MINISTRY OF EDUCATION AND

TRAINING

VIETNAM ACADEMY OF

SCIENCE AND TECHNOLOGY

GRADUATE UNIVERSITY SCIENCE AND TECHNOLOGY

-----------------------------

TRAN THI THOM

FINITE ELEMENT MODELS IN VIBRATION ANALYSIS OF

TWO-DIMENSIONAL FUNCTIONALLY GRADED BEAMS

Major: Mechanics of Solid

code: 9440107

SUMMARY OF DOCTORAL THESIS

IN MATERIALS SCIENCE

Hanoi – 2019

The thesis has been completed at: Graduate University Science and

Technology – Vietnam Academy of Science and Technology.

Supervisors: 1. Assoc. Prof. Dr. Nguyen Dinh Kien

2. Assoc. Prof. Dr. Nguyen Xuan Thanh

Reviewer 1: Prof. Dr. Hoang Xuan Luong

Reviewer 2: Prof. Dr. Pham Chi Vinh

Reviewer 3: Assoc. Prof. Dr. Phan Bui Khoi

Thesis is defended at Graduate University Science and Technology-

Vietnam Academy of Science and Technology at … , on ….

Hardcopy of the thesis be found at :

- Library of Graduate University Science and Technology

- Vietnam national library

1

PREFACE

1. The necessity of the thesis

Publications on vibration of the beams are most relevant to FGM beams

with material properties varying in one spatial direction only, such as the

thickness or longitudinal direction. There are practical circumstances,

in which the unidirectional FGMs may not be so appropriate to resist

multi-directional variations of thermal and mechanical loadings. Optimiz-

ing durability and structural weight by changing the volume fraction of

FGM’s component materials in many different spatial directions is a mat-

ter of practical significance, being scientifically recognized by the world’s

scientists, especially Japanese researchers in recent years. Thus, struc-

tural analysis with effective material properties varying in many different

directions in general and the vibration of FGM beams with effective mate-

rial properties varying in both the thickness and longitudinal directions of

beams (2D-FGM beams) in particular, has scientific significance, derived

from the actual needs. It should be noted that when the material properties

of the 2D-FGM beam vary in longitudinal direction, the coefficients in the

differential equation of beam motion are functions of spatial coordinates

along the beam axis. Therefore analytical methods are getting difficult to

analyze vibration of the 2D-FGM beam. Finite element method (FEM),

with many strengths in structural analysis, is the first choice to replace

traditional analytical methods in studying this problem. Developing the

finite element models, that means setting up the stiffness and mass ma-

trices, used in the analysis of vibrations of the 2D-FGM beam is a mat-

ter of scientific significance, contributing to promoting the application of

FGM materials into practice. From the above analysis, author has selected

the topic: Finite element models in vibration analysis of two-dimensional

functionally graded beams as the research topic for this thesis.

2. Thesis objective

This thesis aims to develop finite element models for studying vibra-

tion of the 2D-FGM beam. These models require high reliability, good

convergence speed and be able to evaluate the influence of material pa-

rameters, geometric parameters as well as being able to simulate the effect

of shear deformation on vibration characteristics and dynamic responses

of the 2D-FGM beam.

3. Content of the thesis

2

Four main research contents are presented in four chapters of the the-

sis. Specifically, Chapter 1 presents an overview of domestic and for-

eign studies on the 1D and 2D-FGM beam structures. Chapter 2 pro-

poses mathematical model and mechanical characteristics for the 2D-

FGM beam. The equations for mathematical modeling are obtained based

on two kinds of shear deformation theories, namely the first shear de-

formation theory and the improved third-order shear deformation theory.

Chapter 3 presents the construction of FEM models based on different

beam theories and interpolation functions. Chapter 4 illustrates the nu-

merical results obtained from the analysis of specific problems.

Chapter 1. OVERVIEW

This chapter presents an overview of domestic and foreign regime of re-

searches on the analysis of FGM beams. The analytical results are dis-

cussed on the basis of two research methods: analytic method and nu-

merical method. The analysis of the overview shows that the numerical

method in which FEM method is necessary is to replace traditional ana-

lytical methods in analyzing 2D-FGM structure in general and vibration

of the 2D-FGM beam in particular. Based on the overall evaluation, the

thesis has selected the research topic and proposed research issues in de-

tails.

Chapter 2. GOVERNING EQUATIONS

This chapter presents mathematical model and mechanical characteris-

tics for the 2D-FGM beam. The basic equations of beams are set up based

on two kinds of shear deformation theories, namely the first shear defor-

mation theory (FSDT) and the improved third-order shear deformation

theory (ITSDT) proposed by Shi [40]. In particular, according to ITSDT,

basic equations are built based on two representations, using the cross-

sectional rotation

θ

or the transverse shear rotation

γ

0as an independent

function. The effect of temperature and the change of the cross-section

are also considered in the equations.

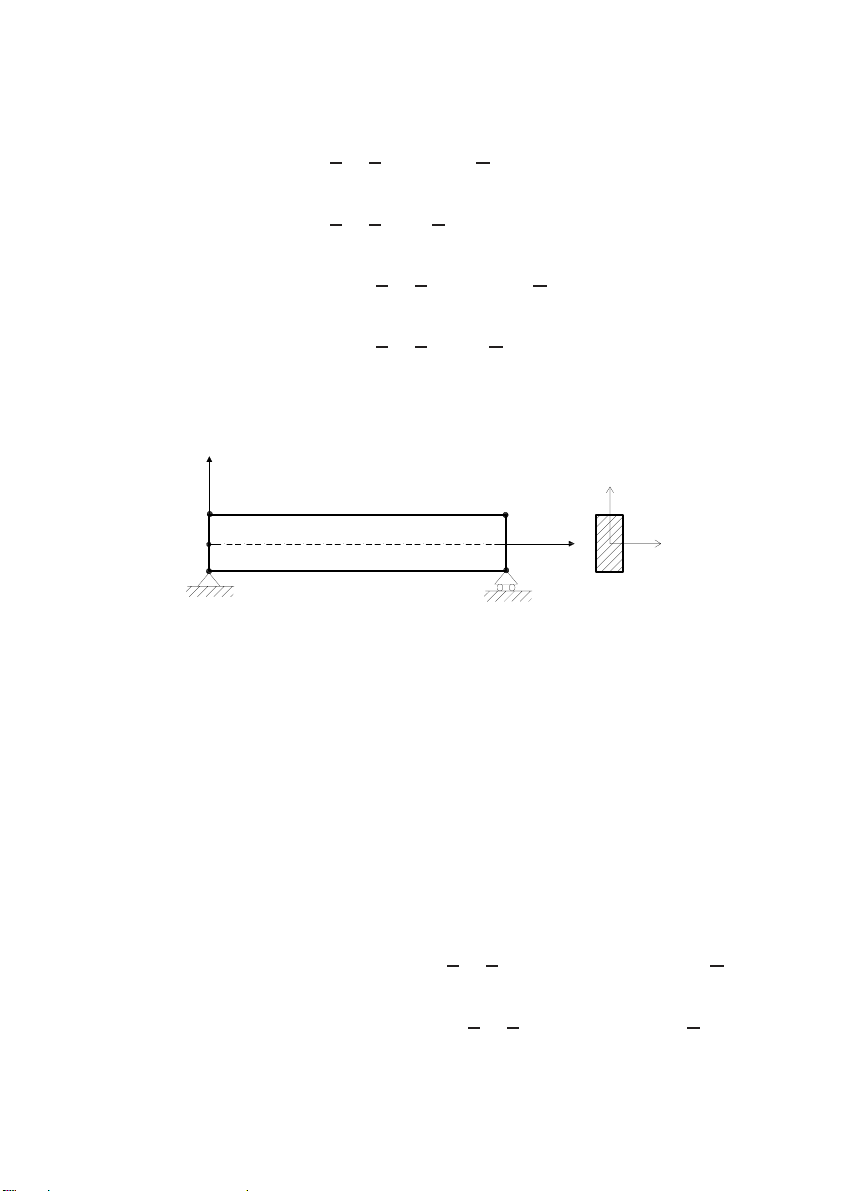

2.1. The 2D-FGM beam model

The beam is assumed to be formed from four distinct constituent mate-

rials, two ceramics (referred to as ceramic1-C1 and ceramic2-C2) and two

metals (referred to as metal1-M1 and metal2-M2) whose volume fraction

3

varies in both the thickness and longitudinal directions as follows:

VC1 =z

h+1

2nzh1−x

Lnxi

VC2 =z

h+1

2nzx

Lnx

VM1 =1−z

h+1

2nzh1−x

Lnxi

VM2 =1−z

h+1

2nzx

Lnx

(2.1)

Fig. 2.1 illustrates the 2D-FGM beam in Cartesian coordinate system

(Oxyz).

C1

0

M1

L, b, h

Z

C2

M2

X

h

b

y

z

Fig. 2.1. The 2D-FGM beam model

In this thesis, the effective material properties P(such as Youngs

modulus, shear modulus, mass density, etc.) for the beam are evaluated

by the Voigt model as:

P=VC1PC1 +VC2PC2 +VM1PM1 +VM2PM2 (2.2)

When the beam is in thermal environment, the effective properties of

beams depend not only on the properties of the component materials but

also on the ambient temperature. Then, one can write the expression for

the effective properties of the beam exactly as follows:

P(x,z,T) =hPC1(T)−PM1(T)iz

h+1

2nz

+PM1(T)h1−x

Lnxi

+hPC2(T)−PM2(T)iz

h+1

2nz

+PM2(T)x

Lnx

(2.4)

![Ô nhiễm môi trường không khí: Bài tiểu luận [Nổi bật/Chi tiết/Phân tích]](https://cdn.tailieu.vn/images/document/thumbnail/2025/20251011/kimphuong1001/135x160/76241760173495.jpg)