodecyldimethylamine good yields of 2,7-octadien-

catalyst showed high activity with TOF-s up to [14,15]. The main

byproducts were octatrienes and 4-vinylcyclohexene. Amines, which do not

form micelles proved much less useful

The beneficial role of the micelle-forming amines may be in the

solubilization of butadiene in the aqueous phase, furthermore, the

hydrogencarbonate salts formed under pressure may also act as phase

transfer catalysts. This reaction also shows the kinetic complexities of the

telomerization of butadiene with water, the outcome of which greatly

depends on the reaction variables [20].

An interesting application of the palladium-catalyzed telomerizations

is the reaction of butadiene with sucrose (Scheme 7.5) and other

carbohydrates. These substrates are water-soluble therefore it is

straightforward to use an aqueous solvent. The products of this reaction

(mono- and dioctadienylethers) are hydrophobic alkyl glucosides which are

biodegradable, have good surfactant properties and can be used as

emulsifiers in various products. From this respect monoalkylated

carbohydrates are more valuable. The reactions were run in water/organic

solvent (methylisobutylketone, methylethylketone, isopropanol) with a

Pd/TPPTS catalyst in the presence of NaOH. Although selective

monoalkylation could not be achieved, the average number of alkadienyl

chains per carbohydrate unit could be made as low as 1.3 [16]. The products

with an average degree of substitution of 4.7-5.3 are clear, almost clourless

viscous liquids, practically insoluble in water [60]. It is worth mentioning,

that this reaction employs (in part) a renewable raw material and provides a

1-ol could be obtained in water alone, under

pressure. The Pd/TPPTS

![Đề thi kết thúc học phần Nguyên lí Hóa học 2 [mới nhất]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20251014/anhinhduyet000/135x160/69761760428591.jpg)